A kind of preparation method of one stone multi-faceted ceramic slab and ceramic slab

A ceramic and formula technology, applied in the field of ceramics, can solve the problems of pattern dislocation, poor decorative effect of ceramic slabs, and difficulty in matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method for a multi-faceted ceramic slab comprising the following steps:

[0028] (1), prepare the green body of ceramic slab;

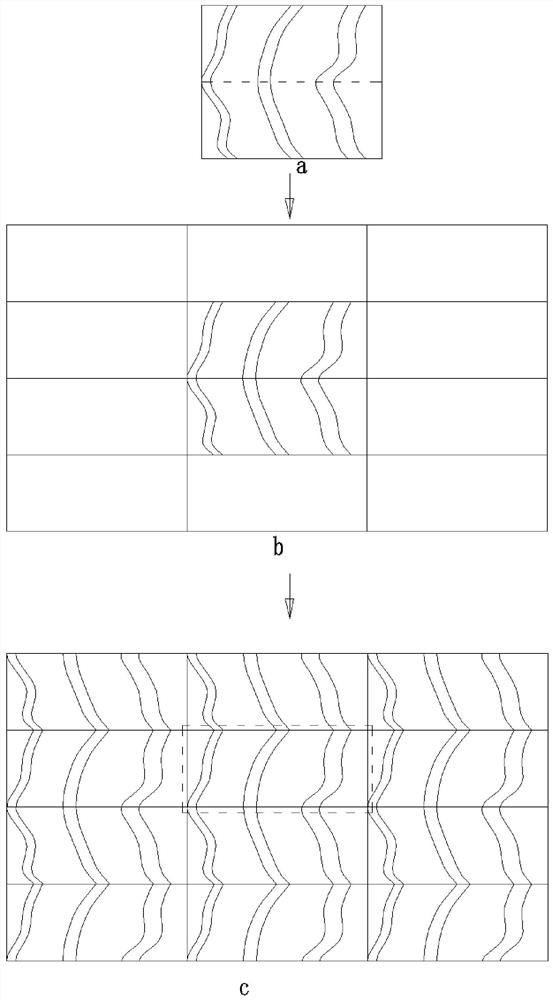

[0029] (2) Decorate the green body with inkjet printing: divide a large picture into multiple small pictures at the input end of the inkjet printer, expand the pattern edge of the small picture and input it to the inkjet printer on the green body For printing, each small picture corresponds to a green body;

[0030] (3), firing in a kiln to obtain a ceramic slab decorated with patterns and textures;

[0031] (4) Edge grinding is performed on the fired ceramic slabs to match the patterns of two adjacent ceramic slabs.

[0032] In the decoration step of the present invention, inkjet printing is carried out after expanding the group edge of the divided small figure, so that the pattern texture printed on the green body is also expanded, which makes the pattern texture on the green body with adjacent pattern texture There is a repe...

Embodiment 1

[0057] A preparation method of one-stone multi-faceted ceramic slab, comprising the following steps:

[0058] (1), prepare the blank of the ceramic slab, and the blank adopts the existing cloth method to complete the cloth and then press and form;

[0059] (2) Decorate the blank in the form of inkjet printing: divide a large image into multiple small images at the input end of the inkjet printer, expand the pattern edge of the small image and then input it into the inkjet printer on the blank For printing, each small image corresponds to a blank, and the pattern expansion edge of the small image expands toward the pattern connected to the small image; the size of the inkjet printing pattern is consistent with the size of the blank, and the pattern of the small image expands The edge is printed on the edge of the green body by inkjet printing to form a pattern expansion edge; the preset grinding amount of one side of the ceramic plate is ⊿L, the width of the pattern expansion e...

Embodiment 2

[0063] A preparation method of one-stone multi-faceted ceramic slab, comprising the following steps:

[0064] (1), prepare the green body of the ceramic slab, and the green body adopts the existing cloth method to complete the cloth and then press and form; on the green body, a primer is applied;

[0065] (2) Decorate the blank in the form of inkjet printing: divide a large image into multiple small images at the input end of the inkjet printer, expand the pattern edge of the small image and then input it into the inkjet printer on the blank For printing, each small image corresponds to a blank, and the pattern expansion edge of the small image expands toward the pattern connected to the small image; the size of the inkjet printing pattern is consistent with the size of the blank, and the pattern of the small image expands The edge is printed on the edge of the green body by inkjet printing to form a pattern expansion edge; the preset grinding amount of one side of the ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com