Patents

Literature

39results about How to "Play the role of protecting equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly effective coal combustion improver and preparation thereof

The invention relates to the fuel additive technical field, in particular to fuel coal additives and a method for preparing the same. The invention discloses the high-efficiency fuel coal additives, which mainly comprises raising agent, combustion improver and sulfur retention smoke agent and also comprises nano silicon dioxide with a weight ratio between 0.5 and 10 percent. The high-efficiency fuel coal additives makes fuel coal in the high temperature state; the boiler steam rate is gradually increased; the furnace temperature is improved by 100 DEG; the boiler thermal efficiency is improved by over 15 percent; the coal-saving rate reaches 5 to 20 percent; the desulfurization is obvious and the desulfurization degree is as high as 40 to 70 percent; the decoking process is quick; the total discharge of clinker is reduced by about 26 percent, thereby the carbon content of furnace cinder is reduced; by addition of the fuel coal additives, metals on the boiler heating surface can not be eroded, thereby the function of protecting equipment is brought into play and the service life of the equipment is prolonged. Moreover, the high-efficiency fuel coal additives can greatly reduce the environmental pollution and the atmospheric greenhouse effect, and greatly reduce the energy consumption so as to obtain obvious economic benefit.

Owner:陈睿红

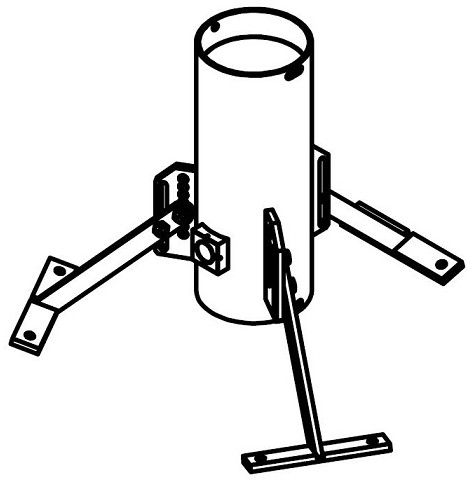

Electric power circuit carrying van

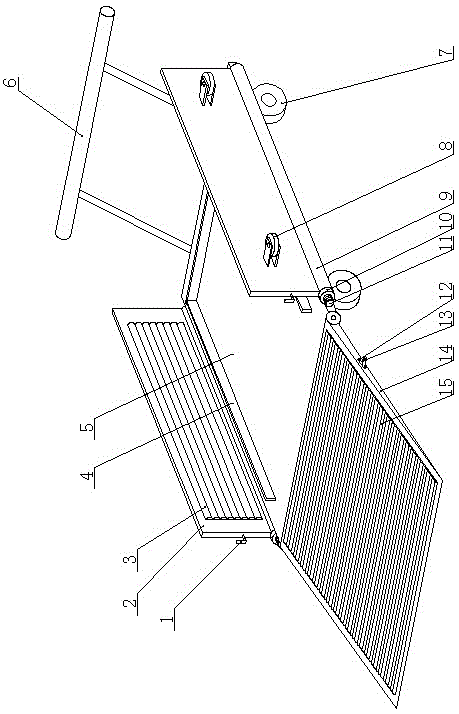

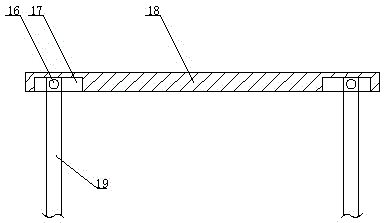

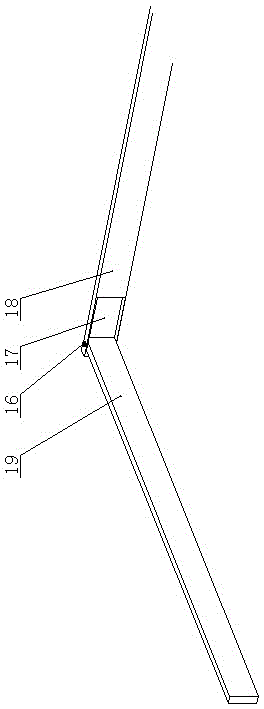

InactiveCN105059336AWon't fall outSimple structureHand carts with multiple axesFixed frameEngineering

The invention relates to an electric power circuit carrying van which comprises a base plate for bearing devices. Walking wheels are installed on the bottom surface of a base, a push rod is installed at the rear end of the base, openable and closable side plates are installed on two sides of the base, the front end of the base is movably connected with a face plate, and roller groups are installed on the inner wall of the face plate and the inner walls of the side plates respectively. The face plate at the front end and the side plates on two sides are of openable and closable structures, so that the devices can be pushed onto the carrying van in any direction and fixed through a fixing frame. If the area of the bottom surface of a certain device is larger than that of the base plate of the carrying van, the side plates on two sides can be opened to increase the whole bearing so as to complete transfer. For containing tools and instruments, the rear end of the electric power circuit carrying van is opened, and the tail ends of a longer insulation rod and other tools and instruments can extend out of the side. Due to the fact that the fixing frame is fixed to the base plate and has a supporting-lifting role on the extended portions of the insulation rod and other tools and instruments to form an internally-low and externally-high state, the insulation rod and other tools and instruments do not drop out in the transfer process.

Owner:国网新疆电力有限公司塔城供电公司 +1

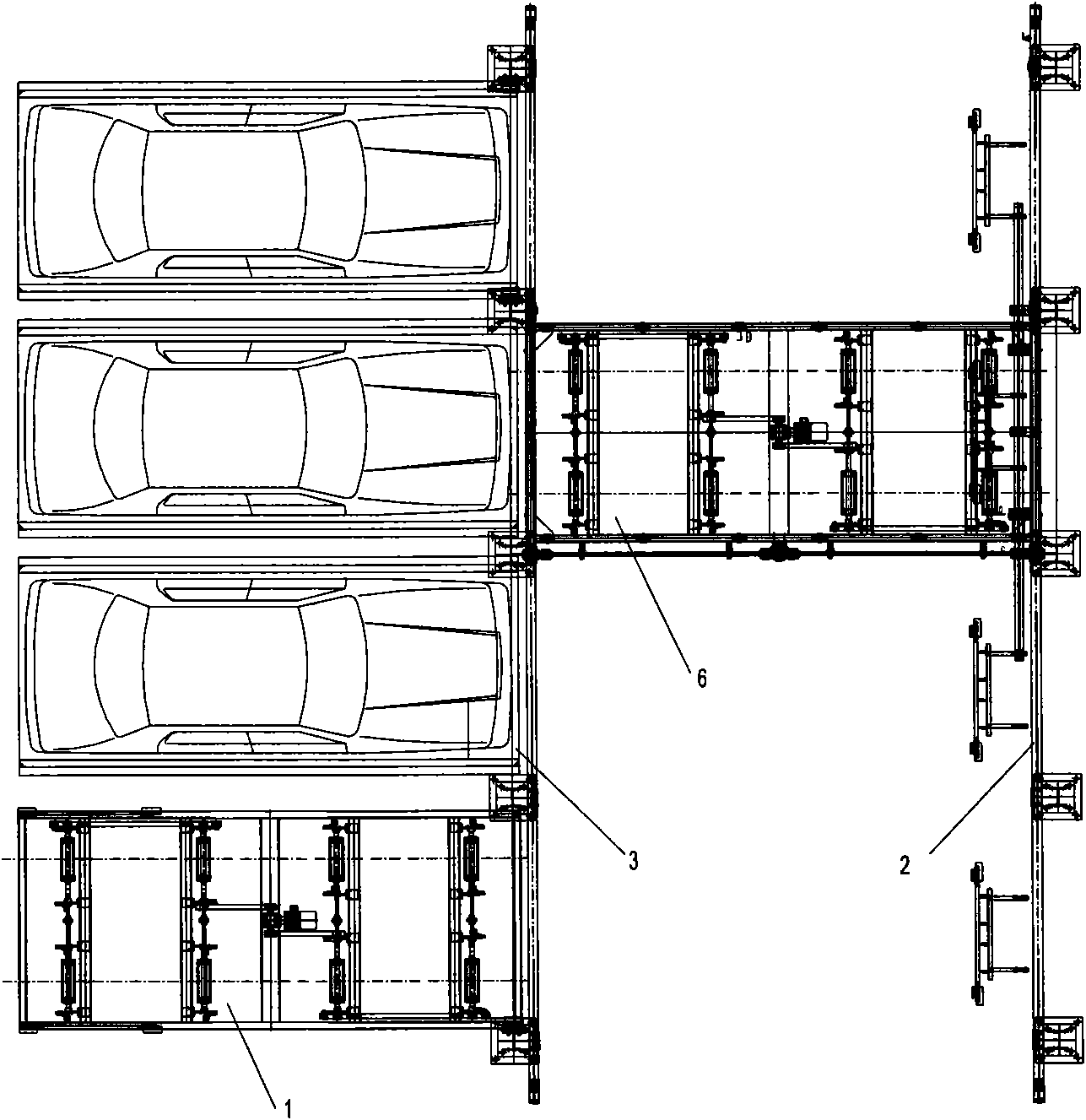

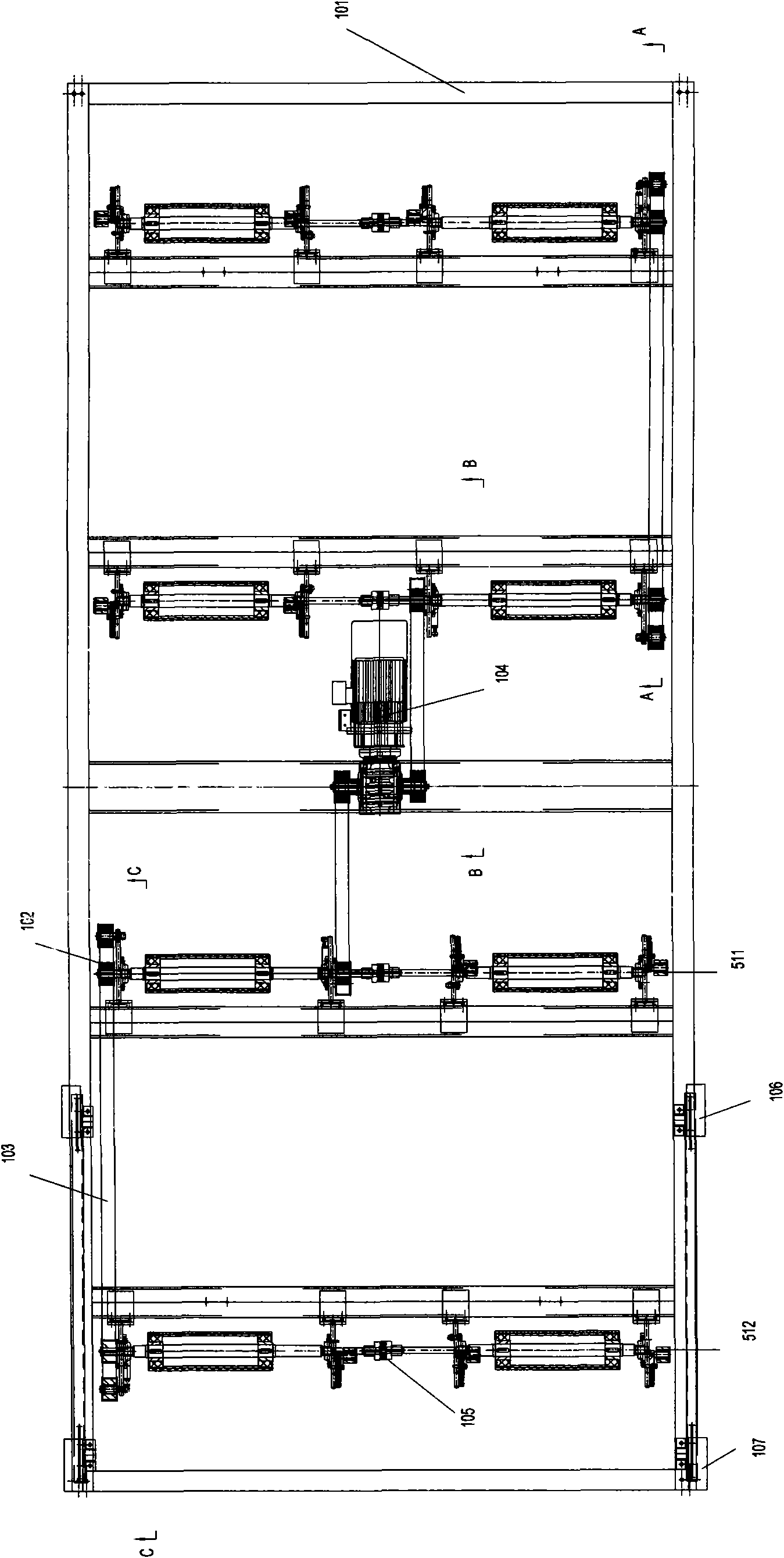

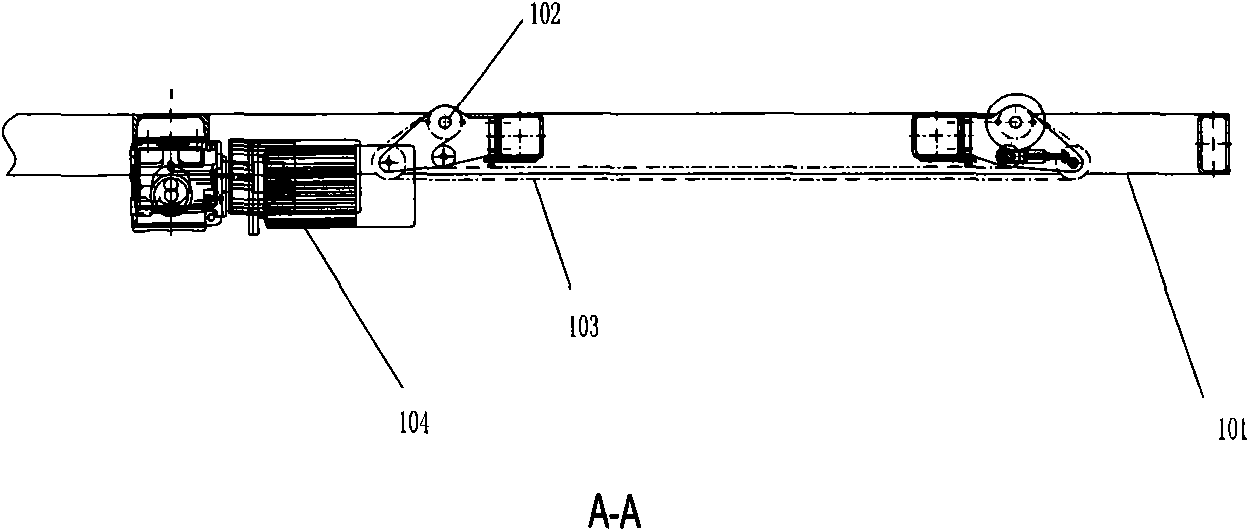

Vehicle transportation device applied to solid garage

A vehicle transportation device comprises a parking unit, a cross feed mechanism and a car carrying board, wherein the driving mechanism of the parking unit is a jugged driving mechanism with a roller and is composed of a driving roller, a belt pulley, a cog belt and a driving mechanism; the driving mechanism transmits power to the driving roller by a driving belt pulley, a driven belt pulley and the cog belt, and the car bearing board is transported and controlled by friction force of the roller. The vehicle transportation device disclosed in the invention adopts belt pulley cog belt drive which runs steadily and quietly with accurate transmission. Besides, each parking unit is independently arranged, overall modularization is realized is modularized, assembly is flexible and convenient, horizontal movement or multiplayer circulation can be assembled at will according to foundation, applicability is strong, damage on the roller which is in high speed rotation for instant stop caused by fault is eliminated, and the service life of the device can be prolonged.

Owner:北京大兆新元停车设备有限公司

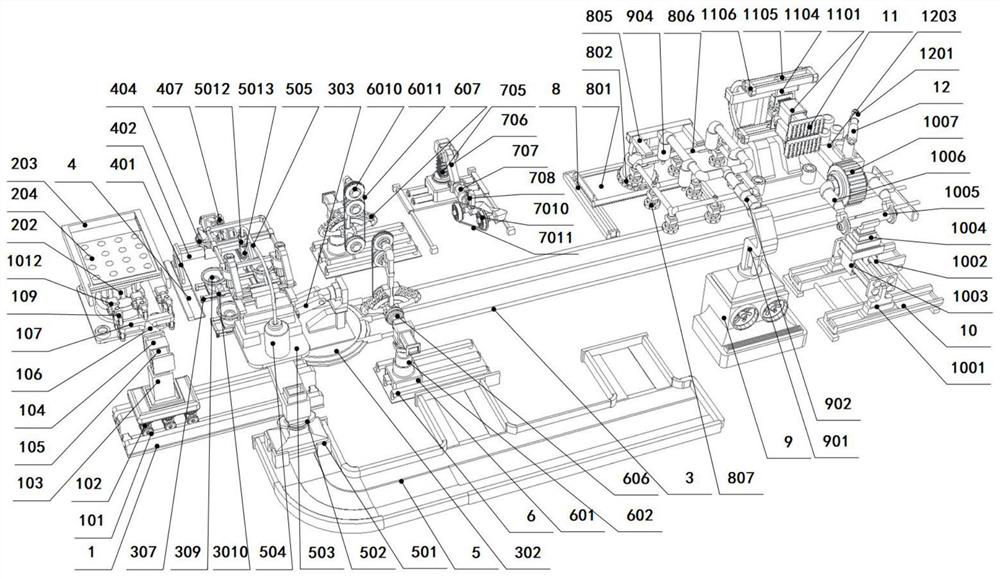

Nitrogen elastic pressing type composite edge cutting device and production process thereof

ActiveCN112192768AReduce production accidentsGuaranteed quality controlEdge grinding machinesWorking accessoriesPolishingNitrogen gas

The invention discloses a nitrogen elastic pressing type composite edge cutting device and a production process thereof. The nitrogen elastic pressing type composite edge cutting device comprises a sample clamping system, a lofting system, a sample moving system, an opening system, a cooling system, fixed cutting systems, a movable cutting system, a cleaning system and a polishing system. According to the nitrogen elastic pressing type composite edge cutting device, by adopting manual intervention, on one hand, the probability of production accidents is greatly reduced, and on the other hand,the sample injection and material moving processes are standardized and unified, and the subsequent processing process can be subjected to quality control. According to the nitrogen elastic pressing type composite edge cutting device, a ceramic material plate is opened by the opening system before cutting and trimming, and an opening is formed in the surface of the ceramic material plate, so thatnot only is a large amount of loss of cutting lines and the like caused by factors such as surface stress in the subsequent cutting process avoided, but also the material plate is prevented from beingdamaged by a large amount of extra heat generated in the machining process due to abraded cutting lines.

