Bidirectional double-helical cooling water jacket

A cooling water jacket, double helix technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment and other directions, can solve the problems of poor cooling effect, uneven cooling effect, worse cooling effect, etc., to achieve cooling effect Uniformity and the effect of solving the problem of uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

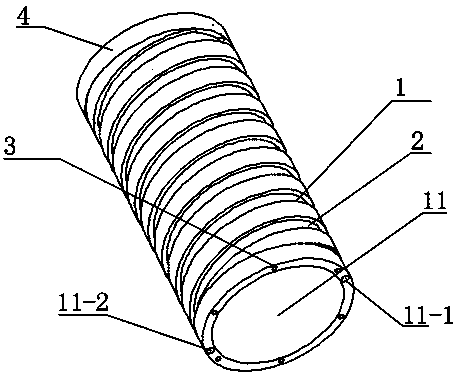

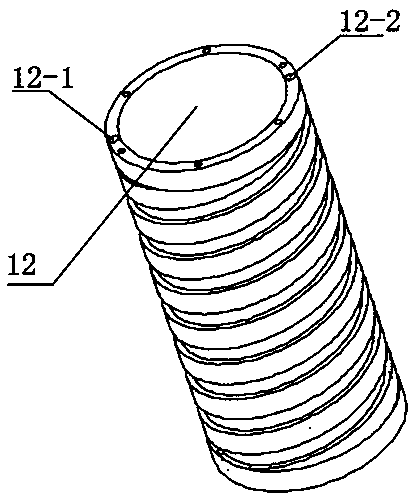

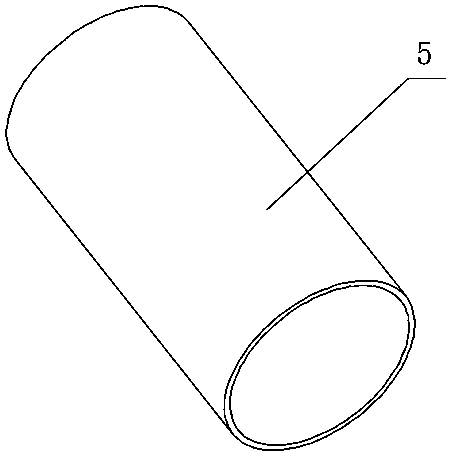

[0021] The object of the present invention is to provide an electric spindle cooling water jacket with uniform cooling effect in the axial direction and the circumferential direction, so as to solve the technical problems existing in the prior art. figure 1 , attached figure 2 , attached image 3 and attached Figure 4 As shown, a bidirectional double-helical cooling water jacket provided by the present invention includes a water jacket main body (4), a water jacket shell (5) and a water jacket end cover (9), and the water jacket main body (4) includes a end face inlet Water outlet (11-1) and b end surface water inlet (12-1), a end surface water outlet (11-2) and b end surface water outlet (12-2), the first spiral water channel (1) and the second spiral The water channel (2) and 6 fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com