Pneumatic pin shaft disassembling tool for oil rig and control system of pneumatic pin shaft disassembling tool

A pneumatic, drilling rig technology, applied in the field of mechanical equipment, to achieve the effect of simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

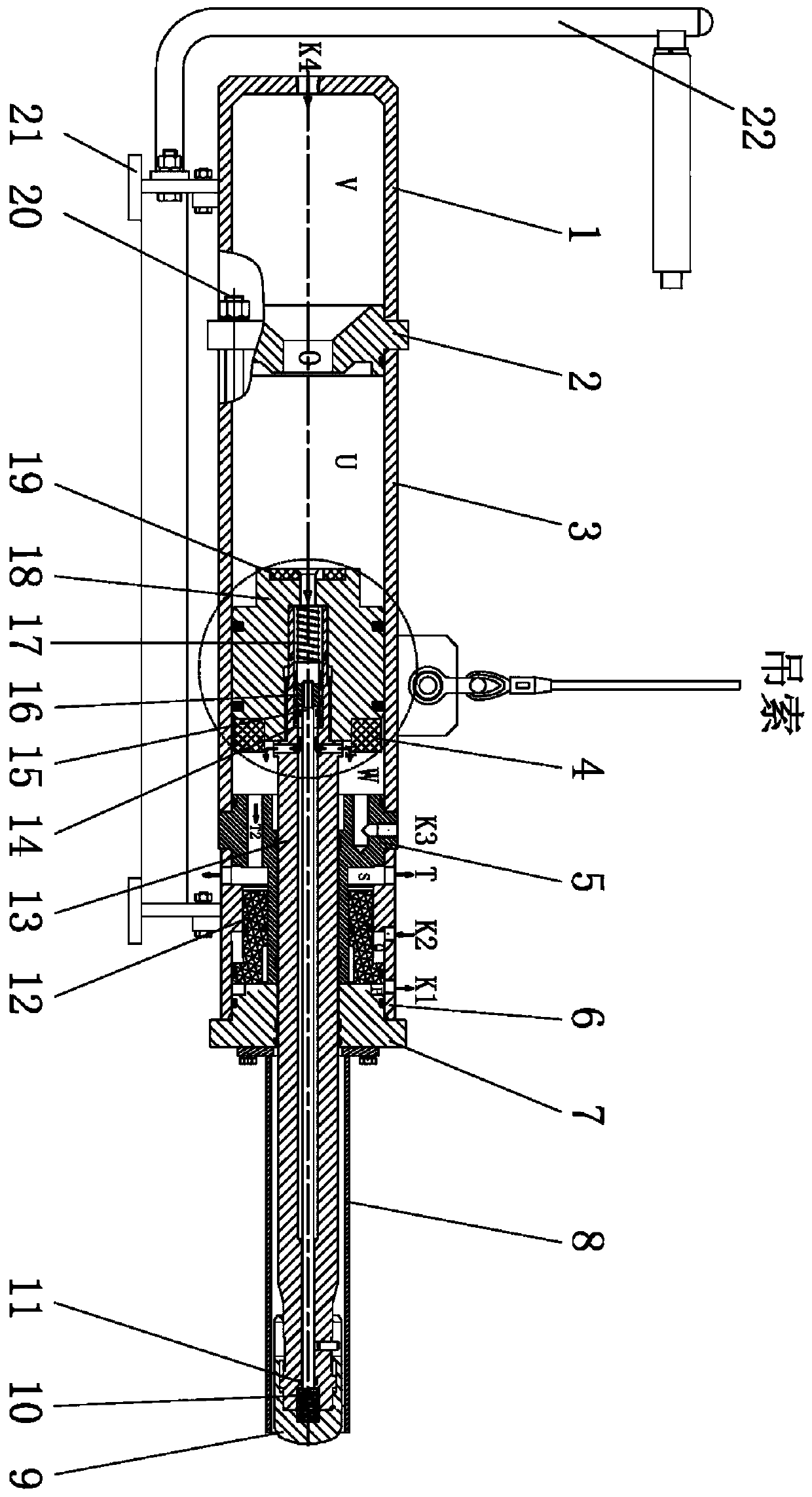

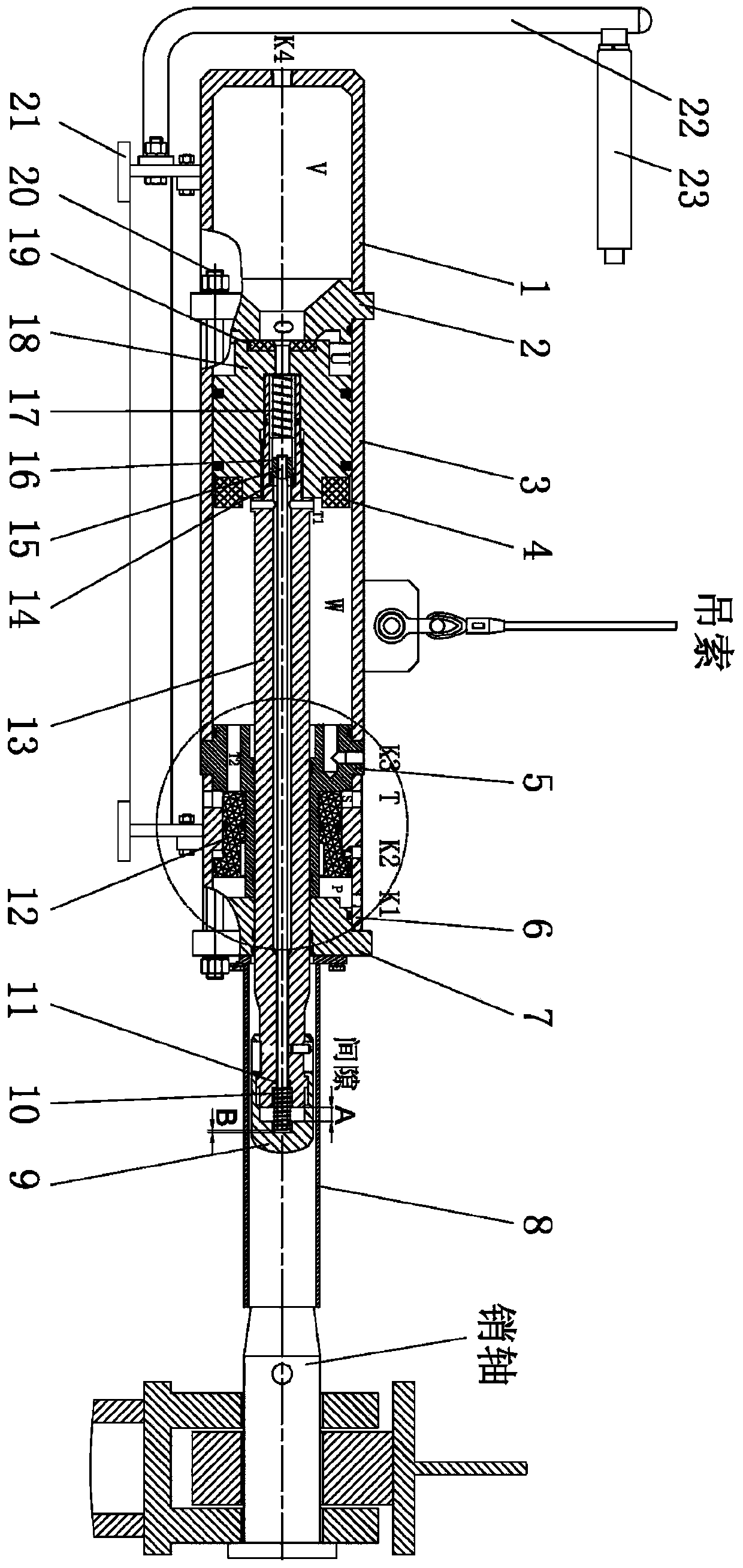

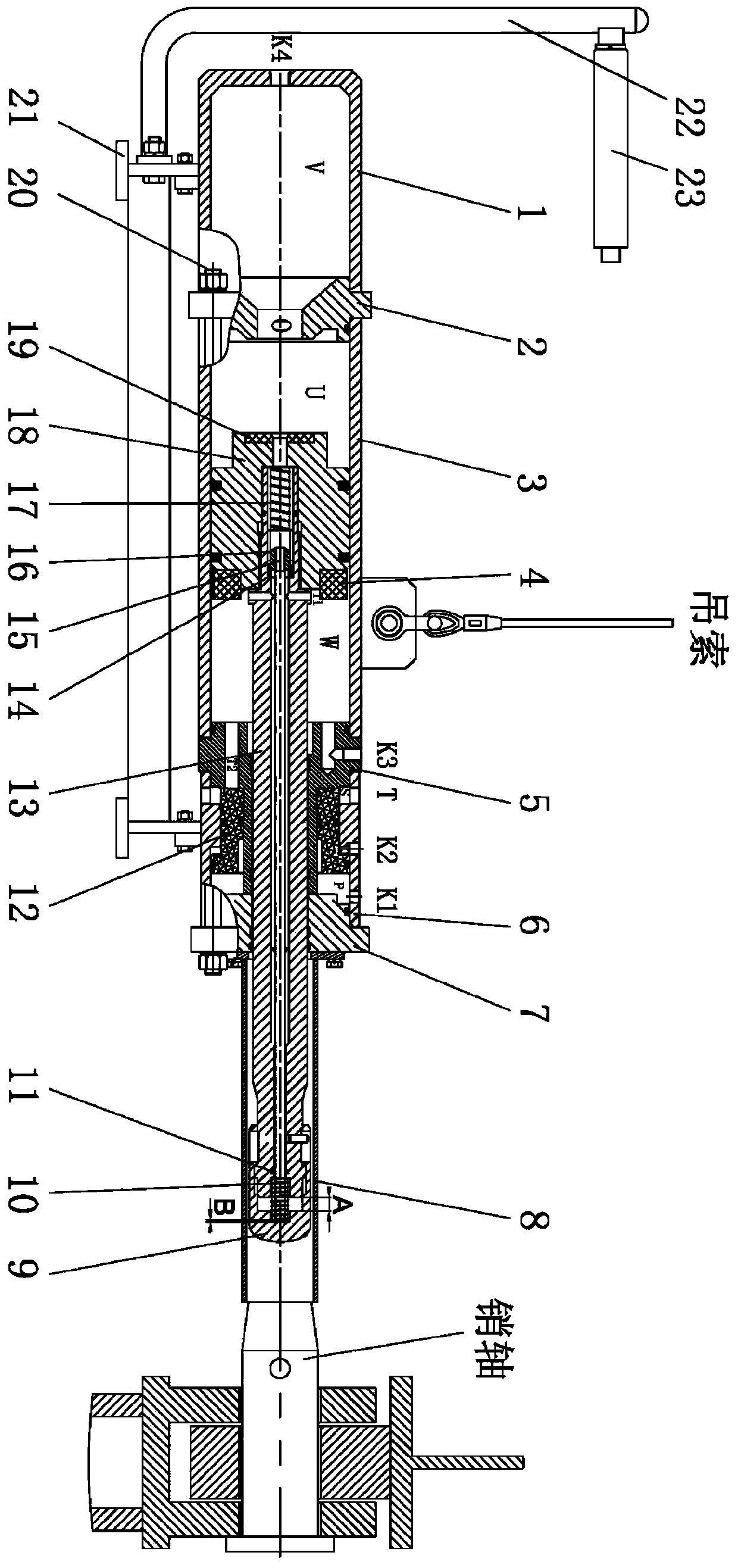

[0032] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0033] The pneumatic pin disassembly tool used in the oil drilling rig of the present invention includes a shell structure and an impact component installed in the shell structure.

[0034] Such as figure 1 As shown, the housing structure includes the housing structure including the energy storage cylinder 1, the middle cover 2, the main piston cylinder 3, the guide cylinder 5, the quick displacement piston cylinder 6, the front cover 7, and Sleeve 8, in which the fixed connection method can be fixed by the tightening screw 20; the energy storage cylinder 1 has an air inlet K4; the middle cover 2 is a rotating body, and the middle cover 2 has a tapered hole in the axial direction. The large end of the hole is close to the energy storage cylinder 1, and the tapered hole facilitates gas introduction; the guide cylinder 5 is provided with a guide cylinder through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com