A kind of high elongation wrought magnesium alloy and preparation method thereof

A wrought magnesium alloy and high elongation technology, applied in the field of metal material processing, can solve the problems of inability to meet the needs of coordinated deformation, poor industrial application prospects, and high production costs, and achieve high elongation, refinement of grains, and reduction of dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The high-elongation wrought magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd2.20%, Zn0.25%, Zr0.30%, Sc0.05%, Ti0.20%, impurity elements are less than 0.10%, and the rest are Mg.

[0032] The preparation method of the high elongation wrought magnesium alloy described in this embodiment, the specific steps are as follows:

[0033] S1. Take pure magnesium ingots, pure zinc ingots, Mg-Gd master alloys, Mg-Zr master alloys, Mg-Sc master alloys, and Zn-Ti master alloys according to the selected mass percentage;

[0034] S2. Mix the raw materials in step S1, in CO 2 with SF 6Heating at 730°C in a protective atmosphere of a mixed gas with a volume ratio of 200:1, smelting for 60 minutes, stirring for 10 minutes, and refining for 20 minutes, after refining, the temperature was raised to 760°C, and stood for 40 minutes to obtain a melt;

[0035] S3. using the melt in step S2 to cast into a semi-continuous ingot at 700°C...

Embodiment 2

[0039] The high elongation wrought magnesium alloy described in this embodiment is composed of the following elements in mass percentage:

[0040] Gd 2.0%, Zn 0.20%, Zr 0.20%, Sc 0.01%, Ti 0.05%, impurity element is less than 0.10%, and the rest is Mg.

[0041] The preparation method of the high elongation wrought magnesium alloy described in this example is the same as that in Example 1.

Embodiment 3

[0043] The high elongation wrought magnesium alloy described in this embodiment is composed of the following elements in mass percentage:

[0044] Gd 2.20%, Zn 0.28%, Zr 0.50%, Sc 0.10%, Ti 0.20%, impurity elements are less than 0.10%, and the rest is Mg.

[0045] The preparation method of the high elongation wrought magnesium alloy described in this example is the same as that in Example 1.

PUM

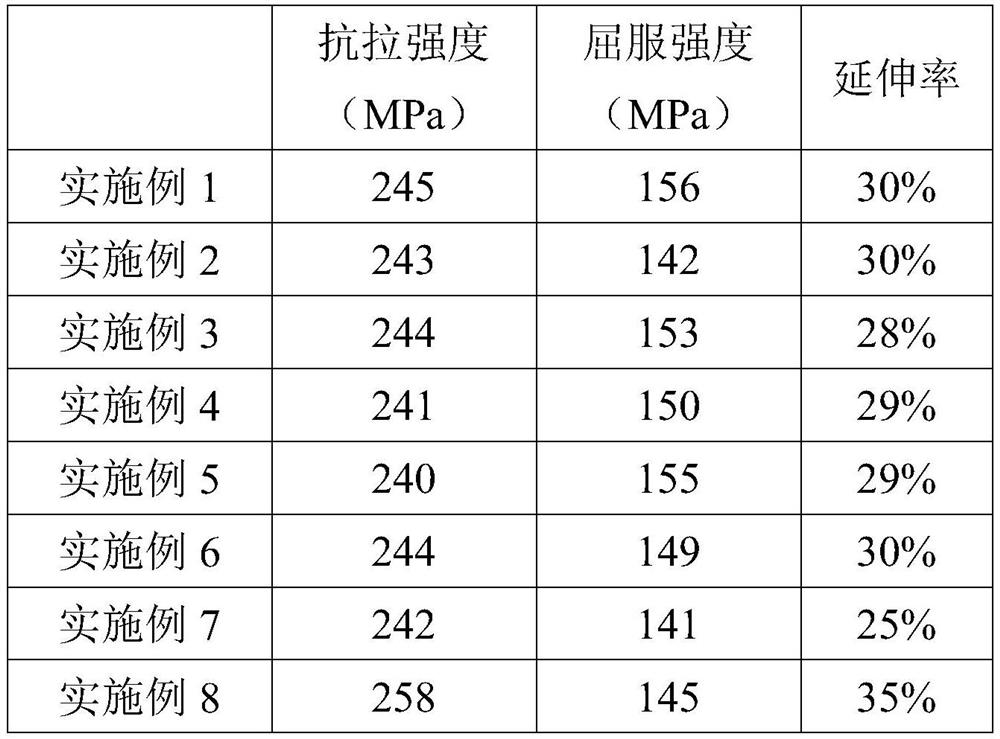

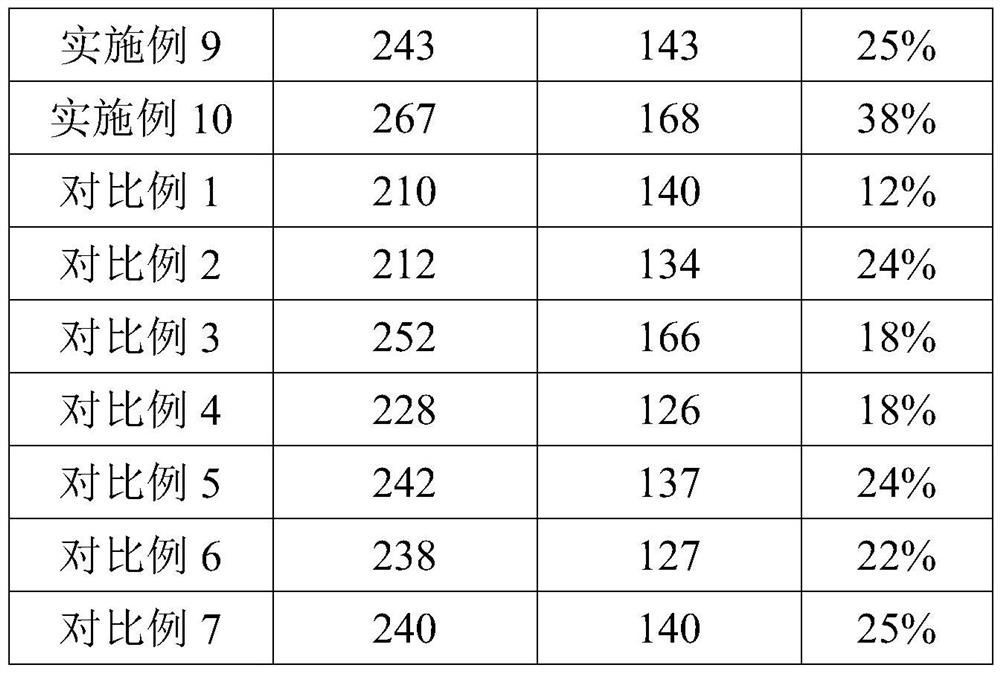

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com