A film automatic feeding device

A technology of automatic feeding and thin film materials, which is applied in thin material processing, transportation and packaging, and object separation, etc., to achieve the effects of saving production costs, professional image processing and high cost performance, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

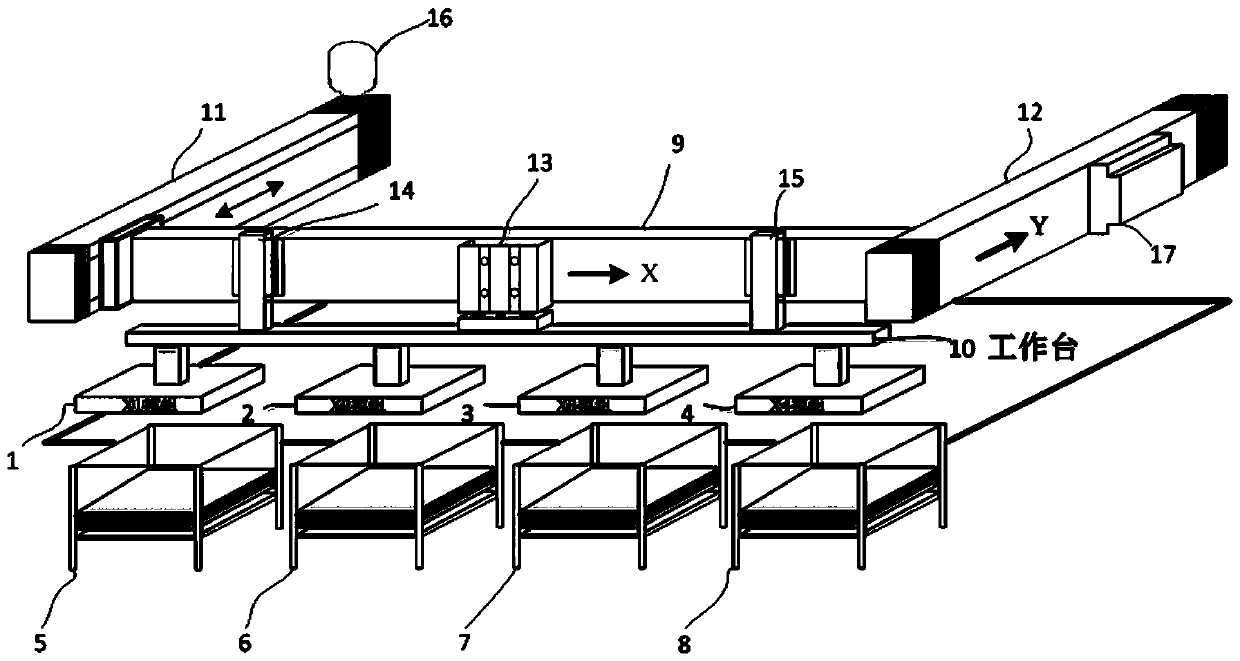

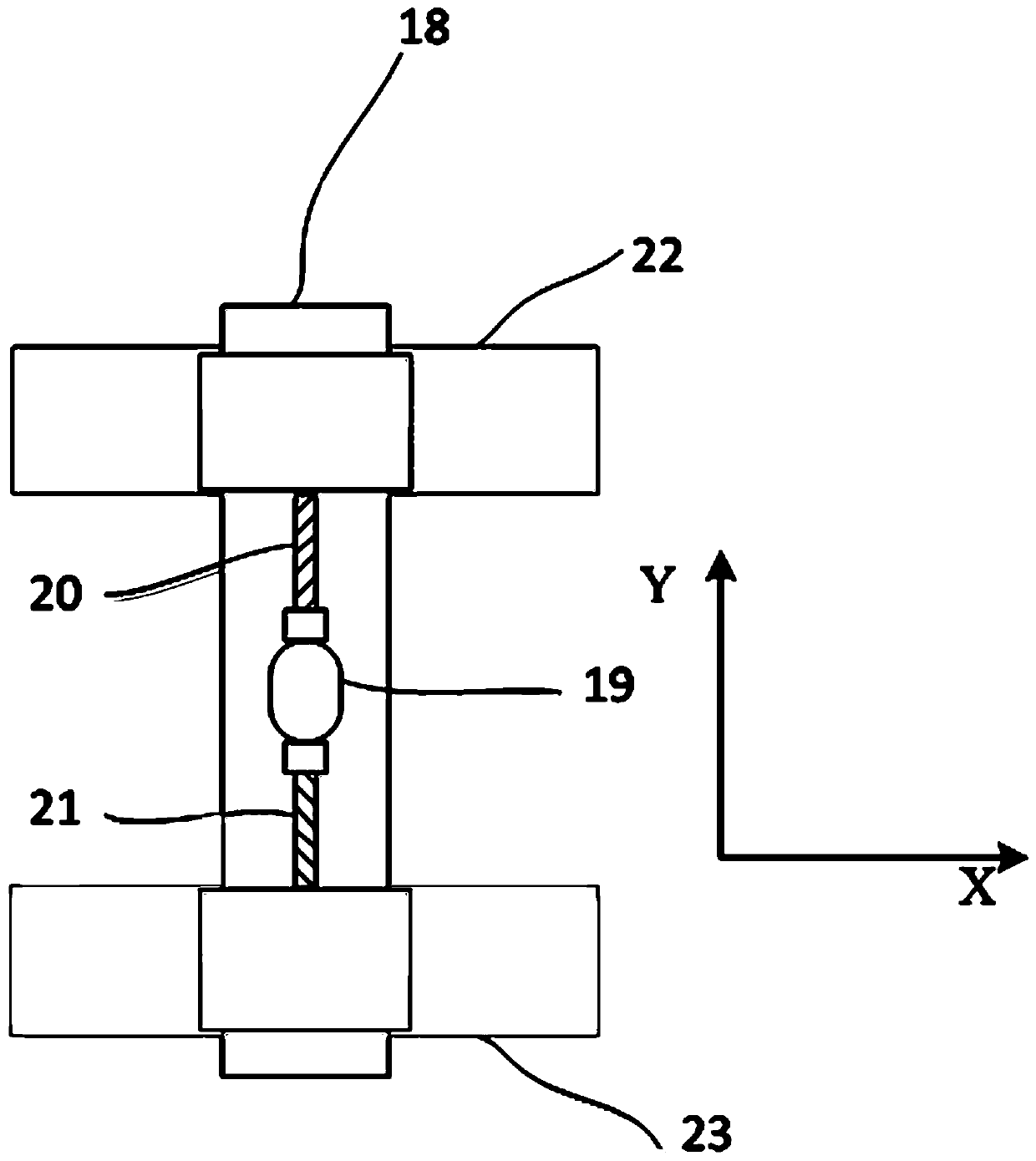

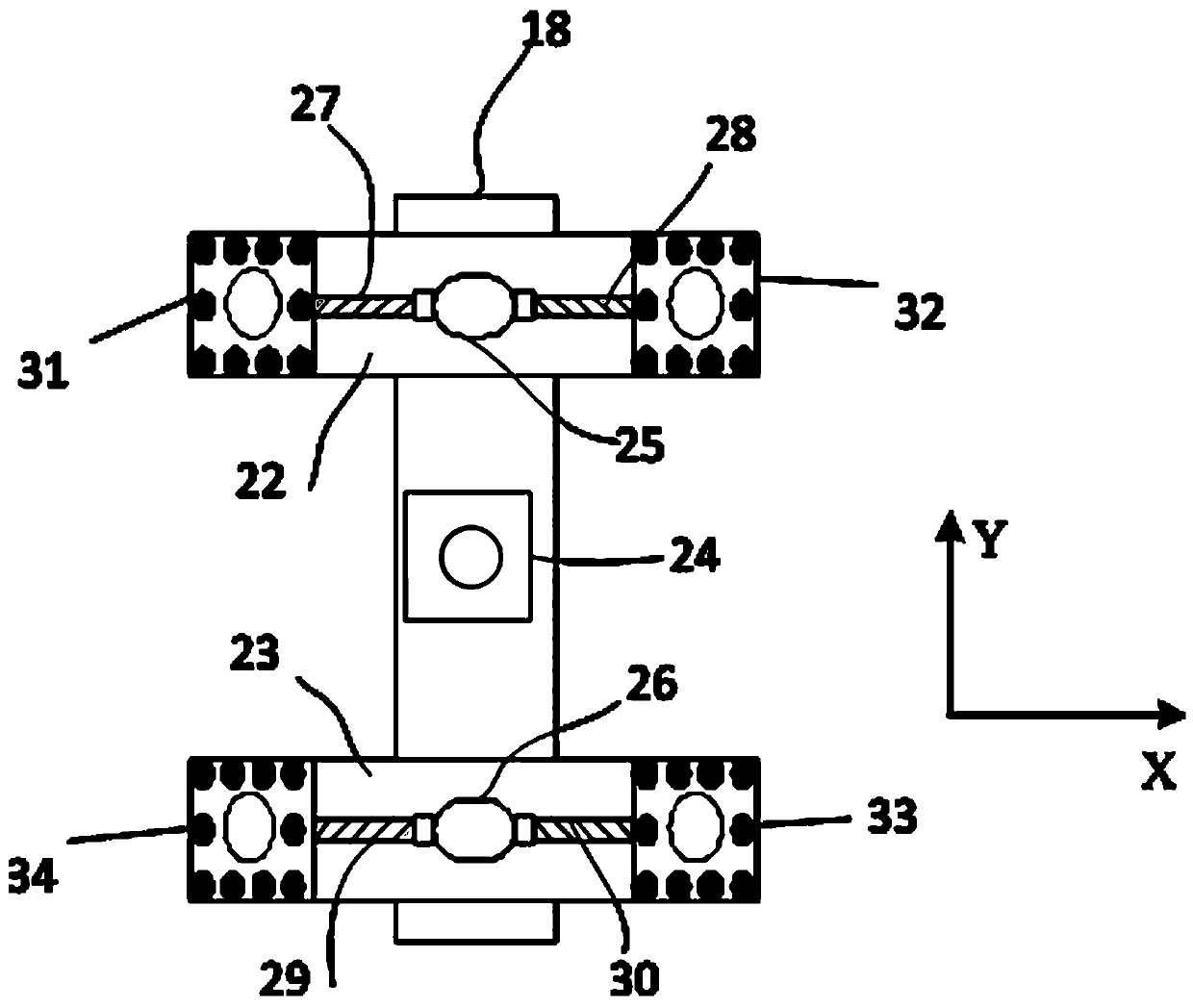

[0048] Refer to attached Figure 1-6, an automatic film feeding device includes multiple sets of feeding suction plate modules, a detection camera 24, a feeding box, a cylinder 13, a slide table and a controller 17. Wherein, each set of feeding and sucking plate modules includes a Y-direction guide rail, and a double-protruded Y-direction stepping motor is fixed in the middle of the Y-direction guide rail, and the two ends of the Y-direction stepping motor are connected to the Two screw rods with opposite thread directions are connected at one end, and the other ends of the two screw rods are connected with the X-direction guide rails, and the movement of the two X-direction guide rails in the Y direction can be realized by the rotation of the stepping motor in the Y direction; the X direction One X-direction stepping motor protruding from both ends is fixed in the middle of the guide rail. The two ends of the X-direction stepping motor are connected to one end of two screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com