Self-adaptive indirect bracket bonding support

A self-adaptive, bracket technology, applied in the direction of the bracket, can solve the problem of small adjustment space and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

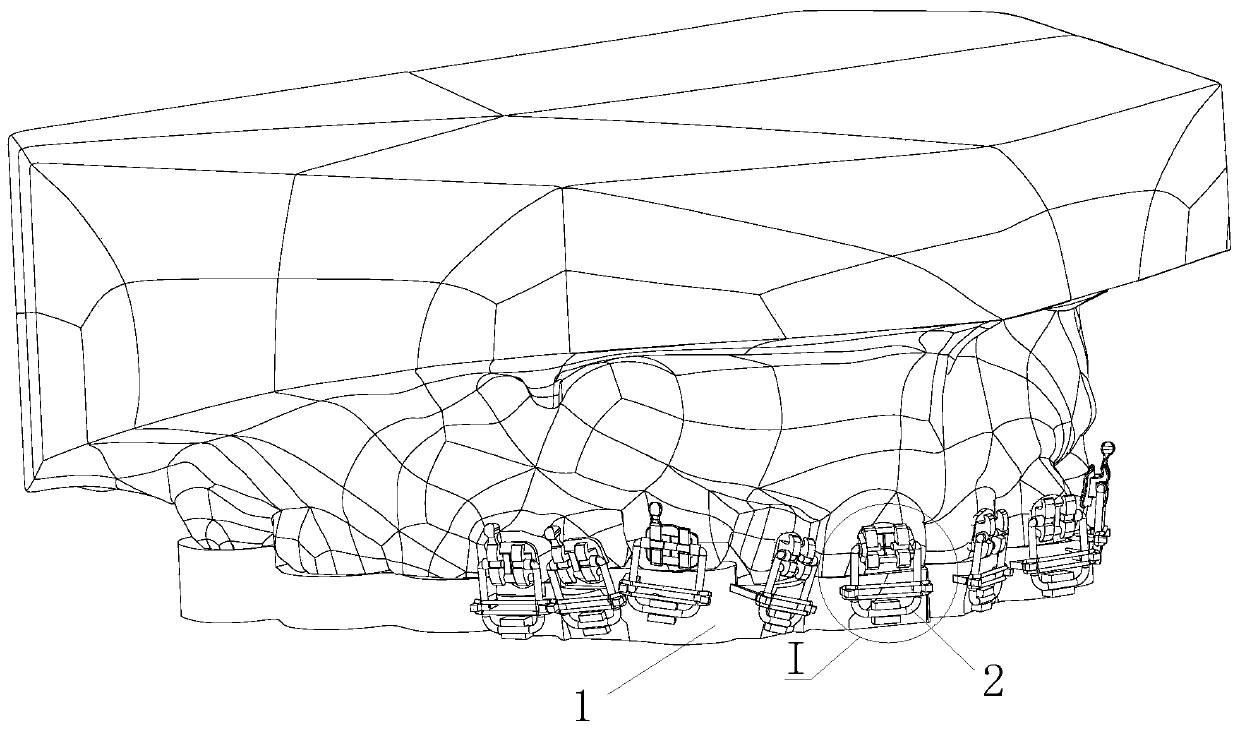

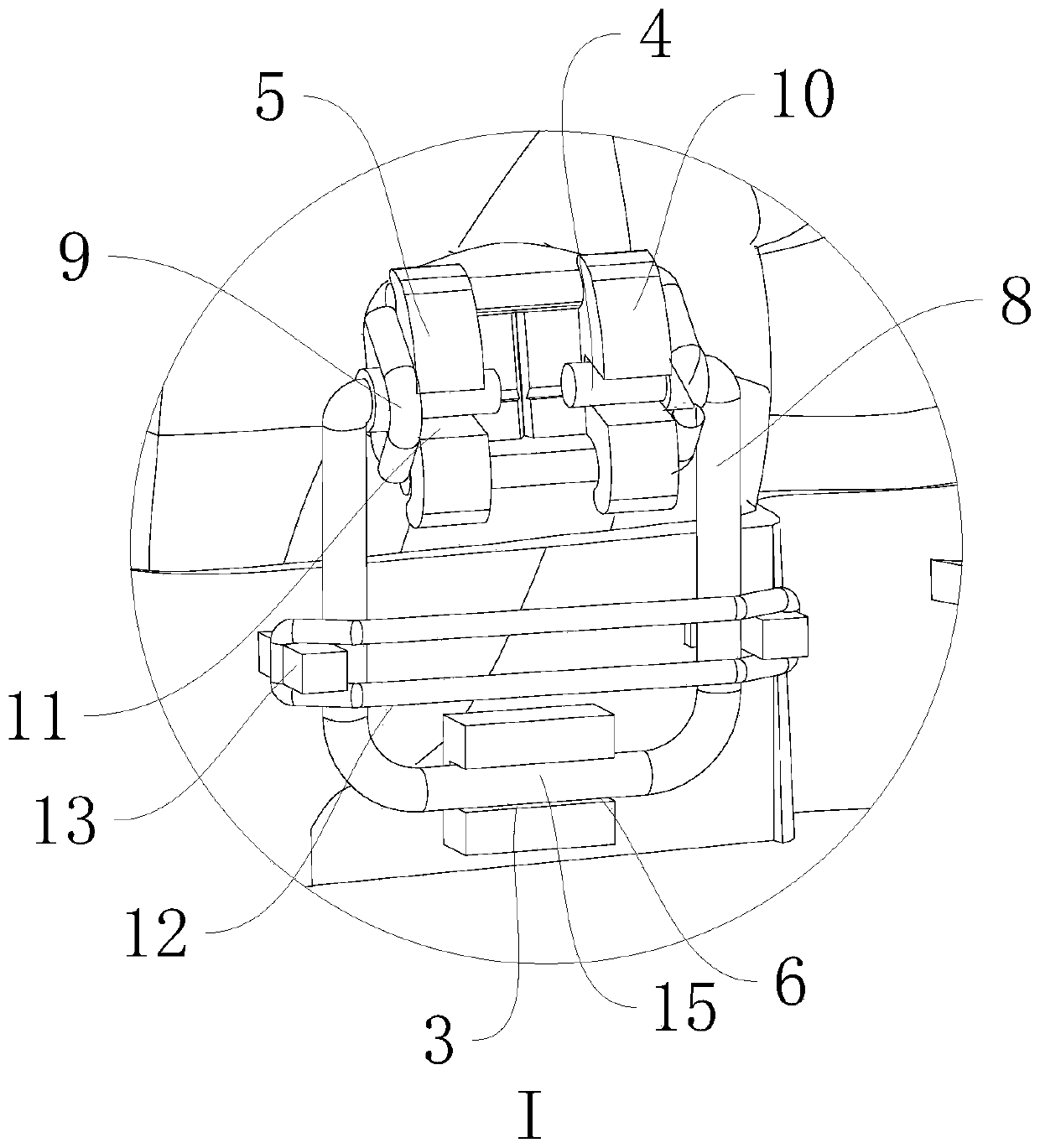

[0029] Such as figure 1 indivual figure 2 As shown, the self-adaptive indirect bracket sticking bracket includes an occlusal plate 1 for occlusion and a positioning spring clip 2 for connecting the occlusal plate 1 and the bracket 5. The occlusal plate 1 is provided with an assembly groove 3 and a positioning spring clip 2 Installed in the assembly groove 3, the positioning spring clip 2 can rotate around the bite plate 1. The occlusal splint 1 is obtained by digital impression taking according to the user's teeth, which is an existing technology and will not be described in detail in this embodiment. The technical solution provided by this embodiment is that the positioning spring clip 2 and the bite plate 1 can rotate around the axis, so that the positioning spring clip 2 is close to or away from the tooth bonding surface. The bracket 5 installed on the positioning spring clip 2 can support the bracket 5, and the bracket 5 can rotate around the positioning spring clip 2 a...

Embodiment 2

