Power transformation equipment overhaul simulation training method

A technology for substation equipment and simulation training, which is applied in space navigation equipment, teaching aids for electrical operation, data processing applications, etc. Operation level, enhance the mastery of skills, and improve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

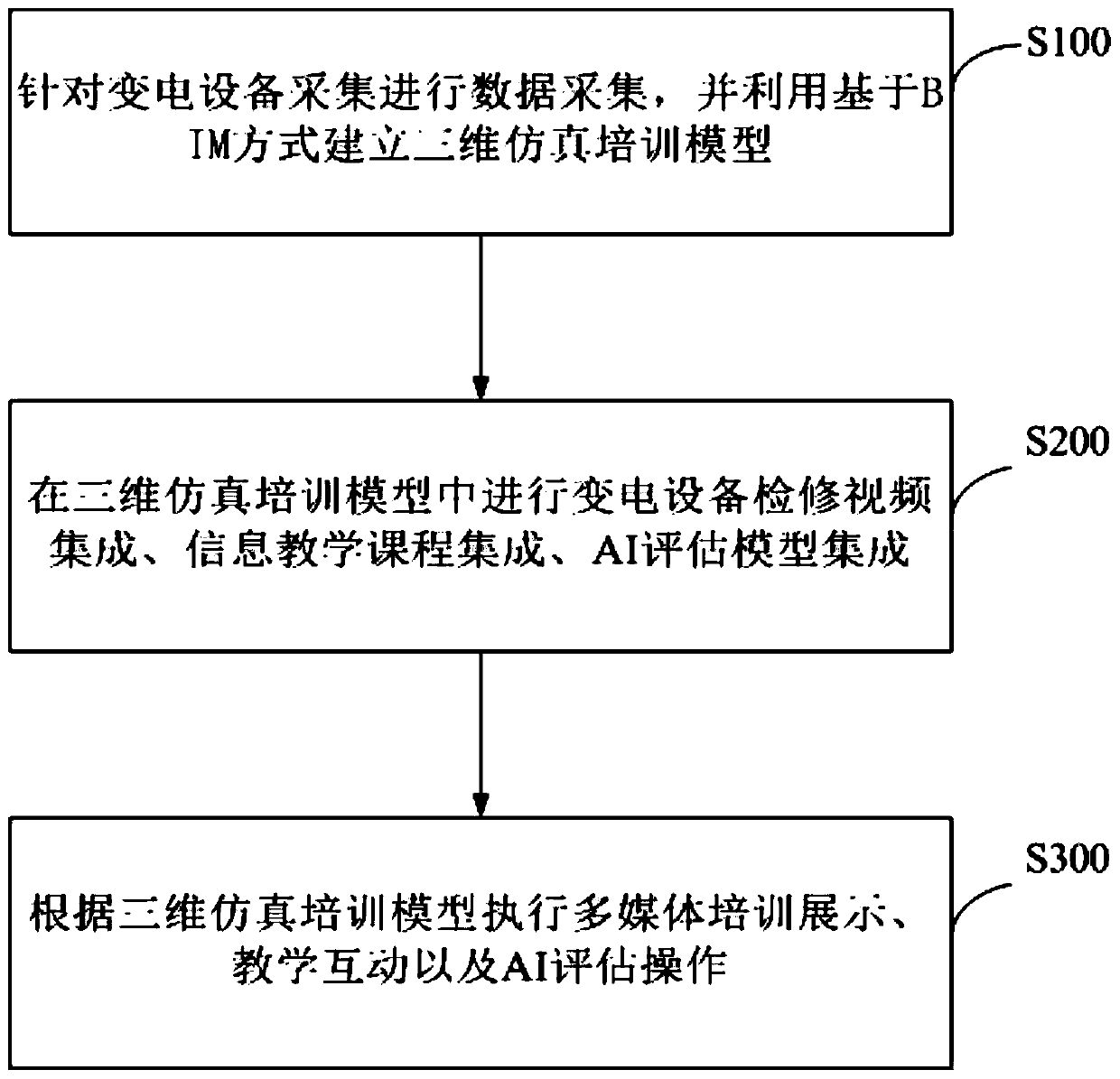

[0037] See figure 1 , The embodiment of the present invention provides a simulation training method for substation equipment maintenance, including the following operation steps;

