Automatic spinning mechanism for spinning frame

A spinning frame and yarn technology, applied in the textile field, can solve the problems of affecting the workshop environment, shaking of the control box, and falling of fiber flying flowers, etc., and achieve the effects of increasing work efficiency, good shock absorption effect, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

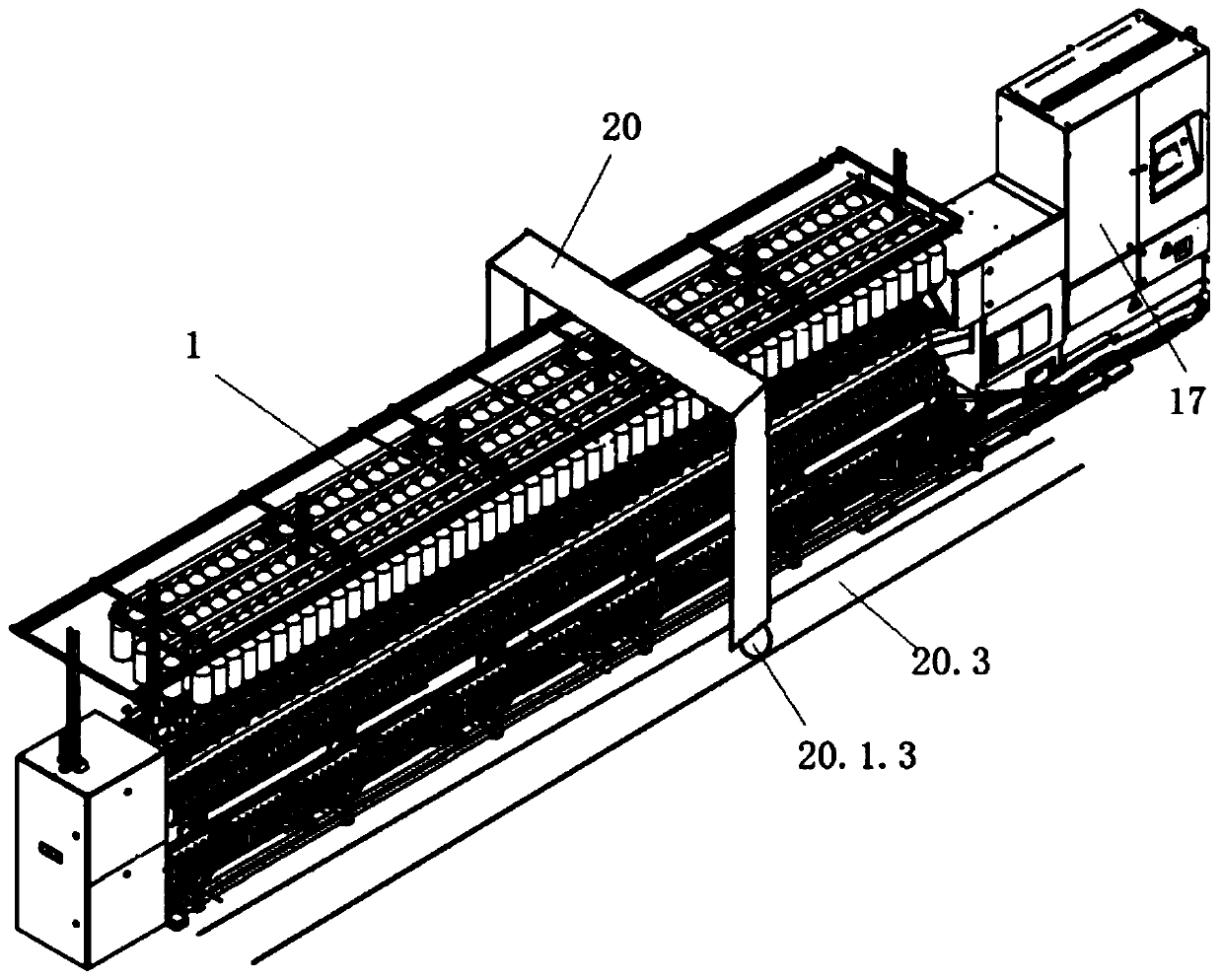

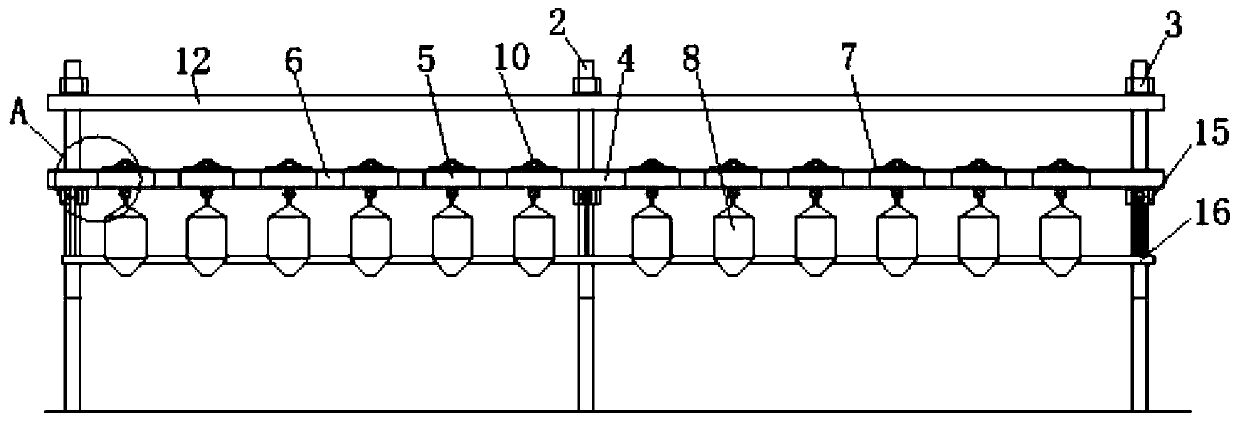

[0029] see Figure 1 to Figure 8 , The present invention relates to an automatic spinning mechanism of a spinning frame, comprising a spinning frame body 1 , a control box 17 , a shock absorbing device 18 and a wool suction mechanism 20 .

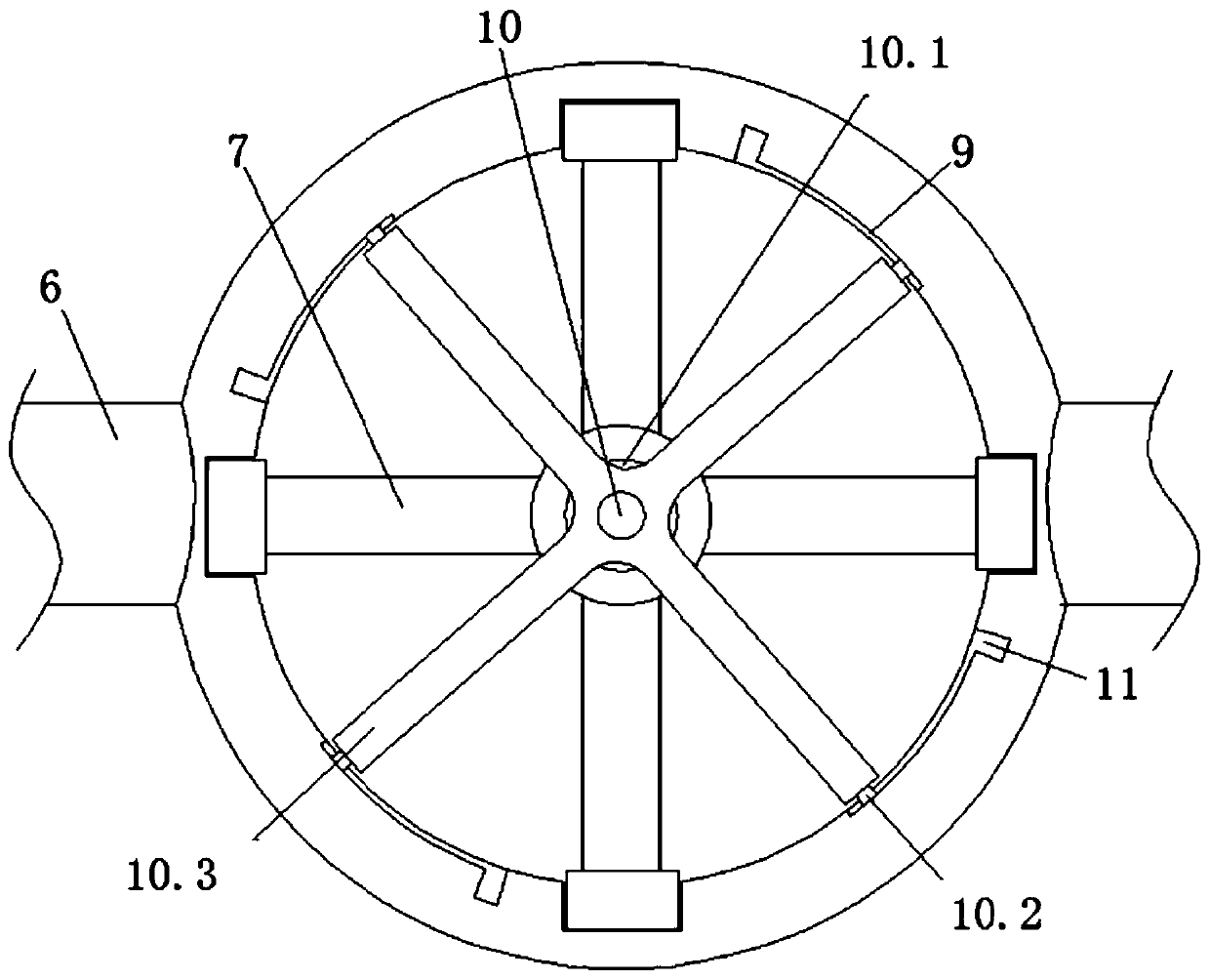

[0030] A roving creel cross bar 2 is installed on the top of the spinning frame body 1, and the roving creel cross bar 2 is provided with two upper and lower horizontally arranged roving creel support rods 3, and the bottom end of the roving creel support rod 3 is equipped with a spindle hanger cross bar 4. A holding support ring 5 is set between two adjacent hanging ingot crossbars 4, and the holding support ring 5 is fixed by the connecting rod 6. The top of the holding support ring 5 is clamped with the hanging ingot 7, and the bottom of the hanging ingot 7 end runs through and extends to the bottom of the holding support ring 5, the bottom end of the hanging spindle 7 is hooked with a roving package 8, and the top of the holding support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com