Rain grate lifter

A rain grate and wheel technology, which is applied to lifting devices, crowbars, etc., can solve problems such as difficulty in lifting, and achieve the effect of convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

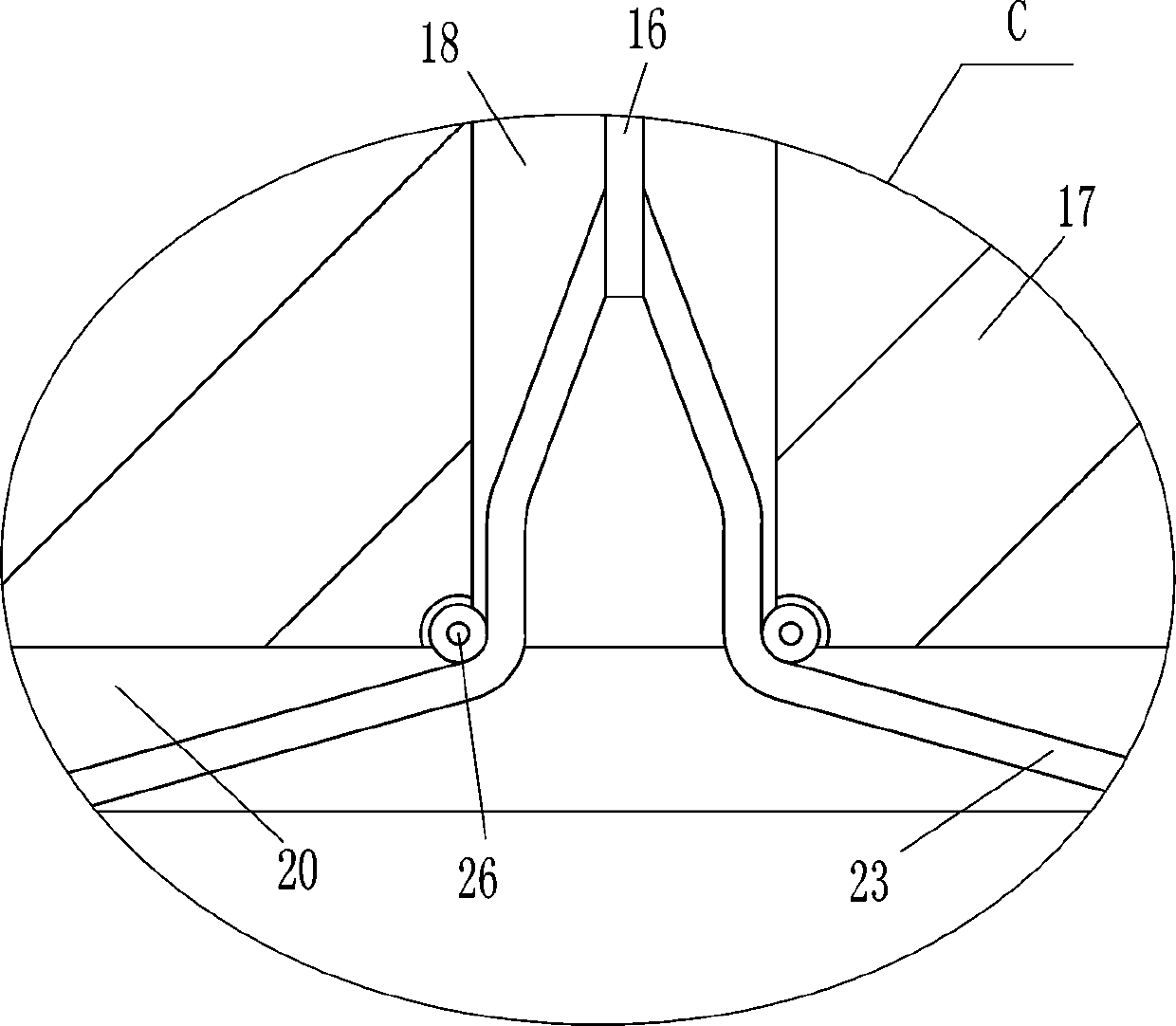

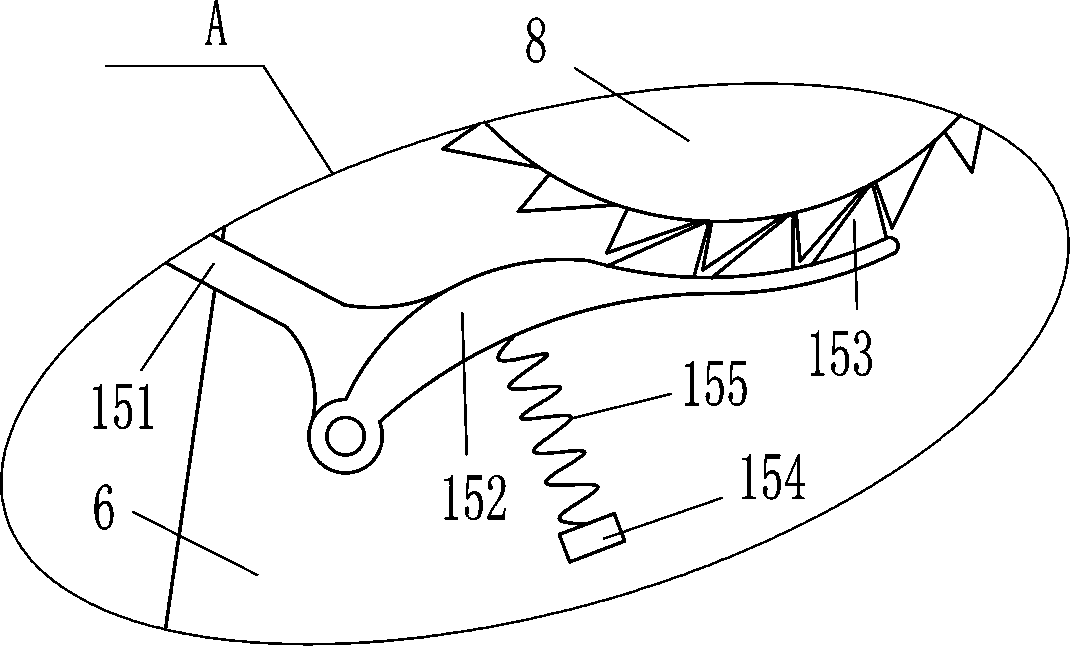

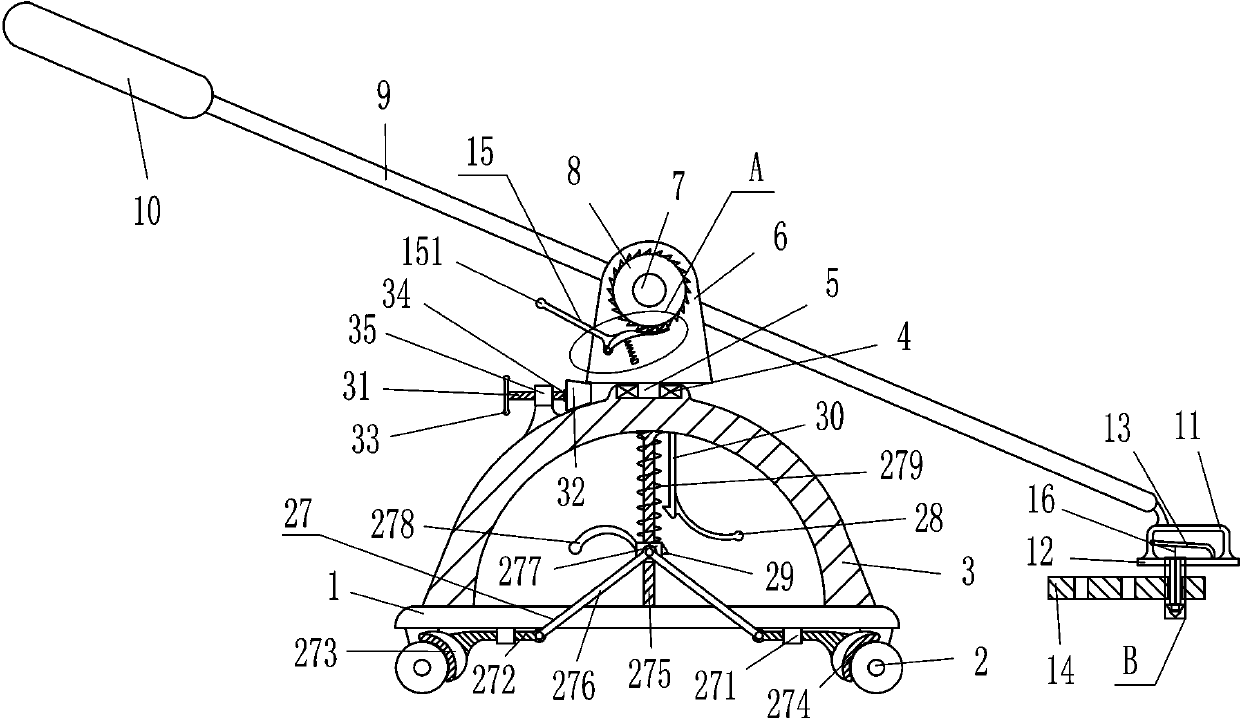

[0017] A rain grate lifter, such as Figure 1-4 As shown, it includes base plate 1, wheel 2, arc frame 3, bearing seat 4, rotating shaft 5, support plate 6, rotating rod 7, ratchet 8, swing rod 9, grip rod 10, n-shaped rod 11, and horizontal plate 12 , the first movable rod 13, the clamping device 15, the pull wire 16, the vertical bar 17, the second spring 21, the block 22, the branch line 23, the sealing ring 24, the horizontal slider 25 and the guide wheel 26, and the left and right sides of the bottom plate 1 The side symmetric type is equipped with wheels 2, the base plate 1 is connected with the wheels 2 through bolt connection, the arc frame 3 is installed in the middle of the top of the base plate 1, the arc frame 3 is connected with the base plate 1 through