Owner:济南吉隆锻造有限公司

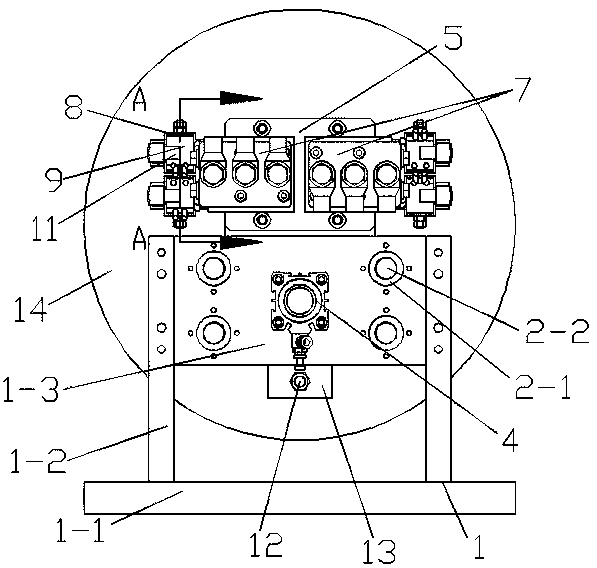

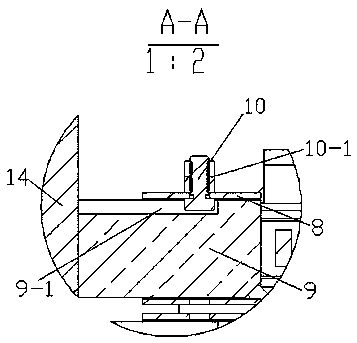

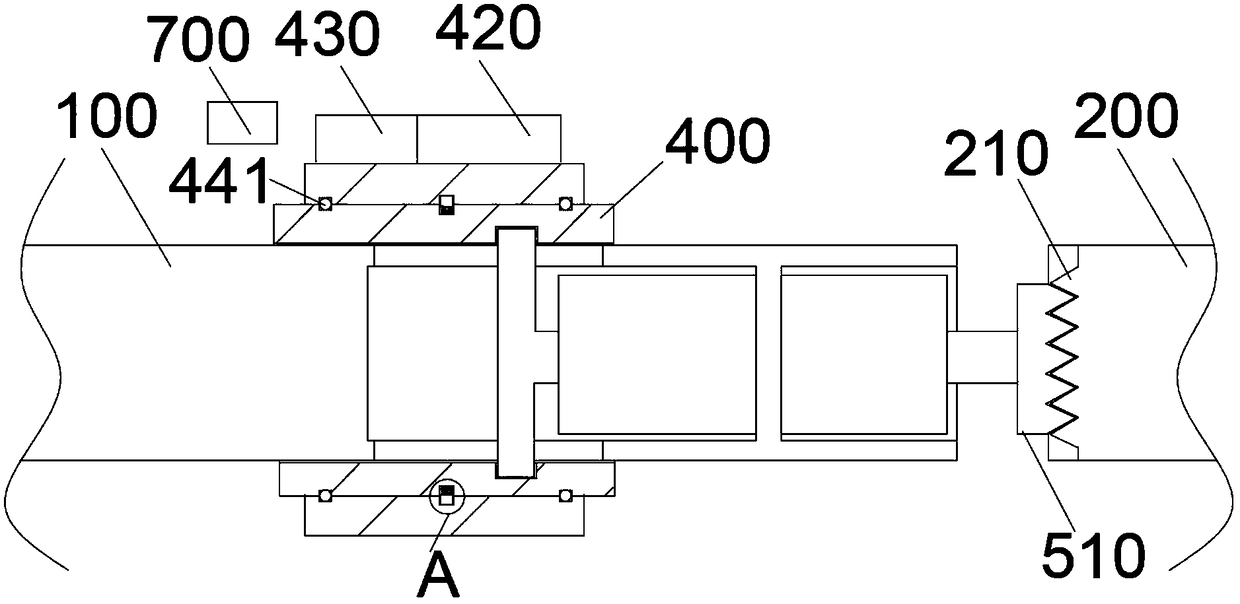

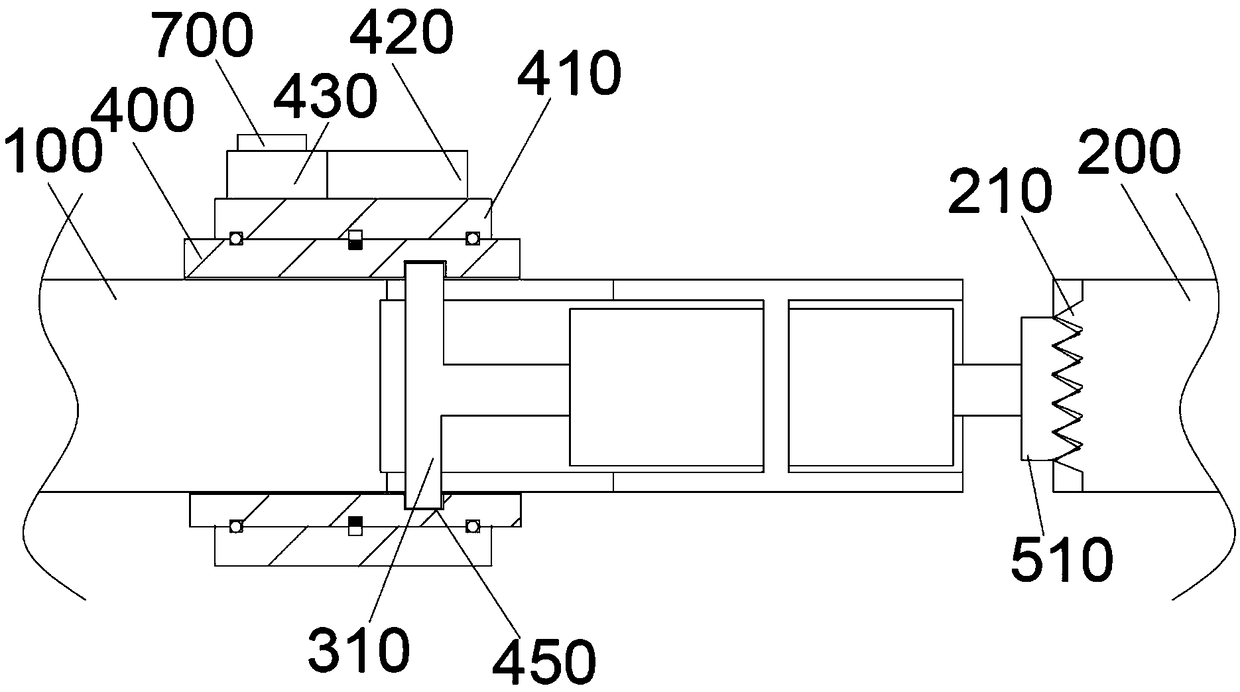

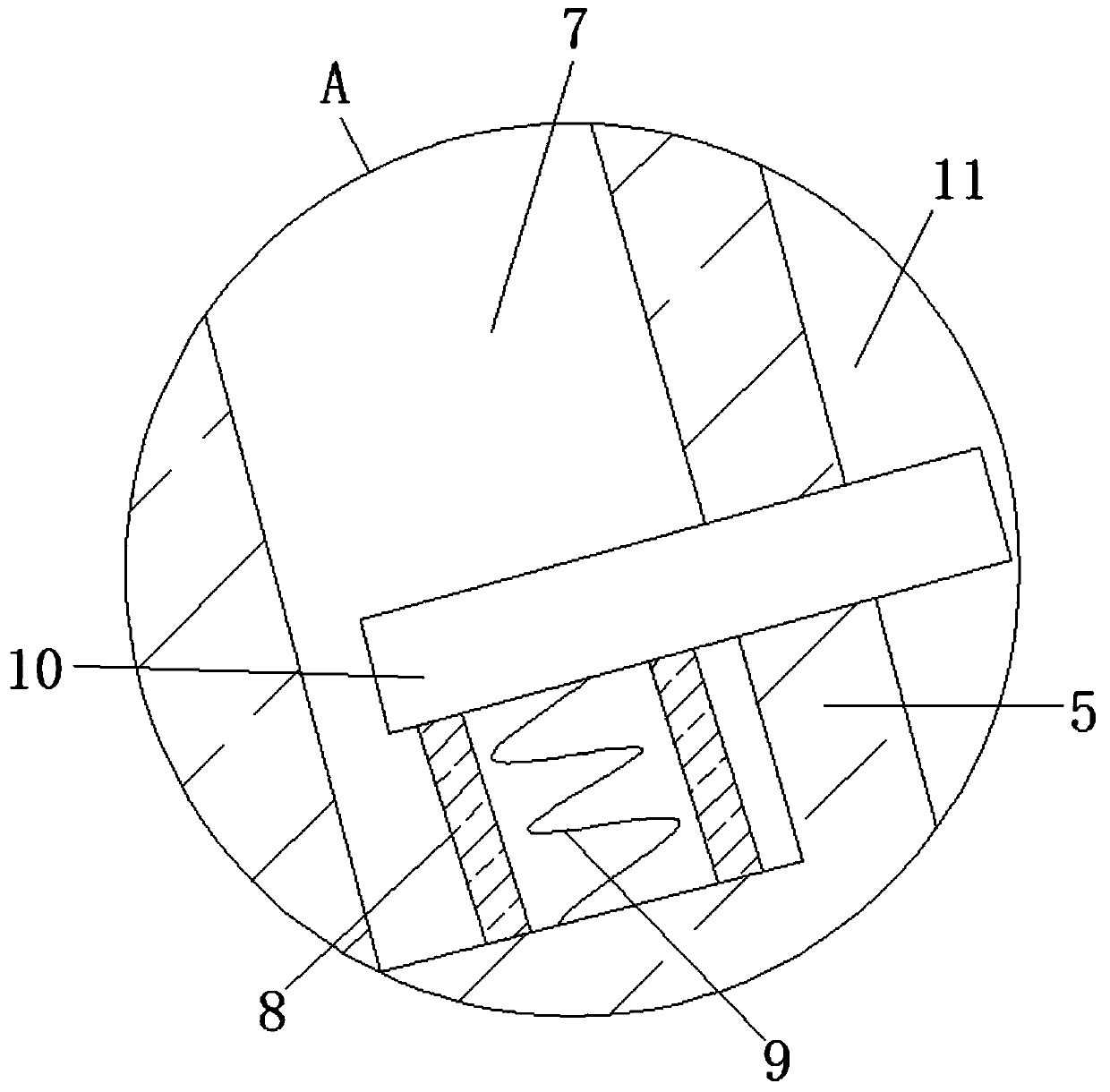

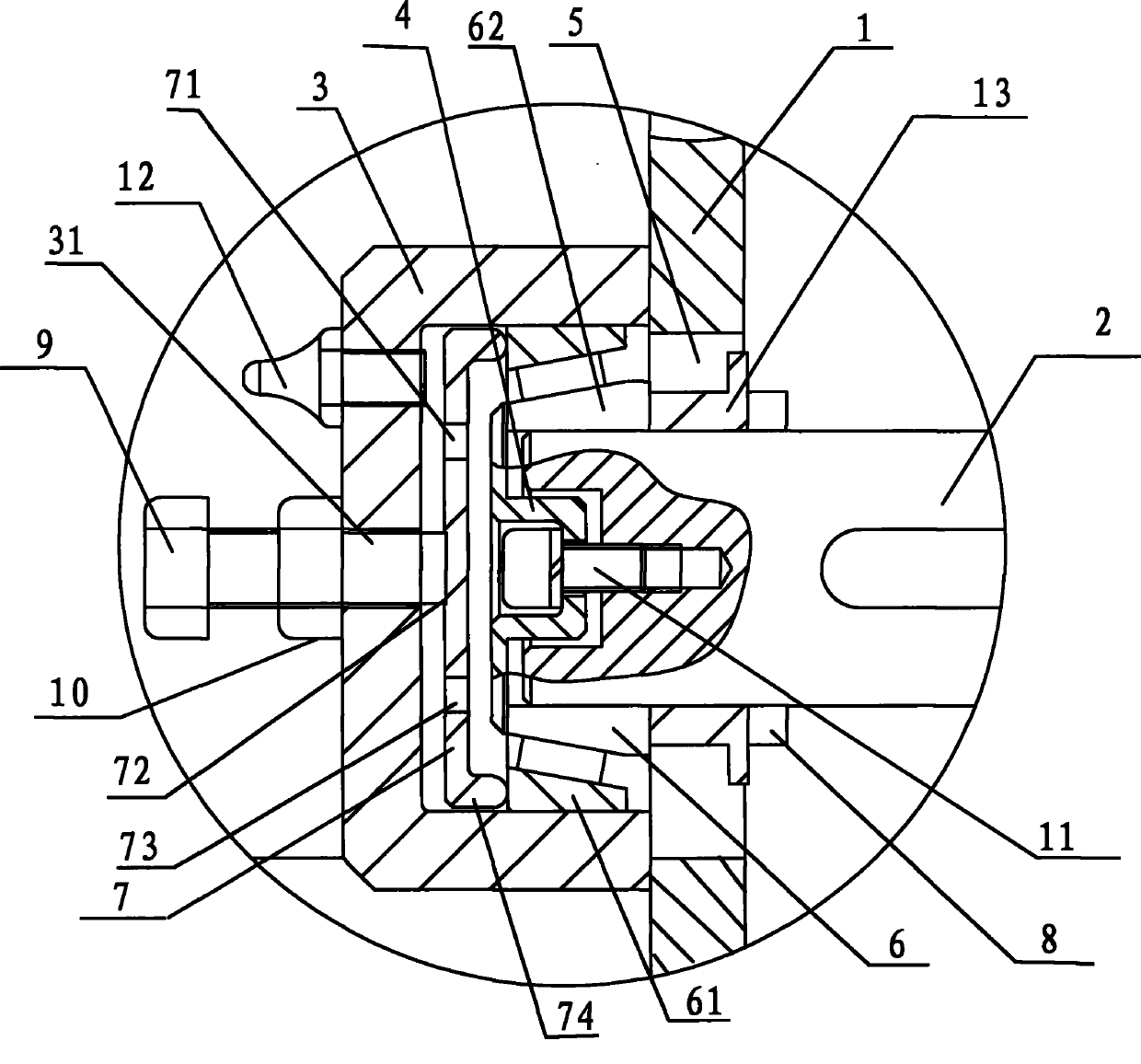

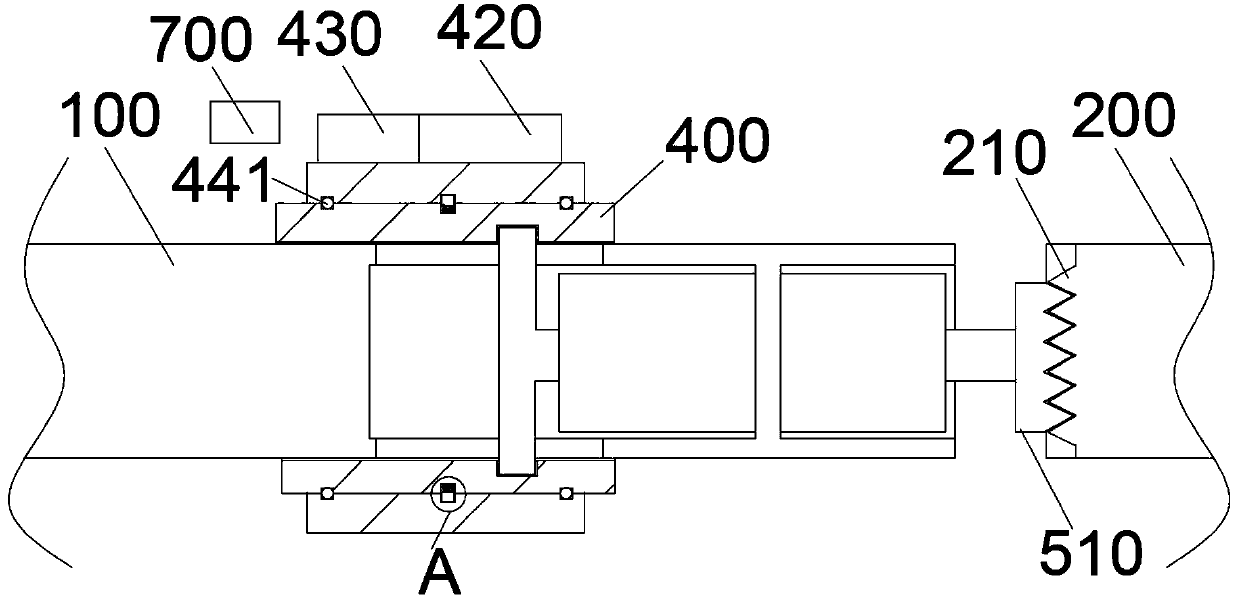

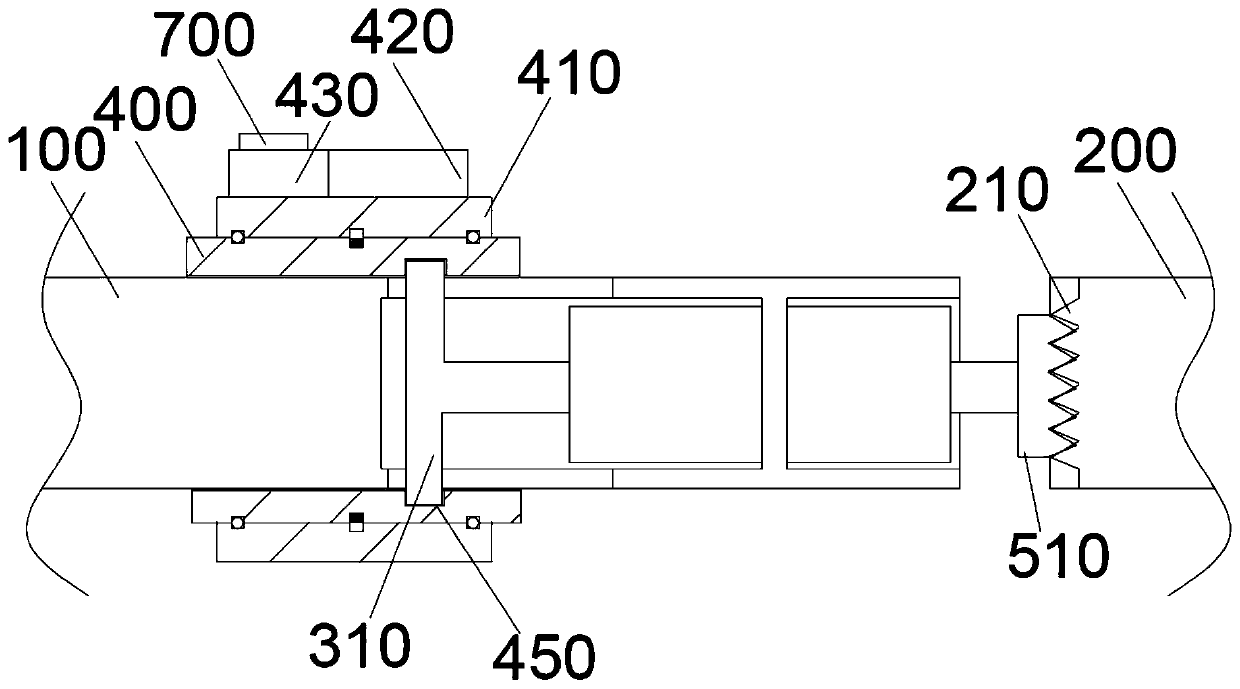

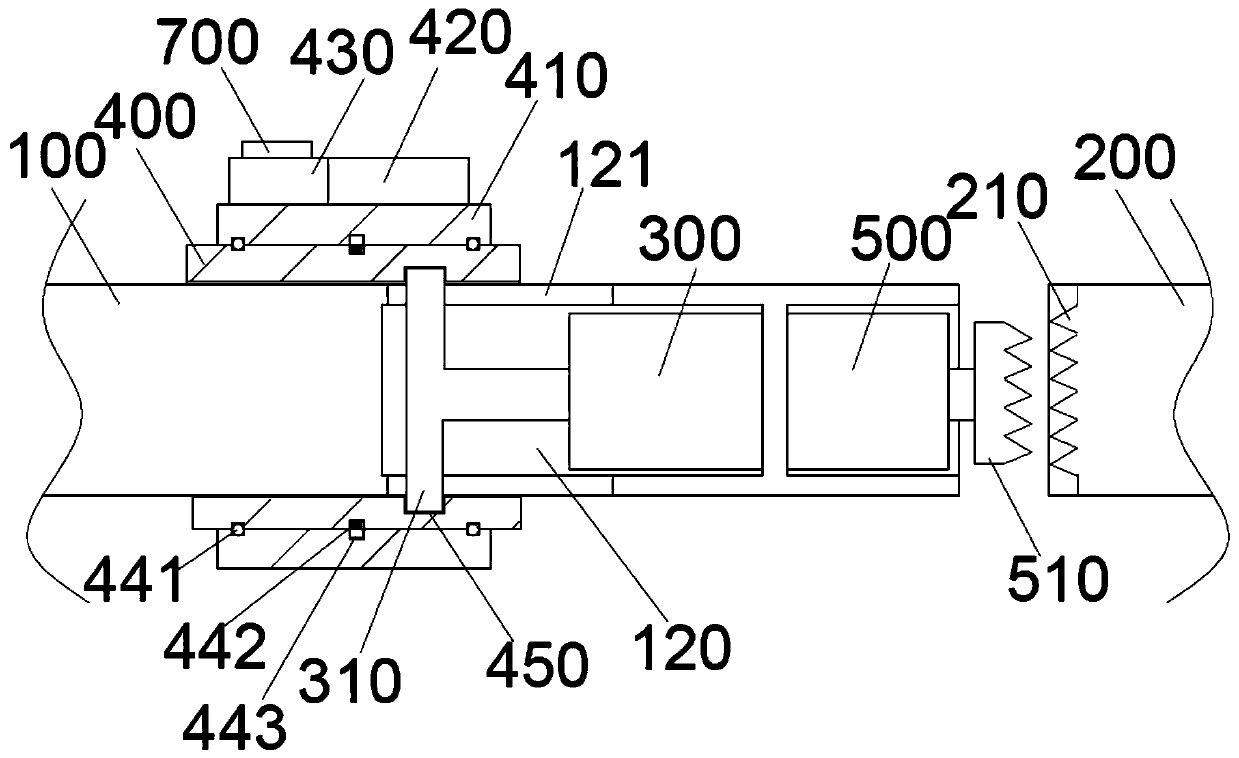

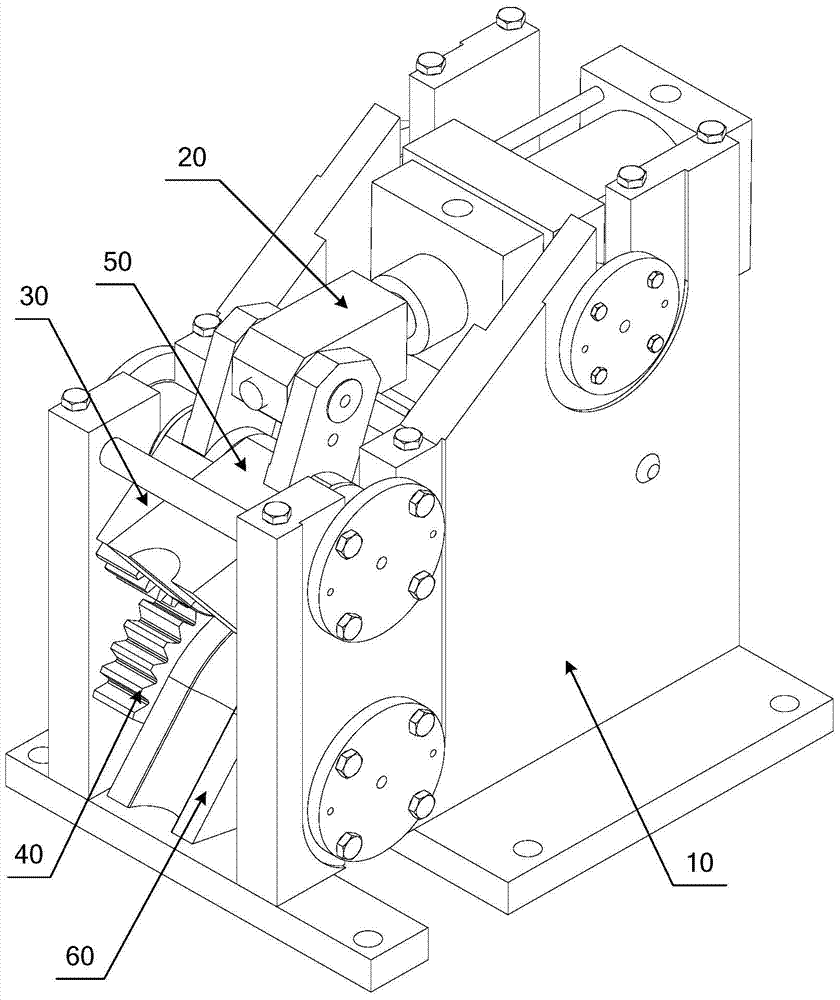

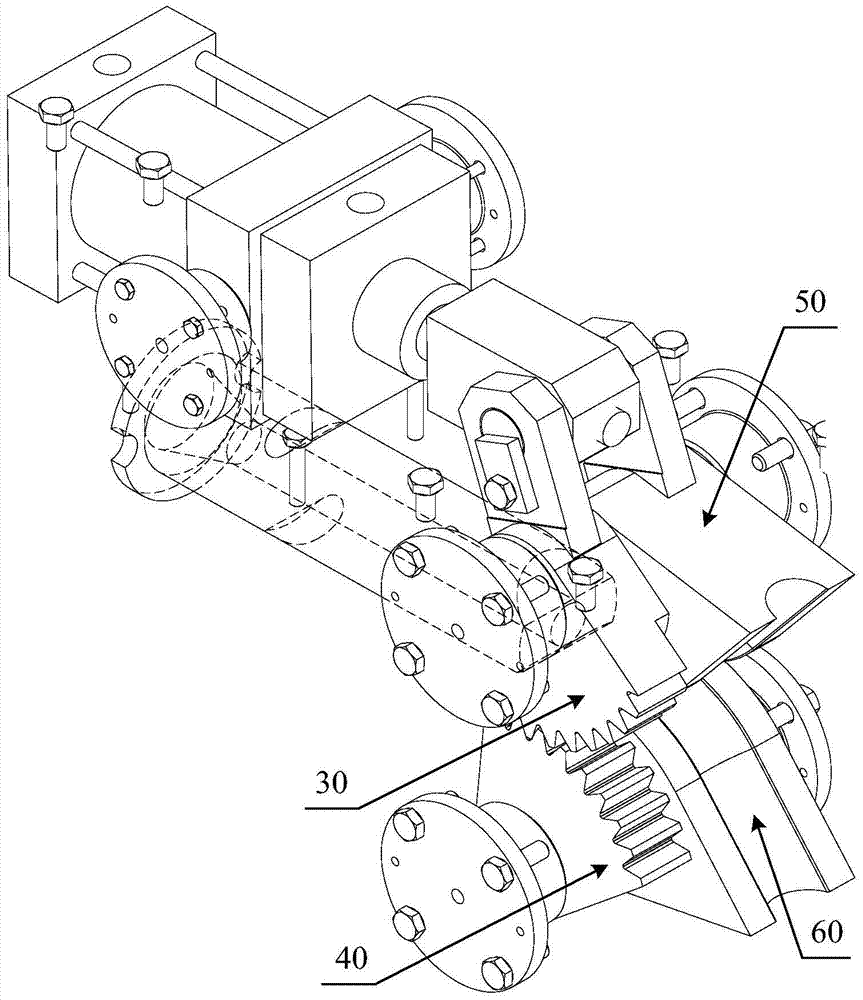

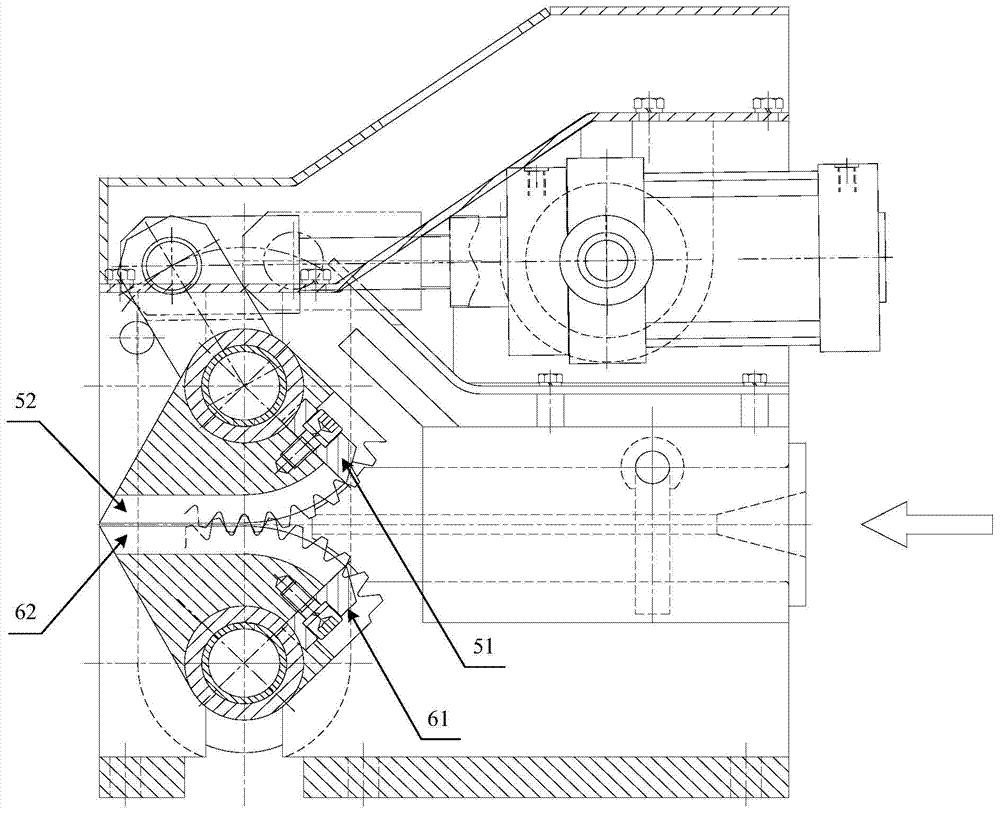

Position-adaptive carbon brush device

PendingCN110695501ASolve the problem of welding conductionEasy to adjust pre-pressureRotary current collectorWelding accessoriesStructural engineeringBrush device

The invention belongs to the technical field of conductive devices, and particularly relates to a position-adaptive carbon brush device. The position-adaptive carbon brush device comprises a fixed seat, wherein a linear guide device is arranged on the fixed seat; a mounting plate is arranged on the linear guide device; a telescopic device is further fixedly arranged on the fixed seat; a telescopicpart of the telescopic device is fixedly connected with the mounting plate; an insulating plate is arranged on the mounting plate; a U-shaped plate is arranged on one surface, far away from the mounting plate, of the insulating plate; a conductive copper plate is arranged at the groove bottom of the U-shaped plate; carbon brush seats are arranged on two outer side surfaces of the U-shaped plate;the carbon brush seats are of hollow closed-loop structures; carbon brush blocks are clamped in the carbon brush seats; blind grooves are formed in one ends, far away from the telescopic device, of the carbon brush blocks in the sliding direction of the carbon brush blocks; limiting devices extending into the blind grooves of the carbon brush blocks are fixed on the carbon brush seats; elastic elements are arranged at the opening ends, far away from the blind grooves of the carbon brush blocks, of the carbon brush seats; and a limiting rod is arranged on one surface, far away from the telescopic device, of the mounting plate. According to the position-adaptive carbon brush device, the problem of electric conduction of a workpiece at a split part of welding equipment is solved, and the position-adaptive carbon brush device can be adaptive to the conductive position.

