A crushing sand making machine with shock absorption function

A kind of sand making machine and functional technology, which is applied in the direction of spring/shock absorber, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of large vibration of the fuselage, dumping of the fuselage, and affecting service life, so as to improve the shock absorption performance Safety, avoiding damage and tilting, good restraint and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

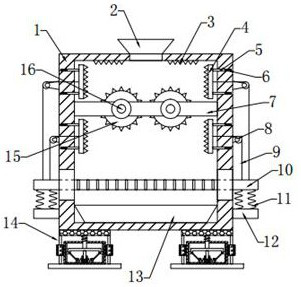

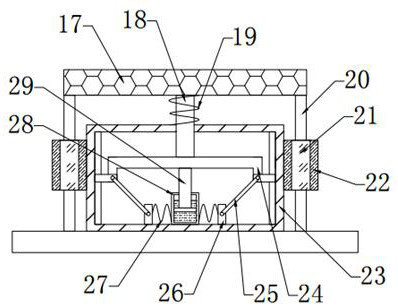

[0022] see Figure 1~2 , in an embodiment of the present invention, a crushing and sand making machine with shock-absorbing function includes a shell 1, a crushing roller 15 and a shock-absorbing foot 14, the top of the shell 1 is provided with a feed port 2, and the feed The lower side of the mouth 2 is provided with a fixed rod 7 fixedly connected with the housing 1, and a pair of crushing rollers 15 are arranged on the fixed rod 7, and the crushing rollers 15 are driven by a motor 16, and the two crushing rollers 15 rotate relatively , the upper and lower sides of the two crushing rollers 15 are provided with toothed plates 4, the outer sides of the toothed plates 4 are fixedly connected with telescopic rods 5, and a first spring 6 is provided between the telescopic rods 5 and the housing 1, One end of the first spring 6 is fixedly connected to the telescopic rod 5, and the other end is fixed on the inner wall of the casing 1. A sieve plate 10 is arranged on the lower side ...

Embodiment 2

[0027] A construction machine, comprising the crushing and sand-making machine described in Embodiment 1 with a shock-absorbing function.

[0028] The crushing sand making machine with shock absorbing function, by setting the crushing tooth 3 and the tooth plate 4, can realize the repeated crushing of the gravel, which is beneficial to strengthen the crushing effect of the sand making machine, and by setting the third spring 19, it can reduce The effect of shock buffering, by setting the fourth spring 27 and damping fluid, can realize further shock absorption to the crushing sand making machine body, so that it has a good shock absorption effect as a whole, by setting the limit rod 20, the limit tube 21 and The limit block 22 can better limit and stabilize the position of the shock-absorbing foot 14, avoid damage and inclination of the shock-absorbing foot 14 during use, and improve the shock absorption and safety of the device.

[0029]The working principle of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com