Paper roll placing mechanism of toilet paper rolling machine

A technology of toilet paper rolls and paper rolls, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., which can solve the problems that the rolling motion cannot continue, and the paper is too late to be involved in the main body of the paper winding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

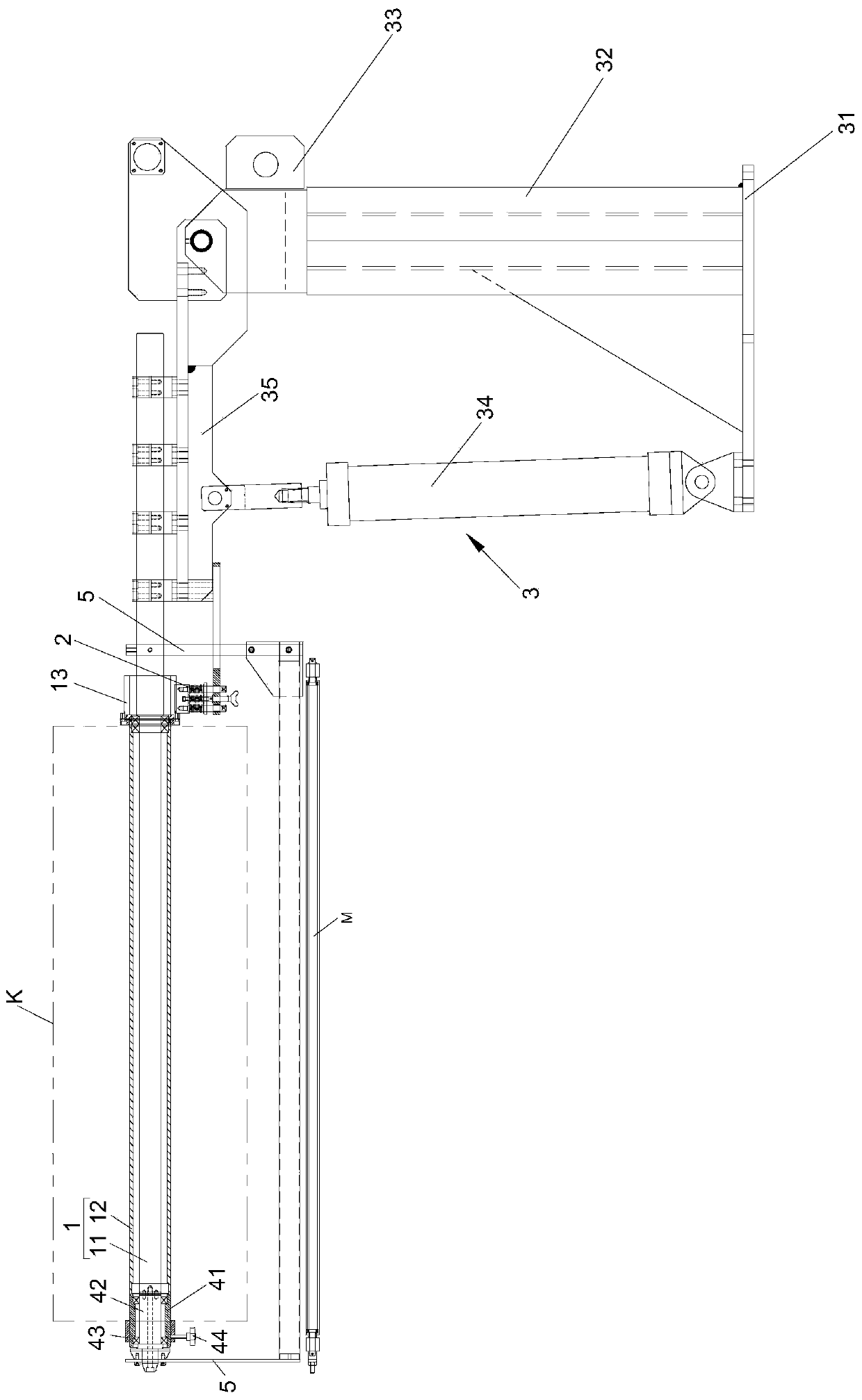

[0021] see Figure 1-2 As shown, the embodiment of the present invention discloses a paper roll placement mechanism of a toilet paper roll machine, including:

