A steel plate leveling machine

A technology of steel plate leveling machine and backing plate, which is applied in the field of steel plate leveling machine and can solve the problems of heavy steel plate and troublesome movement of steel plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

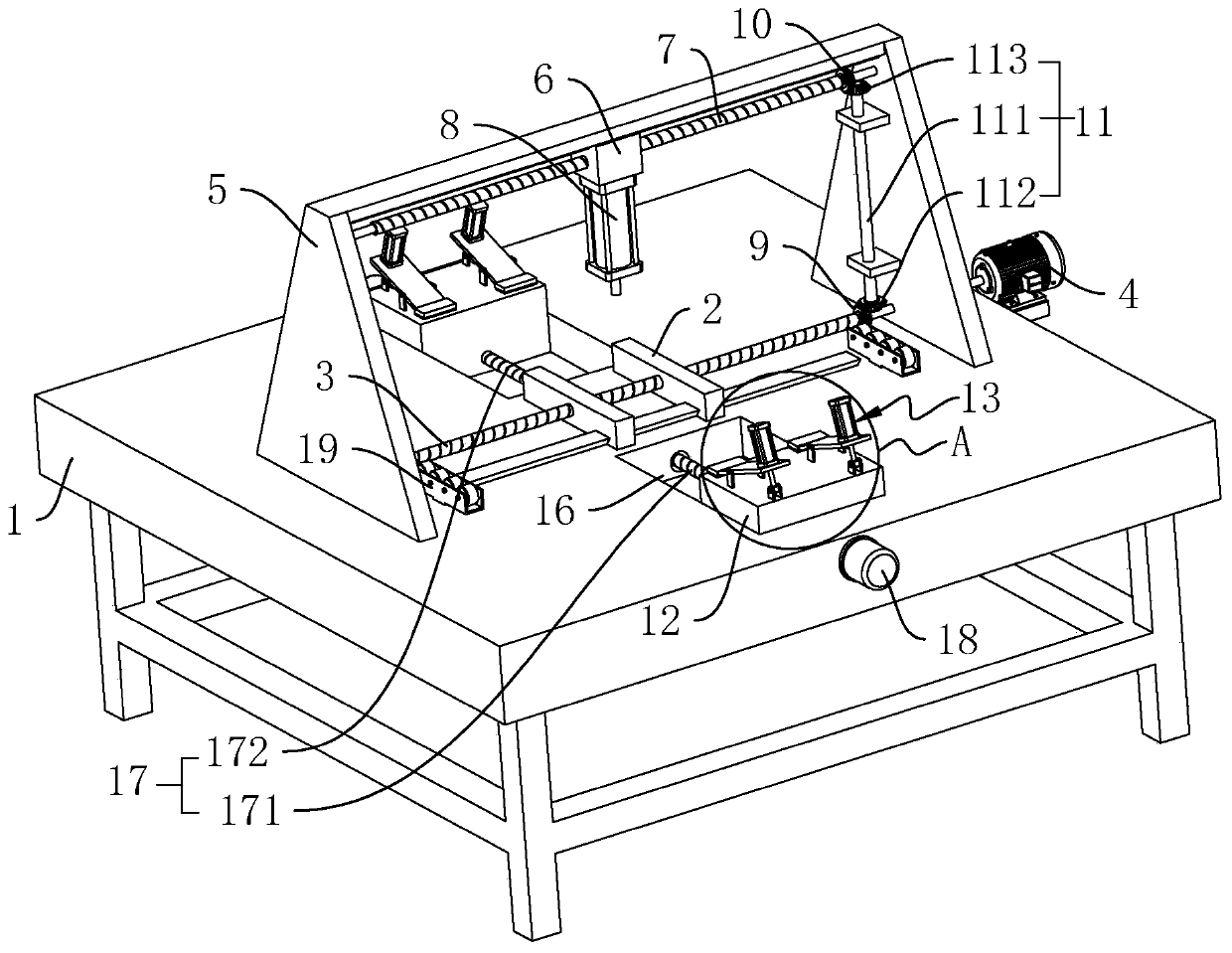

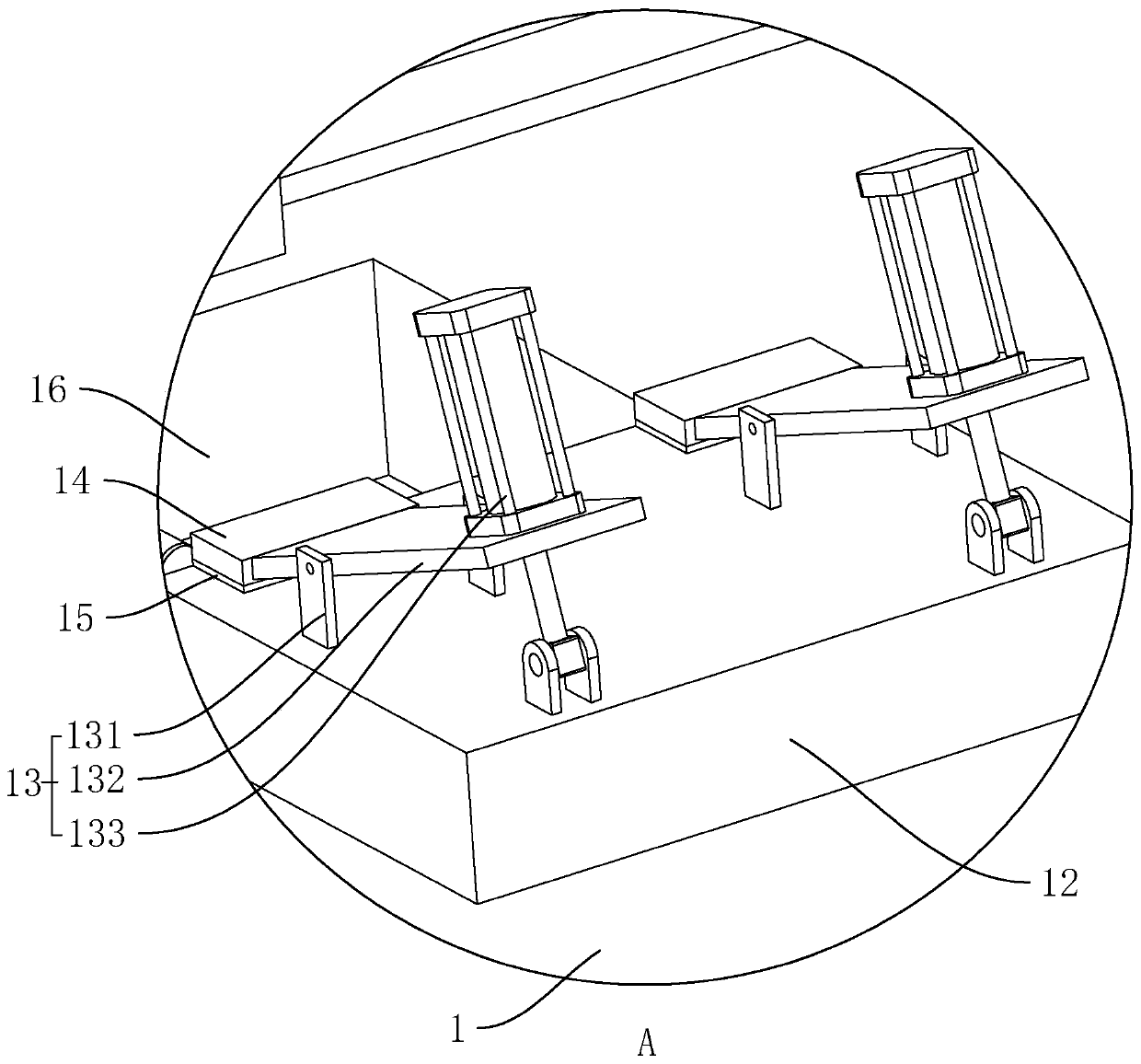

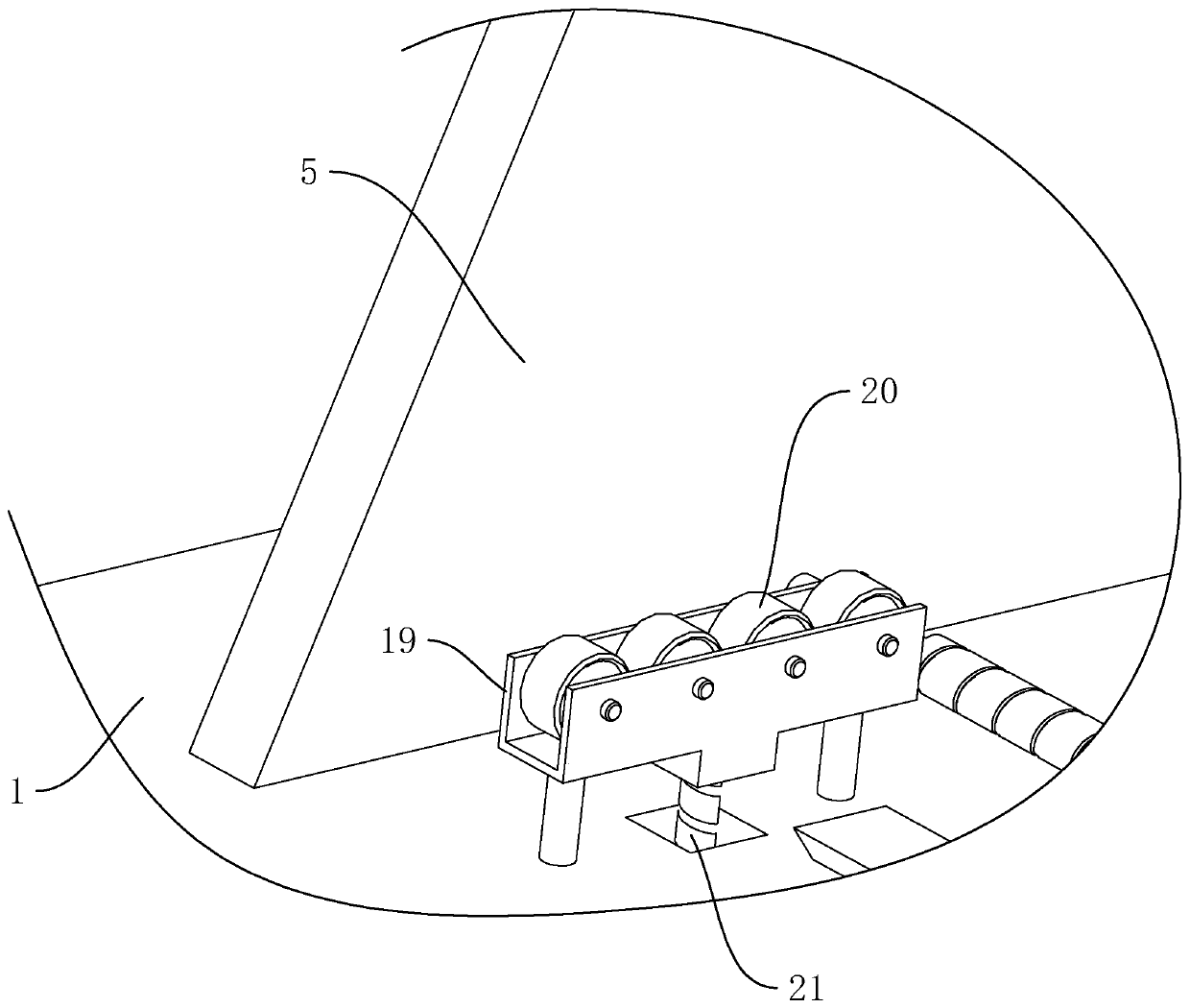

[0036] A steel plate leveling machine, such as figure 1 As shown, a base 1 is included, and two backing plates 2 are arranged in parallel on the base 1, and the upper end surfaces of the two backing plates 2 are arranged flush. The base 1 is provided with slide rails, and the two backing plates 2 are correspondingly provided with slide grooves matching with the slide rails, and the two backing plates 2 are slidably connected to the base 1 in the horizontal direction through the cooperation of the slide rail chute. Usually the backing plate 2 is made of plastic, which reduces the situation of scratching the steel plate when the base 1 slides.

[0037] The base 1 is also rotatably connected with a screw mandrel 3, the axis of the screw mandrel 3 is arranged parallel to the slide rail, and the screw mandrel 3 is screwed to the two backing plates 2 at the same time. Base 1 is also provided with driving motor 4, and driving motor 4 is arranged on the axial end of screw mandrel 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com