Jet-propelled textile machine automatic feeding system

An air-jet textile machine, automatic feeding technology, applied in textile, textile and auxiliary equipment for papermaking and weaving, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

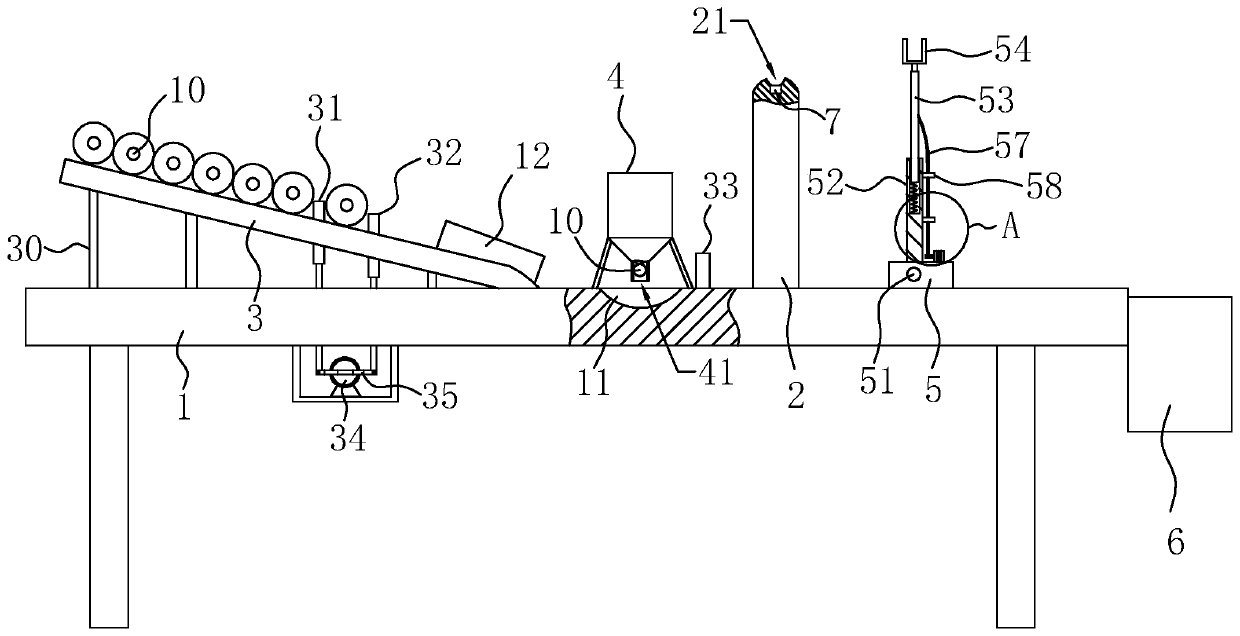

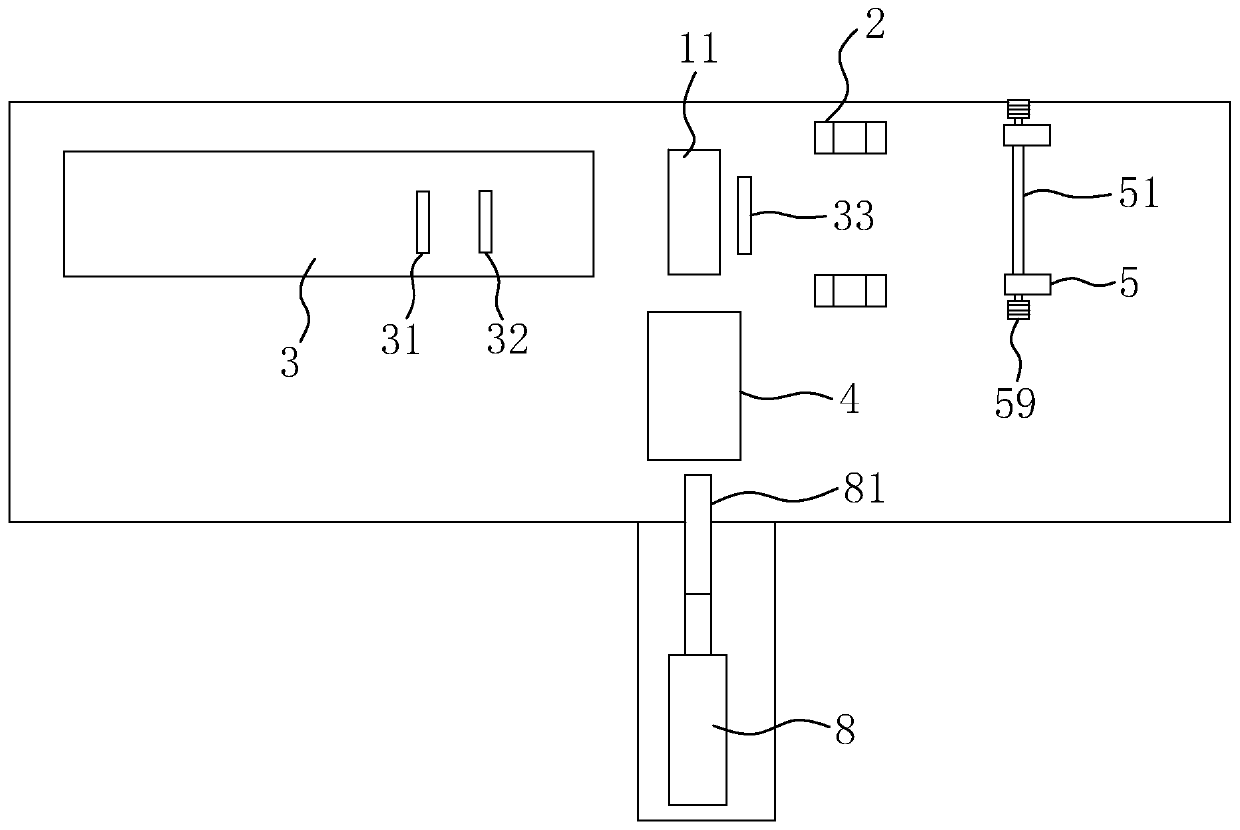

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] Present embodiment: a kind of air-jet type textile machine automatic feeding system, such as figure 1 and figure 2 As shown, a workbench 1 is arranged beside the air-jet textile machine, and a symmetrical vertical board 2 is installed on the bearing surface of the workbench 1, and