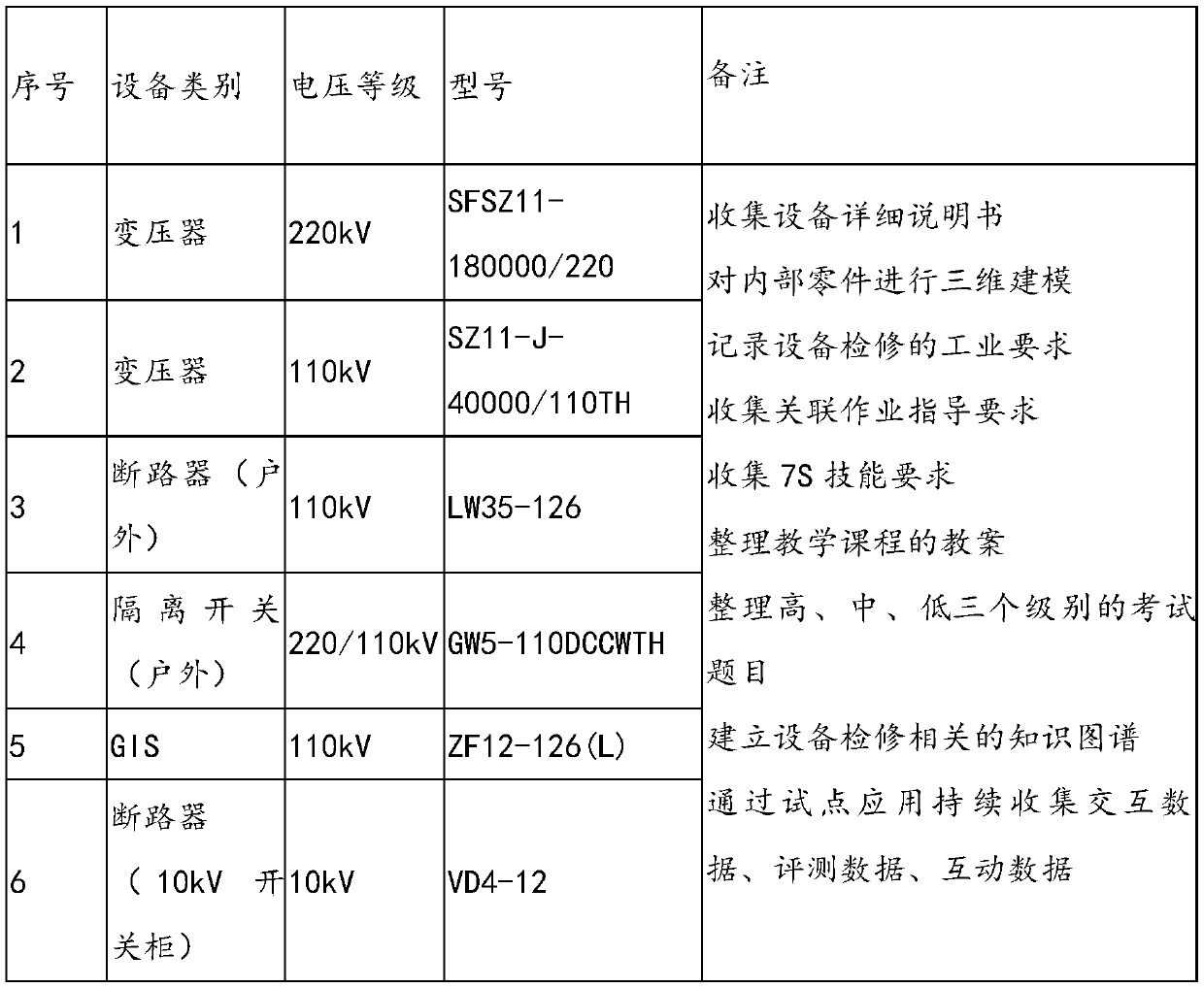

[0038] Step S100: Perform data collection for the collection of substation equipment, and establish a three-dimensional simulation training model based on BIM;

[0039] Step S200: In the three-dimensional simulation training model, perform substation equipment maintenance video integration, information teaching curriculum integration, and AI evaluation model integration;

[0040] Step S300: Perform multimedia training display, teaching interaction, and AI evaluation operations according to the three-dimensional simulation training model.