Owner:XUZHOU HUAHENG ROBOT SYST +1

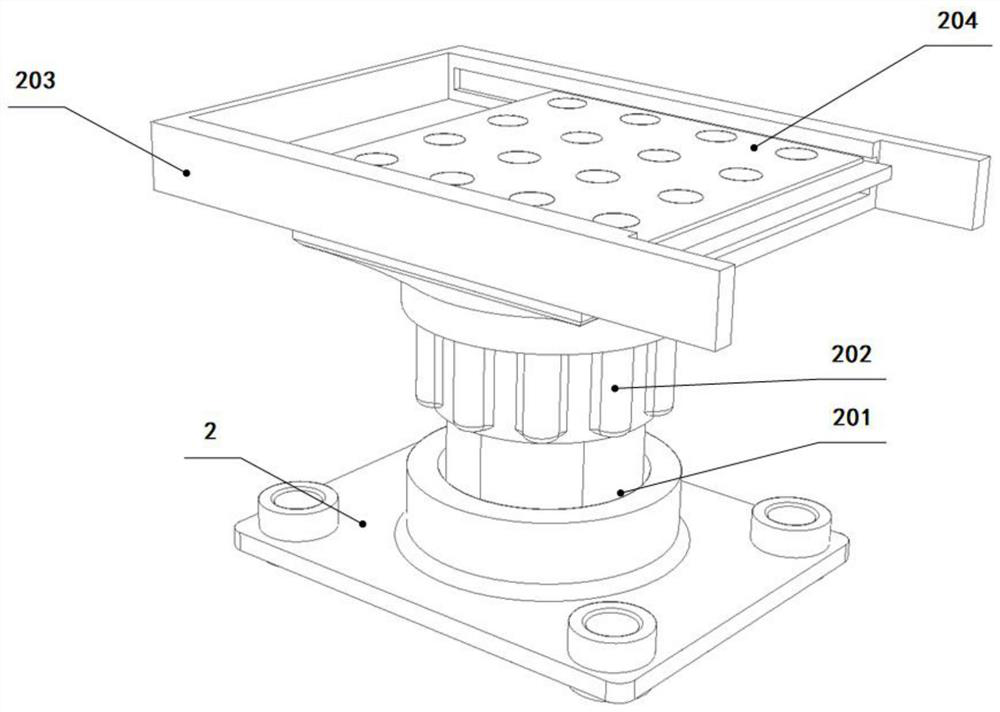

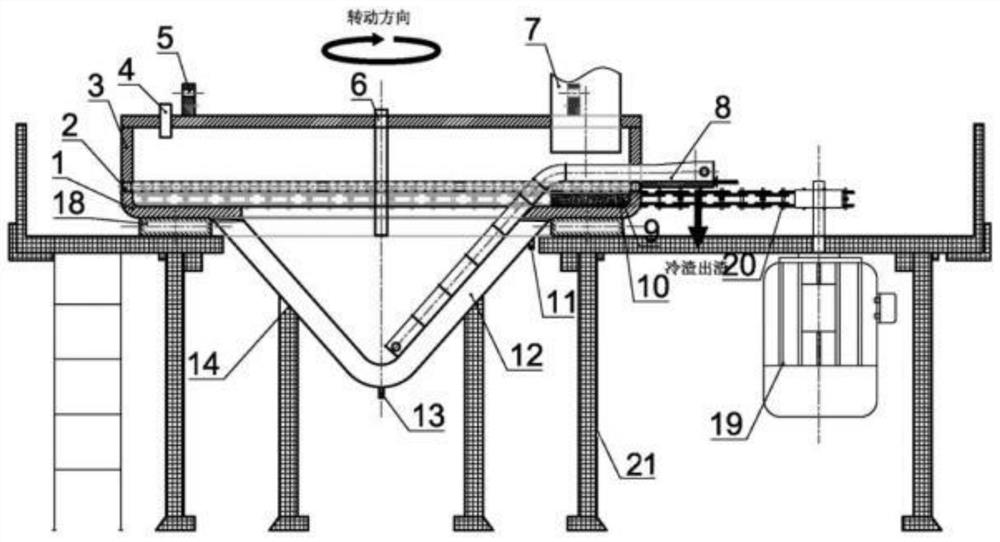

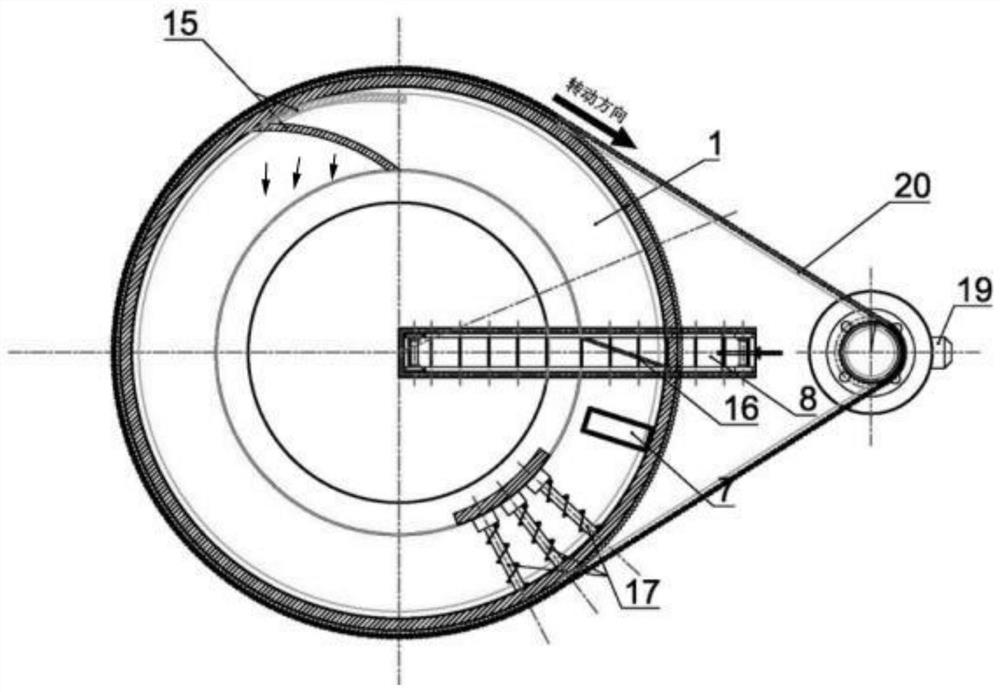

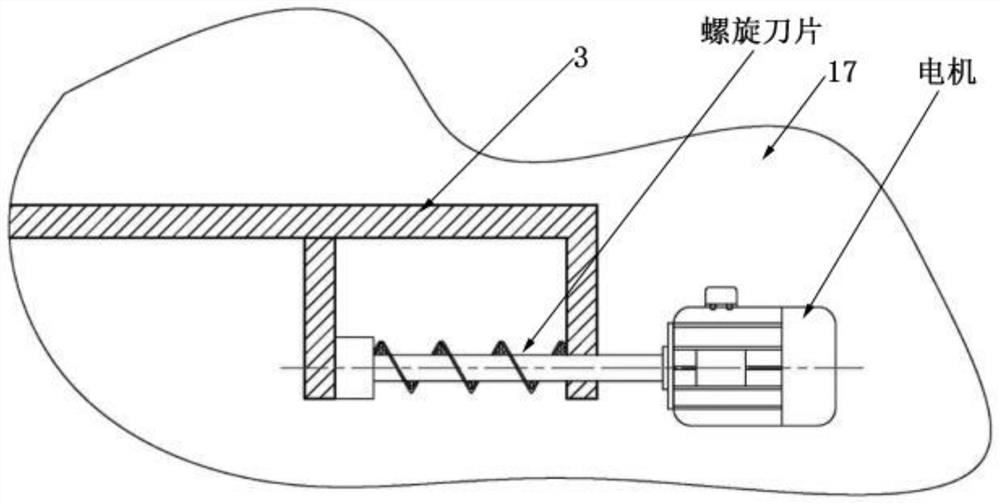

Waste heat recovery deslagging equipment and method for garbage fly ash plasma furnace zone

PendingCN113324254APrevent ConsolidationReduce energy consumptionCharge manipulationIncreasing energy efficiencyThermodynamicsSlag

The invention belongs to the technical field of deslagging equipment, and particularly relates to waste heat recovery deslagging equipment and method for a garbage fly ash plasma furnace zone. The equipment comprises a pre-cooling table, a slag cooling pool, a slag conveying device and a frame body, wherein the pre-cooling table is rotatably connected with the frame body; the pre-cooling table is connected with a driving mechanism, and the driving mechanism drives the pre-cooling table to rotate; a sealing cover is fixed above the pre-cooling table, and the sealing cover is rotationally connected with the pre-cooling table; a scraping plate is arranged in the sealing cover, and the slag cooling pool is located below the pre-cooling table and fixedly connected with the frame body; the slag conveying device is fixedly connected with the slag cooling pool, and materials in the slag cooling pool can be discharged or discharged to the pre-cooling table through the slag conveying device; slag on the pre-cooling table is scraped into the slag cooling pool through the scraping plate; and a slag inlet is formed in the sealing cover. A high-temperature melt is prevented from being solidified on the equipment while the melt is cooled, continuous deslagging cooling can be achieved, and the cooling temperature is controllable. The equipment is provided with a waste heat recovery device and has the advantages of being low in energy consumption and low in water consumption.

Owner:SHANXI UNIV

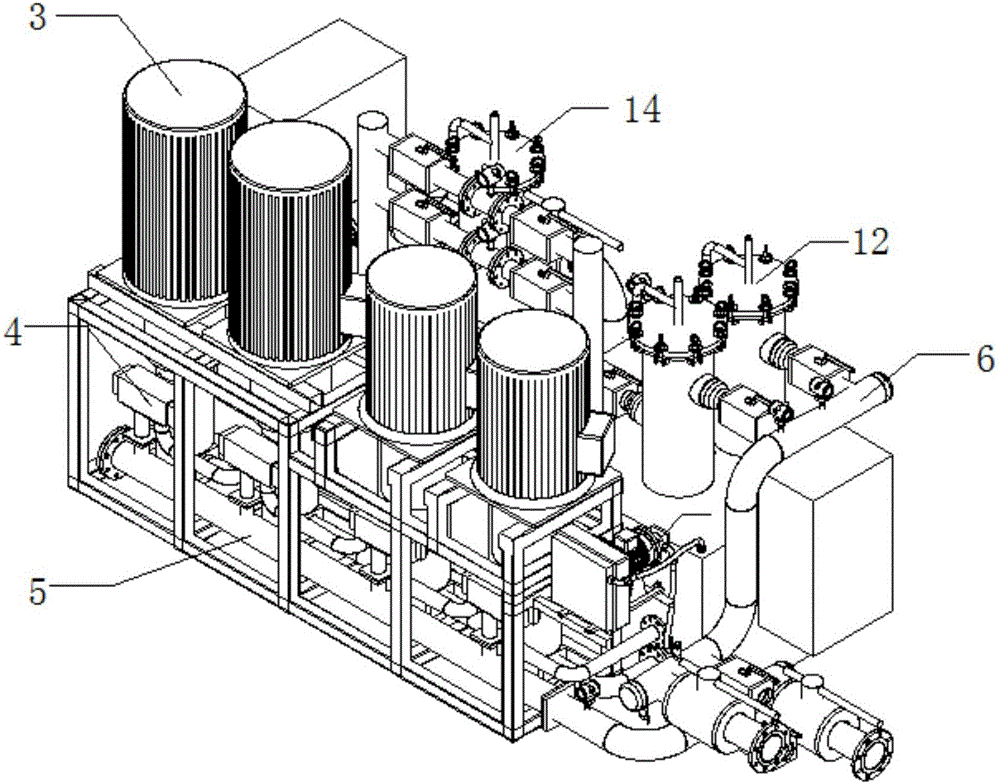

Full-automatic multi-pipeline serial washing and filtering device

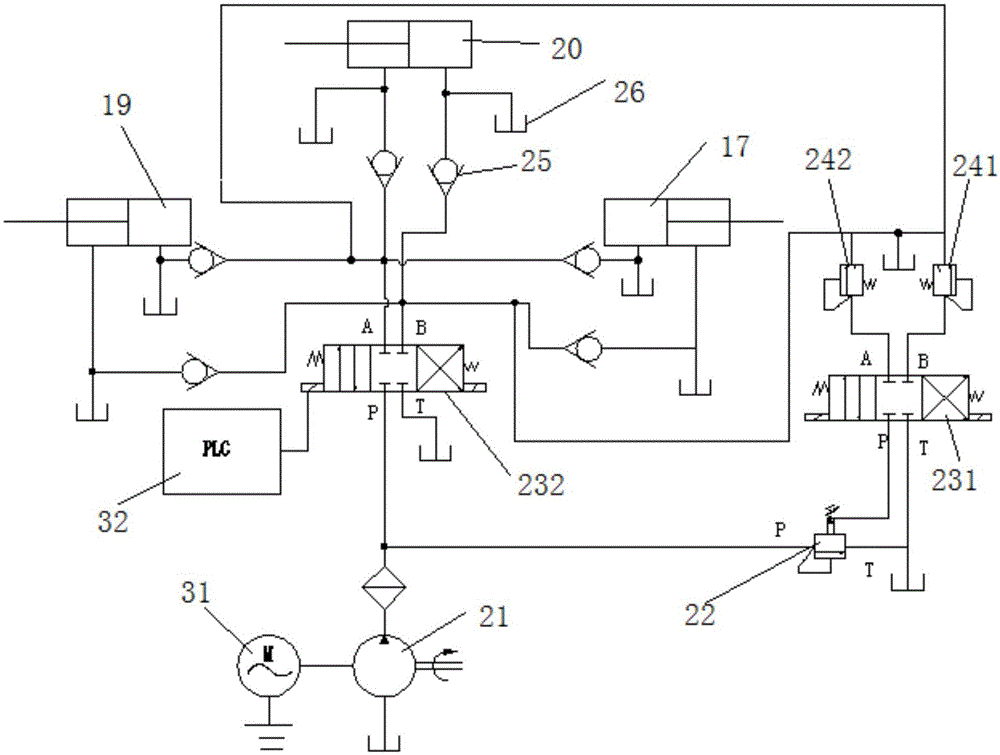

ActiveCN105927621AAvoid destructionPlay a protective effectFluid-pressure actuator componentsAutomatic controlFuel tank

The invention discloses a full-automatic multi-pipeline serial washing and filtering device. The full-automatic multi-pipeline serial washing and filtering device comprises an oil tank, a motor, an electric cabinet, a hydraulic oil pump unit, hydraulic valve blocks, an oil outlet pipeline, an oil returning pipeline and filters. The oil tank is connected with the oil outlet pipeline and the oil returning pipeline. The oil outlet pipeline is connected with the hydraulic oil pump unit and the hydraulic valve blocks in series. Distributors are arranged at an oil outlet of the oil outlet pipeline, oil products are distributed through the distributors and clean a cleaned pipeline in one or more paths, and then the oil products are gathered into a collector. The filters are arranged on the collector and an oil returning port of the oil returning pipeline. By means of the device, high-pressure oil formed in a hydraulic pipeline can effectively clean impurities on the inner wall of the hydraulic pipeline away, the automation degree is high, automatic control and manual control are achieved for double protection, the filtering effect is good, and the service life of a hydraulic system is prolonged. In addition, the device further comprises a radiation type heating system facilitating cleaning and also comprises an integrated heat dissipation system so that the heat dissipation efficiency can be greatly improved.

Owner:烟台裕晟流体设备有限公司

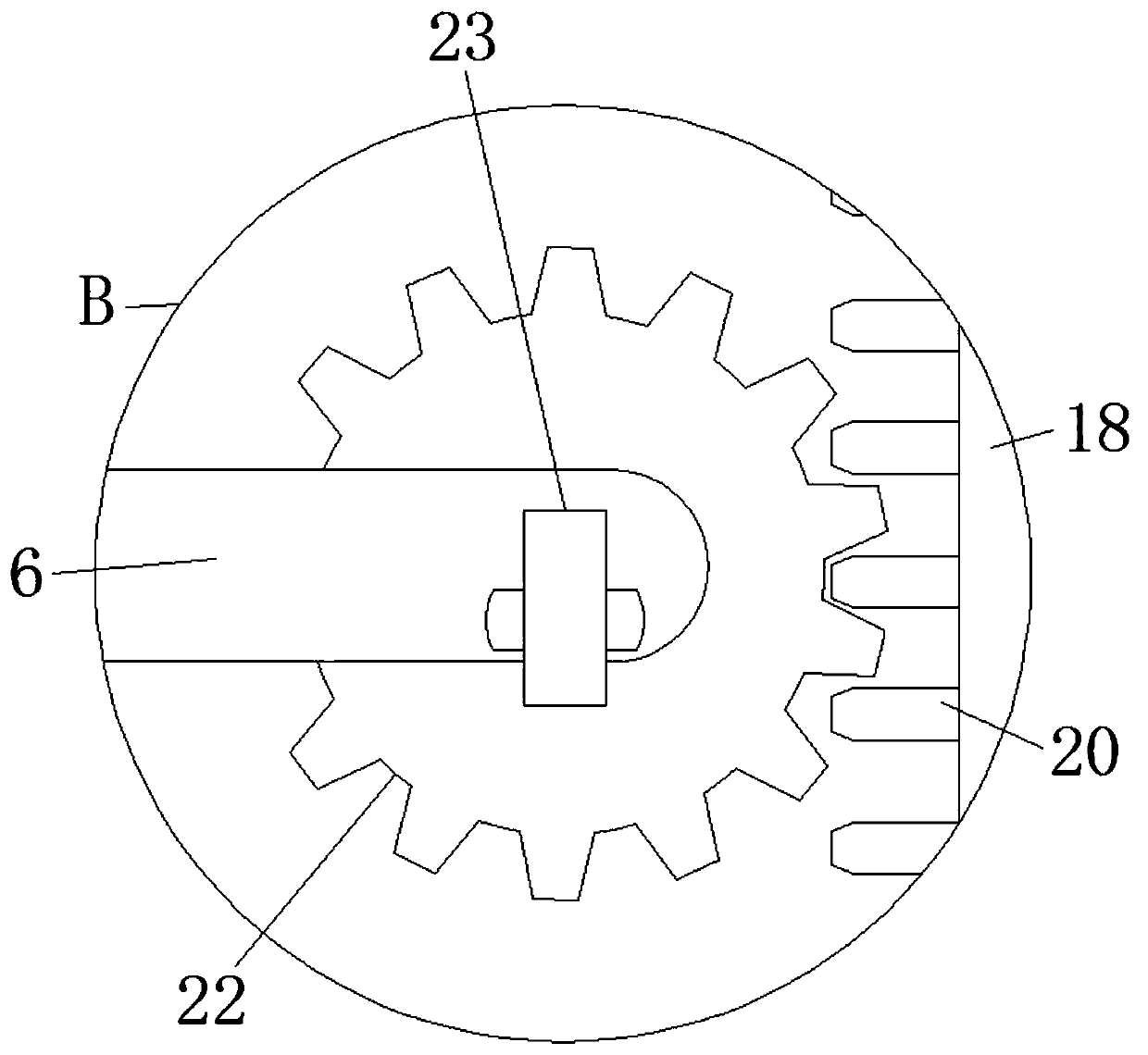

A motor based on rotor position recognition

ActiveCN109245441AHigh precisionAvoid overturningCouplings for rigid shaftsMechanical energy handlingCoupling

The invention discloses a motor based on rotor position identification. The coupling is axially and sliding sleeved on an output shaft of the motor. A first telescopic mechanism for driving the coupling to move axially is arranged in the output shaft of the motor. A rotating sleeve is arranged on the outer periphery of the coupling, a first contact is arranged on the first insulating elastic piece, a second contact is arranged on the second insulating elastic piece, the first contact is in selective contact with the second contact, and the first contact and the second contact are connected inseries in a triggering circuit; The stopper is fixedly arranged in the outer peripheral space of the motor output shaft; a second telescopic mechanism is arranged at that end of the output shaft of the motor; and a first end face gear is arranged on the telescopic end of the second telescopic mechanism; The output shaft of the motor is spaced apart from the load input shaft, the end of the load input shaft is provided with a second end face gear, and the first end face gear is selectively meshed and linked with the second end face gear; The invention solves the technical problem that the rotorposition is difficult to identify in the prior art through the improvement of the mechanical structure.

