A reciprocating filter mud scraping equipment

A reciprocating and equipment technology, applied in separation methods, sedimentation separation, sedimentation tanks, etc., can solve the problems of large water content of sludge and poor fluidity of sludge, and achieve the effect of increasing water resistance and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

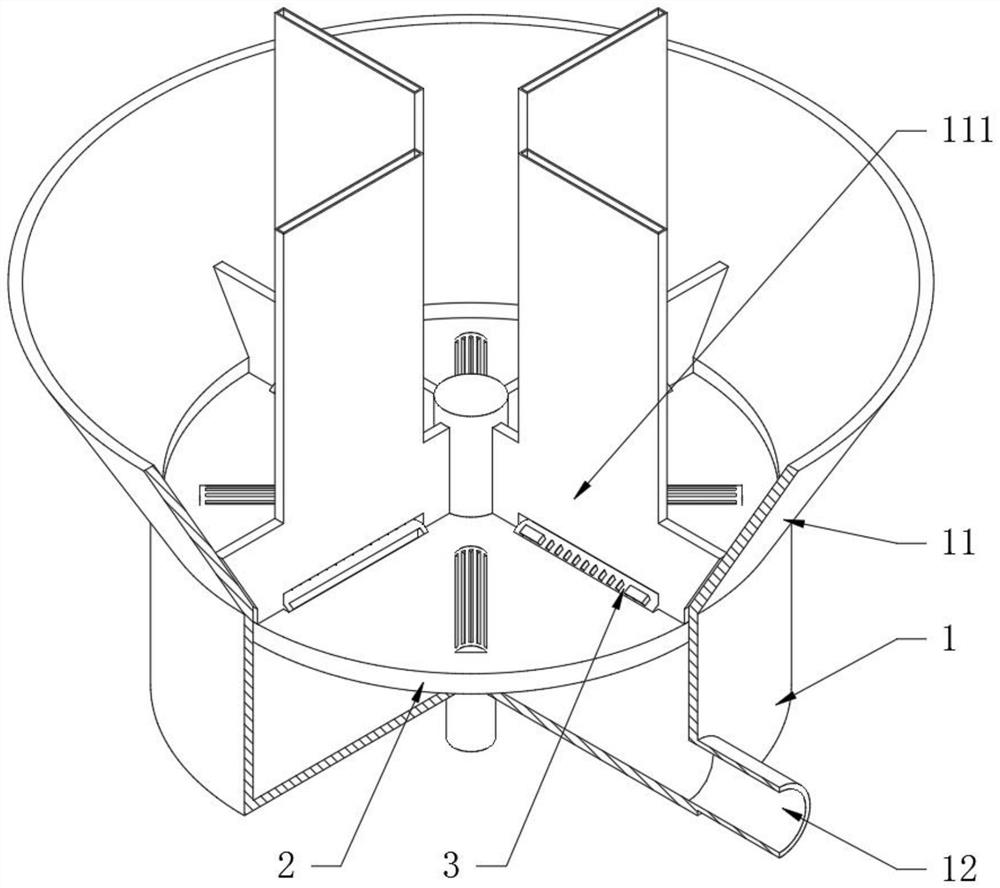

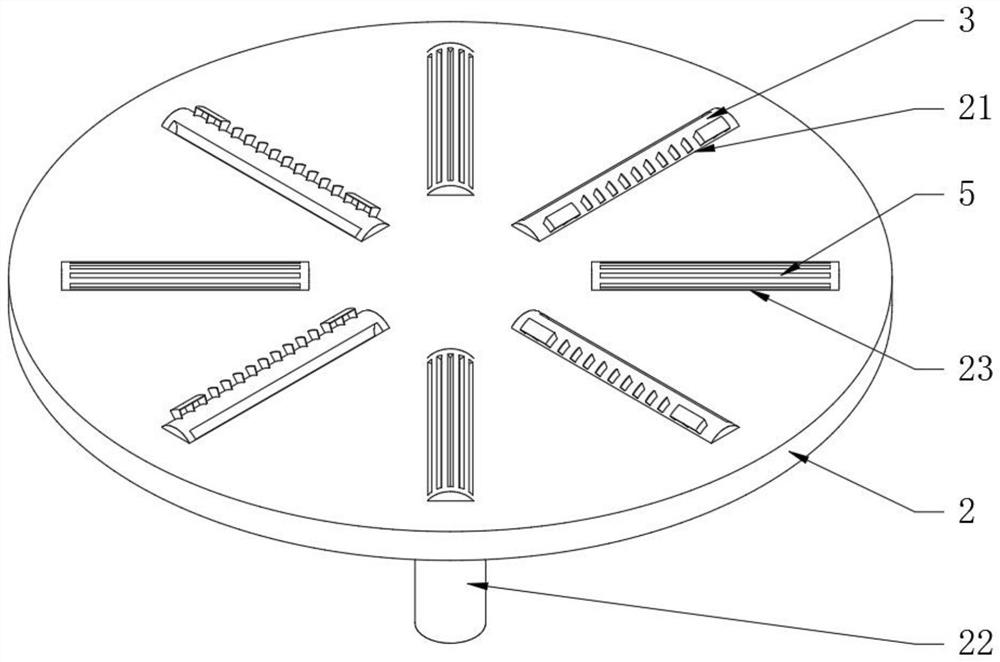

[0031] see Figure 1-4, a reciprocating filtering and scraping equipment, including a collection cylinder 1 and a turntable 2 located in the collection cylinder 1, the turntable 2 and the inner periphery of the collection cylinder 1 rotate and cooperate, and adopt a common rotating and sealing structure, and the turntable 2 can completely seal The function of the partition; the top of the collection cylinder 1 is provided with an integrated conical sleeve 11, and the collection cylinder 1 replaces the sludge tank in the middle of the bottom of the large and medium-sized sewage sedimentation tank through the conical sleeve 11 to collect sludge. The sleeve 11 is fixed with a cross dividing plate 111 on the upper part of the turntable 2. The cross dividing plate 111 divides the sludge entering the collection tube 1 into four equal parts, and can prevent the sludge from following when the turntable 2 rotates at the bottom of the sludge. The turntable 2 rotates, that is to say, whe...

Embodiment 2

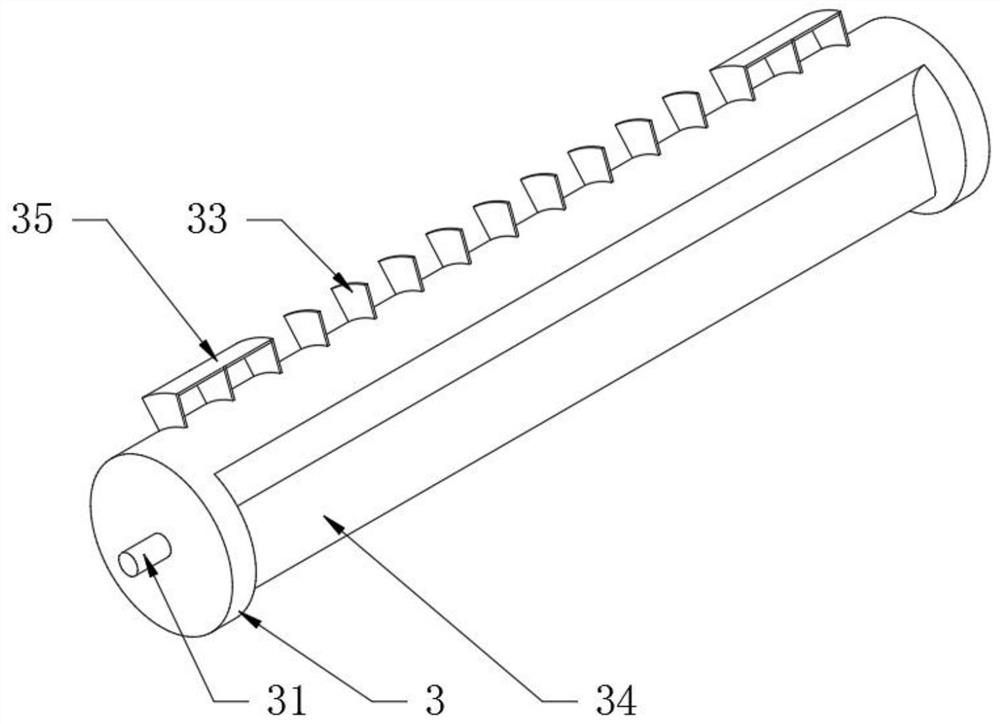

[0033] see image 3 The difference from Embodiment 1 is that an arc plate 35 distributed concentrically with the cylindrical body of revolution 3 is fixedly connected between two adjacent fin plates 33 located at both ends of the cylinder body of revolution 3 , and the arc