Bearing-shearing connector

A technology of shear type and connectors, which is applied in the direction of load-bearing elongated structural components, building components, structural elements, etc., can solve the problems of inconvenient production of precast concrete slabs, weakened concrete structures, and limited deformation capacity, etc., to achieve Reduce the number of reserved holes, reduce the difficulty of production, and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

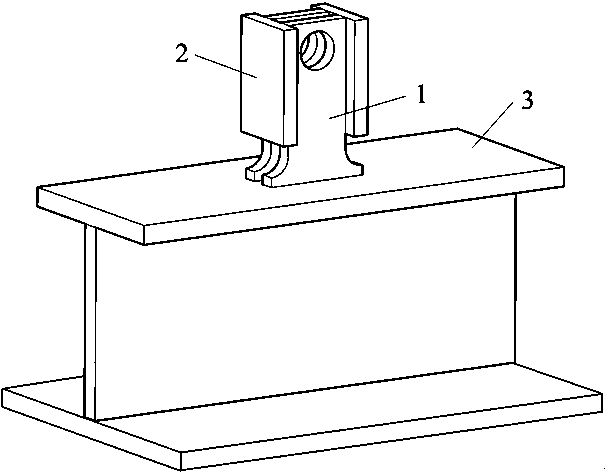

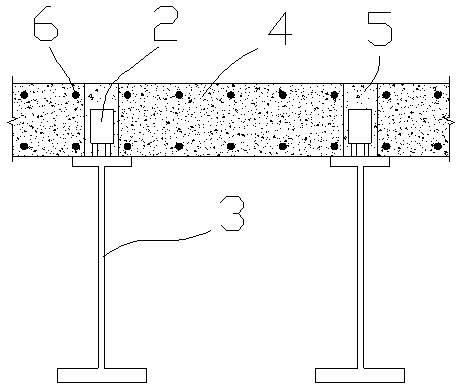

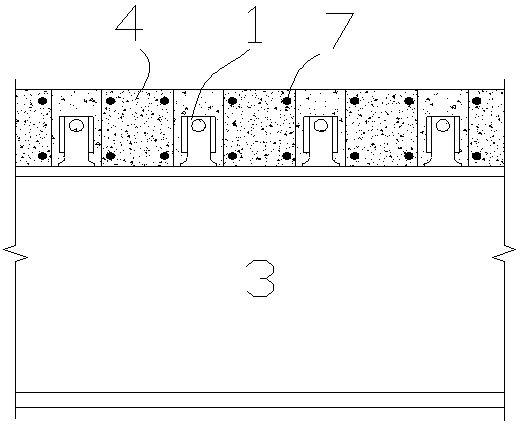

[0018] A pressure-shear type connector, the innovation of which is that the pressure-shear type connector is used to connect steel beams and prefabricated concrete slabs, and make the steel beams and prefabricated concrete slabs form an integrally stressed steel-shear Precast concrete composite beams;

[0019] The cross-section of the steel beam is I-shaped or trough-shaped; the prefabricated concrete slab is a prefabricated reinforced concrete structure;

[0020] The pressure-shear type connector is composed of two shear plates 1 and two pressure plates 2; the plane where the shear plates 1 are located is perpendicular to the horizontal plane, and the lower end of the shear plate 1 is connected to the upper side of the steel beam Welding and fixing, the plane where the shear plate 1 is located is parallel to the axial direction of the steel beam, the two shear plates 1 are distributed along the transverse direction of the steel beam, and there is a gap between the two shear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com