Owner:ZHEJIANG DONGFANG ELECTROMECHANICAL

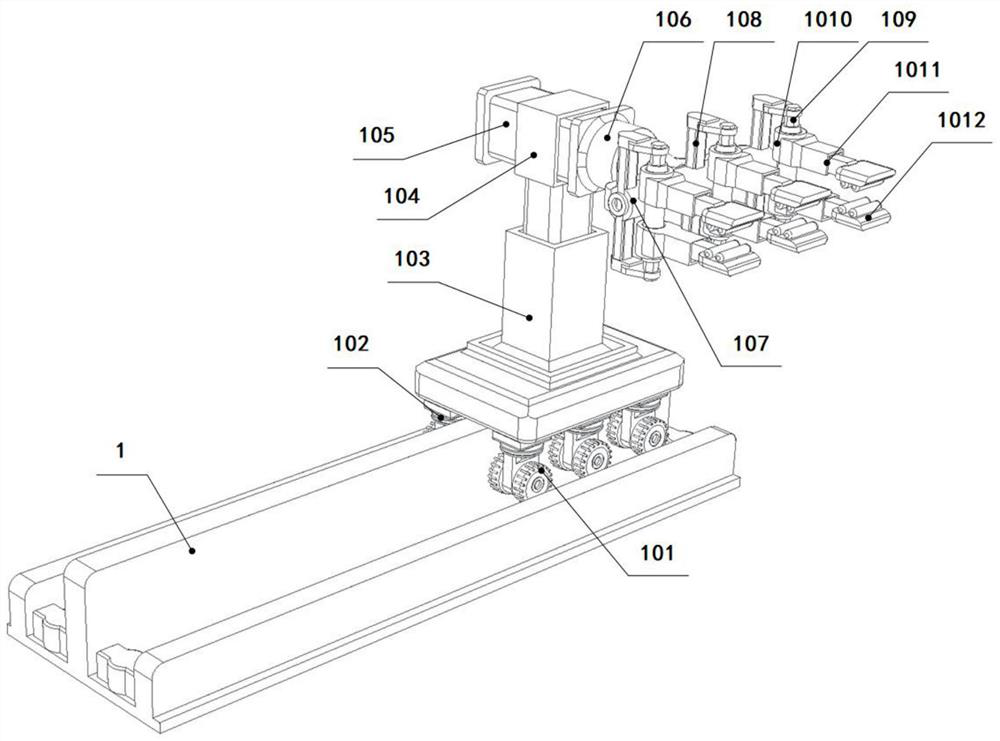

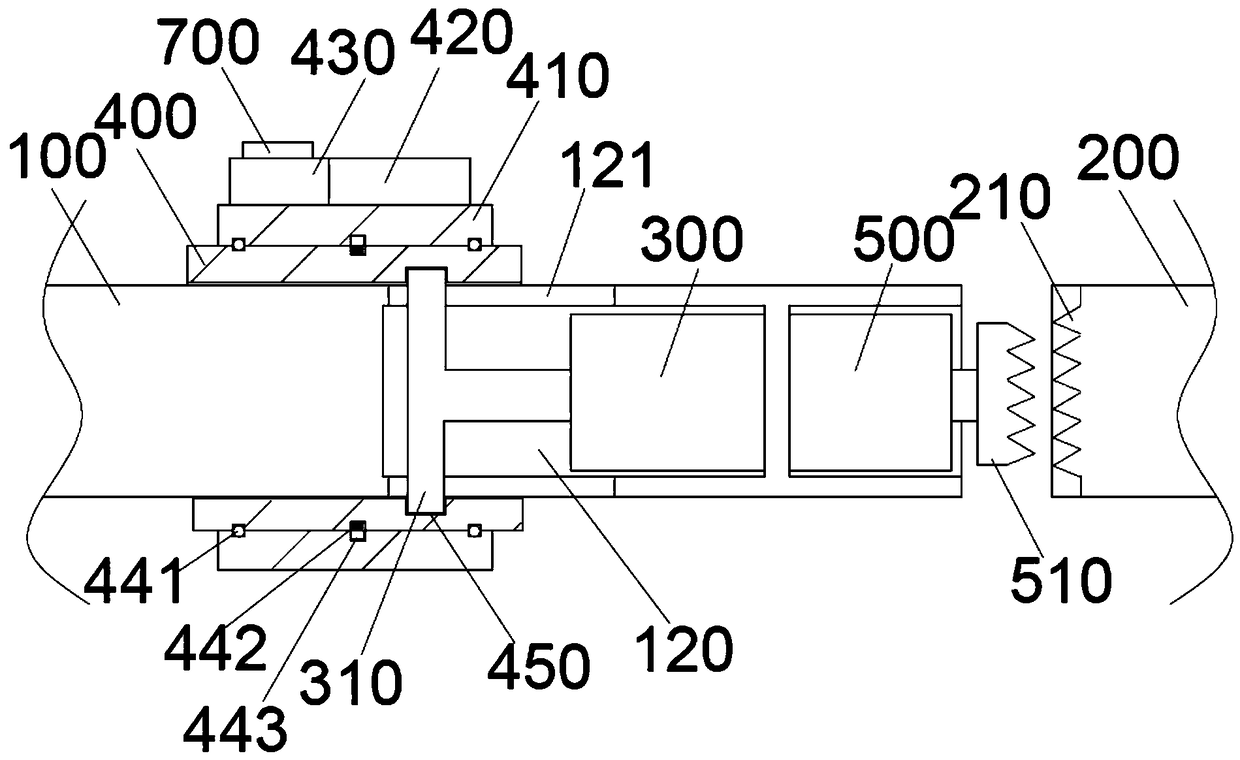

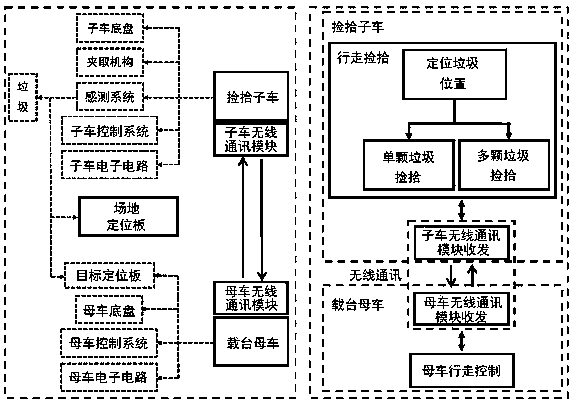

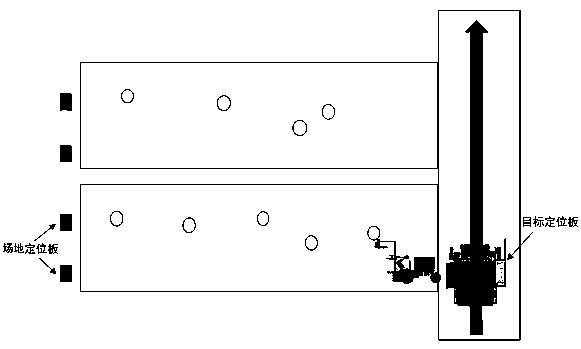

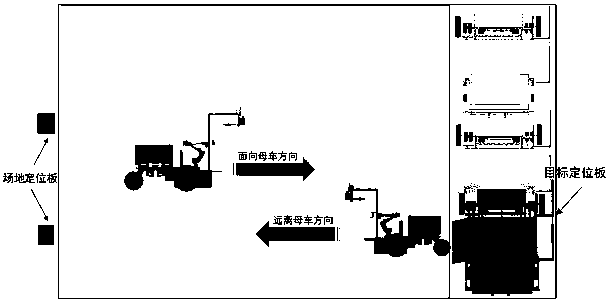

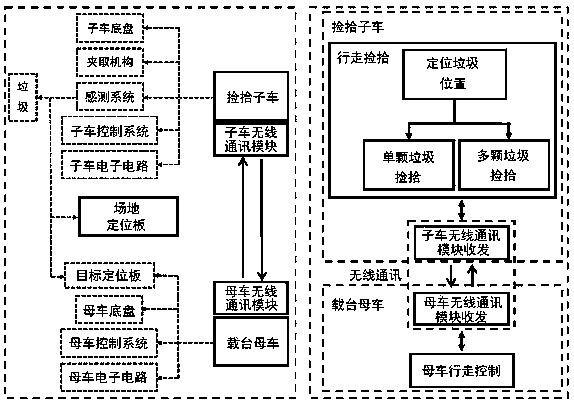

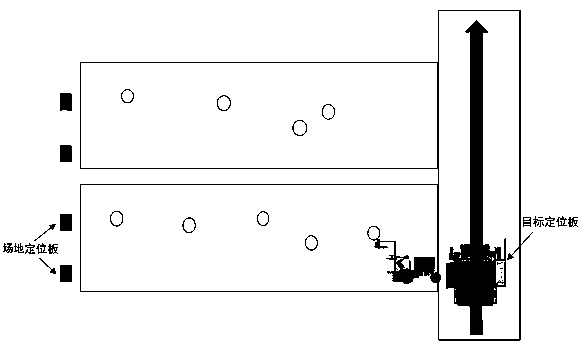

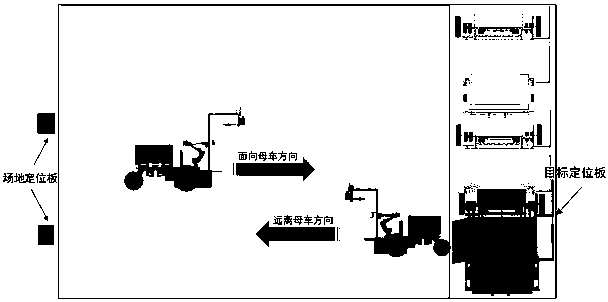

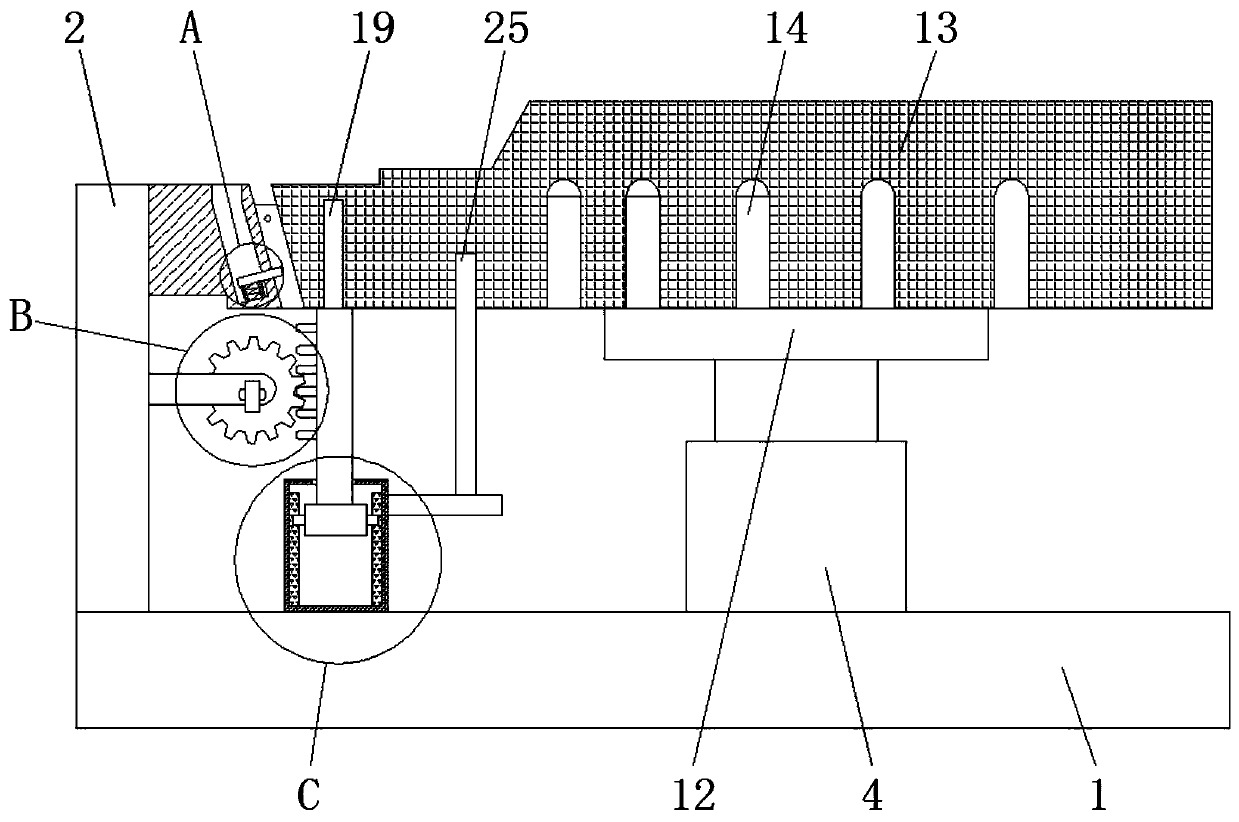

Full-automatic garbage pickup robot

ActiveCN110640759AImprove securityImprove reliabilityRoad cleaningManipulatorControl engineeringRefuse Disposals

The invention discloses a full-automatic garbage pickup robot. The full-automatic garbage pickup robot has the advantages that cooperative primary and secondary vehicles are coordinated with each other, automatic pickup operation during loading garbage into carrying platforms is realized, automatic pickup operation replaces manpower to pick up garbage, and the problem of the influence of insufficient manpower on garbage disposal can be solved; and the pick-up secondary vehicle has the functions of positioning the direction and identifying the position of the garbage and then is coordinated with a clamping mechanism to complete the pickup action, finally a communication bridge between the secondary and primary vehicle carrying platforms is established through a wireless communication module, the carrying platform primary vehicle with the guiding and conveying functions is coordinated with the pickup secondary vehicle to complete the automatic garbage pickup operation, and the full-automatic garbage pickup robot has a good application prospect in the field of environmental protection.

Owner:云笈智能科技(天津)有限公司

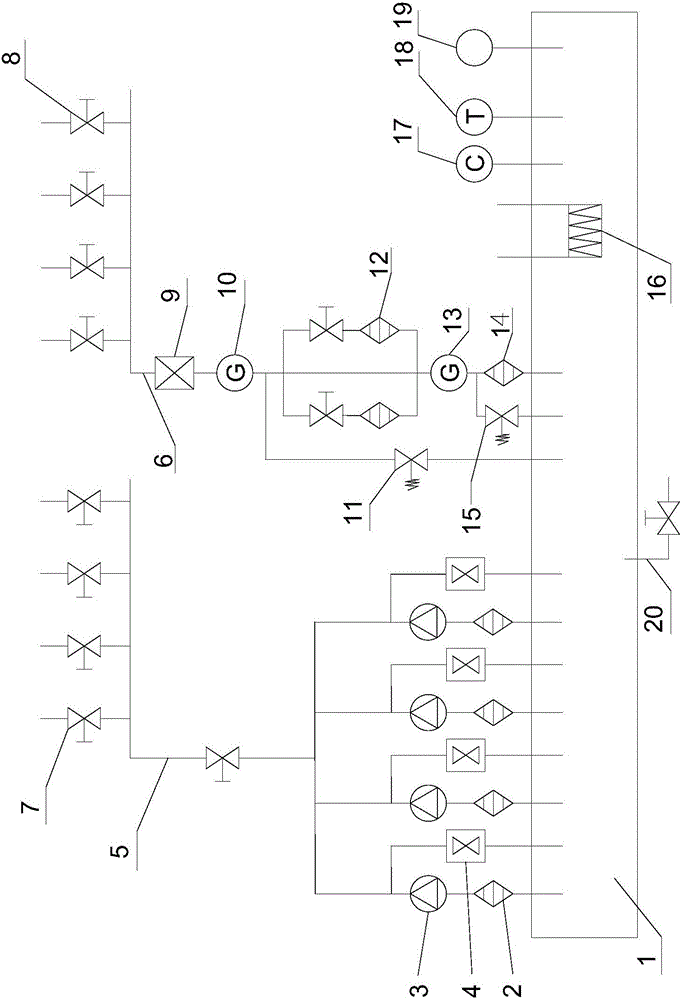

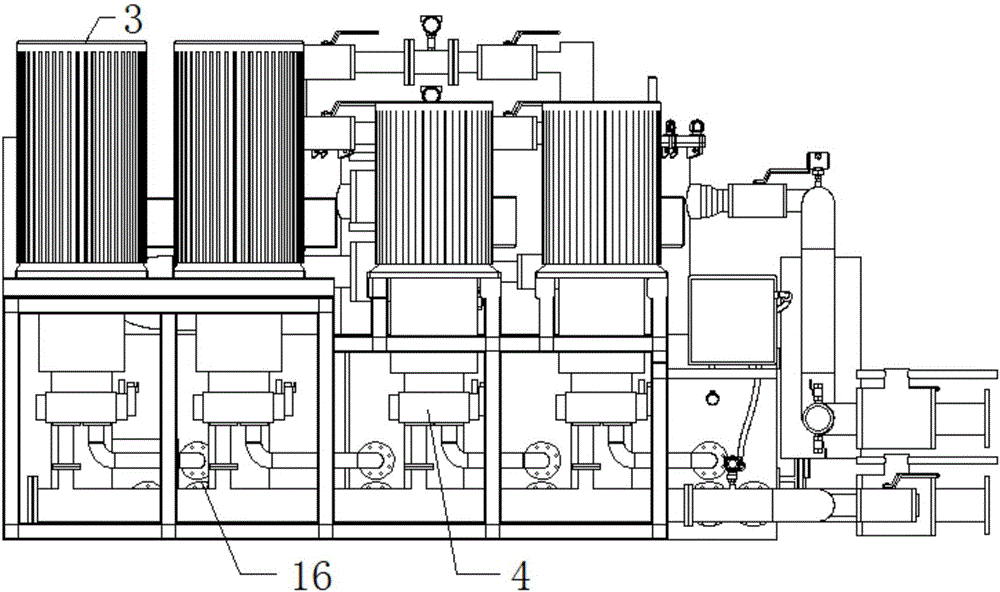

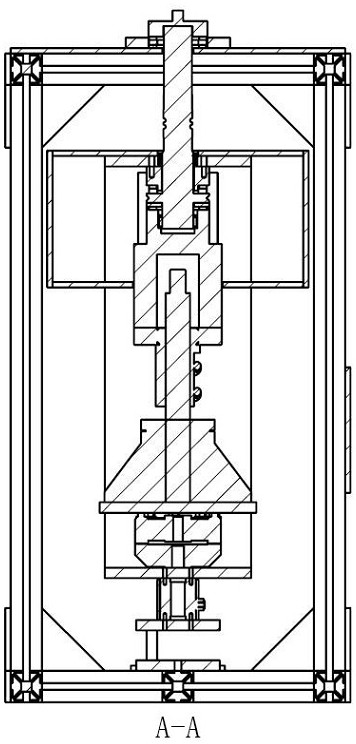

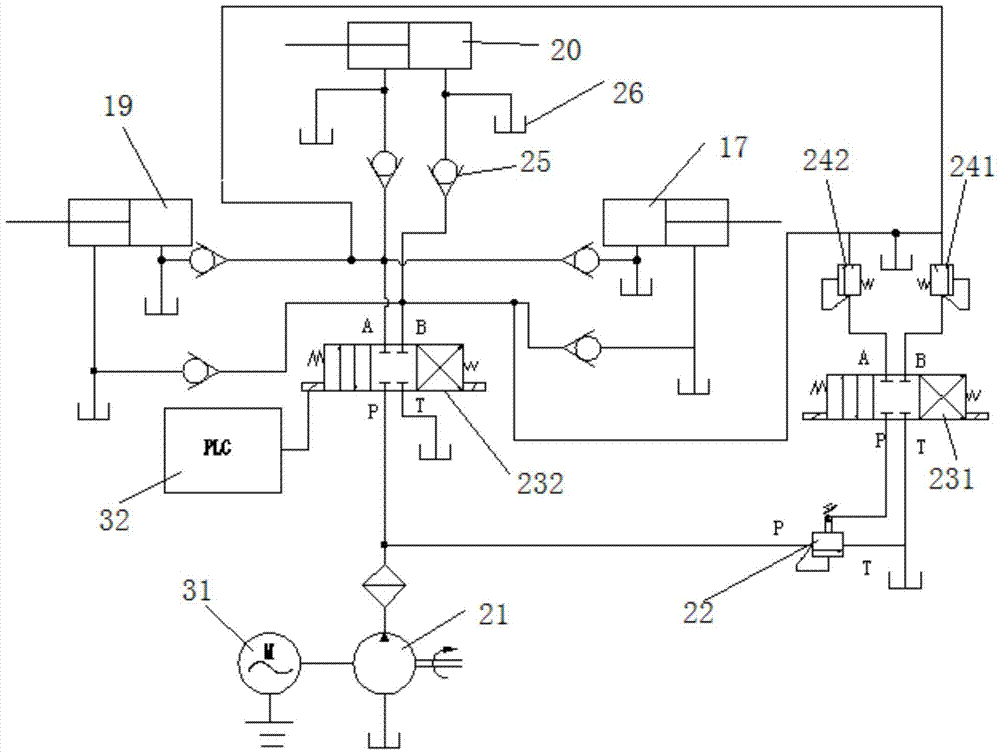

High-pressure long-range conveying device for magnetic material slurry and using method of high-pressure long-range conveying device

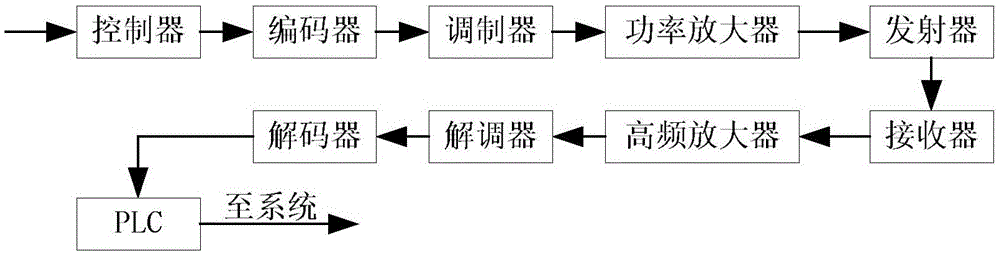

ActiveCN105084003APrevent leakageImprove product qualityMixersBulk conveyorsElectrical controlEngineering

The invention discloses a high-pressure long-range conveying device for magnetic material slurry and a using method of the high-pressure long-range conveying device, and belongs to the field of magnetic material slurry conveying equipment. The high-pressure long-range conveying device comprises a stirring part, an electrical system and a hydraulic system, and further comprises a double helix feeding system, an electrical remote control system and a press; the stirring part comprises a thick stirring part and a thin stirring part, and the slurry is conveyed to the double helix feeding system through the thick stirring part; the slurry is conveyed to the thin stirring part through the double helix feeding system, the thin stirring part conveys the slurry to the press, and the press is connected with an electrical cabinet of a touch screen; and the press is electrically controlled through the electrical cabinet of the touch screen to conduct operation, and therefore the slurry is pressed and molded. The electrical remote control system comprises a remote control transmitting system and a remote control receiving system, the remote control transmitting system transmits signals to the remote control receiving system, the remote control receiving system is connected with the electrical system which is connected with the hydraulic system, and a hydraulic cylinder of the hydraulic system is arranged in the double helix feeding system. By means of the high-pressure long-range conveying device, long-range conveying of the slurry can be achieved, sealing is achieved, and pollution is avoided.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