bolt connection, and the arc frame 3 A bearing seat 4 is embedded in the middle of the outer surface, and the rotating shaft 5 is connected to the bearing in the bearing seat 4. The rotating shaft 5 is connected to...

Embodiment 2

[0019] A rain grate lifter, such as Figure 1-4 As shown, it includes base plate 1, wheel 2, arc frame 3, bearing seat 4, rotating shaft 5, support plate 6, rotating rod 7, ratchet 8, swing rod 9, grip rod 10, n-shaped rod 11, and horizontal plate 12 , the first movable rod 13, the clamping device 15, the pull wire 16, the vertical bar 17, the second spring 21, the block 22, the branch line 23, the sealing ring 24, the horizontal slider 25 and the guide wheel 26, and the left and right sides of the bottom plate 1 The side symmetrical type is equipped with wheels 2, the arc frame 3 is installed in the middle of the top of the bottom plate 1, the middle part of the outer surface of the arc frame 3 is embedded with a bearing seat 4, the rotating shaft 5 is connected with the bearing in the bearing seat 4, and the top of the rotating shaft 5 The support plate 6 is fixedly connected, and the rotating rod 7 is rotatably installed in the middle of the upper part of the supporting pla...

Embodiment 3

[0022] A rain grate lifter, such as Figure 1-4 As shown, it includes base plate 1, wheel 2, arc frame 3, bearing seat 4, rotating shaft 5, support plate 6, rotating rod 7, ratchet 8, swing rod 9, grip rod 10, n-shaped rod 11, and horizontal plate 12 , the first movable rod 13, the clamping device 15, the pull wire 16, the vertical bar 17, the second spring 21, the block 22, the branch line 23, the sealing ring 24, the horizontal slider 25 and the guide wheel 26, and the left and right sides of the bottom plate 1 The side symmetrical type is equipped with wheels 2, the arc frame 3 is installed in the middle of the top of the bottom plate 1, the middle part of the outer surface of the arc frame 3 is embedded with a bearing seat 4, the rotating shaft 5 is connected with the bearing in the bearing seat 4, and the top of the rotating shaft 5 The support plate 6 is fixedly connected, and the rotating rod 7 is rotatably installed in the middle of the upper part of the supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com