3D (Three-Dimensional) printing machine

A technology of 3D printers and printing devices, applied in coating devices, additive processing, etc., can solve problems such as reduced production efficiency and variable production conditions, and achieve the effects of improving production efficiency, shortening time, and accelerating production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

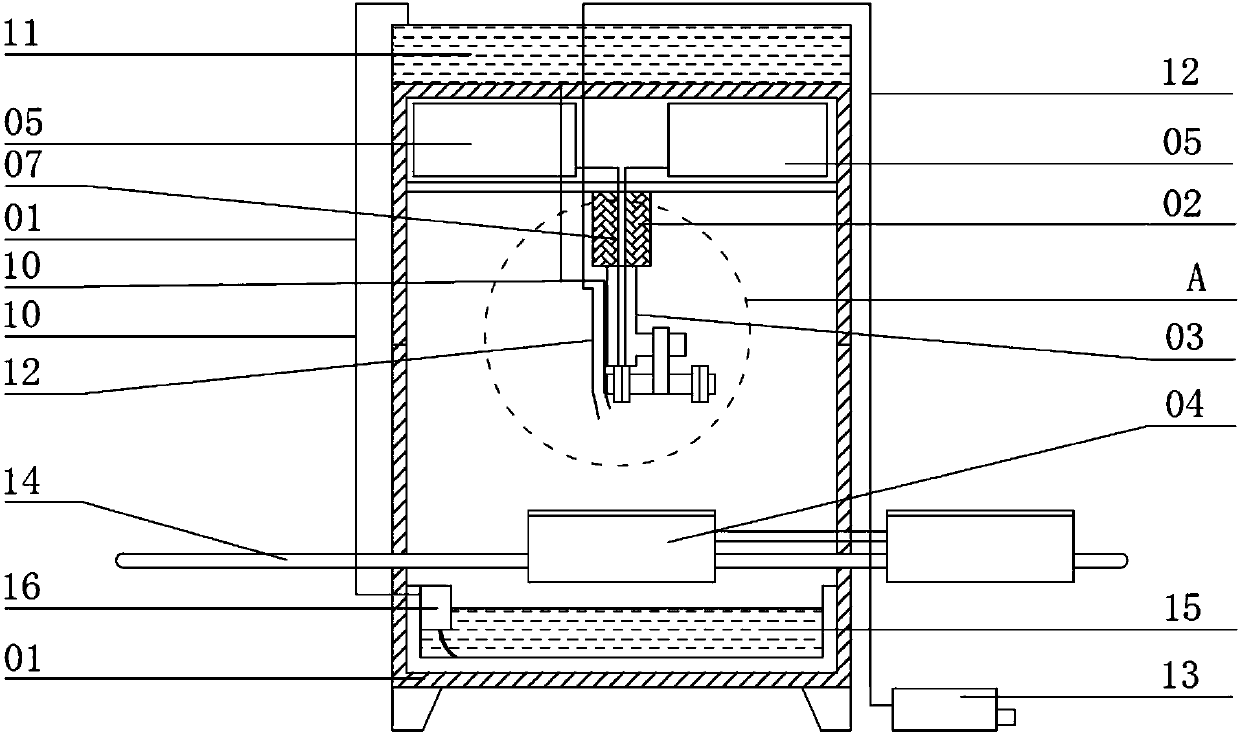

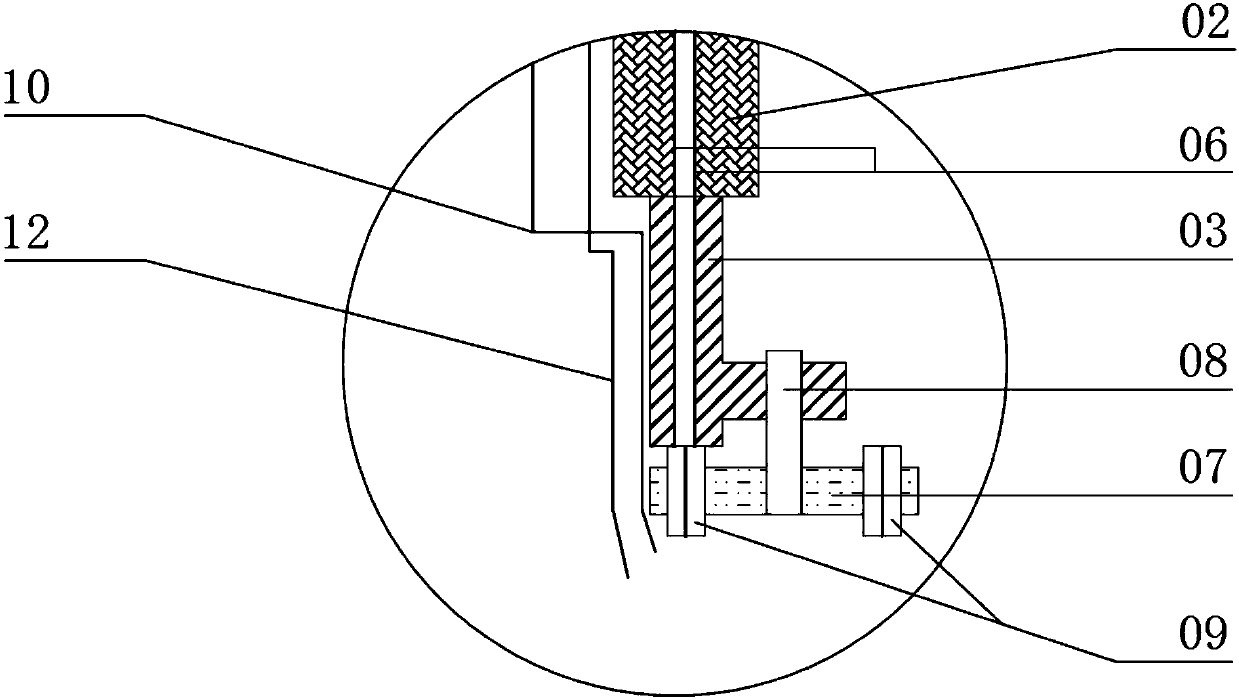

[0018] combine Figure 1-2 The specific structure of a 3D printer of the present invention is described in detail. The 3D printer includes a frame 01, a moving module 02, a printing device 03, and a carrying device 04. The printing device 03 is connected to the frame 01 through the moving module 02. The motion module 02 can control the movement of the printing device 03 according to the input motion data, the printing device 03 is arranged on the upper part of the frame 01, the carrying device 04 is arranged on the lower part of the frame 01, and the printing device 03 Relative to the carrying device 04 in the vertical direction, more than two groups of material boxes 05 are installed on the printing device 03, and the material boxes 05 are connected to the printing device 03 through a material transmission pipeline 06. In the material box 05 Different types of materials for metal materials and plastic materials are respectively installed. The printing device 03 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com