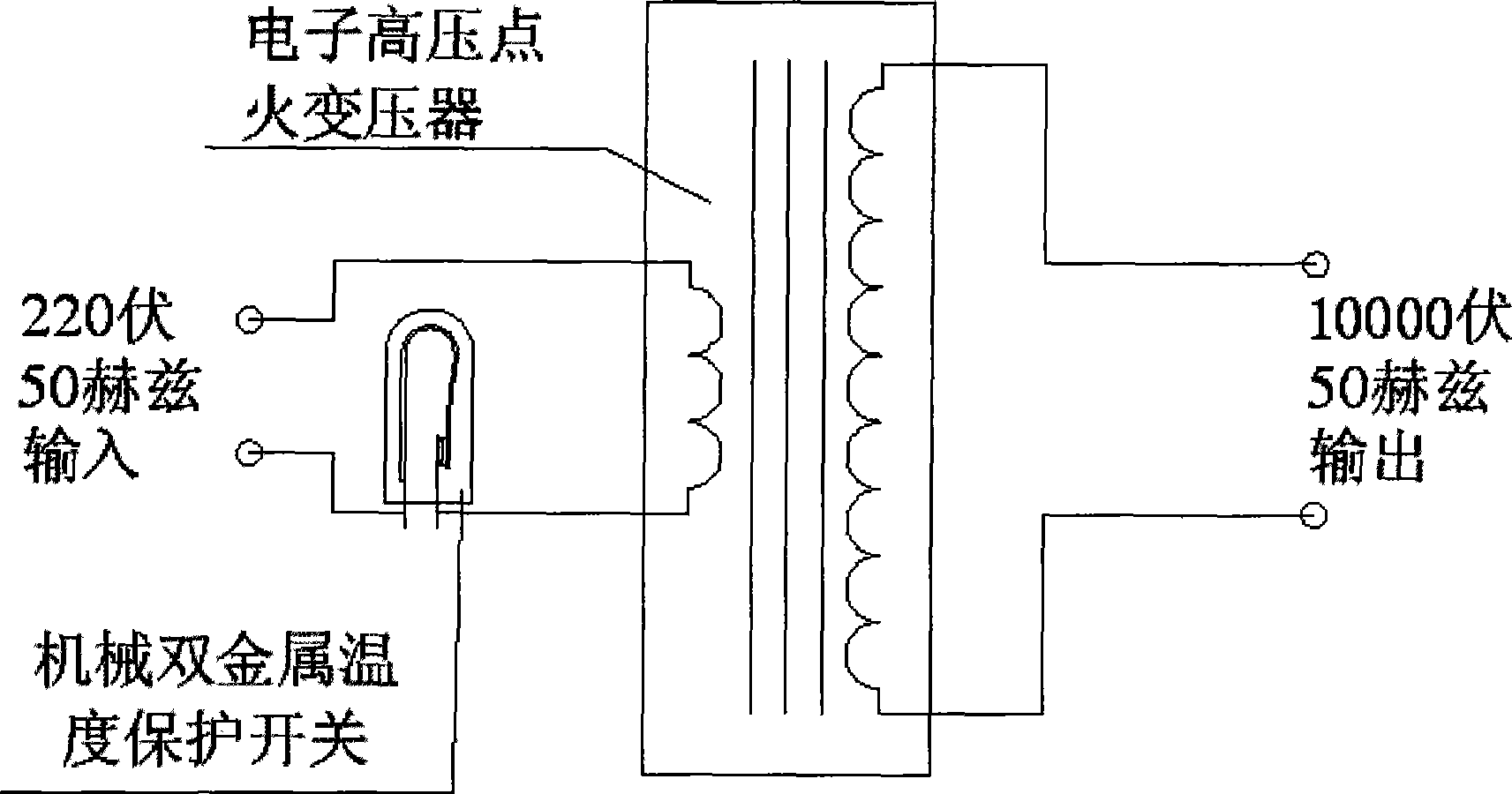

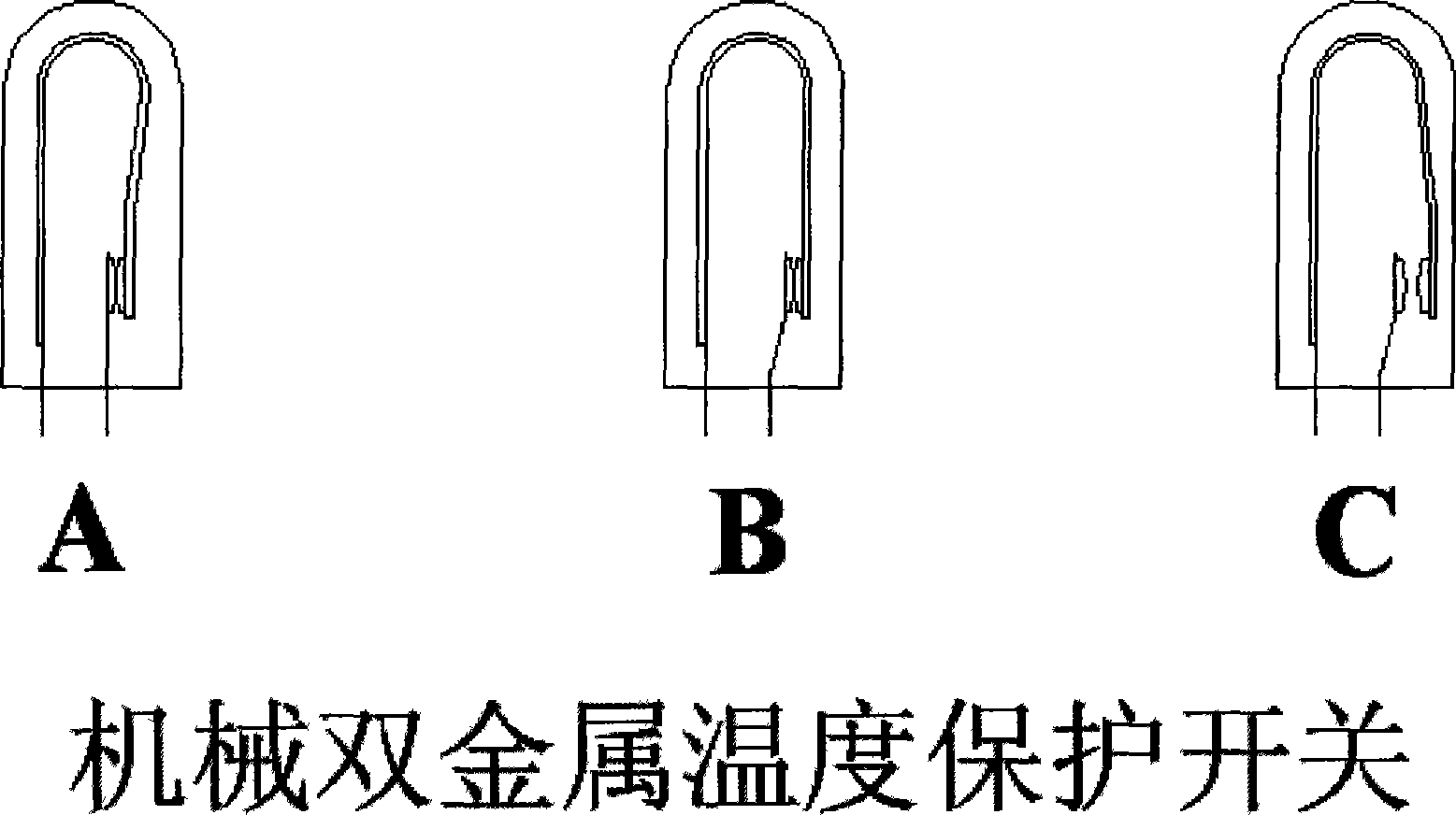

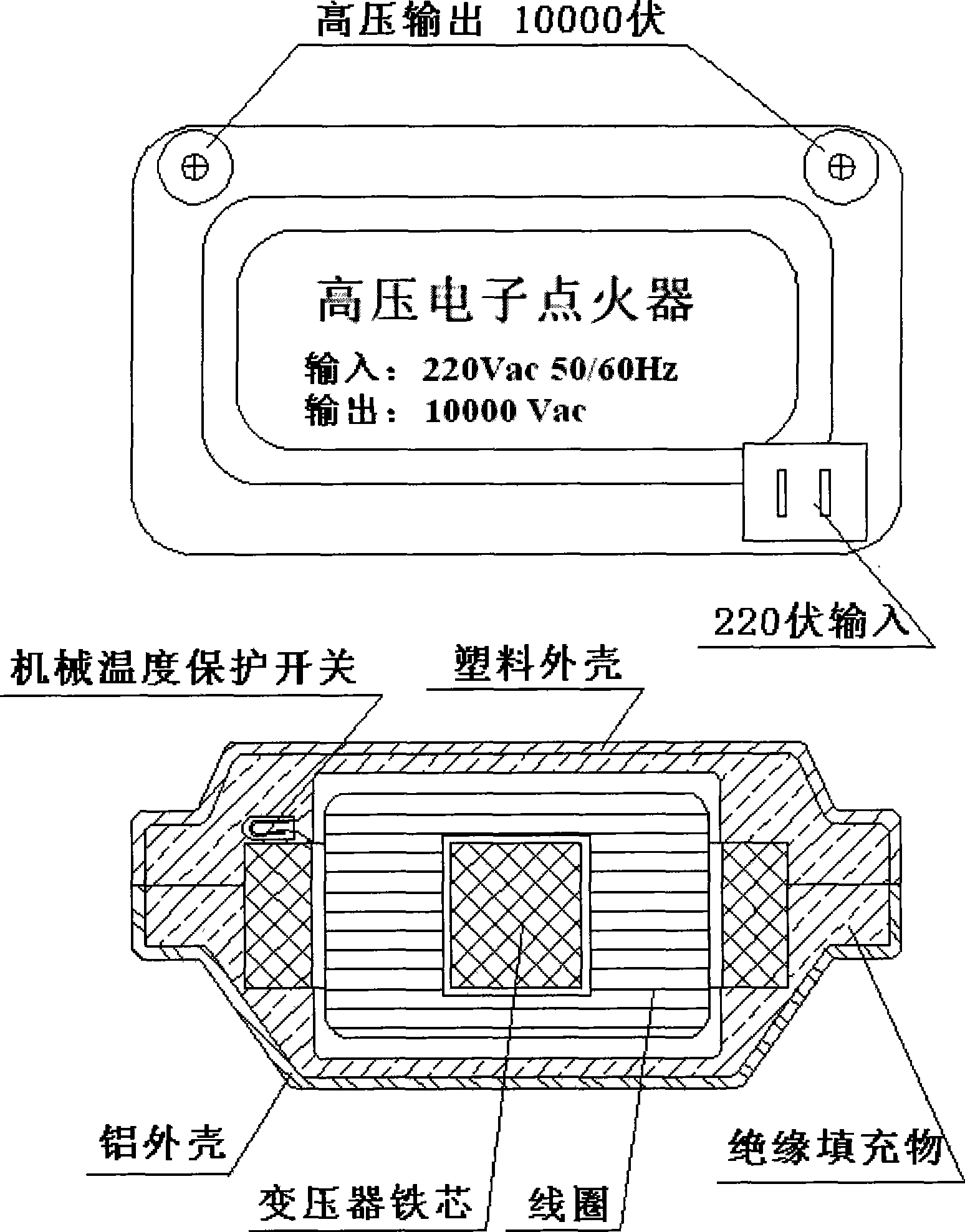

High-pressure electronic igniter with mechanical temperature protection

InactiveCN101440964AEnhanced radiationPlay the role of protecting equipmentIncandescent ignitionElectric spark ignitersStopped workElectromagnetic interference

The present invention comprises a high voltage electronic generator, a mechanical type temperature protection switch and a low radiation insulation seal housing. A bimetal plate machinery temperature switch ensures a high voltage igniter to work in a safe temperature range, when the temperature is higher than the set dangerous temperature, the switch will cut off, the device stop working and the temperature is decreased. When the temperature is lower than the dangerous temperature, the switch will cut on, and the igniter works continuously again. The device can be effectively used in industry on site which is under the complicated surroundings, because the mechanical bimetal switch has the advantages of strong electromagnetic interference resistant ability, long service life, simple structure, low cost and the like.

Owner:北京润瓯科技有限公司

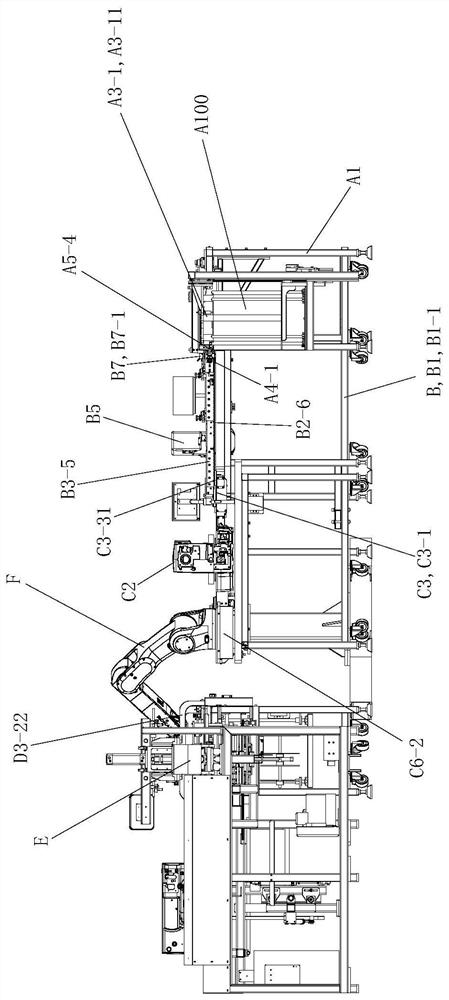

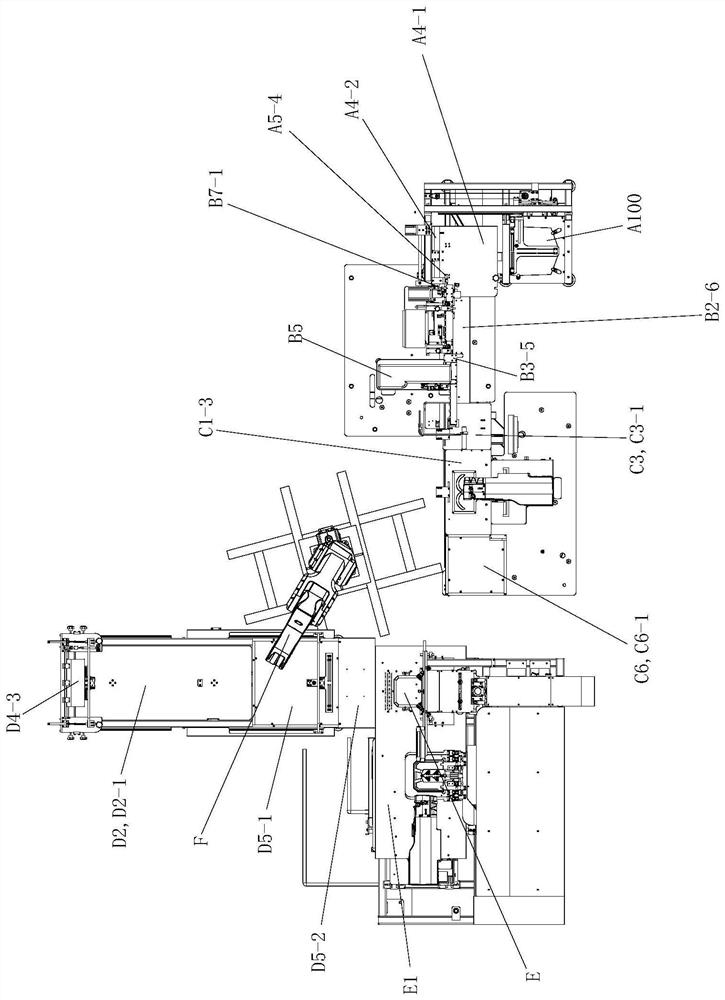

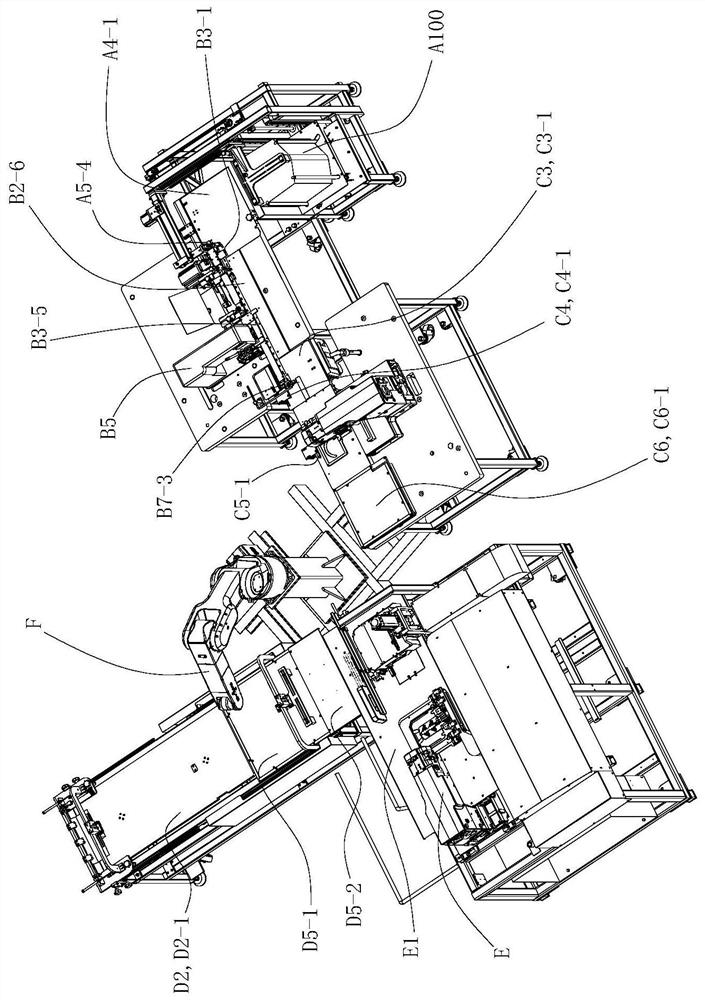

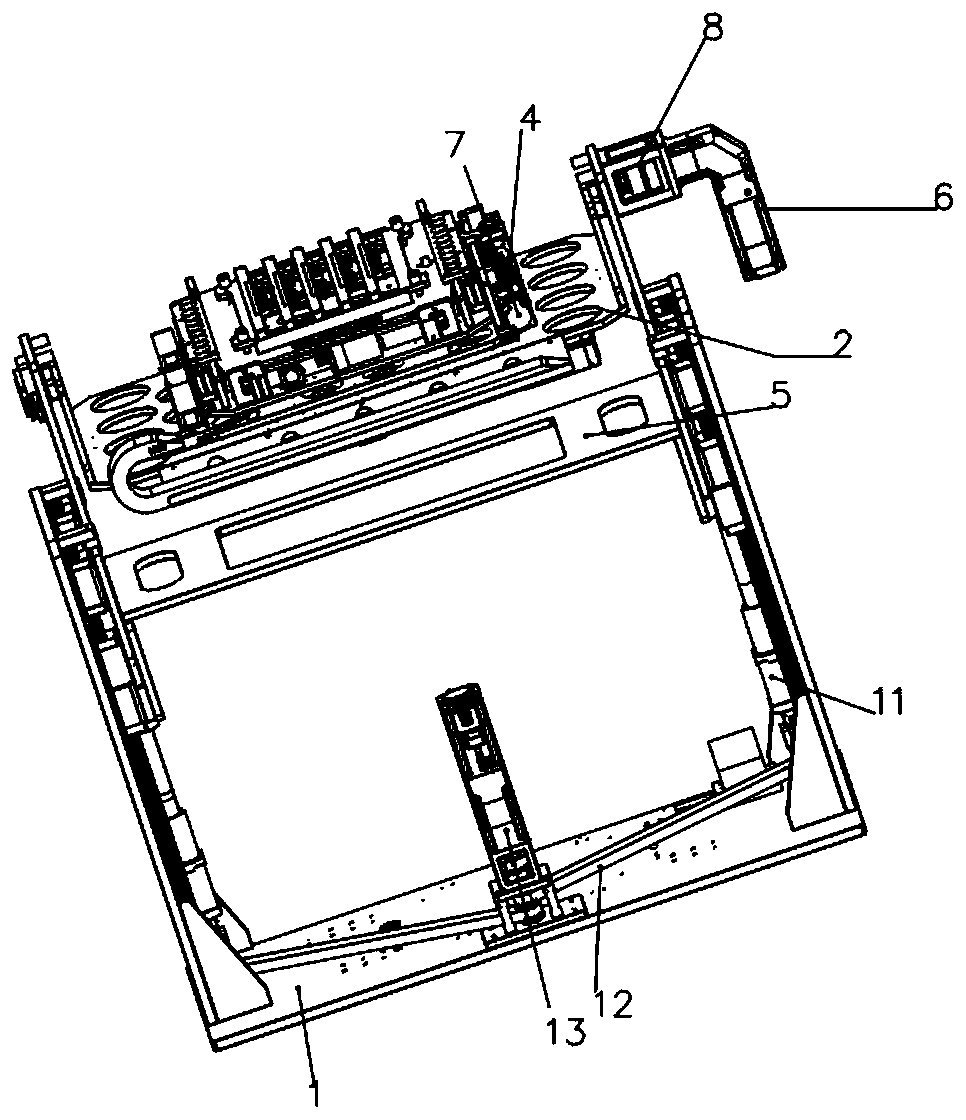

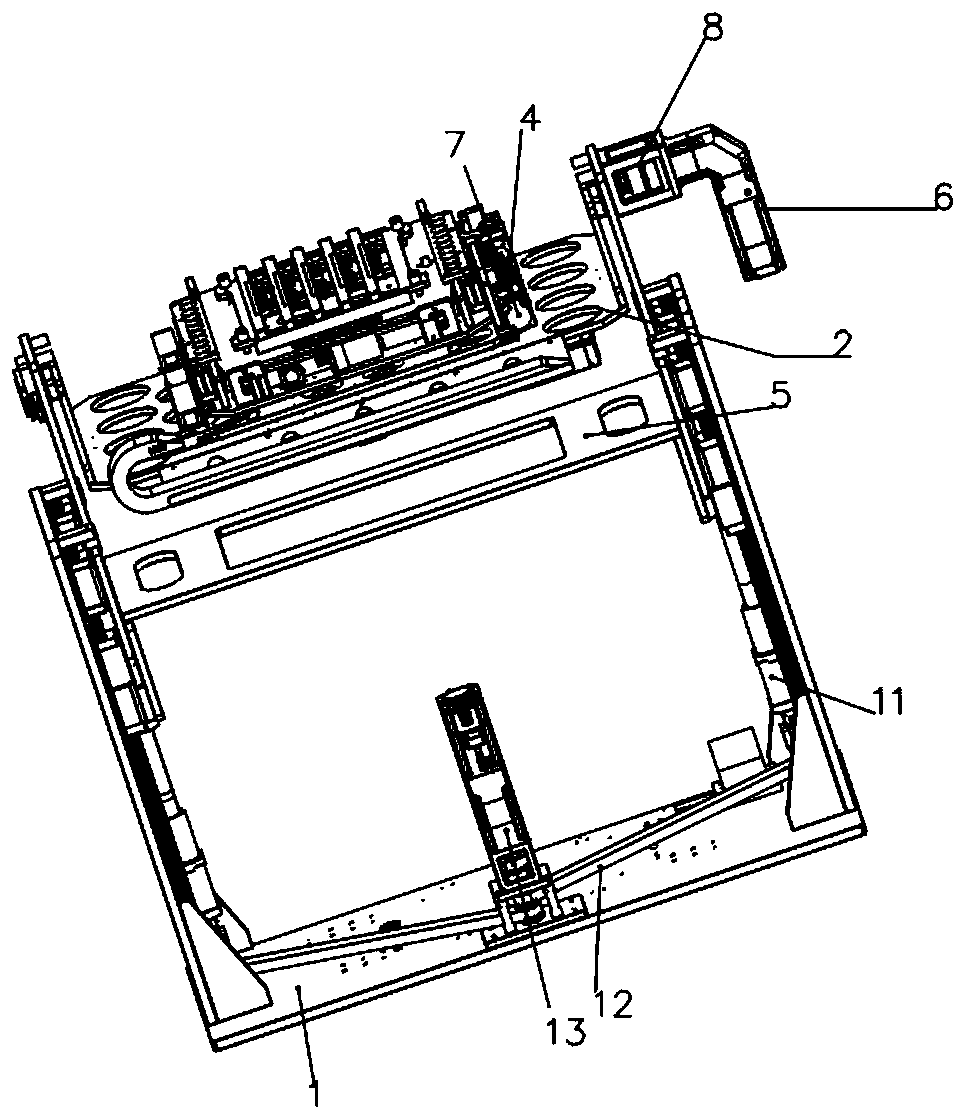

Pocket patching machine workstation

InactiveCN112359501ASimple structureEasy constructionWorkpiece carriersWork-feeding meansIndustrial roboticsIndustrial engineering

The invention discloses a pocket patching machine workstation. According to the key point, the pocket patching machine workstation comprises a pocket cloth feeding device, a hemming machine, a pocketpattern machine, a main body feeding device, a pocket patching machine and an industrial robot. The pocket cloth feeding device feeds pocket cloth on a pocket cloth bearing plate to a feeding mechanism of the hemming machine, and after hemming sewing of the hemming machine, the feeding mechanism feeds the pocket cloth to a receiving mechanism of the pocket pattern machine. A material taking mechanism of the pocket pattern machine conveys the pocket cloth on the receiving mechanism of the pocket pattern machine to a sewing mechanism of the pocket pattern machine for sewing stitches. A pocket patching machine is arranged on the left side of the pocket pattern machine. The front part of a main body material bearing mechanism is connected and flush with a working panel of the pocket patching machine. The industrial robot is located between the pocket patching machine and the pocket pattern machine, and the industrial robot grabs the pocket cloth on the material bearing mechanism of the pocket pattern machine and sends the pocket cloth to an edge folding device of the pocket patching machine. The industrial robot feeds the front part of the main body cloth on the large body bearing mechanism into a working panel below an edge folding device of the pocket patching machine.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

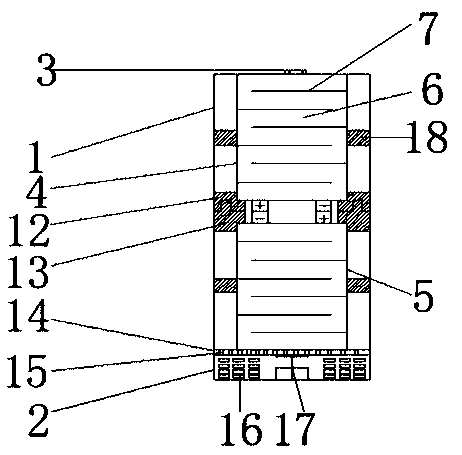

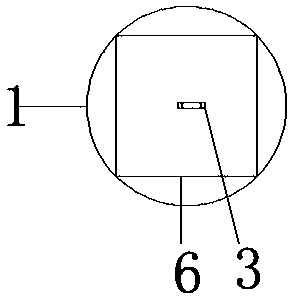

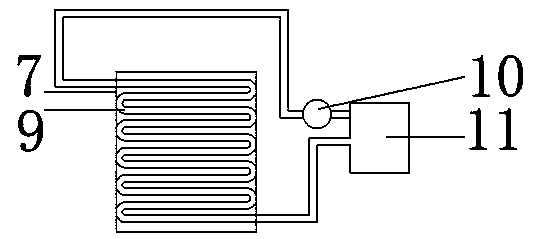

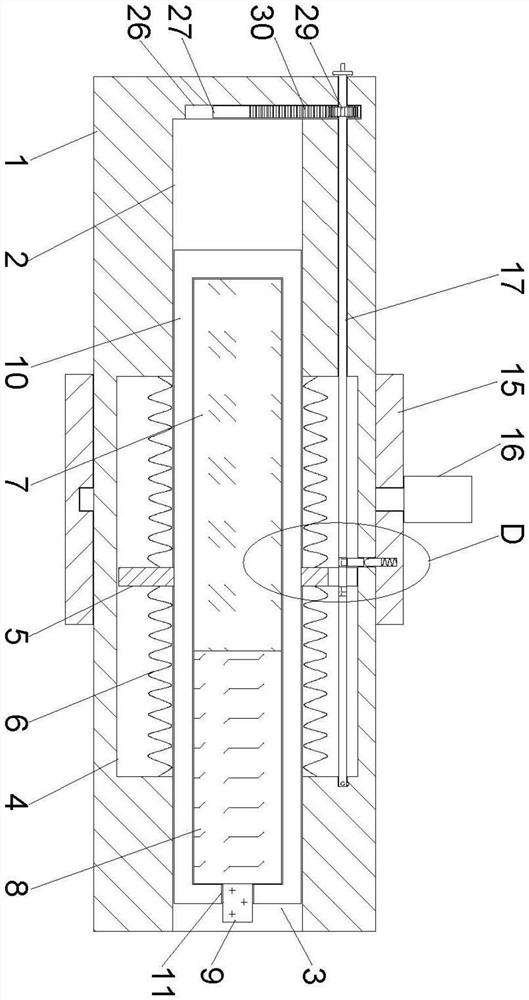

Novel lithium ion battery pack

InactiveCN108807780AImprove protectionIncrease removalSecondary cellsCell component detailsEngineeringLiquid tank

The invention discloses a novel lithium ion battery pack. The novel lithium ion battery pack comprises a barrel and a base, wherein an output electrode is arranged at the top end of the barrel; a first battery chamber and a second battery chamber are formed in the barrel; a shell is arranged outside the first battery chamber and the second battery chamber; partition boards are arranged inside thefirst battery chamber and the second battery chamber; battery plates are arranged above the partition boards; a U-shaped bent tube is arranged inside the partition boards; the liquid inlet end of theU-shaped bent tube is connected with a liquid supply pump; the other end of the liquid supply pump is connected with the outlet end of a cooking liquid tank. Through arrangement of the partition boards in the battery chambers, two battery plates do not directly contact with each other to produce a heat superposing effect; the U-shaped bent tube is arranged inside the partition boards, cooking liquid flows in the U-shaped bent tube, and the U-shaped bent tube is circularly connected to the cooking liquid tank, so that the liquid supply pump provides a driving force, heat is quickly removed andthus batteries are protected better.