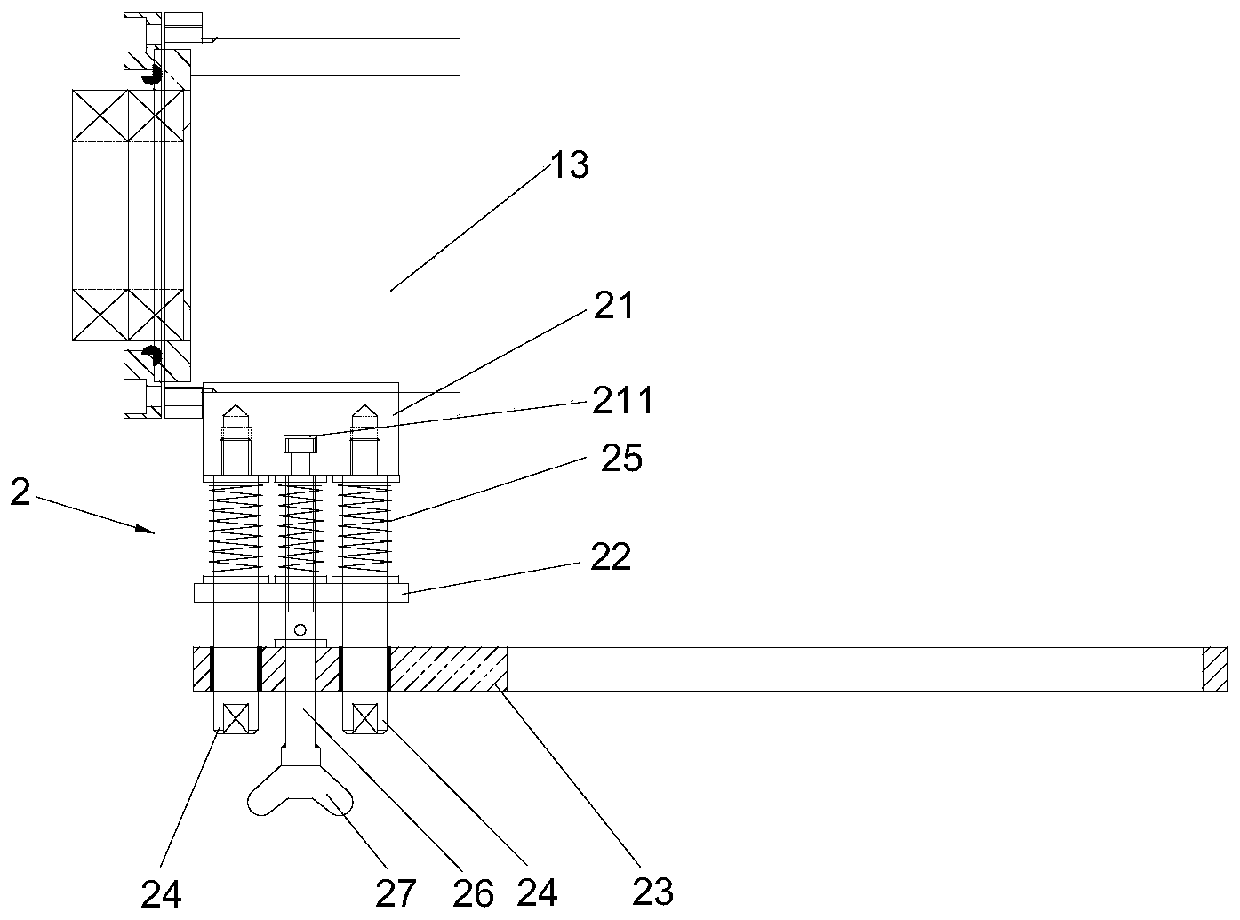

[0022] Placement frame 1, placement frame 1 comprises central axis 11 and the paper roll cylinder 12 that is sleeved on the central axis 11, is used for installing paper roll K on the paper roll cylinder 12, and paper roll cylinder 12 is positioned at the top of paper-leading roller M, and guides The paper roll M is used to introduce the paper roll on the paper roll drum 12 into the reel body, and one end of the paper roll drum 12 is fixedly connected to the small shaft sleeve 13 which is also sleeved on the central shaft 11;

[0023] The friction adjustment group 2, the friction adjustment group 2 in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap