Intelligent warehousing system, processing terminal, warehousing robot and intelligent warehousing method

A technology for intelligent warehousing and processing terminals, which is applied in the direction of control/regulation systems, instruments, manipulators, etc., and can solve problems such as inability to realize automation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

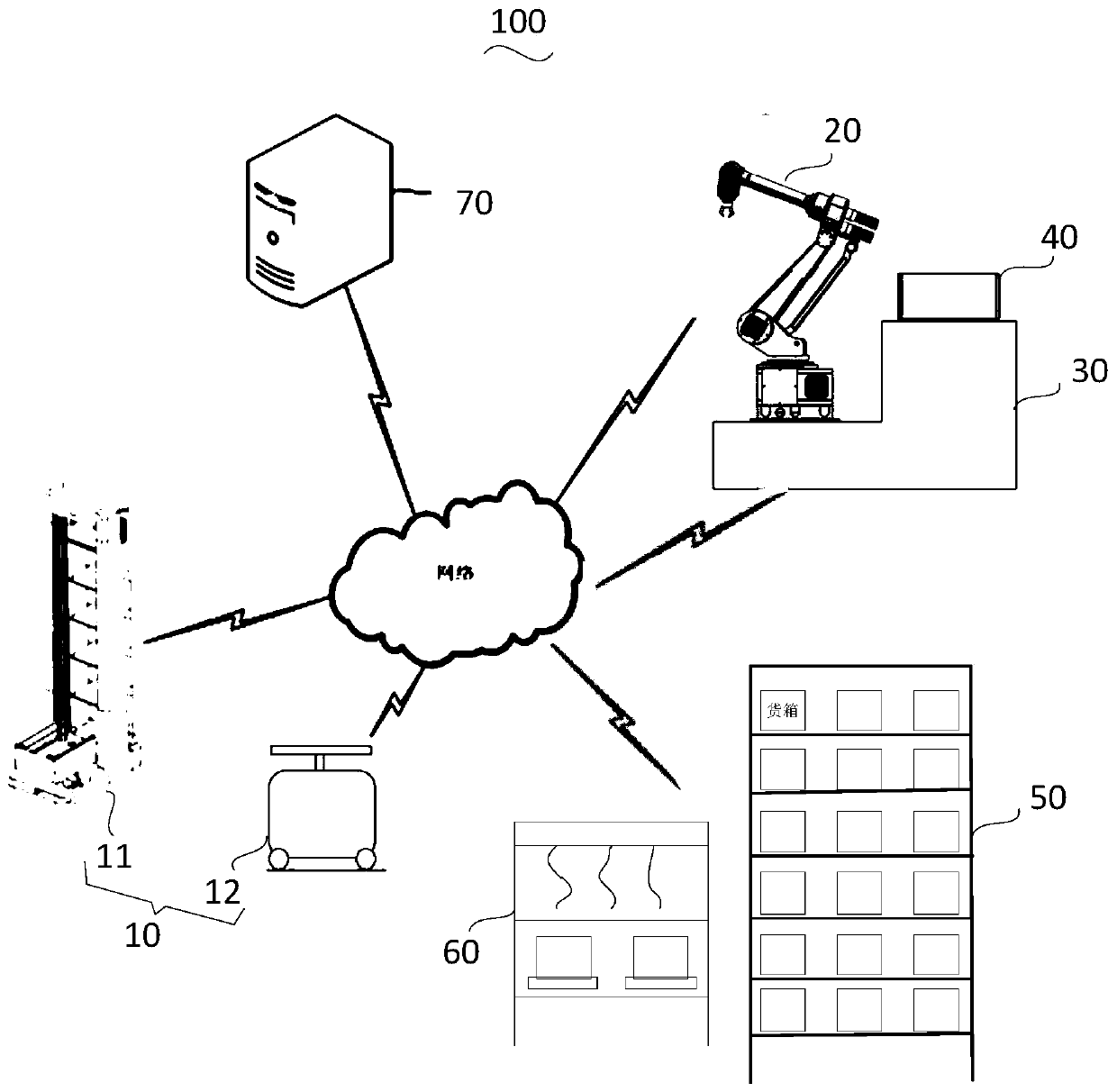

[0099] figure 1 It is a schematic diagram of the composition of the intelligent storage system provided by the embodiment of the present invention. see figure 1 , the intelligent storage system 100 includes a storage robot 10 and a picking device 20 .