Owner:谢志汉

A fully automatic road garbage picking robot and its use method

ActiveCN110640759BImprove securityImprove reliabilityRoad cleaningManipulatorControl engineeringRefuse Disposals

The invention discloses a full-automatic garbage pickup robot. The full-automatic garbage pickup robot has the advantages that cooperative primary and secondary vehicles are coordinated with each other, automatic pickup operation during loading garbage into carrying platforms is realized, automatic pickup operation replaces manpower to pick up garbage, and the problem of the influence of insufficient manpower on garbage disposal can be solved; and the pick-up secondary vehicle has the functions of positioning the direction and identifying the position of the garbage and then is coordinated with a clamping mechanism to complete the pickup action, finally a communication bridge between the secondary and primary vehicle carrying platforms is established through a wireless communication module, the carrying platform primary vehicle with the guiding and conveying functions is coordinated with the pickup secondary vehicle to complete the automatic garbage pickup operation, and the full-automatic garbage pickup robot has a good application prospect in the field of environmental protection.

Owner:云笈智能科技(天津)有限公司

Novel negative pressure door suction ejection device

The invention discloses a novel negative pressure door suction ejection device. The device comprises a base; a support column, an adjustment box and a hydraulic cylinder are sequentially and fixedly mounted at top of the base from left to right; a mounting bar and two brackets distributed front and back are sequentially welded to the right side surface of the support column from top to bottom; a cavity is formed in the mounting bar; a sleeve is fixedly mounted in the cavity; a spring is fixedly mounted at the bottom of the cavity; the spring is located in the sleeve; a connecting block is fixedly mounted at the end, away from the cavity, of the spring; an outward-folded bar is fixedly mounted at the right end of the connecting block; the left side surface of the outward-folded bar is attached to the right side surface of the mounting bar; a support plate is fixedly mounted at the top of the hydraulic cylinder; a mold main body is arranged at the top of the support plate; mold cavitiesare formed in the mold main body; sliding rails are fixedly mounted on the left inner wall and the right inner wall of the adjustment box; sliding blocks are movably connected to the ends, close to each other, of the two sliding rails; and a strip-shaped block is fixedly mounted between the two sliding blocks. By driving an inward-folded bar and the outward-folded bar to move, products are rapidlyejected.

Owner:滁州市锴模装备模具制造有限公司

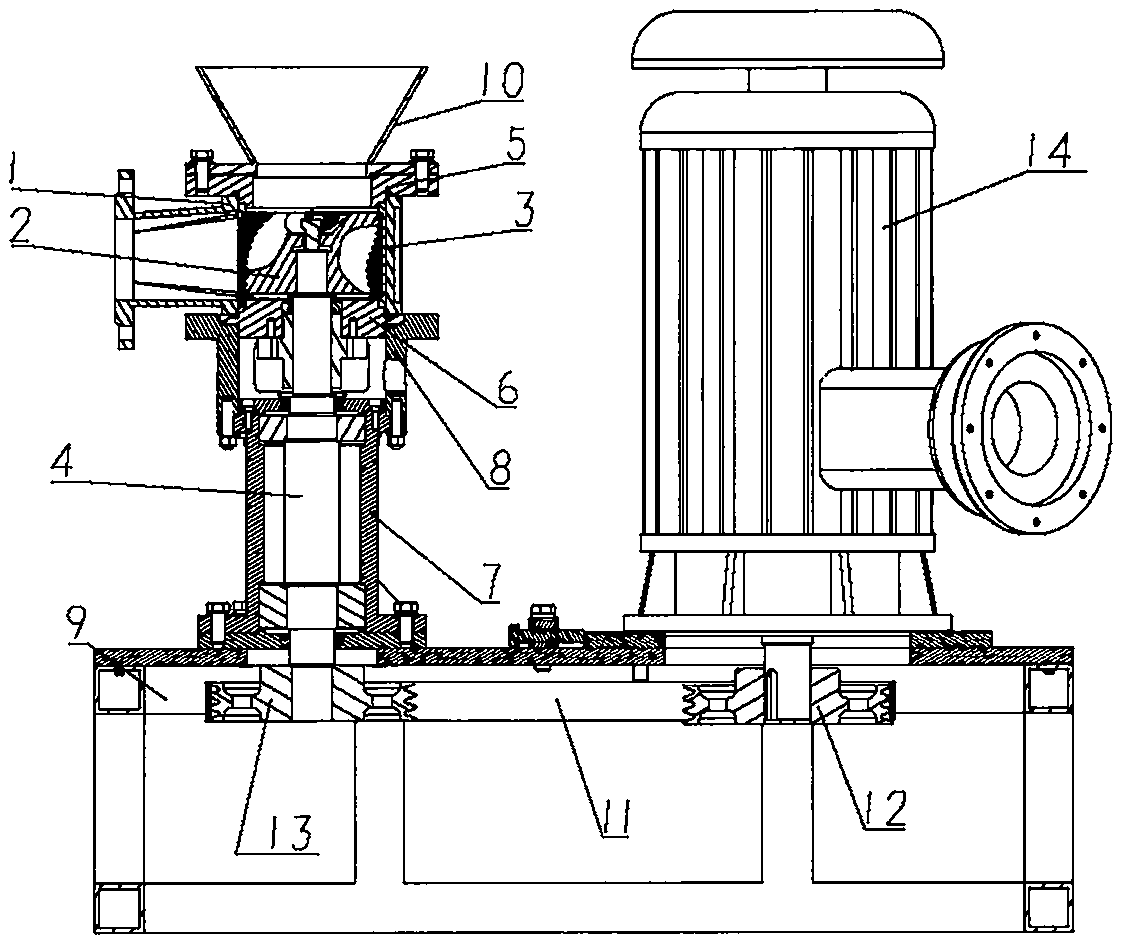

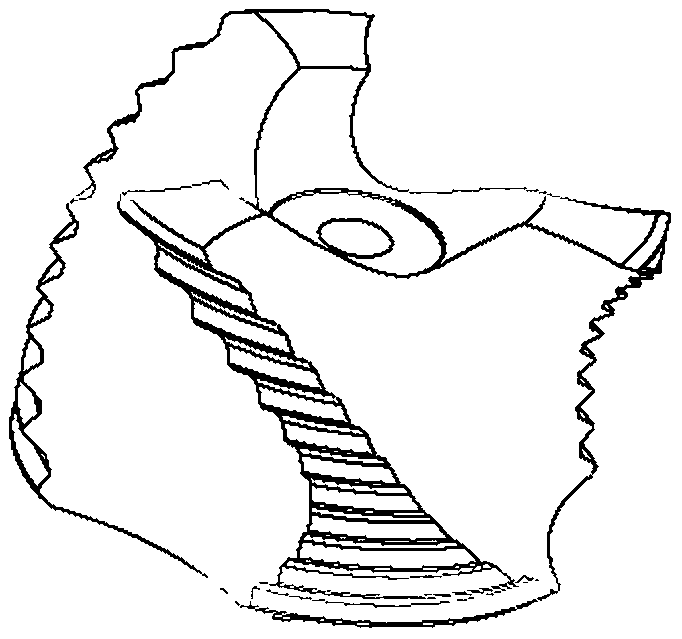

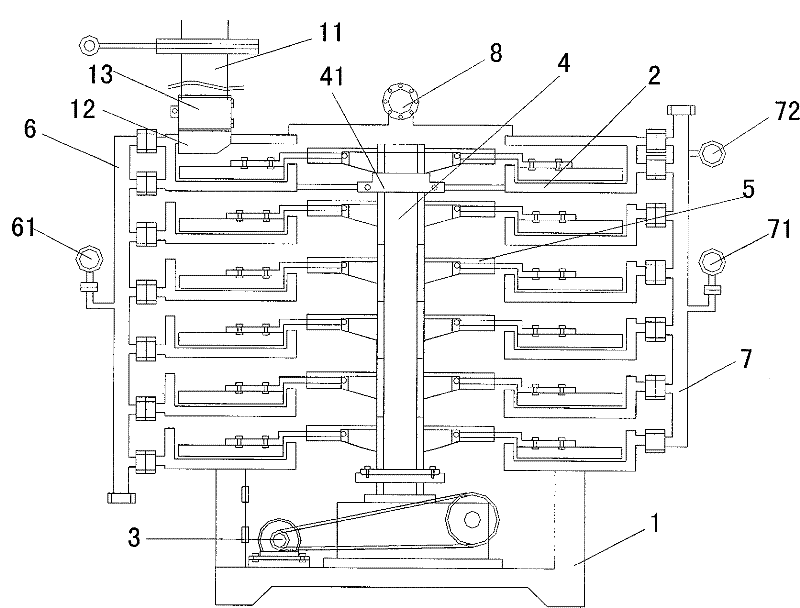

Colloid mill for efficiently and uniformly crushing particles

InactiveCN110090694AGuaranteed uptimePlay the role of protecting equipmentGrain treatmentsColloidColloid mill

A colloid mill for efficiently and uniformly crushing particles is composed of a grinding body, a rotor, a screening mesh, a main shaft, a pressing plate, a rotor rear cover, a transmission box, a supporting seat, a base, a feeding inlet, a belt, a primary belt pulley, a secondary belt pulley, and a motor. The rotor of the colloid mill for efficiently and uniformly crushing the particles adopts atechnology combining a special triangular tooth fluid dynamic optimization spiral groove rotor and a triangular tooth groove array abrasive disc screening mesh; and the screening mesh of the colloid mill for efficiently and uniformly crushing the particles is a specially designed diffuse type taper hole array screening mesh, the screening mesh consists of two half sheets, special triangular teethare uniformly distributed on one half sheet of the screening mesh, the other half sheet of the screening mesh is opposite to a discharge opening on the grinding body, the half sheet of the screening mesh opposite to the discharge opening is provided with screening holes and the special triangular teeth, arrays of the screening holes are uniformly distributed on the half sheet of the screening mesh, and the screening holes are diffusion type tapered holes with small inside and large outside.

Owner:宁波领智机械科技有限公司

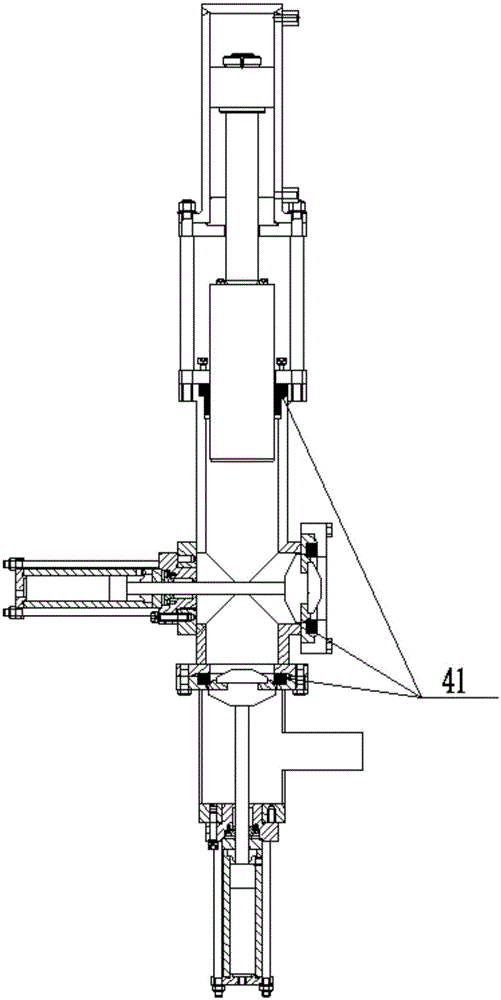

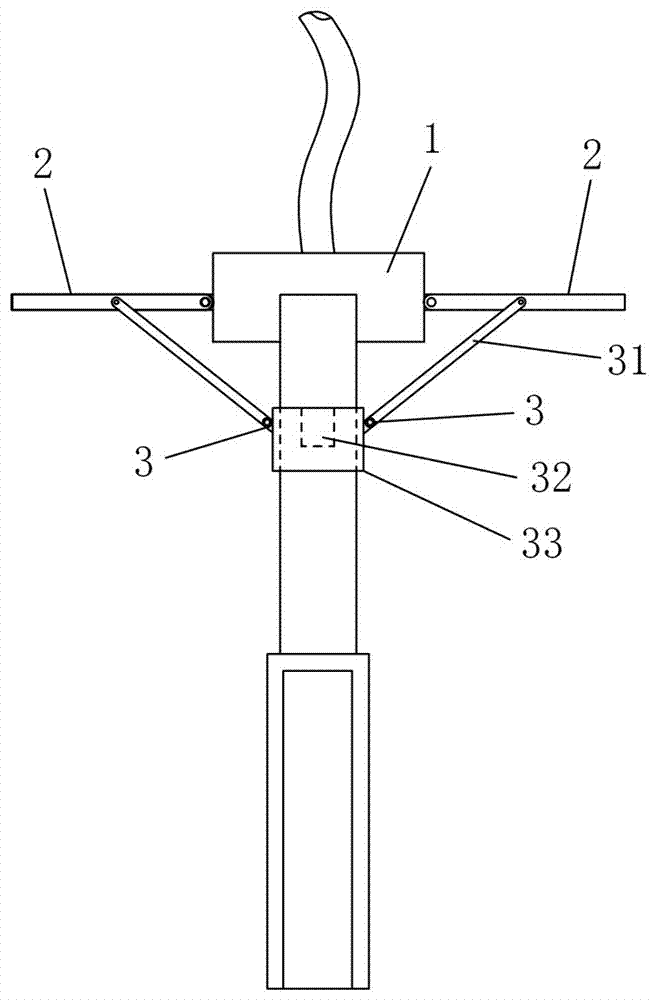

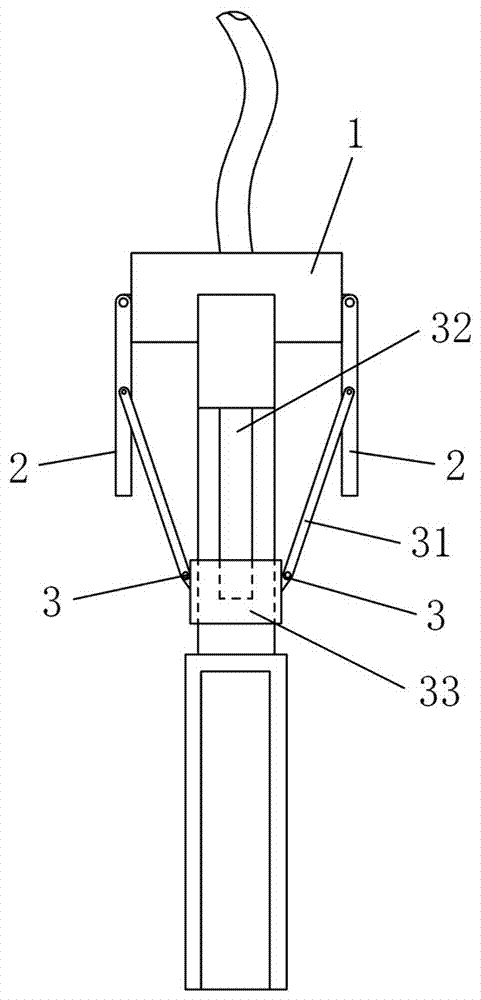

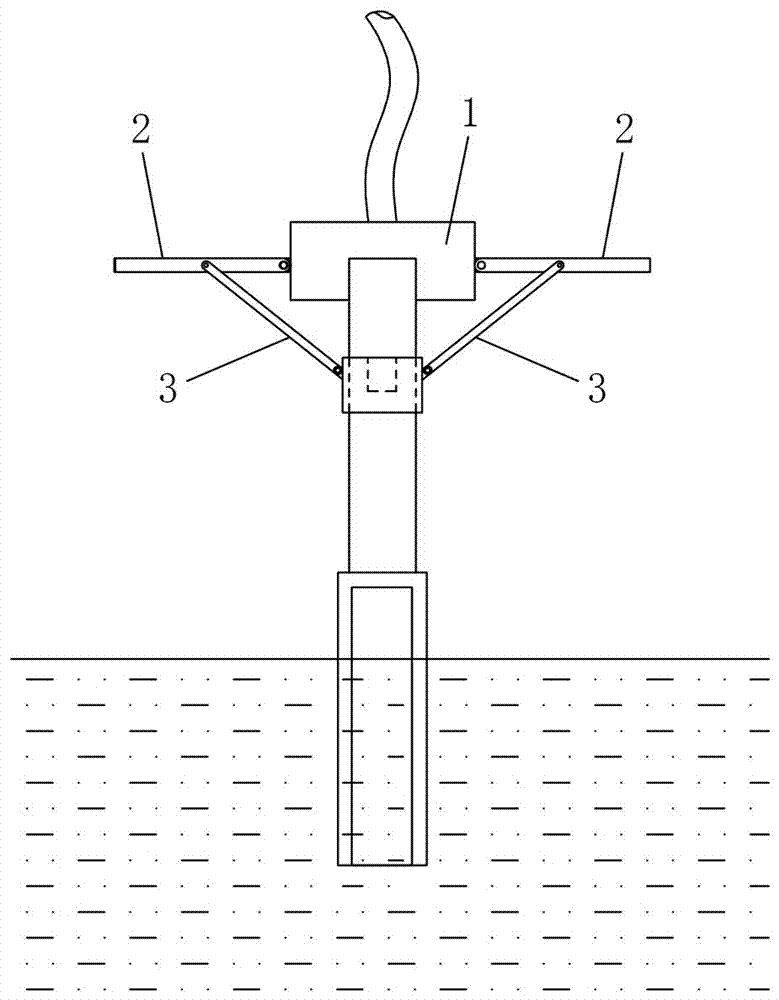

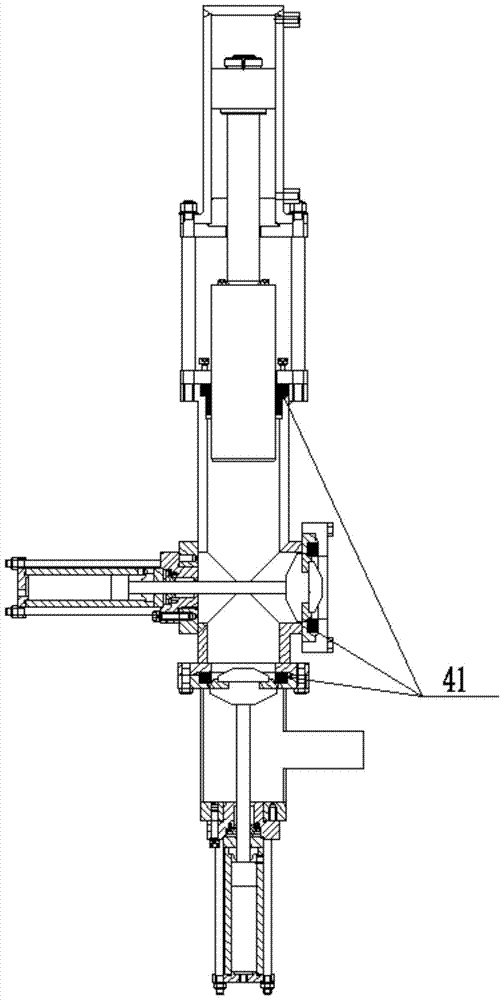

A hydrodynamic pressure device for deep sea operation equipment

ActiveCN104802968BIncrease water resistanceGreat depth of workWithdrawing sample devicesUnderwater equipmentMarine engineeringGravity line

The invention discloses a water power pressuring device and a pressuring method for deep ocean working equipment. The pressuring device comprises a water resistance pressuring mechanism arranged on the equipment, wherein the water resistance pressuring mechanism is used for enlarging water resistance acting surfaces of the equipment in the gravity direction; the water resistance acting surfaces are symmetrically distributed about the equipment center of gravity line; the pressuring device is simple in structure and capable of improving the work stability of the equipment and deepening the work depth of the equipment. The pressuring method comprises the following steps: controlling the sizes of the water resistance acting surfaces according to the actual requirement, and reducing the water resistance acting surfaces in an addressing releasing process and a recovering process of the equipment to avoid increase of the water resistance of the equipment, so as not to influence the releasing speed and the descending posture of the equipment, but play the function of protecting the equipment.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

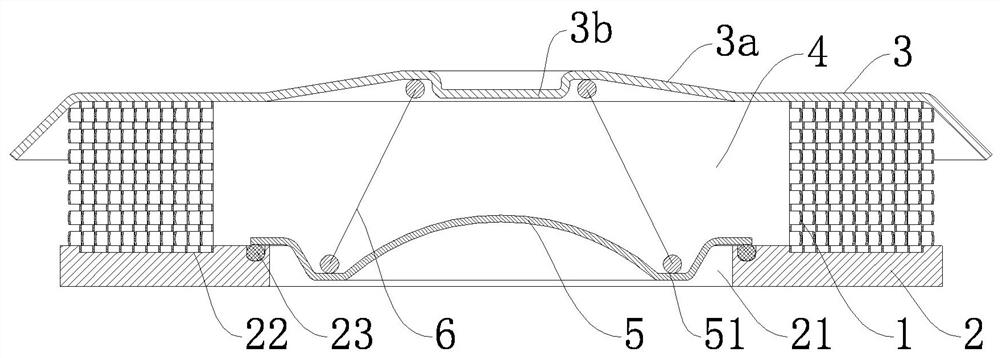

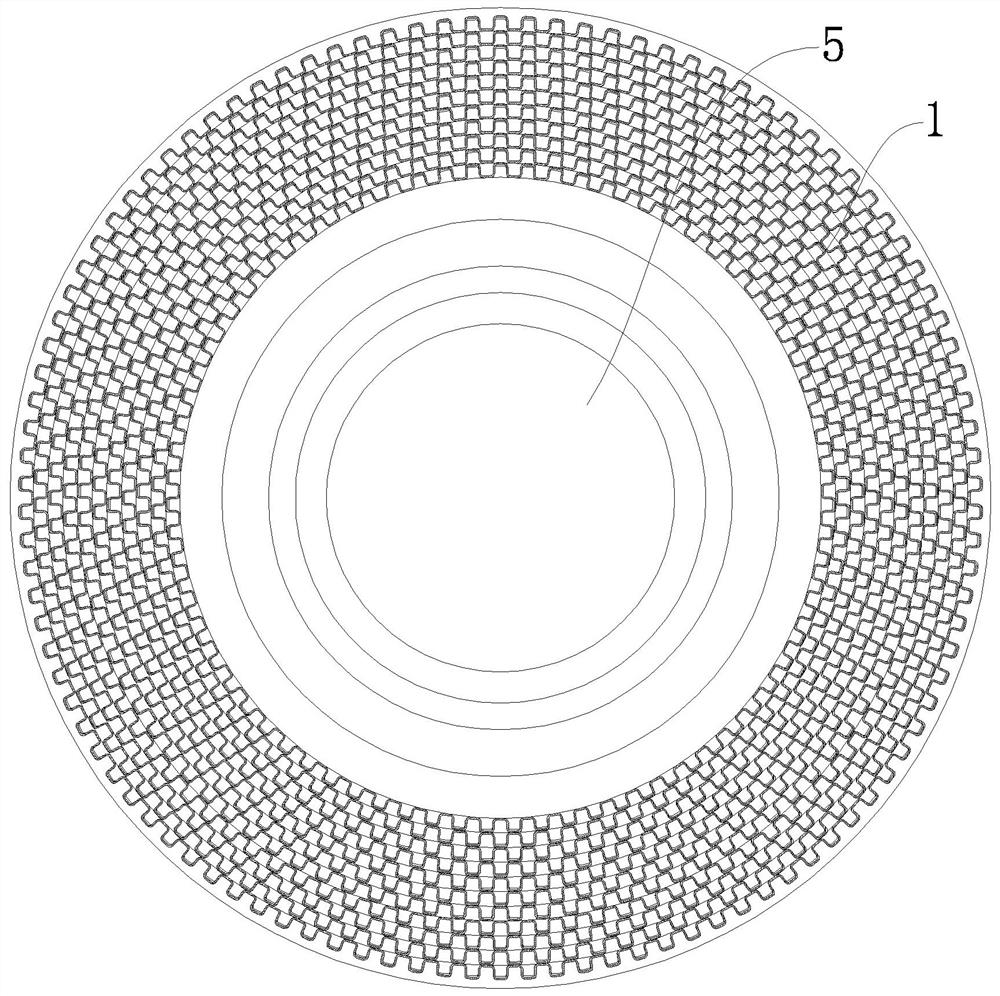

A counter-type flame-resisting component and a flame-resisting explosion-proof valve

ActiveCN106677900BPlay the role of protecting equipmentMachines/enginesEngine componentsEngineeringMechanical engineering

The invention discloses a counter-type flame-resisting component and a flame-resisting explosion-proof valve. The counter-type flame-resisting component comprises at least three layers of ring-shaped flame retardant sheets that are coaxially nested. The flame retardant sheet of each layer has an annular body composed of elongated sheet-shaped bodies connected end to end, and bosses protruding radially outward are formed at intervals on the annular body. There are horizontal airflow passages and vertical airflow passages between adjacent bosses. The side wall of each boss has at least one through hole penetrating through the ring body. In the present invention, several layers of flame retardant sheets are used to form a hedging type flame retardant assembly, and the convex structure on the flame retardant sheet and the relative through hole are used to make the flame generated by the explosion perform hedging action and wall collision for many times. After several times of hedging and collision, the energy is greatly lost, and it can be quickly extinguished and released as hot gas, which plays a role in protecting the equipment.

