Method for producing a diene elastomer modified with a 1,3-dipolar compound by means of reactive extrusion

A technology of diene elastomer and dipole compound, which is applied in the field of diene elastomer modification, can solve the problems of difficult preparation stage, fluctuation of graft yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

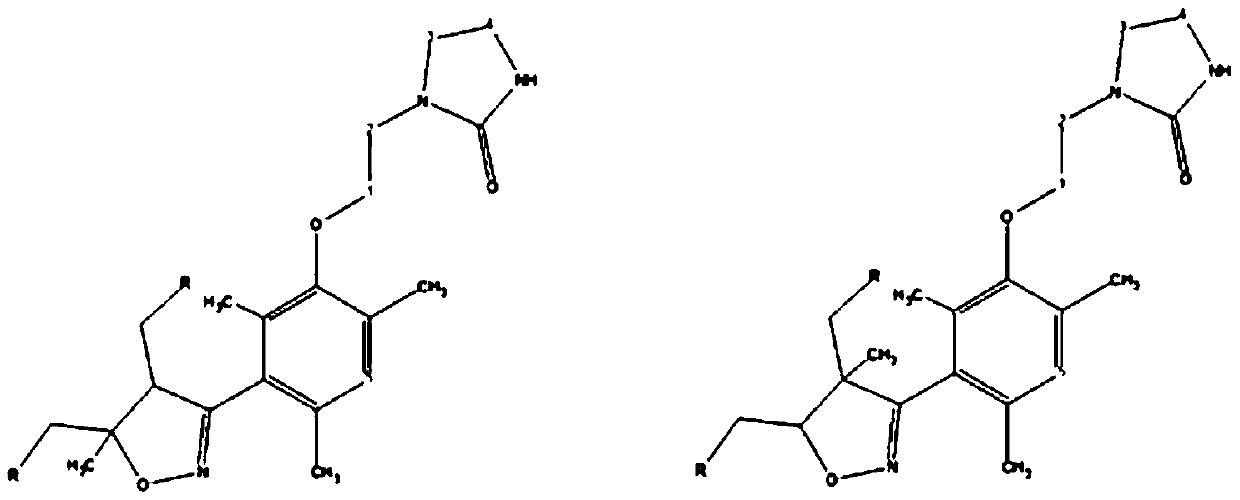

Image

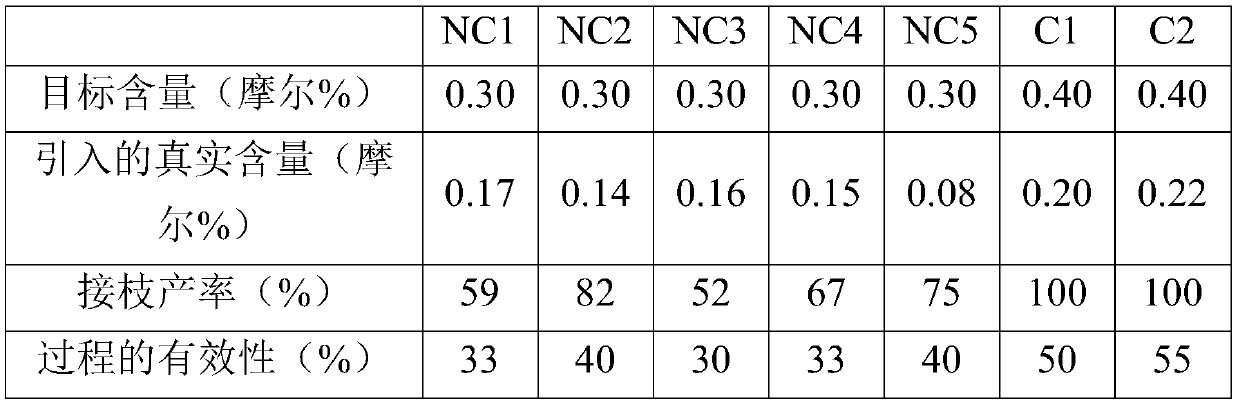

Examples

Embodiment Construction

[0010] I. Detailed description of the invention

[0011] In this specification, all percentages (%) shown are % by weight unless otherwise expressly stated. The abbreviation "phr" denotes parts by weight per hundred parts of elastomer (or the sum of the elastomers if several elastomers are present).

[0012] Any numerical interval marked by the expression "between a and b" denotes a numerical range extending from greater than a to less than b (i.e. excluding the limits a and b), whereas any numerical range marked by the expression "from a to b" A numerical range is indicated from a to b (ie including the strict limits a and b).

[0013] The expression "composition based on" is understood in this description to mean that the composition comprises a mixture and / or in situ reaction product of the various components used, some of these basic components (e.g. elastomers, fillers or conventionally used Other additives of the rubber composition intended for the manufacture of tire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com