Novel submersible water impeller

A submersible thruster, a new type of technology, applied in water aeration, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance, sinking at the bottom, and high failure rate, so as to reduce the failure rate and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

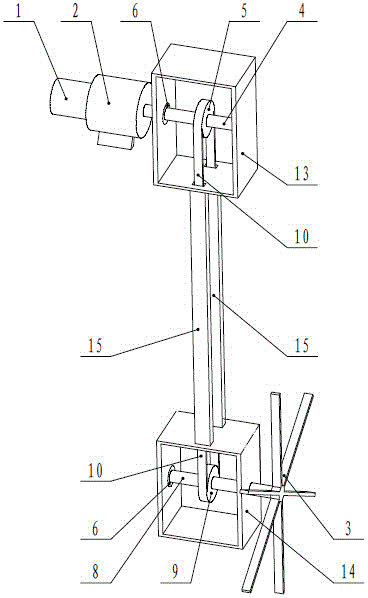

[0025] figure 1 It is a schematic diagram of its structure, in order to conveniently show the internal structure of the upper box and the lower box, the front panels of the upper box and the lower box are removed in the figure, which does not mean that they are non-hermetic structures. like figure 1 As shown, a new type of submersible flow propeller includes a motor 1, a reducer 2 and a propeller blade 3. The motor 1 and the reducer 2 are both arranged on the water surface of the sewage pool; the motor 1 is connected to the reducer 2, and the reducer 2 The first horizontal shaft 4 is connected, a first sprocket 5 is fixedly arranged on the first horizontal shaft 4, a second horizontal shaft 8 is arranged below the first horizontal shaft 4, and a second sprocket 9 is fixedly arranged on the second horizontal shaft 8, The first sprocket 5 and the second sprocket 9 are connected by the chain 10; the first sprocket 5, the second sprocket 9 and the chain 10 are all isolated from t...

Embodiment 2

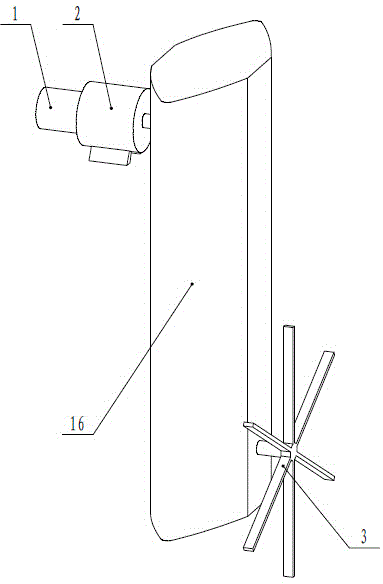

[0031] like figure 2 As shown, the difference between the second embodiment and the first embodiment is:

[0032] The sealing device is an integral case 16 that seals the first sprocket 5, the second sprocket 9 and the chain 10; the first horizontal shaft 4 and the second horizontal shaft 8 are connected to the integral case through the bearing 6. Body 16 is connected.

[0033] The front and rear sides of the integral box body 16 are arranged in a streamline shape that bulges outward.

[0034] The front and rear sides of the integral box body 16 are set to bulge outwards, so that the water resistance in the left and right directions is increased, so that it is easier to overcome the reaction force caused by the propelling blade 3 when it works, Enhance the stability of this new submersible flowmaker in slops.

Embodiment 3

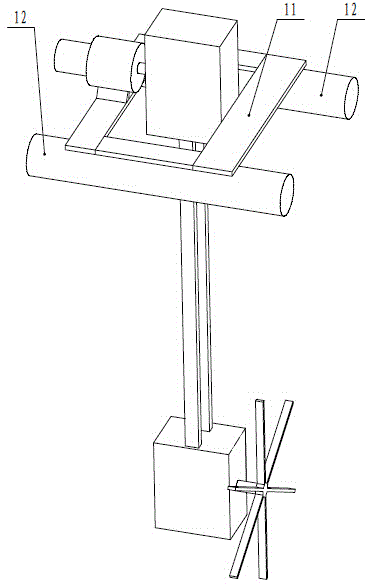

[0036] like image 3 As shown, the difference between the third embodiment and the first embodiment is:

[0037] The novel submersible flow propeller is fixedly connected to a frame 11 through the feet of the reducer 2 and the upper box 13, and the frame 11 is fixedly arranged on two buoys 12, and the buoys 12 float on the water surface of the sewage pool.

[0038] Setting the new type of submersible flow propeller on the two buoys 12 not only facilitates flexibly setting its position in the sewage pool according to the actual situation, but also facilitates automatic adjustment of its working state during operation to ensure its smooth operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com