Owner:谢函

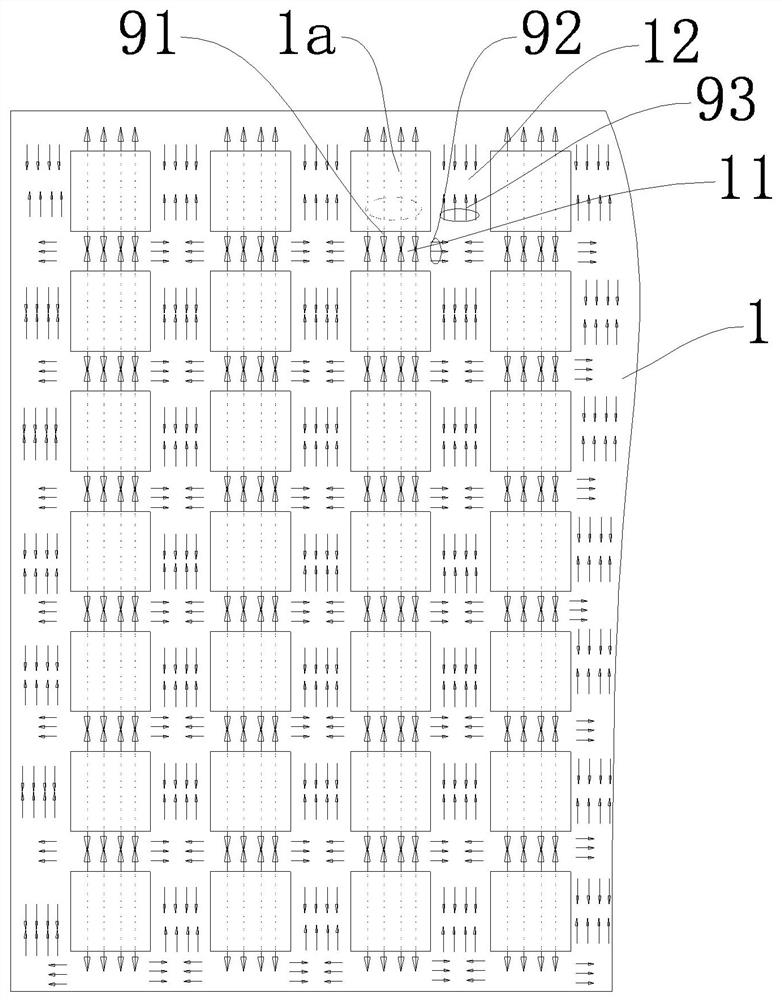

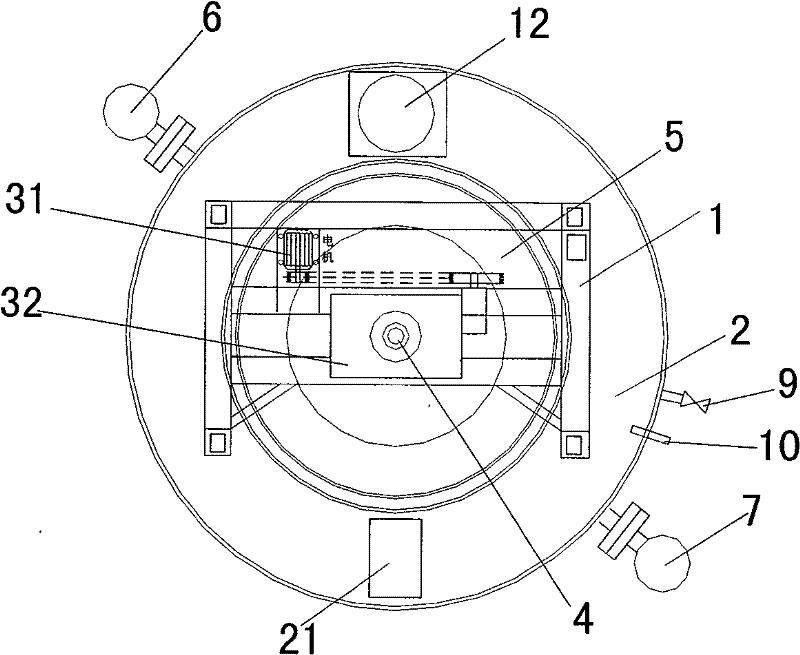

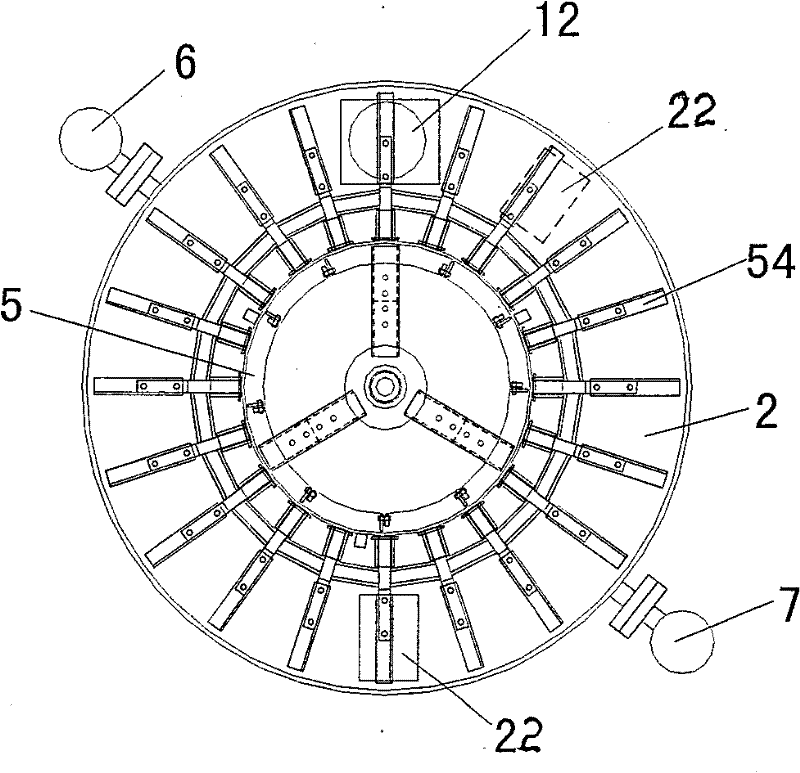

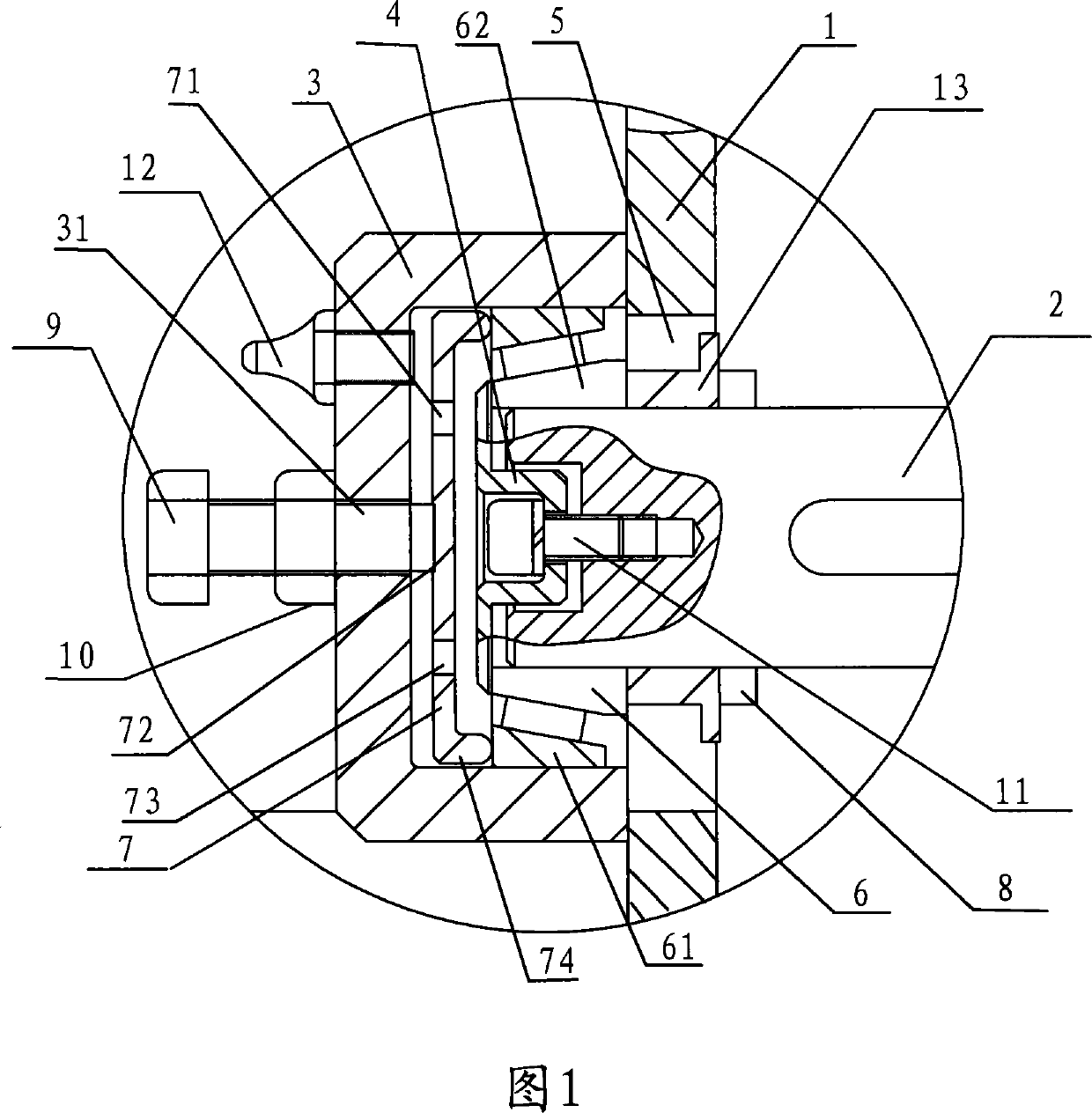

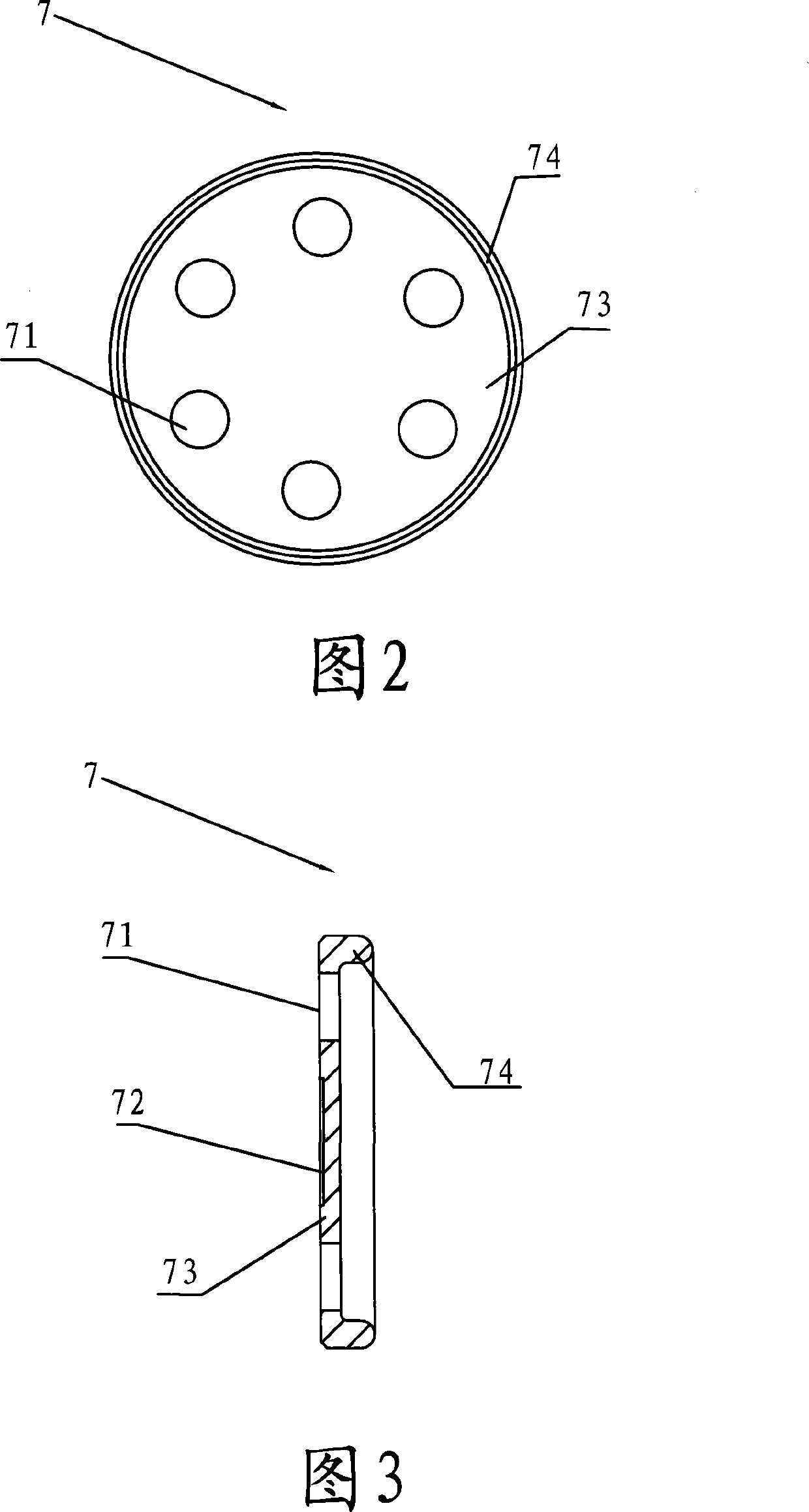

Dry-type multilayer disc cold residue machine

ActiveCN101865473BExercise balanceExtended service lifeLighting and heating apparatusEngineeringSafety valve

The invention relates to a dry-type multilayer disc cold residue machine which comprises a stand, multilayer circular grooves, a motor transmission mechanism, a vertical shaft, a plurality of turntable scraper mechanisms, a water intake main pipe, a water effluent main pipe and an exhausting and cooling mechanism. The motor transmission mechanism comprises a double-worm gearbox which is in directtransmission connection with the vertical shaft. The dry-type multilayer disc cold residue machine also comprises a safety valve and a temperature sensor which are respectively mounted on a circular groove on the upmost layer. The dry-type multilayer disc cold residue machine has more balance motion states, safer use, longer service life and convenient maintenance.

Owner:山东盛宝传热科技有限公司

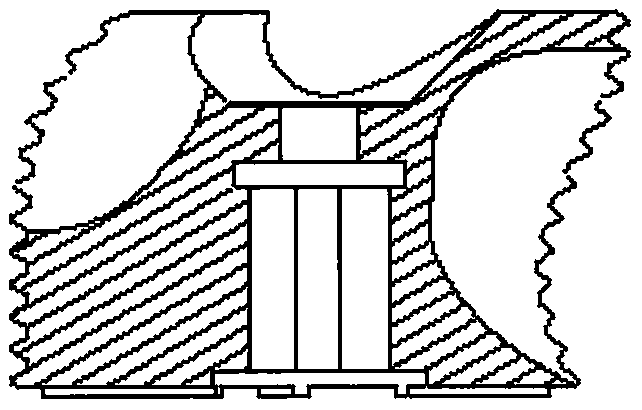

Cone roller bearing mounting structure

InactiveCN101187403BReduce gapAutomatic gap adjustmentBearing unit rigid supportInterference fitEngineering

The invention discloses an installation structure of a conical roller bearing, comprising a base body plate which is provided with a shaft hole, a shaft which is passed through the shaft hole, a bearing base which is fixedly arranged on the base body plate, and the conical roller bearing which is arranged in the bearing base. The inner ring of the conical roller bearing is fixedly installed on the shaft, and the small end face of the inner ring is rightly relative to the bearing base. The outer ring of the conical roller bearing and the bearing base are assembled in method of transition fit or interference fit, a top cover is arranged in the bearing base, a threaded hole is opened on the end face of the bearing base, a first screw is engaged with the inner portion of the threaded hole andis pressed on the top cover to tightly press the top cover with the large end face of the outer ring of the conical roller bearing, and the bearing clearance can be regulated through rotating the first screw, which can avoid the problem that the clearance between the inner ring and the outer ring of the bearing is over larger or smaller.

Owner:三六零安全科技股份有限公司 +2

Adjustable infrared temperature sensor structure based on Internet of Things

The invention discloses an adjustable infrared temperature sensor structure based on the Internet of Things. The device comprises a box body, a movable groove is formed in the box body, an infrared sensing mechanism is arranged in the movable groove, an axial sliding groove is formed in the side wall of the movable groove, a sliding block matched with the axial sliding groove is fixed to the infrared sensing mechanism, and the infrared sensing mechanism is in sliding connection with the movable groove through matching of the axial sliding groove and the sliding block. Conductive springs are arranged in the axial sliding groove and located on the two sides of the sliding block, one end of each conductive spring is fixed to the sliding block, the other end of each conductive spring is fixed to the end wall of the axial sliding groove, the infrared sensing mechanism comprises a distance measuring module, a temperature measuring module and an infrared emitting head, and the infrared emitting head is arranged on the side, close to an opening of the movable groove, of the infrared sensing mechanism. The distance measuring module and the temperature measuring module are electrically connected with the infrared emission head, and the distance measuring module is electrically connected with the conductive spring. The method has the beneficial effects that the effect of improving the measurement precision is achieved; and the authenticity and comprehensiveness of a temperature measurement result are improved.

Owner:浙江博控自动化技术有限公司

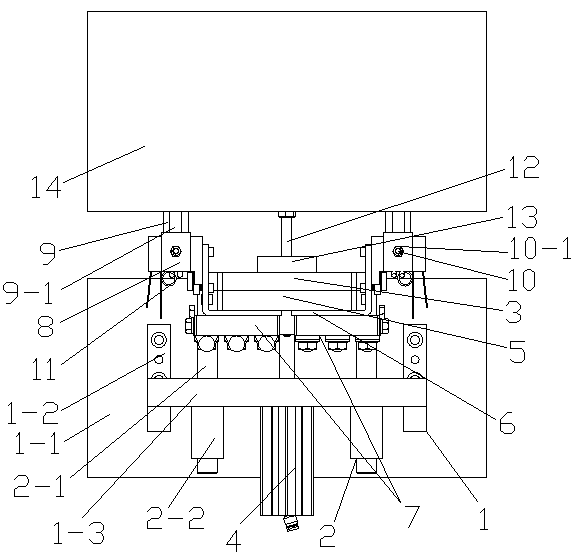

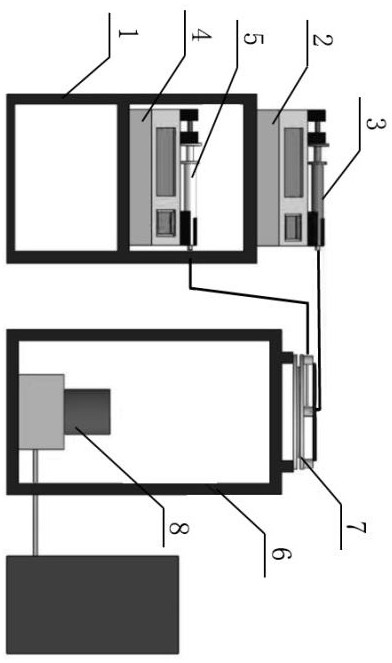

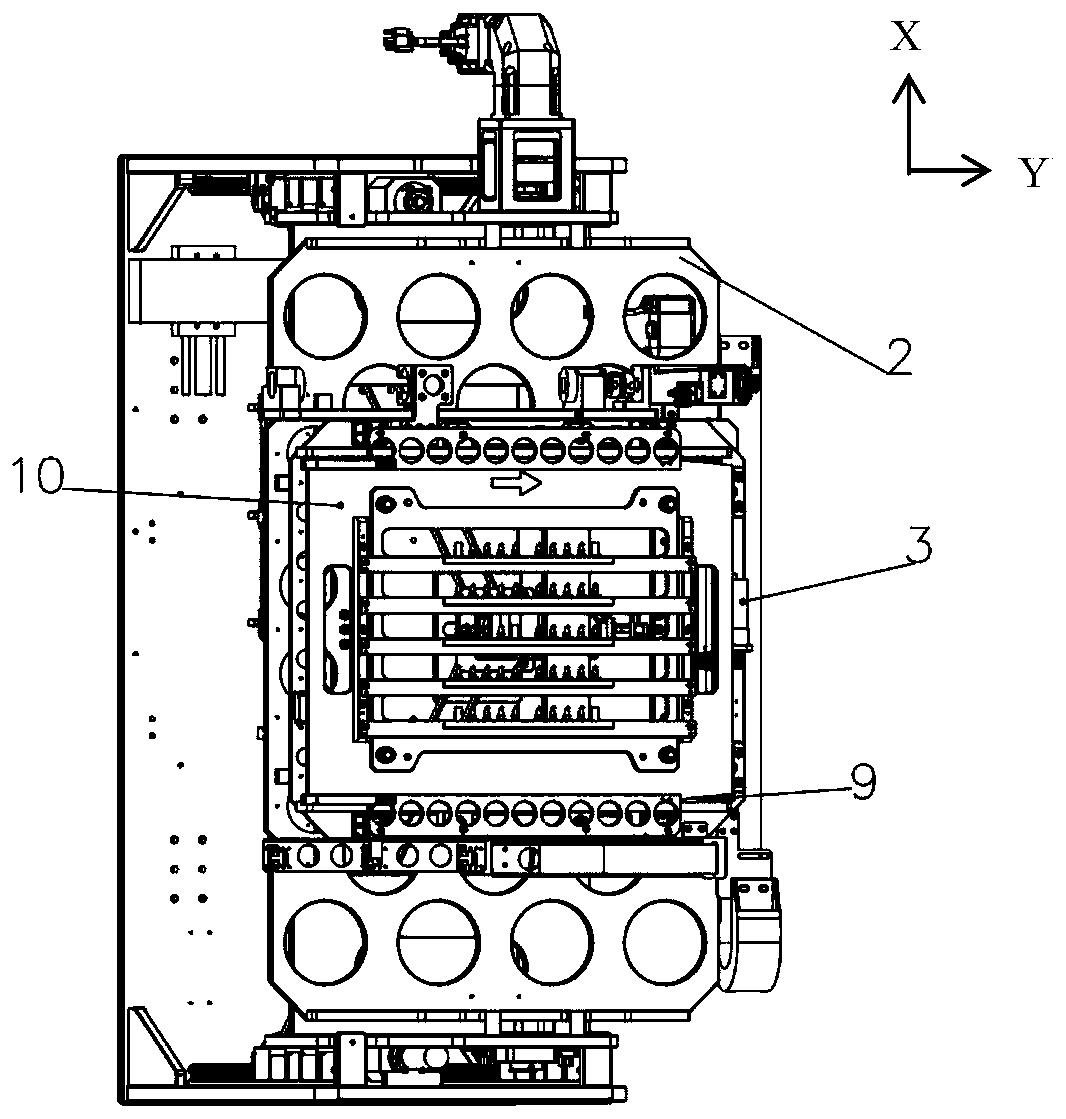

A kind of x-ray imaging detection system

ActiveCN110487224BImplementation locationImplementation angleUsing wave/particle radiation meansImage detectionX-ray

Owner:俐玛精密测量技术(苏州)有限公司

A motor based on rotor position recognition

ActiveCN109245441BHigh precisionAvoid overturningCouplings for rigid shaftsStructural associationCouplingEngineering

The invention discloses a motor based on rotor position identification. The coupling is axially and sliding sleeved on an output shaft of the motor. A first telescopic mechanism for driving the coupling to move axially is arranged in the output shaft of the motor. A rotating sleeve is arranged on the outer periphery of the coupling, a first contact is arranged on the first insulating elastic piece, a second contact is arranged on the second insulating elastic piece, the first contact is in selective contact with the second contact, and the first contact and the second contact are connected inseries in a triggering circuit; The stopper is fixedly arranged in the outer peripheral space of the motor output shaft; a second telescopic mechanism is arranged at that end of the output shaft of the motor; and a first end face gear is arranged on the telescopic end of the second telescopic mechanism; The output shaft of the motor is spaced apart from the load input shaft, the end of the load input shaft is provided with a second end face gear, and the first end face gear is selectively meshed and linked with the second end face gear; The invention solves the technical problem that the rotorposition is difficult to identify in the prior art through the improvement of the mechanical structure.

