Extraction back pressure heating steam turbine connected with exhaust steam recovery system

A technology of steam extraction back pressure and recovery system, which is applied in the direction of steam engine device, mechanical equipment, steam application, etc. It can solve the problems of unfulfilled industrial steam supply demand, waste of equipment resources, long-term shutdown, etc., and achieve strong engineering application value, Increased utilization, sufficient equipment and energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

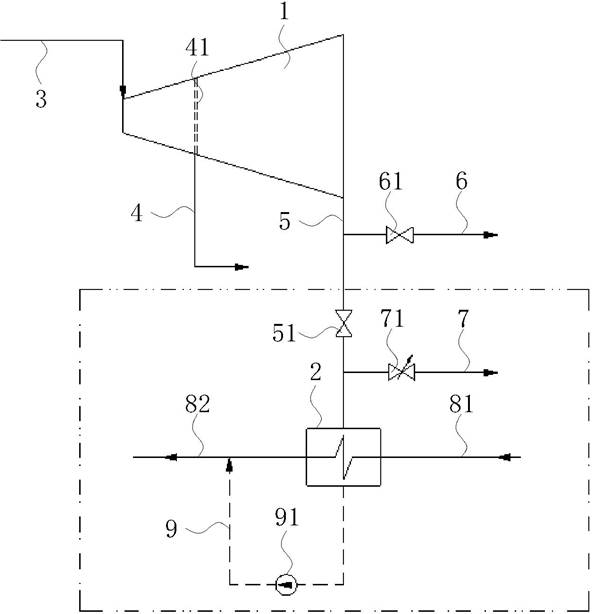

[0026] Such as figure 1 As shown, a steam extraction backpressure heating type steam turbine connected with an exhaust steam recovery system in this embodiment includes a steam extraction backpressure steam turbine 1 and an exhaust steam recovery system. The exhaust steam recovery system includes a heat exchanger 2 , the exhaust port of the extraction back pressure steam turbine 1 communicates with the steam inlet of the heat exchanger 2 through the exhaust pipeline 5, the exhaust pipeline 5 is equipped with a first valve 51, and the upstream side of the first valve 51 A heating and steam supply pipeline 6 is communicated with the steam exhaust pipeline 5 , and a second valve 61 is installed on the heating and steam supply pipeline 6 .

[0027] When the present invention is adopted, the steam extraction back pressure steam turbine 1 is connected with the main steam inlet pipeline 3, and the industrial steam extraction port of the steam extraction back pressure steam turbine 1...

Embodiment 2

[0035] Based on the design of Embodiment 1, such as figure 1 As shown, a method of using a steam extraction backpressure heating steam turbine connected with an exhaust steam recovery system in this embodiment, in the heating season, close the first valve 51, open the second valve 61, and the steam extraction backpressure steam turbine The exhaust steam of 1 enters the heating steam supply pipeline 6 for heating; in the non-heating season, the first valve 51 is opened, the second valve 61 is closed, and the exhaust steam of the extraction back pressure steam turbine 1 enters the heat exchanger 2 for heating. exchange. Please refer to Embodiment 1 for the detailed usage method.

[0036] Optionally, in another embodiment, in non-heating seasons, the actual exhaust steam volume of the extraction backpressure steam turbine 1 is 10%-20% of the design exhaust steam volume. On the premise of ensuring the normal operation of the steam extraction backpressure steam turbine 1, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com