X-ray imaging detection system

An imaging detection and X-ray technology, applied in the direction of measuring devices, using wave/particle radiation, instruments, etc., to achieve the effect of multi-angle detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

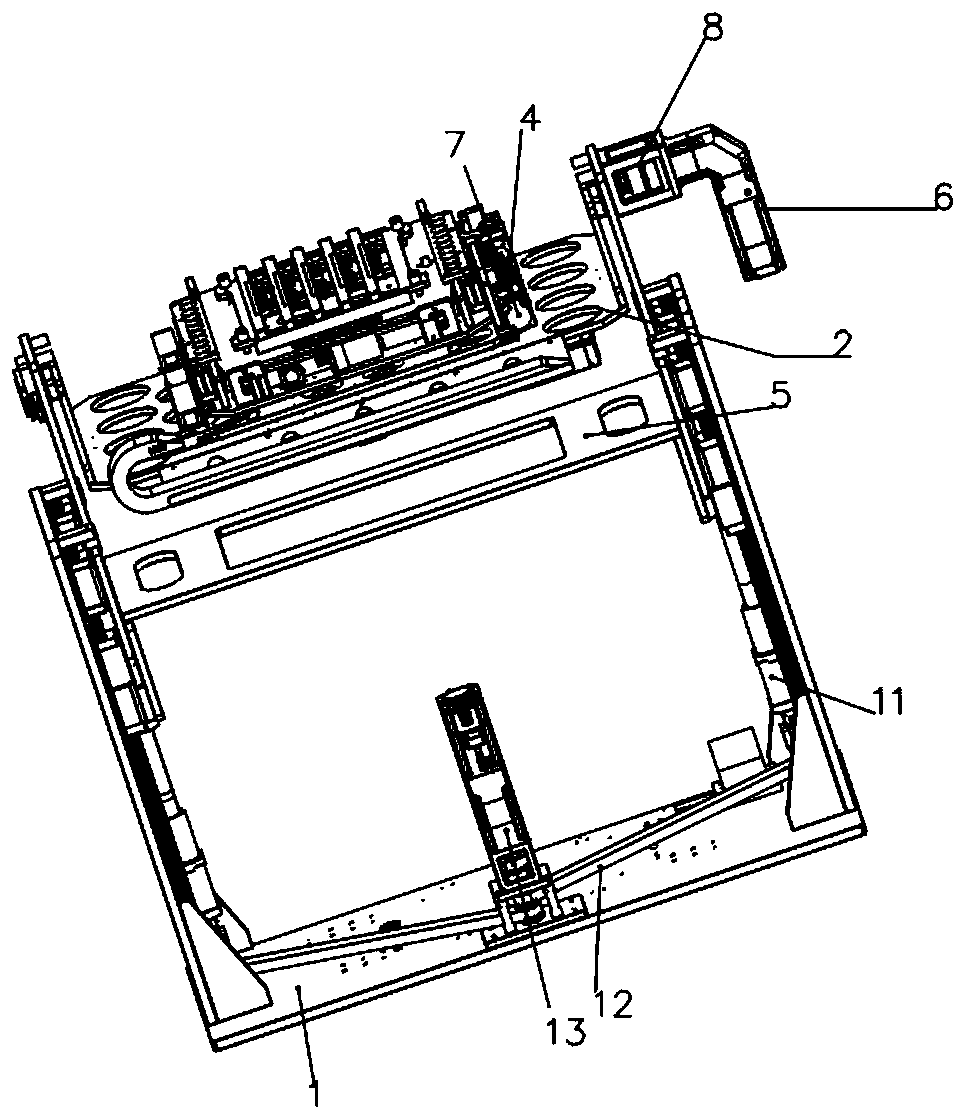

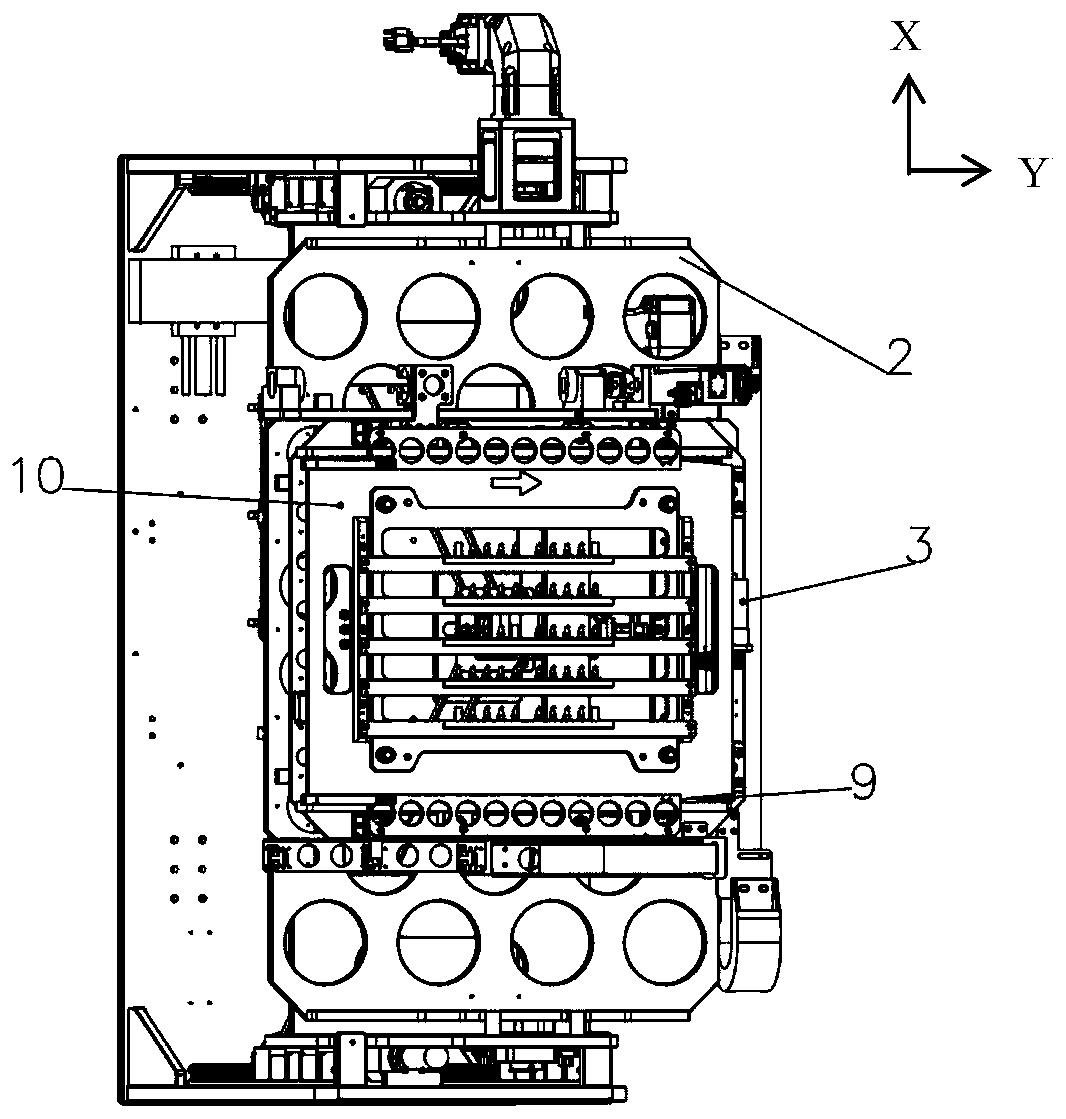

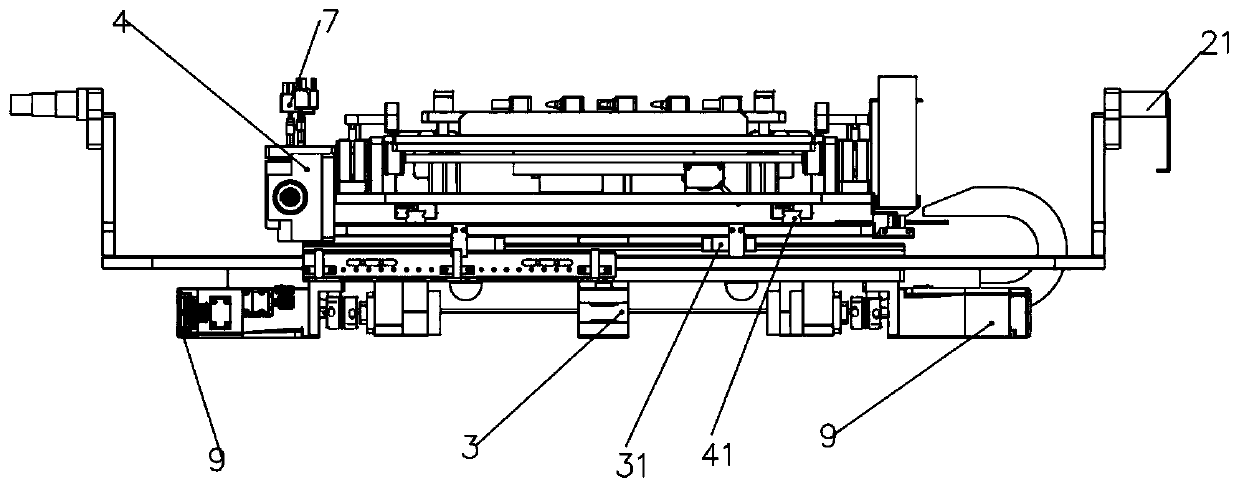

[0042] Such as Figure 1-5 As shown, the present invention provides an X-ray imaging detection system, which includes an X-ray emitting assembly and an X-ray receiving assembly 16, the X-ray emitting assembly includes an X-ray source, and the X-ray receiving assembly 16 includes an X-ray receiver 164, the X-rays emitted by the X-ray source are irradiated vertically downward and received by the X-ray receiver 164, and also include a rotating mechanism arranged between the X-ray emitting assembly and the X-ray receiving assembly to drive the workpiece to rotate , the rotating mechanism is fixed above the U-shaped fixed bracket 1,

[0043] The rotating mechanism includes a first base plate 2, a first screw mandrel 3, a second screw mandrel 4, a first motor 9, a second motor 7, a third motor 6 and a first coupling 8, and the first base plate is vertical a connection between the x-ray source and the x-ray receiver;

[0044]The first screw mandrel 3 and the second screw mandrel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com