A hydrodynamic pressure device for deep sea operation equipment

A technology of pressure application device and operation equipment, applied in the directions of underwater operation equipment, sampling device, transportation and packaging, etc., can solve the problems of lifting, dumping, equipment instability, etc., to prevent lifting or dumping, and increase the working depth. , the effect of protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

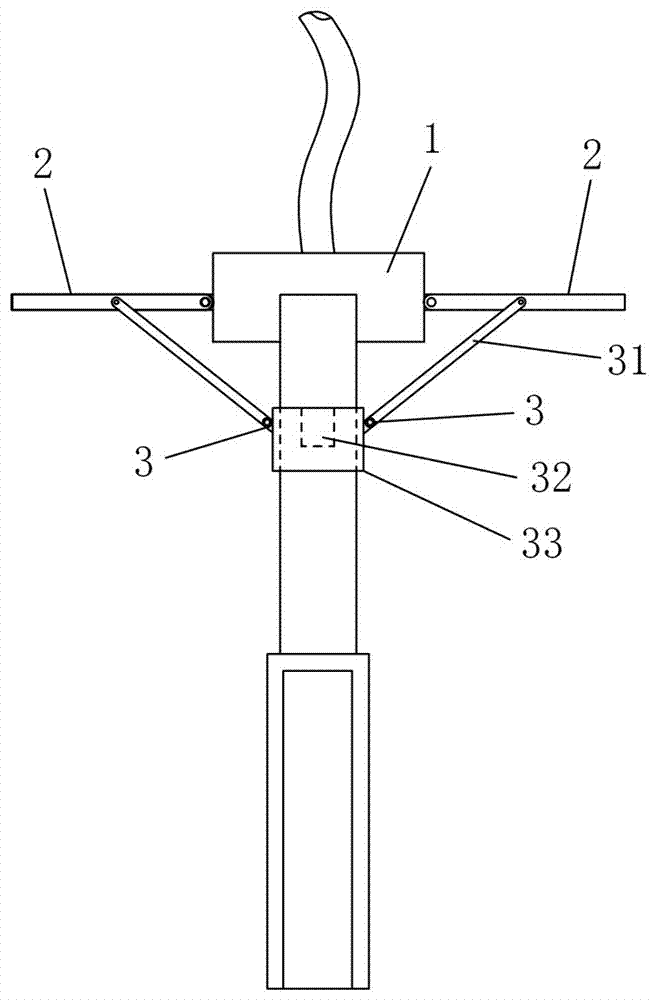

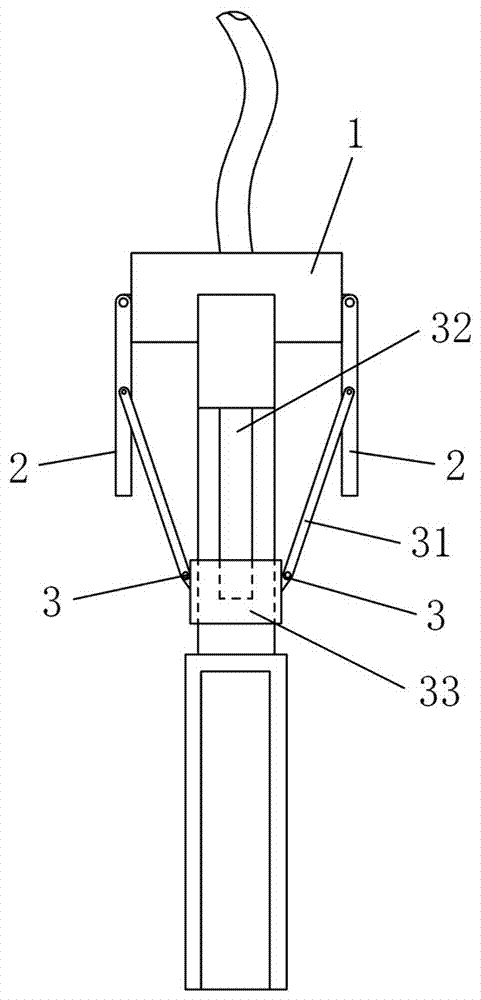

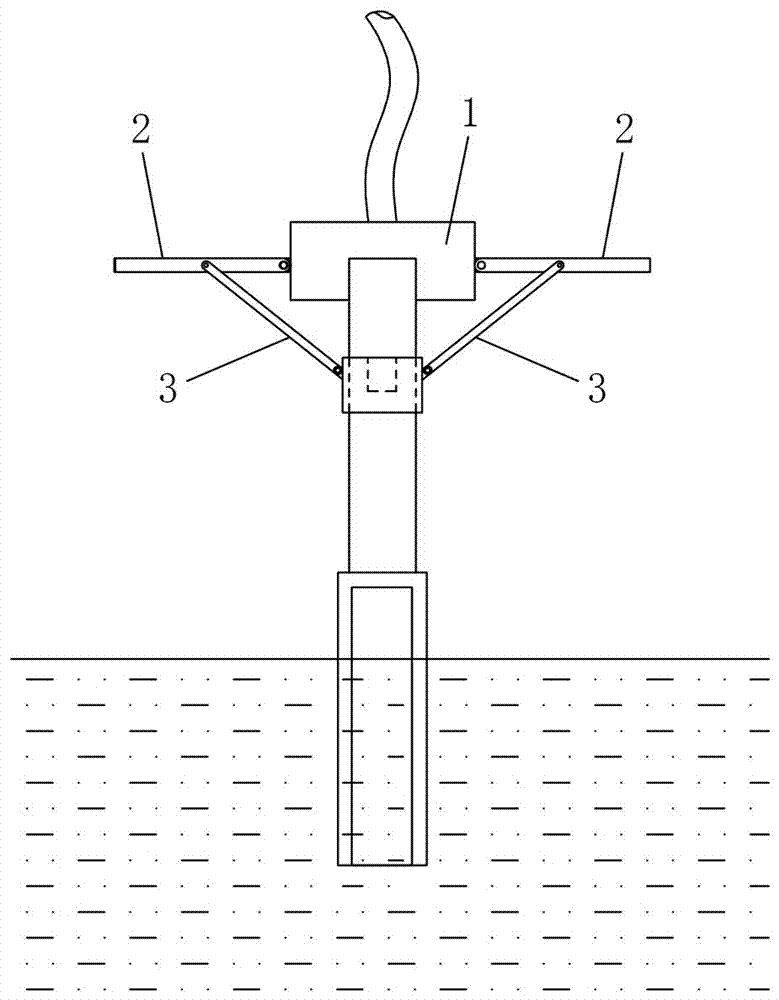

[0025] like Figure 1 to Figure 3 As shown, the hydrodynamic pressure applying device of the deep-sea operation equipment of the present invention includes a water resistance pressure applying mechanism installed on the equipment 1, and the water resistance pressure applying mechanism is provided with a water resistance for increasing the water resistance of the equipment 1 in the direction of gravity. The action surface, the water resistance action surface is distributed symmetrically with respect to the center of gravity of the equipment 1, and ensures the balance of the equipment 1 when subjected to water resistance in the vertical direction. When equipment 1 is in operation, it relies on its own gravity to provide positive pressure (i.e. operating propulsion). Resistance, the water resistance is superimposed on the positive pressure of the equipment 1, which is equivalent to increasing the positive pressure of the equipment 1, which can prevent the equipment 1 from being l...

Embodiment 2

