Variant wing vertical takeoff and landing unmanned aerial vehicle

A technology of vertical take-off and landing and modified wings, which is applied in vertical take-off and landing aircraft, wing adjustment, unmanned aircraft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

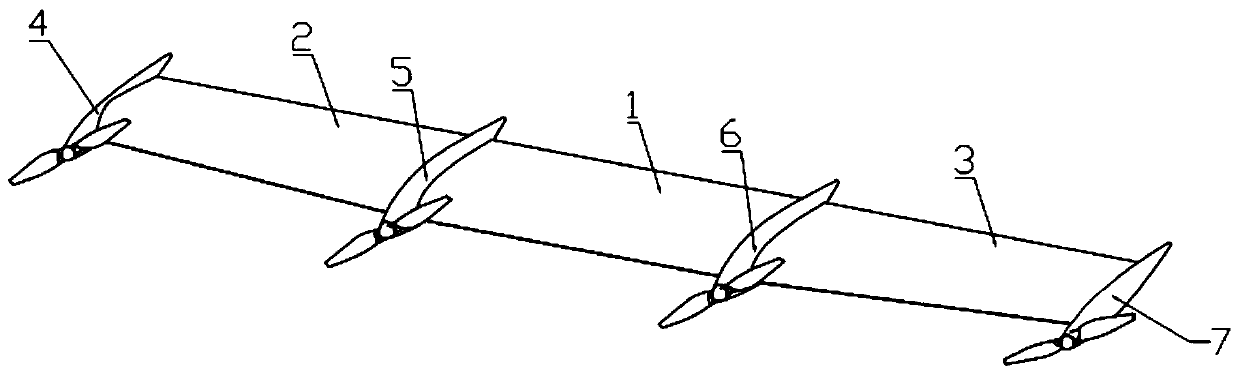

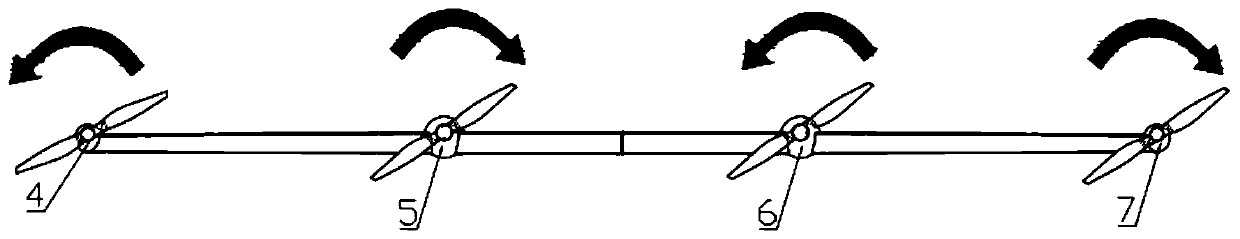

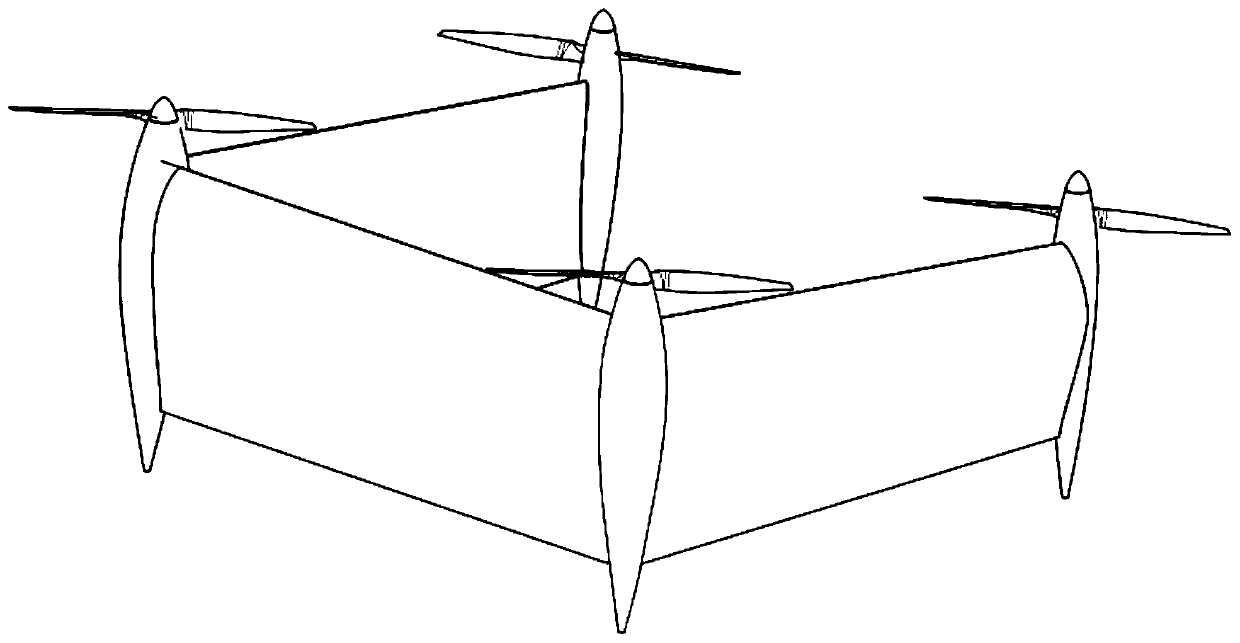

[0047] Such as Figure 1 to Figure 7 As shown, a variant wing vertical take-off and landing UAV includes a UAV body and a plurality of power components installed on the UAV body, the UAV body includes wings, and the power components use For generating thrust or pulling force along the longitudinal direction of the UAV body, the power components are arranged along the transverse direction of the UAV body;

[0048] In the lateral direction of the UAV body, the UAV body is composed of a plurality of sub-sections in series, and any two adjacent sub-sections can be flipped relative to each other, and the direction of the flip axis of the flip is: one end faces the The front end of the man-machine body and the other end face the rear end of the drone body;

[0049] There are at least three power assemblies, and the power assemblies are distributed on different subsections.

[0050] For the existing traditional fixed-wing UAVs: Although the fixed-wing UAVs have the advantages of high...

Embodiment 2

[0055] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 7 As shown, as a specific implementation form of the subsection, the subsection includes the first wing 2, the second wing 1 and the third wing 3 arranged in sequence along the lateral direction of the drone body. Power components are fixed on the first wing 2, the second wing 1 and the third wing 3;

