Micro-fluidic chip detection method based on magnetic bead uniform mixing

A microfluidic chip and detection method technology, applied in chemical instruments and methods, measuring devices, biological testing, etc., can solve problems such as difficult integration and miniaturization, inaccurate detection results, and experimental failures, and improve specific binding Efficiency, increased accuracy and stability, and reduced detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

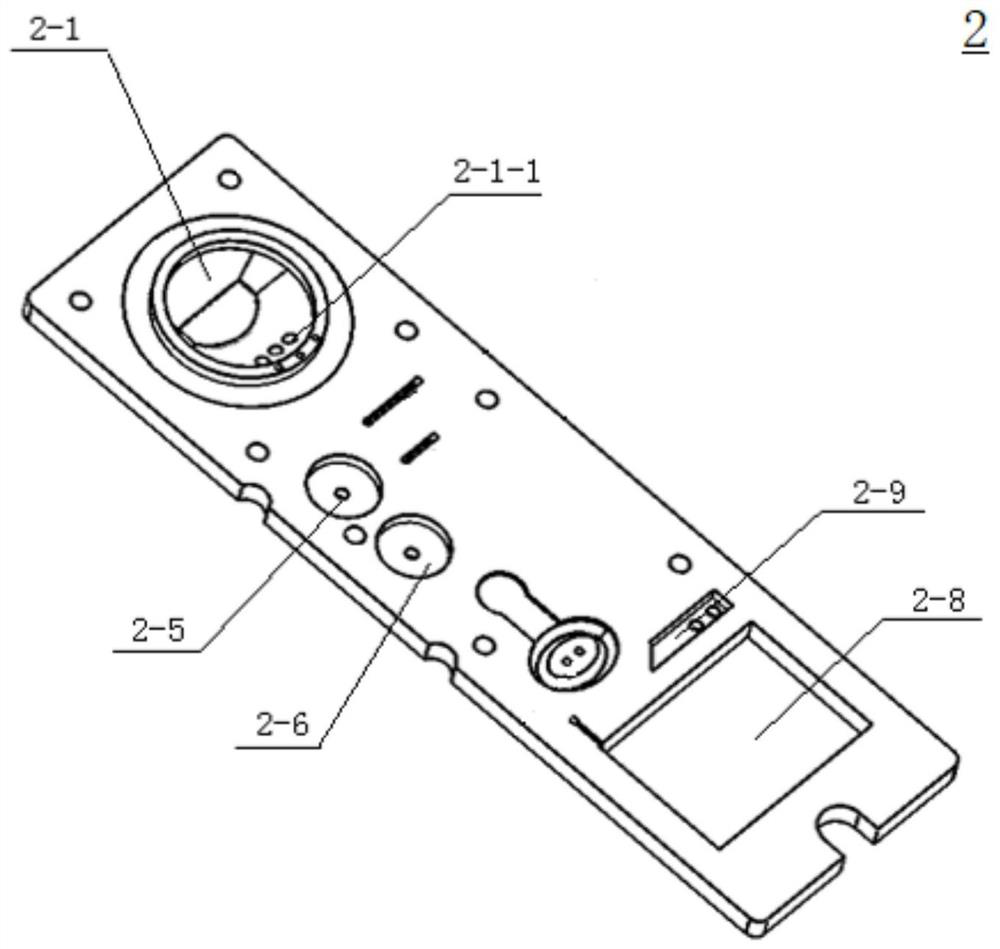

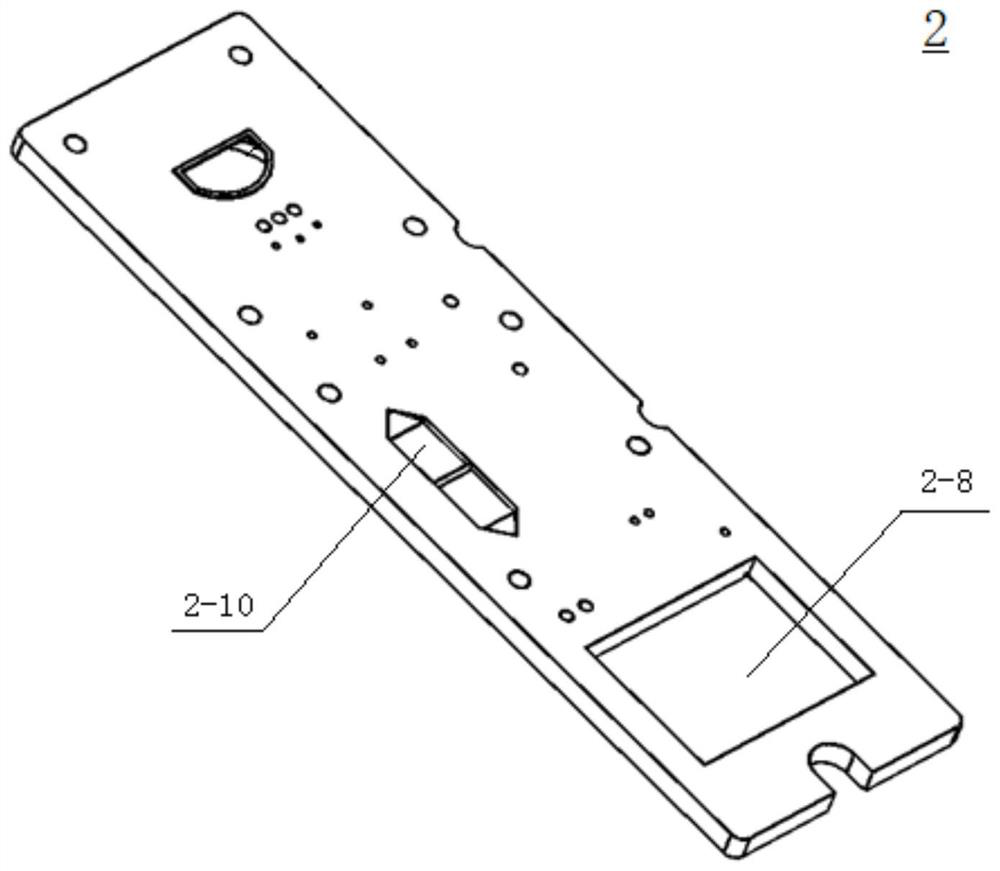

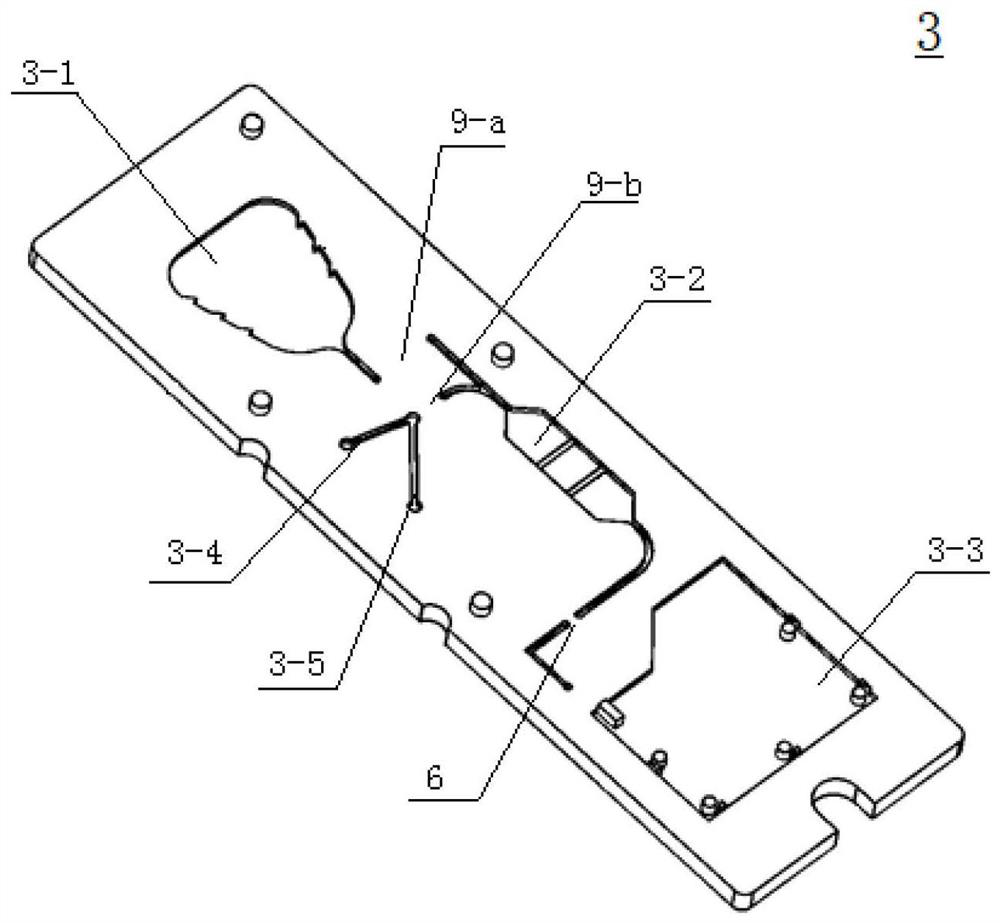

[0044] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0045] The invention provides a detection method for a microfluidic chip based on magnetic bead mixing. The detection is carried out by means of supporting equipment such as a chip carrier and a chip contact device. To realize the detection, the chip contact device contains a gas circuit device, a valve pressure point with a conductive rubber probe, and an adjustable strong magnet.

[0046] In one embodiment, the microfluidic chip used in the detection of the present invention can adopt the chip structure in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com