installation grooves 21 are provided on the top of the vertical board 2, and on the workbench 1 Also installed on the bearing surface of the slant plate 3 that is 5-10 °, the slant plate 3 is fixed on the bearing surface of the workbench 1 by the support rod 30, and the support rod 30 is screwed on the workbench 1.

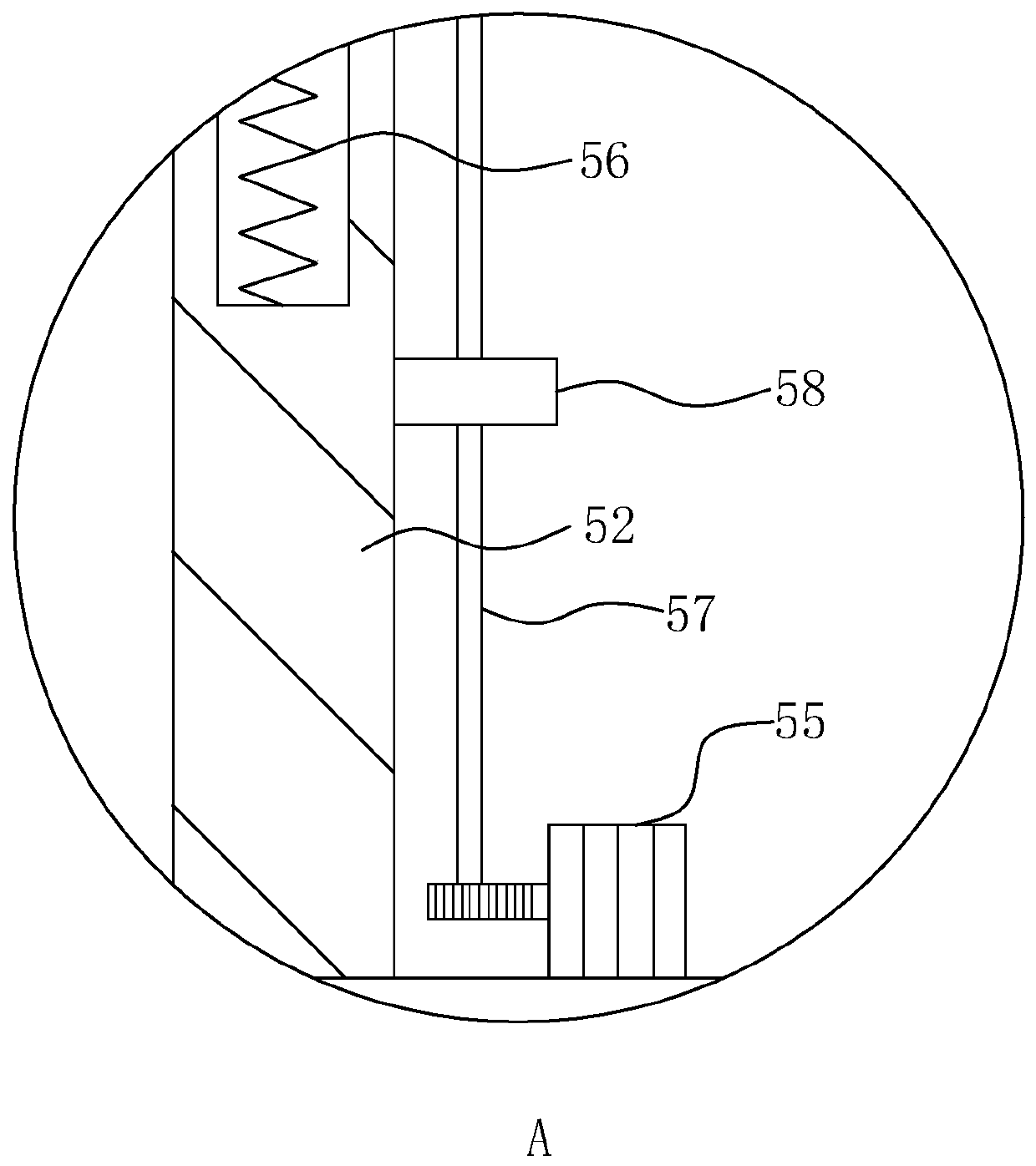

[0035] A limit device is provided on the workbench 1, which can limit the rolling of the bobbin, so that the bobbin rolls to the predetermined position of the workbench 1 one by one. In this embodiment, the limit device includes: vertically movable interspersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com