Colloid mill for efficiently and uniformly crushing particles

A homogenization and colloid milling technology, applied in grain processing and other directions, can solve the problems of inability to homogenize colloidal particles, cutting and cutting efficiency, low shearing and grinding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

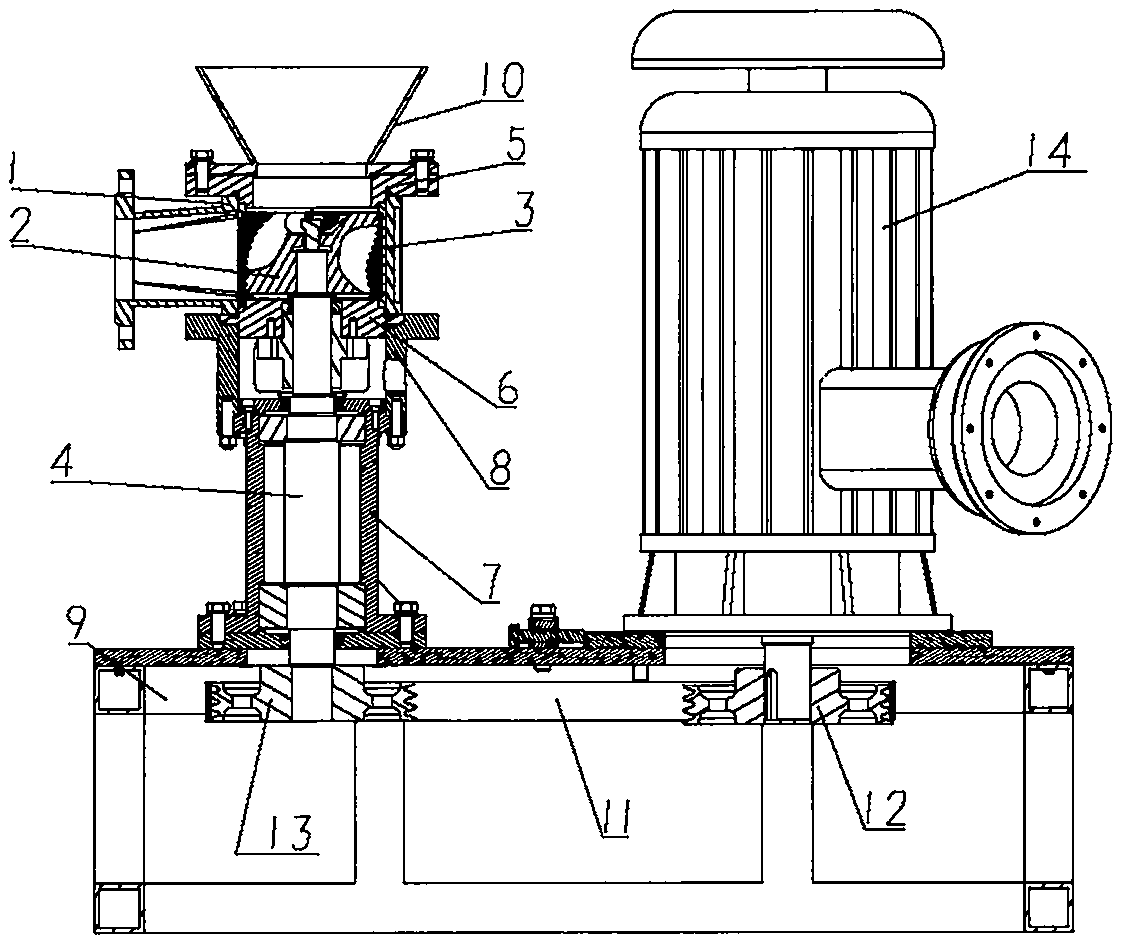

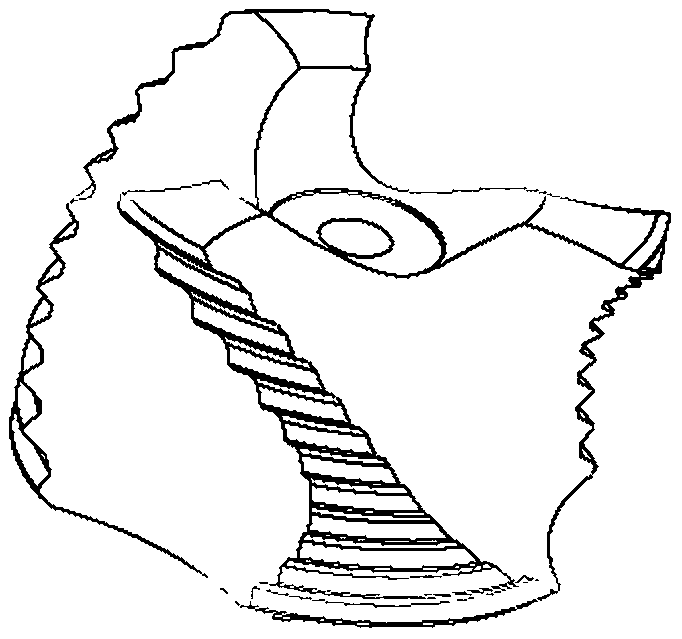

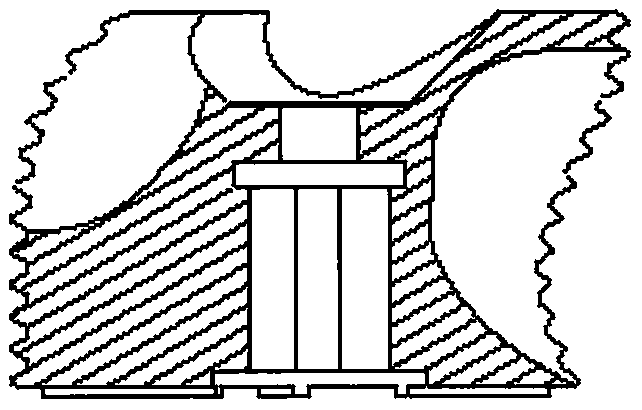

[0012] A colloid mill for high-efficiency homogenization of broken particles, consisting of a grinding body 1, a rotor 2, a screen 3, a main shaft 4, a pressure plate 5, a rotor back cover 6, a transmission box 7, a support seat 8, a base 9, and a material inlet 10 , belt 11, main pulley 12, secondary pulley 13, motor 14 are formed. The rotor 2 of the colloid mill for efficiently homogenizing broken particles is installed on the main shaft 4 and fixed by a compression nut. The rotor back cover 6 is installed on the support seat 8. There are positioning pins on the rotor back cover 6 and a screen. 3 is installed on the outside of the rotor 2 through positioning pins and attached to the inner wall of the grinding body 1. The feed port 10 is connected to the pressure plate 5 through a screw, the pressure plate 5 is installed above the grinding body 1, the middle boss of the pressure plate 5 is inserted into the middle of the screen 3, and the pressure plate 5 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com