plate 35 The function is to increase the effect of water resistance. For example, when the sludge concentration in the collection tube 1 is at the lowest state, the rotation of the turntable 2 is controlled. If the arc plate 35 is not provided, the cylindrical rotary body 3 is difficult to swing phenomenon, it is not convenient to realize the self-flushing of the mud scraping equipment at this time, by setting the arc plate 35, when the control turntable 2 rotates at a high speed, the arc plate 35 will increase the water resistance, and then drive the cylindrical rotating body 3 to swing Therefore, one of the arc-shaped mud guide grooves 34 communicates with the upper part and the lower part of the turntable...

Embodiment 3

[0035] see Figure 5 The difference from Embodiment 1 is that the top of each vertical plate on the cross partition 111 is fixedly provided with a drainage plate 112, and the top of the drainage plate 112 is provided with a drainage channel 1121, and the bottom of the drainage channel 1121 extends into the gap 1111, The mouth of the drainage channel 1121 is equipped with a filter screen 6, and the mouth of the drainage channel 1121 has two positions, the top and the bottom. When the sludge in the collection tube 1 is concentrated and transitional, or the sludge fluidity is poor, the drainage channel 1121 can remove the sediment The supernatant water at a high place in the pool is introduced into the sludge, and by controlling the swing of the turntable 2, the supernatant water will be guided into the sludge with poor fluidity under the drainage of the drainage channel 1121, so as to improve the fluidity of the sludge and facilitate the implementation of Example 1. Operation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com