Pyromellitic dianhydride teaching factory for teaching and training

A technology of pyromellitic dianhydride and factories, which is applied in the training field of chemical technicians and senior technicians, can solve the problems of not being real enough, false simulation devices, etc., so as to improve understanding, improve operation level, cultivate collaboration ability and team awareness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a pyromellitic dianhydride teaching factory for teaching and training includes a chemical plant production area 1 , a chemical plant control area 2 , and a teaching discussion area 3 .

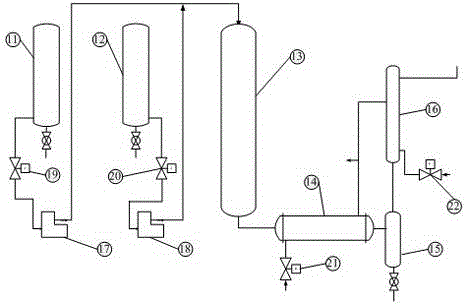

[0020] Among them, there is a small pyromellitic dianhydride production device in the chemical plant production area. The small pyromellitic dianhydride production plant includes chemical equipment, chemical instruments and device frames. The device frame is a steel platform, and the chemical equipment and chemical instruments are set. On the steel platform, chemical instruments and chemical equipment are connected by pipelines and cables.

[0021] The control area of the chemical plant is composed of a control cabinet and an industrial computer, and is connected with the above-mentioned small pyromellitic dianhydride production plant through a sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com