A Screw Assembly Tool Based on Pneumatic Slip Ring Structure

A technology for assembling tools and screws, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of increasing weight, occupying a large space, and trachea entanglement, and achieve the effect of avoiding air leakage and trachea entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

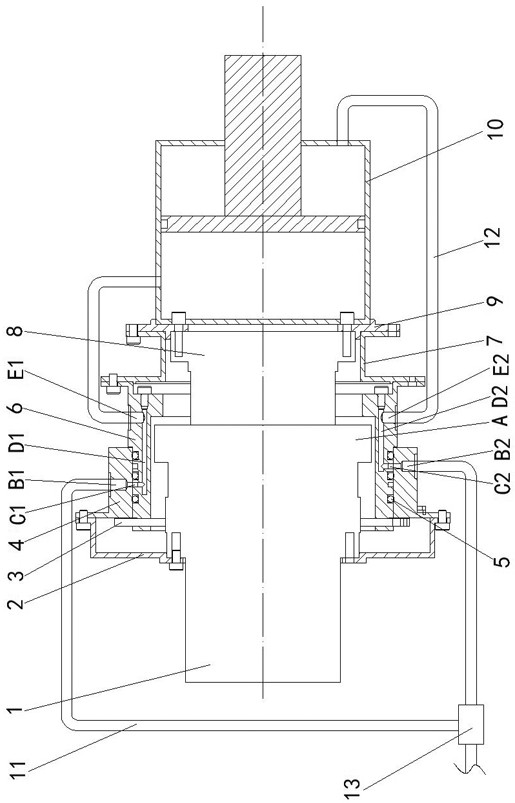

[0009] Specific implementation manner one: such as figure 1 As shown, the present invention discloses a screw assembly tool based on a pneumatic slip ring structure, including flange one 2, limit ring 3, fixed ring 4, rotating ring 6, flange two 7, flange three 9. , Cylinder 10, switch valve 13, electric rotating mechanism, two intake pipes 11 and two outlet pipes 12,

[0010] The electric rotating mechanism includes a fixed shaft 1 and a rotating shaft 8. One end of the fixed shaft 1 is detachably and fixedly connected to the end of the mechanical arm, and the other end of the fixed shaft 1 is sleeved on the outside of one end of the rotating shaft 8. The outer side wall is provided with an annular mounting boss A along the circumferential direction. The outer side of the electric rotating mechanism is sequentially covered with flange 1, stop ring 3, fixed ring 4, rotating ring 6, and flange 2, 7 from the fixed shaft to the rotating shaft. One end of the rotating ring 6 is slee...

specific Embodiment approach 2

[0011] Specific implementation manner two: such as figure 1 As shown, this embodiment is a further description of the first embodiment. Three sealing rings 5 are provided between the fixed ring 4 and the rotating ring 6, and the three sealing rings 5 are alternately arranged with two annular grooves. ; The sealing rings 5 on both sides are to ensure the sealing between the adjacent annular grooves and the outside world, and the sealing ring 5 in the middle is to ensure that there will be no communication between the two annular grooves. The assembly process In each channel, a certain amount of grease is added to reduce the rotational resistance between the fixed ring 4 and the rotating ring 6.

[0012] The cylinder 10 is an SMC type finger cylinder, the model is: MHS3-40D, which is an existing technology and can be purchased from outside.

[0013] When using the clamping screw of the present invention, turn the switch valve 13 to one side, and pass high-pressure gas into one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com