[0032] like Figure 4 and Figure 5 As shown, this embodiment is basically the same as Embodiment 1. The difference is that the wing plate 2 of this embodiment is a folding plate, and the folding plate is composed of more than two flat plates 21 hinged in turn. Folding or unfolding the conversion driving mechanism in a horizontal shape, through the function of the conversion driving mechanism, the folding plate can be folded to reduce the area of the water resistance acting surface, or the folding plate can be unfolded into a horizontal shape to maximize the area of the water resistance acting surface change. The above conversion mechanism can adopt various driving components in the prior art, for example, a horizontally installed telescopic cylinder and the like.

Embodiment 3

[0034] A hydrodynamic pressure application method for deep sea operation equipment, comprising the following steps:

[0035] (1) A water resistance pressure mechanism is installed on the equipment 1. The water resistance pressure mechanism is provided with a water resistance surface for increasing the water resistance of the equipment 1 in the vertical direction, and the area of the water resistance surface is Adjustable; the water resistance pressure applying mechanism specifically adopts the water resistance pressure applying mechanism described in the above-mentioned embodiment 1;

[0036] (2) Adjust the water resistance surface of the water resistance pressure-applying mechanism to the minimum area, and use conventional methods to place the equipment 1 at the predetermined operating position in the deep sea; during this process, the water resistance of the sampling equipment in the water will not be increased, so that no It will affect the lowering speed and downward att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com