[0056] The axial direction of the turning axis is along the longitudinal direction of the drone body, and the relative turning can be turned so that the first wing 2, the second wing 1 and the third wing 3 are on the same plane. In this solution, by defining the axial direction of the turning axis, the corresponding wings of the UAV can be parallel to the output direction of the power assembly no matter during the take-off and landing multi-rotor flight process or the fixed-wing flight process, so that , to facilitate the optimization of the resistance of the UAV during flight....

Embodiment 3

[0066] Such as Figure 7 As shown, more specifically, this solution provides a wing folding mechanism with self-locking function and a specific solution: it also includes a wing folding mechanism for realizing the relative turning, and the wing folding mechanism includes a drive Motor 13, transmission shaft 15 and worm gear 16 worm screw 17 mechanism, described transmission shaft 15 is connected with the output end of driving motor 13, under the effect of driving motor 13, described transmission shaft 15 can rotate around self axis;

[0067] Described worm wheel 16 worm screw 17 mechanism comprises worm wheel 16 and the worm screw 17 that matches with described worm wheel 16, and described worm screw 17 links to each other with transmission shaft 15, and worm screw 17 is coaxial with transmission shaft 15;

[0068] A worm gear shaft 18 is coaxially installed on the worm gear 16;

[0069]Also include the second connecting lug, in the two subsections connected by the wing foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com