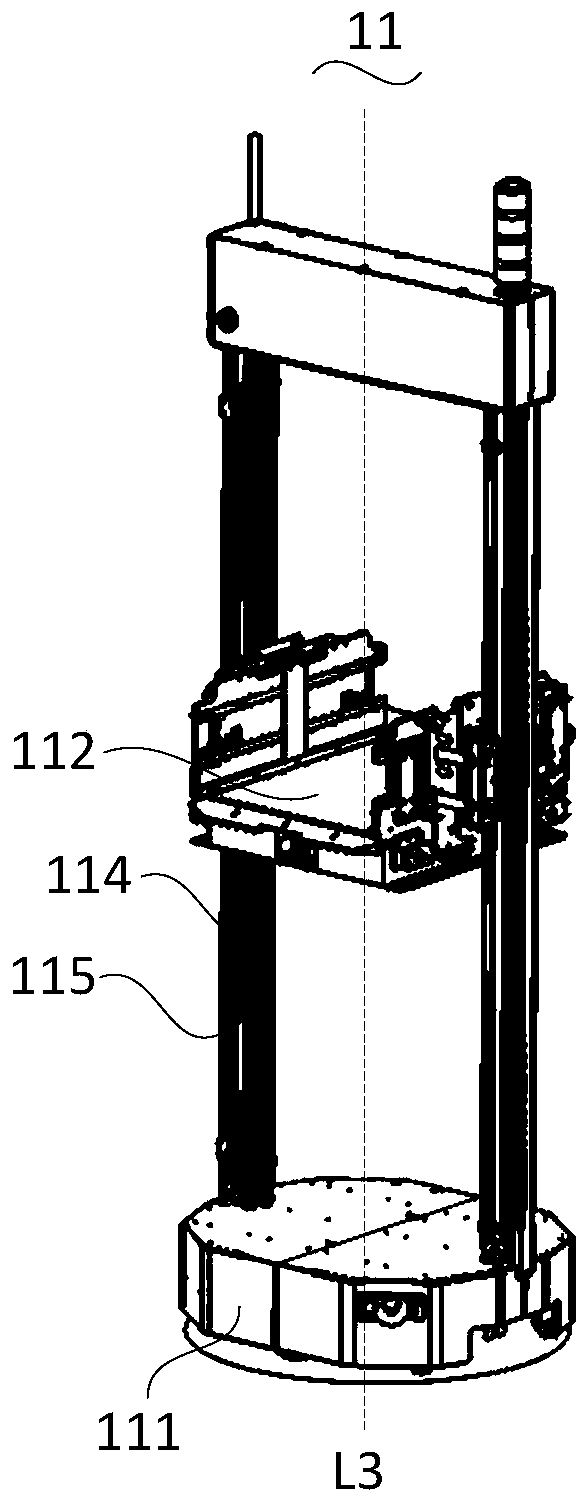

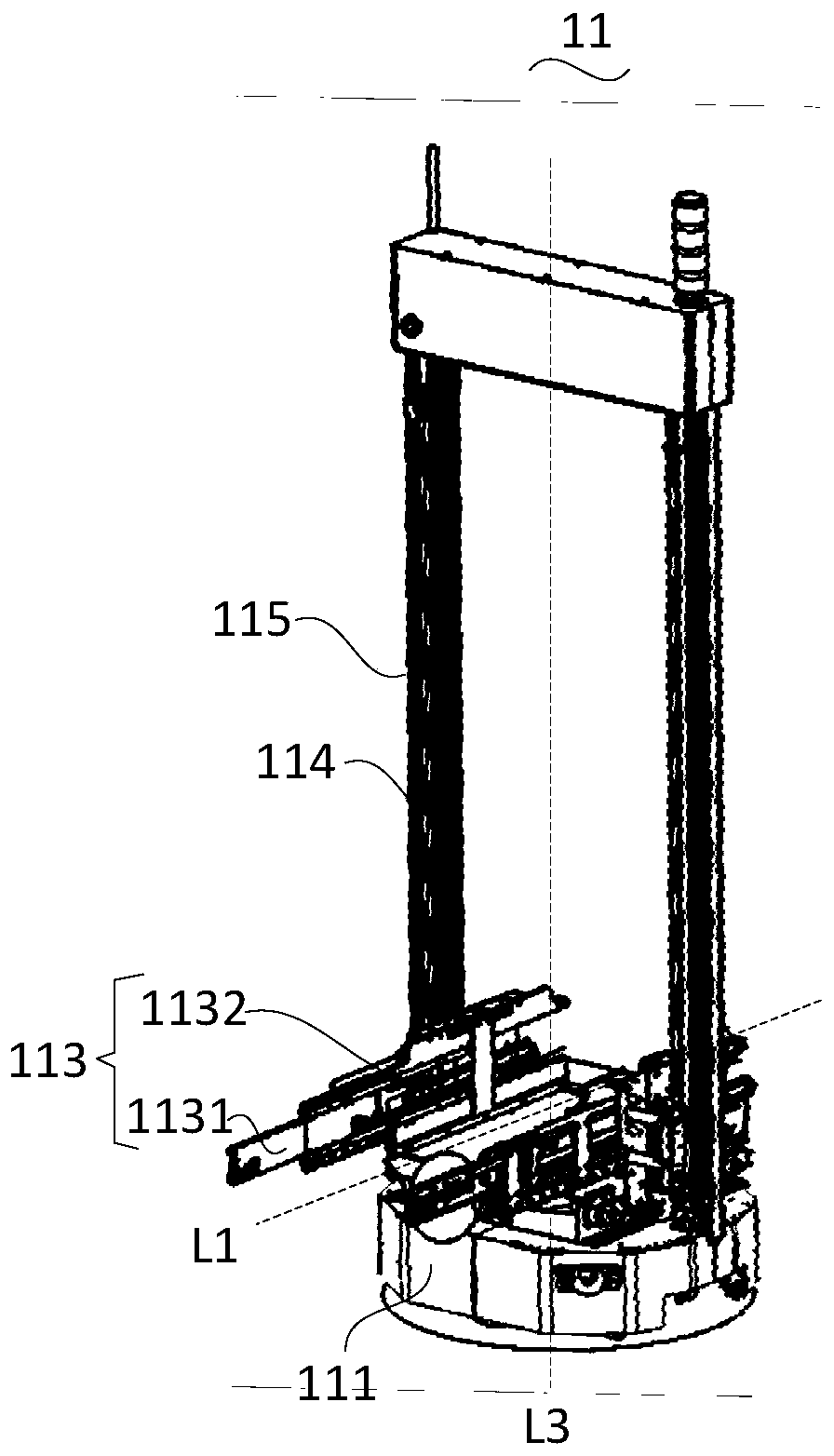

[0100] The warehouse robot 10 may include one or more robots. Wherein, the storage robot 10 may include a first storage robot 11 and / or a second storage robot 12 . Specifically, the storage robot 10 includes a first storage robot 11 , or, the storage robot 10 includes a second storage robot 12 , or, the storage robot 10 includes both the first storage robot 11 and the second storage robot 12 .

[0101]The first storage robot 11 can be used to pick and place cargo boxes or goods, and goods can be stored in the cargo boxes. In this embodiment, the first warehouse robot 11 is configured to receive a first scheduling instruction, and transport the container to the first target location according to the first scheduling instruct...

Embodiment 2

[0128] Figure 5 The first application provided for the embodiment of the present invention is as figure 1 The schematic flow chart of the intelligent storage method of the intelligent storage system shown. see Figure 5 , the smart storage method may include but not limited to the following steps:

[0129] S210. The processing terminal sends the first scheduling instruction to the first storage robot, so that the first storage robot transports the container to the first target location according to the first scheduling instruction, and / or sends the second scheduling instruction to the second storage robot , so that the second storage robot transports the portable shelf to the second target location according to the second scheduling instruction.

[0130] In this embodiment, the "scheduling instruction" is used to indicate the movement of the warehouse robot. For example, the dispatching instruction may include start and end point information, a moving route, and the like. ...

Embodiment 3

[0178] Figure 7 The second application provided for the embodiment of the present invention is as figure 1 The schematic flow chart of the intelligent storage method of the intelligent storage system shown. Specifically, see Figure 7 , which differs from Example 2 in that:

[0179] In this embodiment, when the storage robot includes the first storage robot, the picking instruction includes at least one third picking instruction, and S230 includes: S233. The processing terminal sends at least one third picking instruction to the picking device. Correspondingly, S250 includes: S253. The pick-up device receives at least one third pick-up instruction, and each third pick-up instruction corresponds to at least one container; S254. The pick-up device selects from the corresponding Remove the goods from at least one of the cargo boxes.

[0180] Wherein, the specific implementation manner of S230 may be: sending one third picking instruction each time, and sending several third ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap