Cooling system and projection equipment

A technology for cooling systems and electronic devices, applied in instruments, projection devices, optics, etc., can solve problems such as affecting product reliability and performance, foreign matter splashing in radiators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

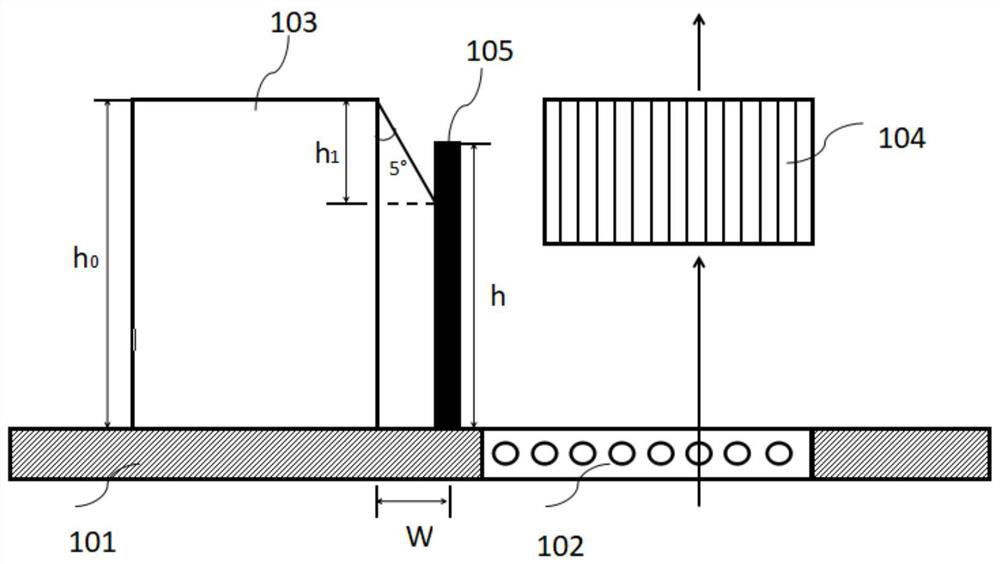

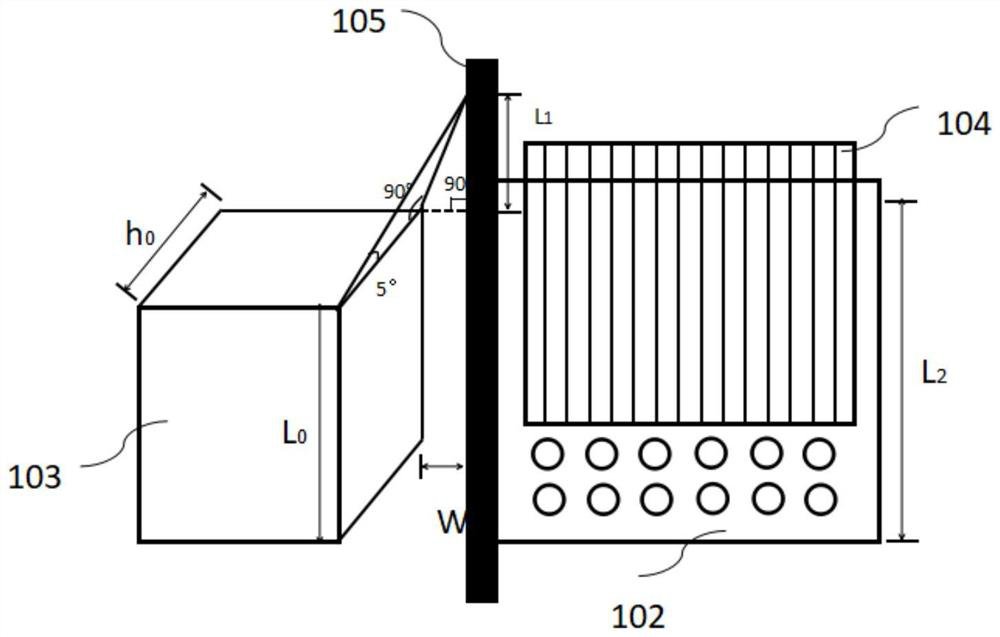

[0042] Such as figure 1 and figure 2 As shown, the heat dissipation system of the present invention includes a housing 101 , an opening area 102 disposed at the bottom of the housing 101 , an electronic device 103 accommodated in the housing 101 , a heat sink 104 and a baffle 105 .

