Lens defect detection device

A lens and lens technology, applied in the field of lens defect detection devices, can solve the problems of easy introduction of human error, difficulty in detection of lens defects, and inability to guarantee the reliability of manual detection, and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below in conjunction with the accompanying drawings and examples.

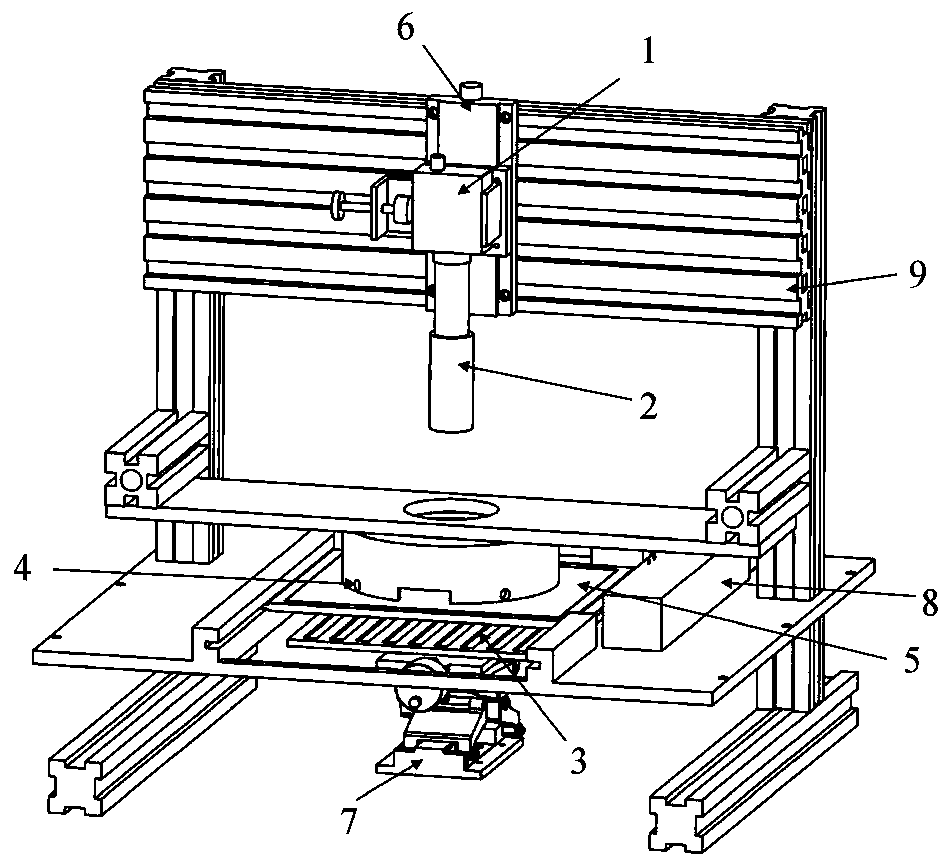

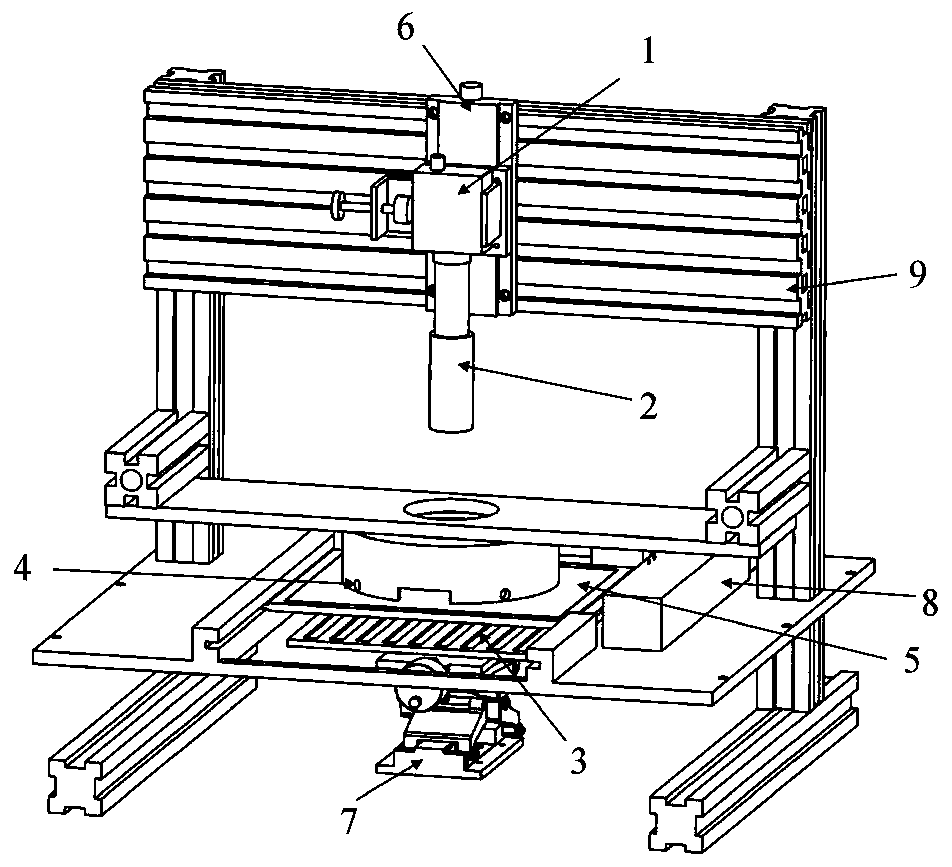

[0013] Such as figure 1 As shown, the lens defect detection device provided by the present invention is mainly composed of a camera 1, a lens 2, a display screen 3, an LED light source 4, a glass plate 5, an electric displacement table 6, an electric lifting table 7 and an electric slide rail 8.

[0014] The system frame is a gantry structure constructed of aluminum profiles. The electric translation platform 6 is fixed in the middle of the gantry beam. The camera 1 is connected to the lens 2 and fixed on the electric translation platform 6. The electric translation platform can move up and down to adjust the field of view of the camera. Design a ring lampshade, install four LED light sources 4 inside the lampshade, evenly distributed in four directions, open a ring hole in the center of the rectangular metal plate to reserve a shooting area, connect the ring lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com