Automatic blowing and drying machine

A drying machine, automatic technology, applied in the direction of drying machine, drying, drying of solid materials, etc., can solve the problems of drying LED material, increase labor costs, low efficiency, etc., to improve the operation level, improve drying quality, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the following examples.

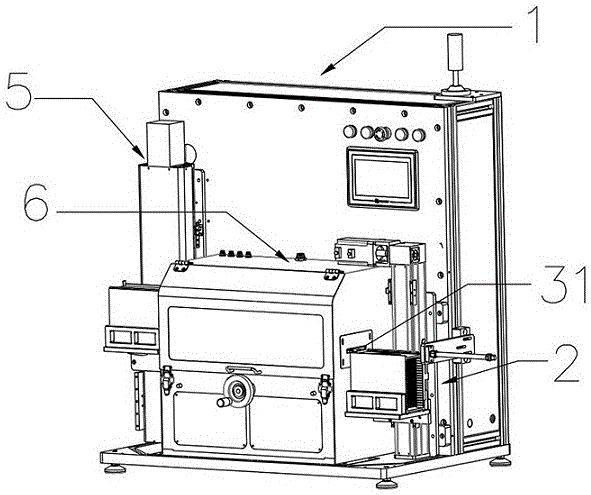

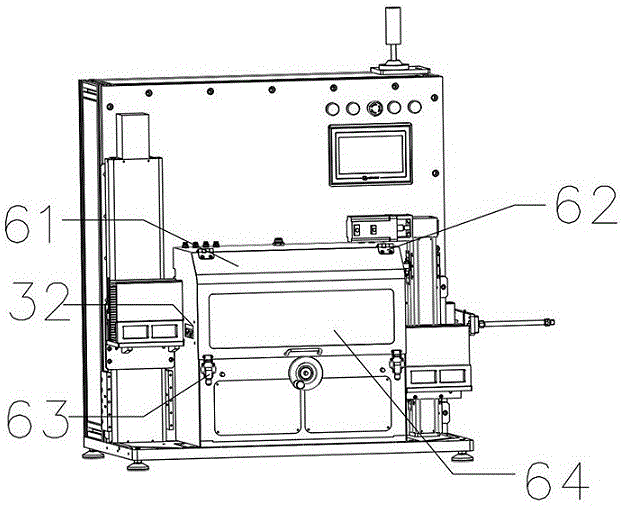

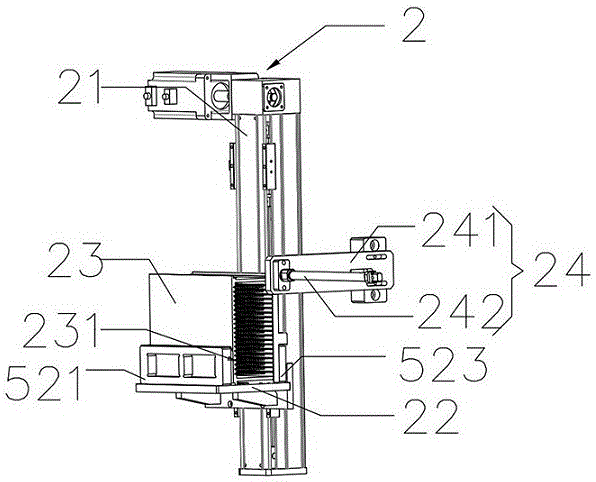

[0027] The automatic blow dryer described in this embodiment includes a frame 1, the frame 1 is provided with a feeding unit 2 for carrying the material to be dried, a conveying unit 3 for conveying the material, and The drying unit 4 for air-drying the web is a discharge unit 5 for carrying the dried material; the feeding unit 2 is arranged at the entrance 31 of the conveying unit, and the discharging unit 5 is arranged at The outlet end 32 of the transfer unit. Such as figure 1 , figure 2 , Figure 5 As shown, the specific working process is as follows: a person skilled in the art places a plurality of sheets to be blown-dried neatly on the feeding unit 2, and the feeding unit 2 feeds the sheets to be blown dry by a rising action To the inlet end 31 of the conveying unit and push the material to be blown into the conveying unit 3. The shell 6 is used to isolate most of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com