[0043] Wherein the electronic device 103 is an electronic circuit with a power greater than 100W. figure 1 The straight line with the arrow in the middle indicates the flow direction of the wind. The external cold air flows in from the opening area 102 of the bottom shell, passes through the radiator 103, takes away the internal heat, and flows out in the state of internal hot air.

[0044] The baffle 105 is arranged between the electronic device 103 and the opening area 102. The position of the baffle 105 should exceed the edge of the opening area 102 of the casing 101 and is close to the edge of the electronic circuit. The opening area of the enclosure is isolated to avoid the ejection of s...

Embodiment 2

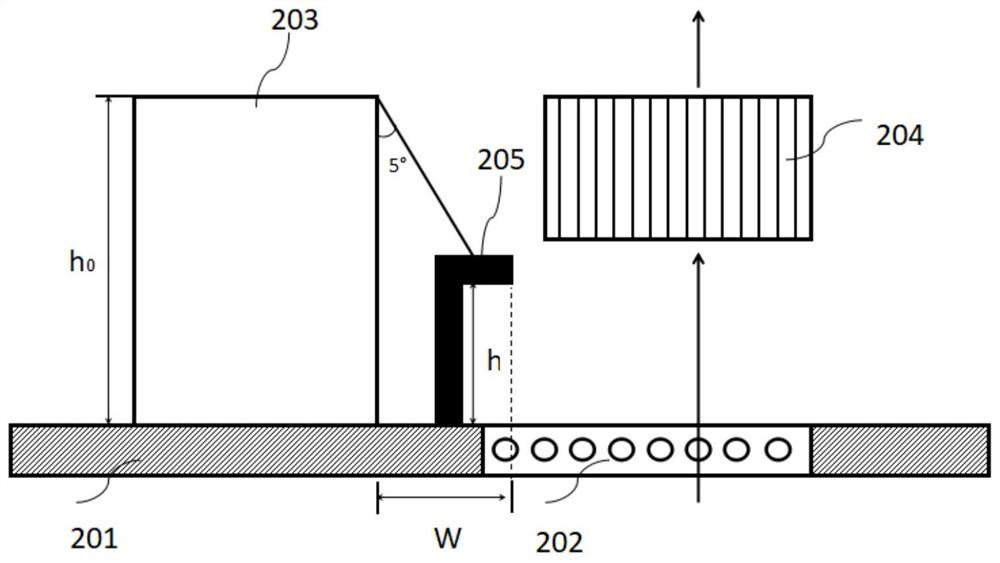

[0069] refer to image 3 As shown, it is the second embodiment of the present invention, which is improved on the basis of the previous embodiments. The principle and structure are roughly the same. The heat dissipation system includes a casing 201, an opening area 202 arranged at the bottom of the The electronic device 203, the heat sink 204 and the baffle 205 in the housing 201 differ only in that the structure of the baffle is different. The baffle in Embodiment 1 is elongated, which can effectively block the potential fire source within a 5° angle range. The molten metal or burning material inside, but due to structural limitations, there is often the problem that there is not much space in the vertical direction of the baffle, so the baffle here is designed as L-shaped in this embodiment.

[0070] Specifically, the baffle includes a longitudinal baffle extending along the longitudinal direction and a transverse baffle bent and extended from the longitudinal baffle, wherei...

Embodiment approach

[0075] refer to Figure 4 As shown, it is the third embodiment of the present invention, which is improved on the basis of the previous embodiments, and its principle and structure are roughly the same. The heat dissipation system includes a housing 301, an opening area 302 arranged at the bottom of The electronic device 303, the heat sink 304 and the baffle 305 in the housing 301 differ only in that the structure of the baffle is different. The baffle in Embodiment 1 is elongated, which can effectively block the potential fire source within a 5° angle range. Molten metal or burning material inside, but due to structural limitations, there is often the problem that there is not much space in the vertical direction of the baffle; while the L-shaped baffle in Embodiment 2 requires a larger width in the horizontal direction, That is to say, W is required to be large, and the minimum width requirement cannot be met if limited by the free structure in the horizontal direction. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com