Flow guiding and cooling system comprising fan and flow guiding structure

A diversion cooling and fan technology, applied in engine cooling, engine components, machines/engines, etc., can solve the problems of reducing fan air volume and efficiency, large back pressure, etc., to improve airflow direction, increase efficiency, and reduce exhaust The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

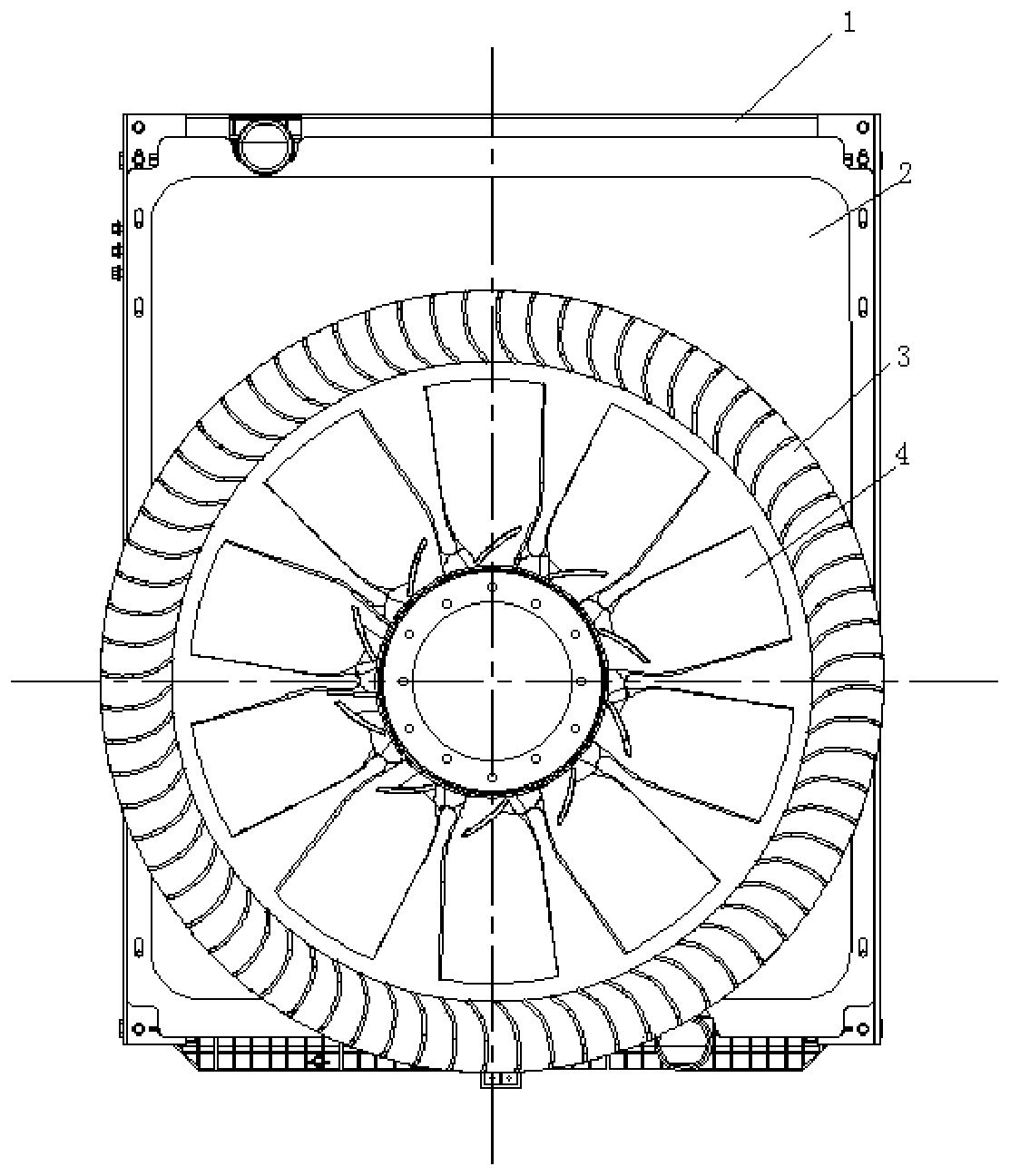

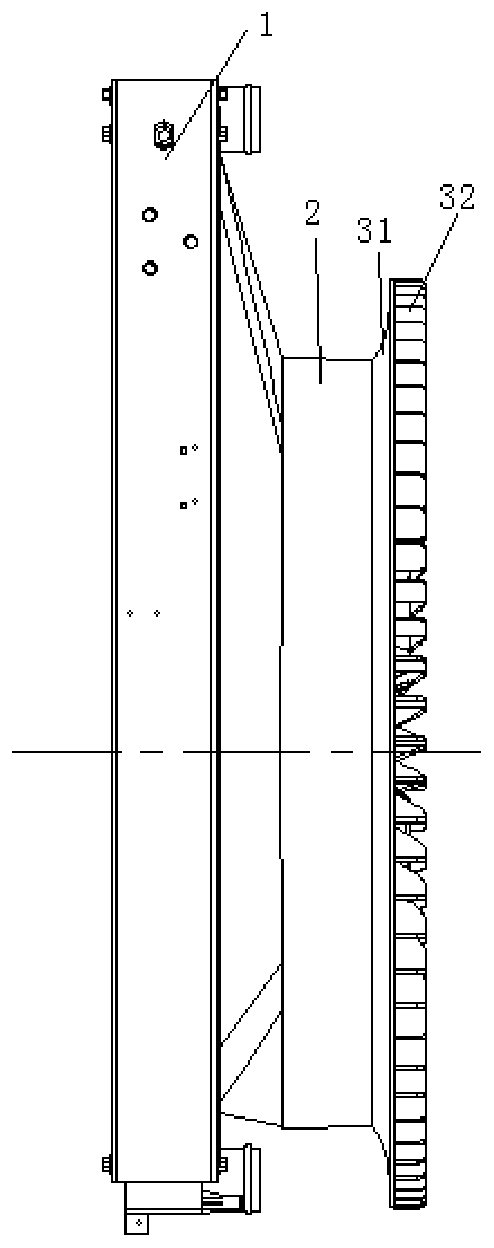

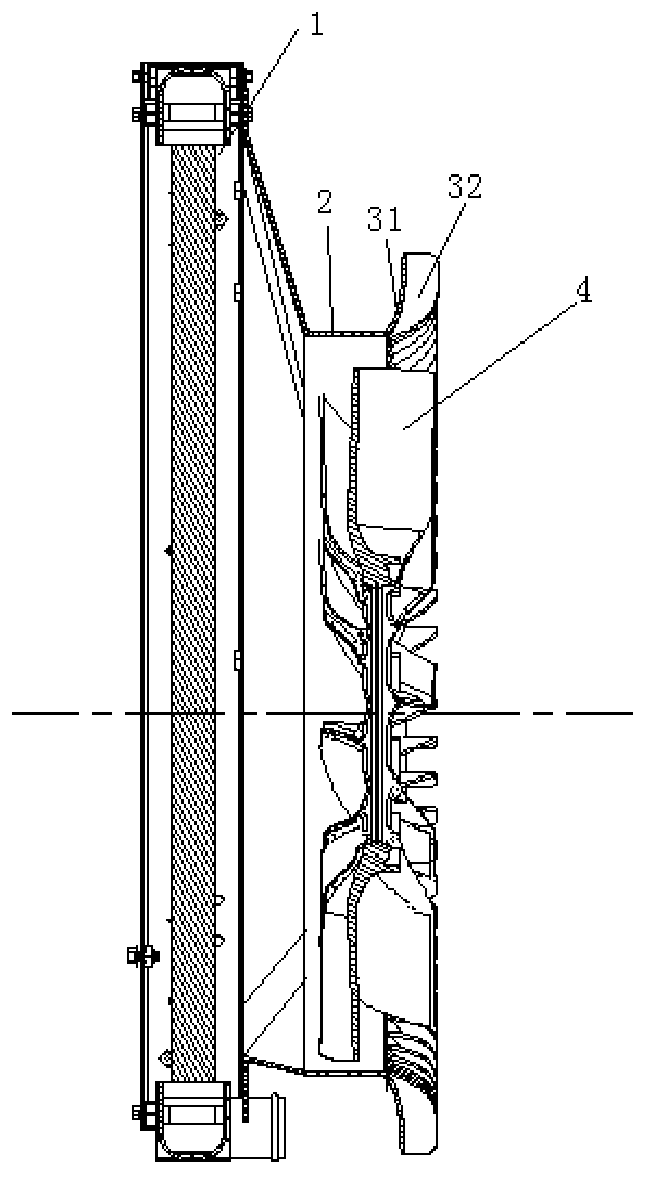

[0024] When the cooling fan 4 rotates, the air is sucked in by the air inlet 61 of the air guide channel at the end of the radiator 1, compressed by the rotation of the fan, and discharged by the air outlet 62 of the air guide channel.

[0025] Such as Figure 5 , Figure 6 As shown, when the cooling fan 4 rotates, in the area of the air outlet 62 of the fan, the air is guided radially outward along the guide vane 32 due to the air outlet guide structure 3, thereby avoiding the "crowding" of the air in the area of the air outlet 62 of the guide channel. ", reducing the exhaust pressure in the area of the air outlet 62 of the diversion channel, indirectly reducing the intake pressure of the air inlet, that is, increasing the air volume of the cooling fan 4 and increasing the efficiency of the cooling fan 4, especially at the outlet of the diversion channel There is a large blocker in the air port 62, such as an engine, the effect of the air outlet guide structure 3 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com