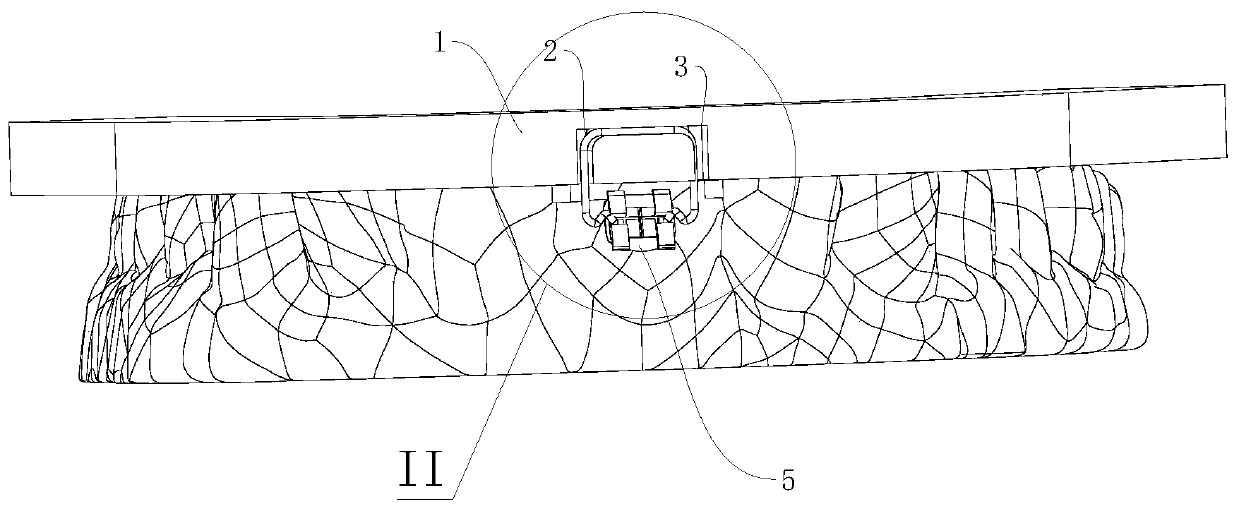

[0039] Such as image 3 and Figure 4 As shown, this embodiment also provides an adaptive indirect bracket sticking bracket, the difference from Embodiment 1 is that the installation groove is an inverted U-shaped groove, and the installation groove is opened on the outside of the occlusal plate 1 on the side. The mounting groove 3 includes a first mounting groove 6 in the horizontal direction and a side groove 7 that forms a U-shaped groove with the first mounting groove 6 on both sides of the first mounting groove 6. The first mounting groove 6 is arranged in a horizontal direction. It should be noted that Whether the first installation groove 6 is horizontal needs to be related to the installation angle of the bracket 5, and the level here is not a limitation of this solution, because it can also be inclined upward or downward according to actual needs. The rotating shaft 15 is connected to the card shaft 4 through a connecting rod 8, and the connecting rod 8 is arranged ...

Embodiment 3

[0041] Such as Figure 5 As shown, this embodiment also provides an adaptive indirect bracket sticking bracket, which differs from Embodiment 2 in that no bending portion 14 is preset on the clamping shaft 4, and the clamping shaft 4 is an optical axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com