Owner:ZHEJIANG DONGFANG ELECTROMECHANICAL

Fluid device

InactiveCN113008892AImprove securityImprove reliabilityMaterial analysis by optical meansMedicineEngineering

A fluid device is disclosed. The fluid device comprises a parameter setting mechanism, a fluid generating mechanism and a data capturing mechanism, the parameter setting mechanism is used for effectively setting parameters used in the whole operation process, the fluid generating mechanism serves as an area where two kinds of solution operation occur, and the data capturing mechanism is used for capturing data of the two kinds of solution operation. The data capturing mechanism is used as necessary equipment for image acquisition and analysis, fluid which is immiscible with each other is immiscible with each other, a flow field can generate a multi-layer structure, and the interface length is greatly increased, so that the interaction between interfaces becomes more important, and the performance of the flow field is further influenced; the fluid device disclosed by the invention plays a role in effectively observing and analyzing immiscible fluids.

Owner:建湖瑞力达科技有限公司

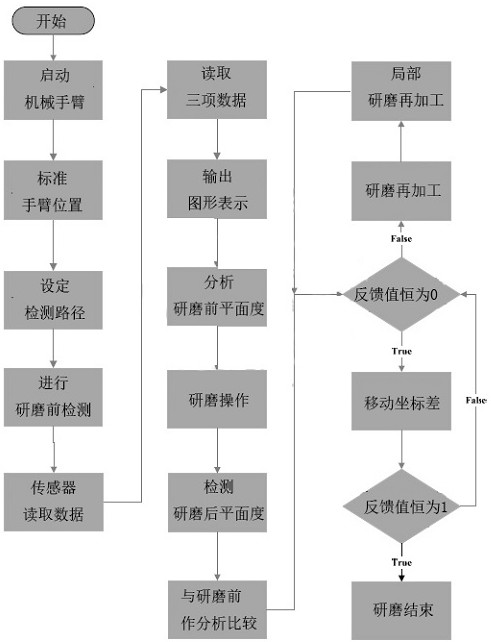

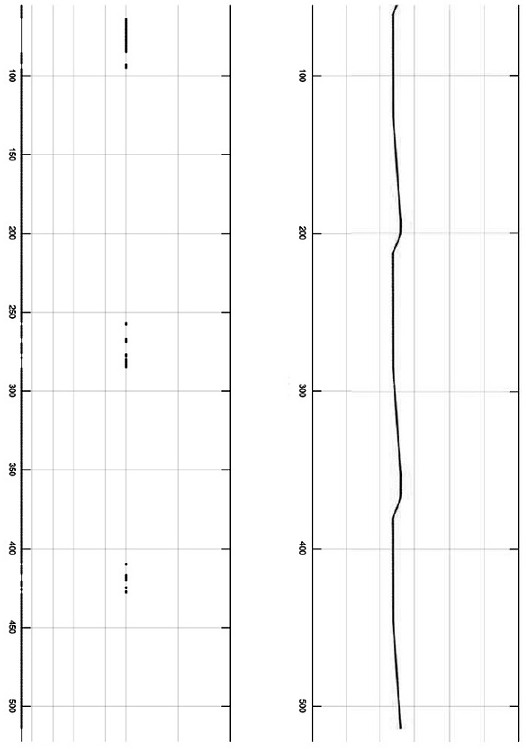

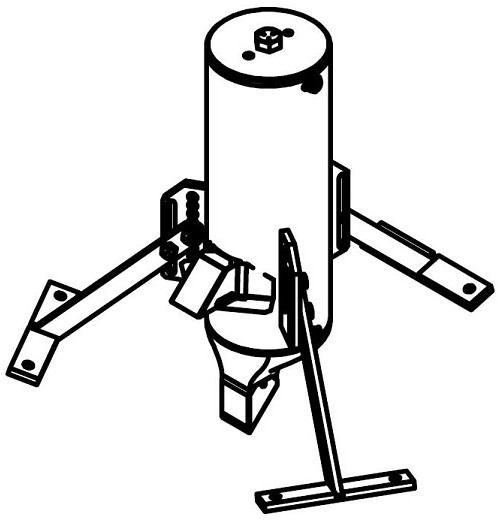

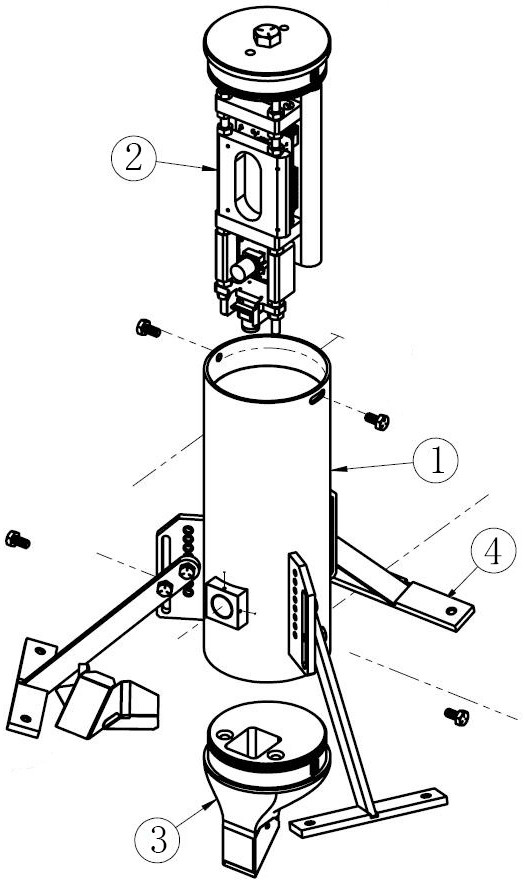

A kind of grinding system and grinding process

ActiveCN111070017BImprove securityImprove reliabilityEdge grinding machinesGrinding feed controlRobotic armMachining

The invention discloses a grinding system and a grinding process. A deflection angle type sensor is mounted on a mechanical arm; measurement before and after grinding is performed on a ground workpiece on a plane in space; the measurement results are analyzed; whether a convex point exists in a grinding path is determined; when it is determined that the convex point exists in the grinding path, local grinding is performed and then machining is performed; according to the grinding system, the planeness before and after grinding is analyzed; the mechanical arm can perform re-machining in real time, so that a remounting step is omitted; and the purpose of online detection automation is achieved.

Owner:江苏融威实业有限公司

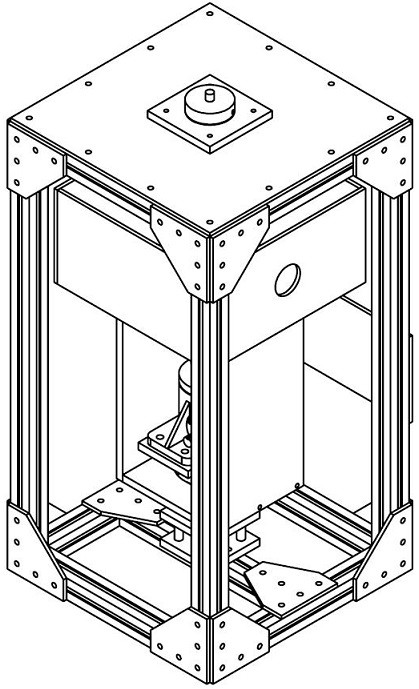

Underwater operation mechanism

InactiveCN112678133AImprove securityImprove reliabilityUnderwater equipmentMarine engineeringStructural engineering

The invention discloses an underwater operation mechanism, and the mechanism is mainly composed of four parts, and comprises a container carrier; a control assembly is assembled in the container carrier, a bottom assembly is assembled below the container carrier and a supporting assembly is assembled on the container carrier, and the whole equipment gets rid of the defect that traditional equipment is heavy. Large hoisting equipment does not need to be deployed, deployment can be conducted only through manpower or a small crane, and the whole mechanism is miniaturized, easy to operate and control, controllable in cost, suitable for general civil or single-person operation and particularly suitable for shallow water.

Owner:苏州慧导昱控自动化科技有限公司

A steel rolling production line and its snap-off shears

ActiveCN105689394BEffective time is shortRealize emergency stopMetal rolling arrangementsProduction lineTime to effect

The invention discloses cutoff scissors. A first scissor body and a second scissor body of the cutoff scissors are constantly attached through matched molded surfaces. A channel allowing a rolled piece to penetrate is formed by a groove between the first scissor body and the second scissor body. When a rolling line works normally, blades are in an open state. When steel rolling is abnormal, the blades can be closed only through rotation of a small angle. The entry-into-force time is short, the rolled piece can be cut off in time, the rolled piece is prevented from passing, and therefore emergency stop is achieved, and the function of protecting equipment is achieved. The invention further discloses a steel rolling production line with the cutoff scissors.

Owner:安徽诺泰工程技术有限公司

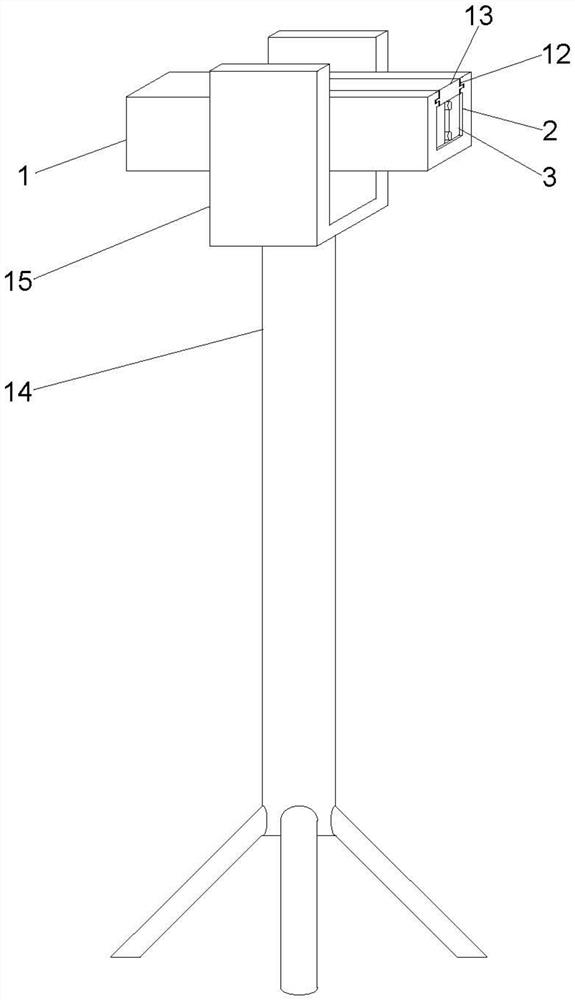

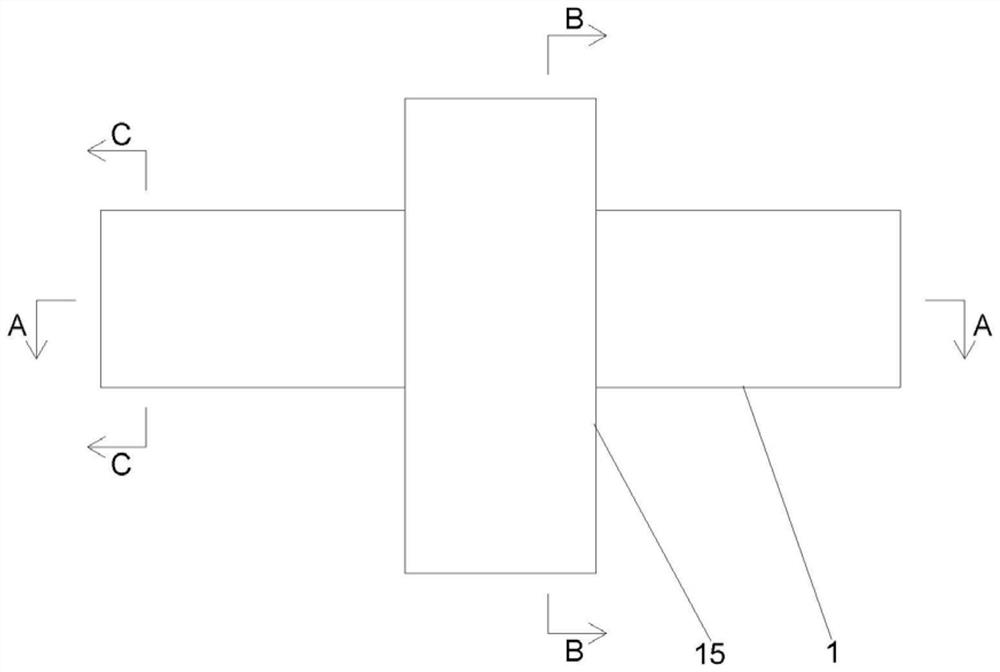

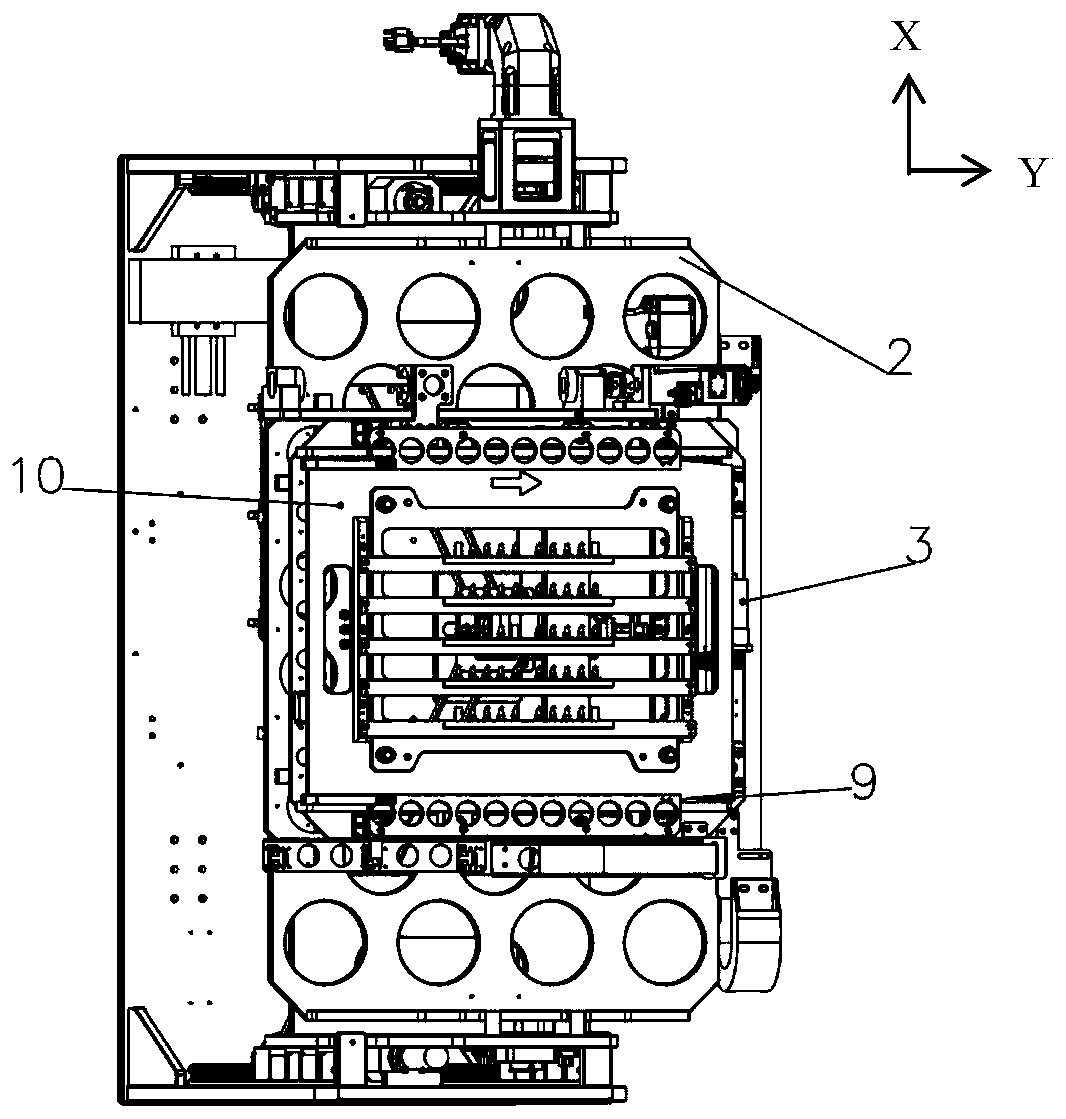

X-ray imaging detection system

ActiveCN110487224ADetection structureDetection sizeUsing wave/particle radiation meansSoft x rayCoupling

The invention, which belongs to the technical field of image detection systems, particularly relates to an X-ray imaging detection system comprising an X-ray emitting assembly and an X-ray receiving assembly. The X-ray emitting assembly includes an X-ray source. The X-ray receiving assembly includes an X-ray receiver. An X ray emitted by the X-ray source is irradiated vertically and downwardly andis received by the X-ray receiver. The system also includes a rotating mechanism arranged between theX-ray emitting assembly and the X-ray receiving assembly. The rotating mechanismincludes a first substrate, a first lead screw, a second lead screw, a first motor, a second motor, a third motor, and a first coupler; the first substrate is provided with a rotating shaft; and the first coupler is connected to the rotating shaft. With the X-ray imaging detection system, the detection of the internal structure and size of the product can be realized; and the multi-angle detection of the workpiececan be realized by detecting the position and anglechanges in the process.

Owner:俐玛精密测量技术(苏州)有限公司

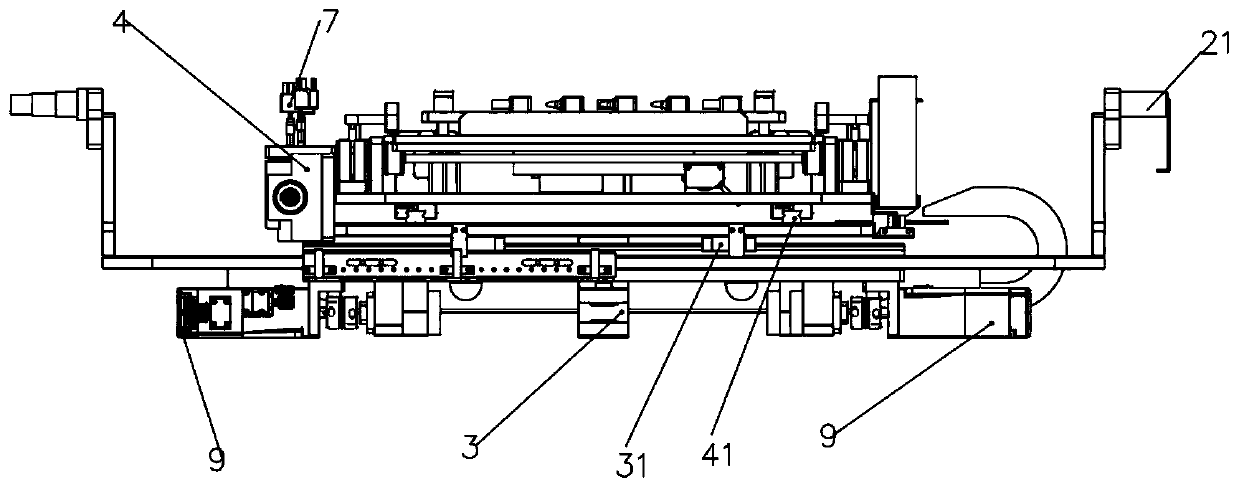

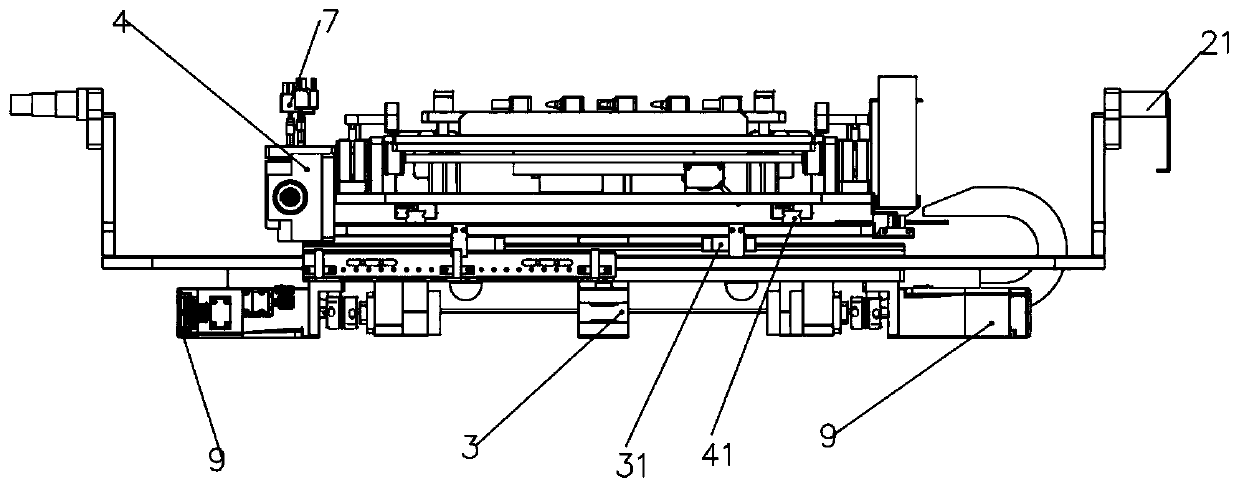

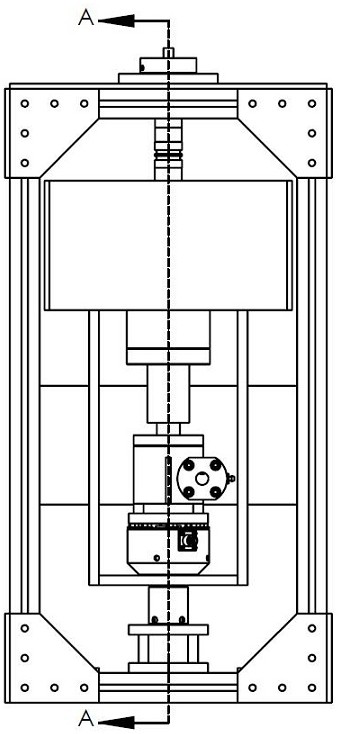

A test mold mechanism for rolling bearings and its application method

ActiveCN112345246BImprove securityImprove reliabilityMachine bearings testingLinear motionRolling-element bearing

A test mold mechanism for skewed rolling bearings is disclosed. The test mold mechanism includes a shell assembly, a frame assembly is arranged inside the shell assembly, the frame assembly includes an upper plate and a lower plate, and an action assembly is assembled on the frame assembly. The component integrates the main test area, the action component is assembled on the load sleeve, the load sleeve is assembled with the linear drive device, the weight sensor is installed under the linear drive device, and the torque sensor is installed under the weight sensor, and the linear drive device produces linear motion The action or tendency of the whole frame assembly produces an action or tendency along a straight line, so that the upper or lower plate of the frame assembly generates an impact load force, and then the weight sensor is measured, and the rotation or rotation tendency of the frame assembly is also The torque sensor is used for measurement, and the test mold mechanism has the characteristics of efficient, reliable, stable and precise operation.

Owner:佛山市喜舍机械设备有限公司

A high-pressure remote conveying device for magnetic material slurry and its application method

ActiveCN105084003BPrevent leakageCreate pollutionMixersBulk conveyorsHydraulic cylinderRemote control

The invention discloses a high-pressure remote conveying device for magnetic material slurry and an application method thereof, belonging to the field of magnetic material slurry conveying equipment. It includes a stirring part, an electrical system, a hydraulic system, and a double-screw feeding system, an electrical remote control system, and a press; the stirring part includes a coarse mixing part and a fine mixing part, and the coarse mixing part transmits the slurry to the double-screw feeding system The double-screw feeding system transmits the slurry to the fine mixing part, and the fine mixing part delivers the slurry to the press, which is connected to the touch-screen electrical cabinet; the touch-screen electrical cabinet controls the electrical control of the press to perform operations and press the slurry forming. The electrical remote control system includes a remote control sending system and a remote receiving system. The remote sending system sends signals to the remote receiving system. The remote receiving system is connected to the electrical system. The electrical system is connected to the hydraulic system. The hydraulic cylinder of the hydraulic system is set in the double-screw feeding system. It can transport slurry remotely, and it is sealed and pollution-free.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com