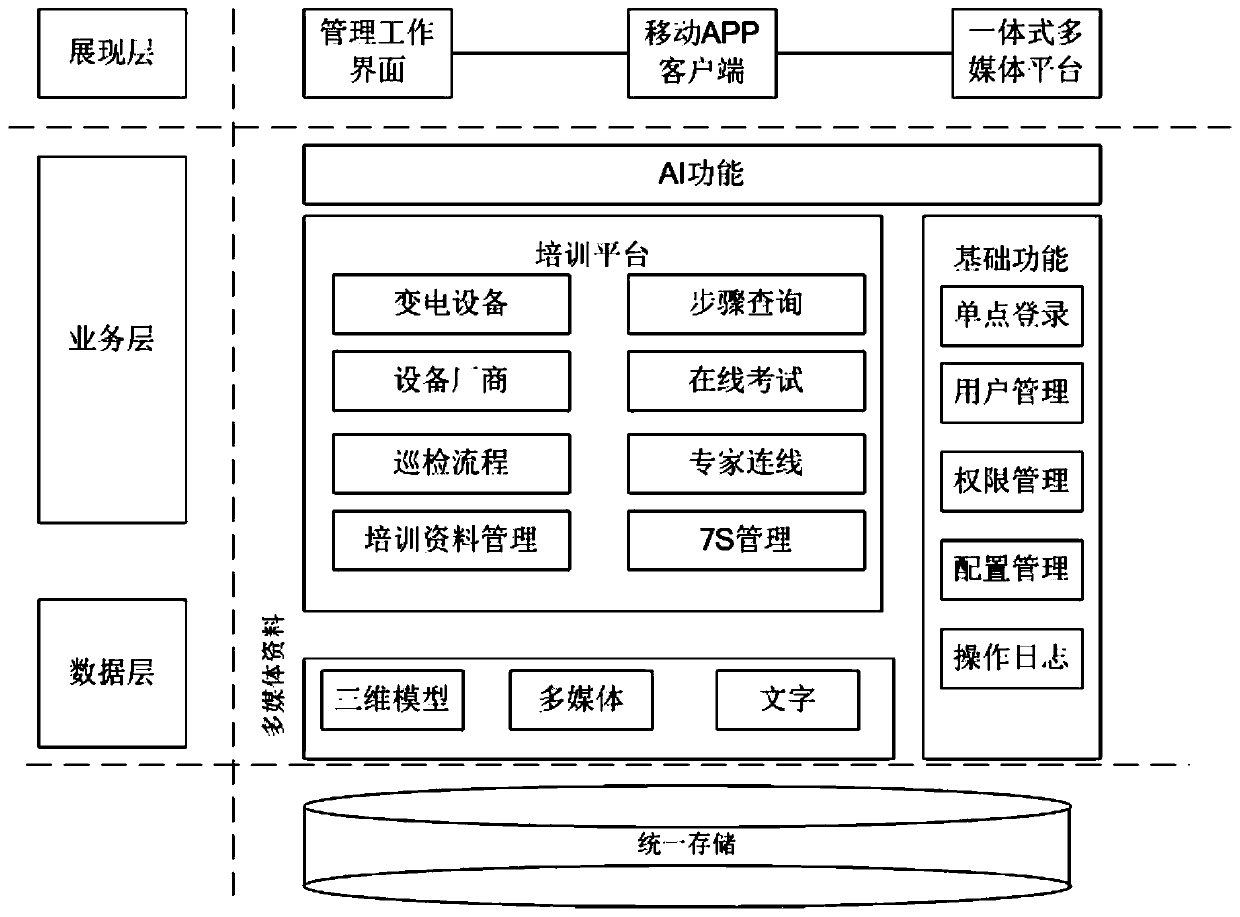

[0041] Analyzing the main content of the above simulation training method for substation equipment maintenance, it can be seen that: the above substation equipment maintenance simulation training method establishes a set of substation equipment training and evaluation syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com