A counter-type flame-resisting component and a flame-resisting explosion-proof valve

A hedging type, explosion-proof valve technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of unable to extinguish the flame, and achieve the effect of protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

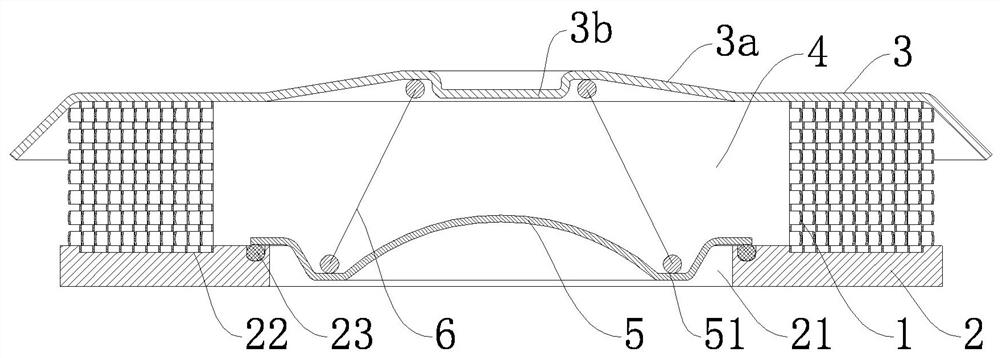

Embodiment 1

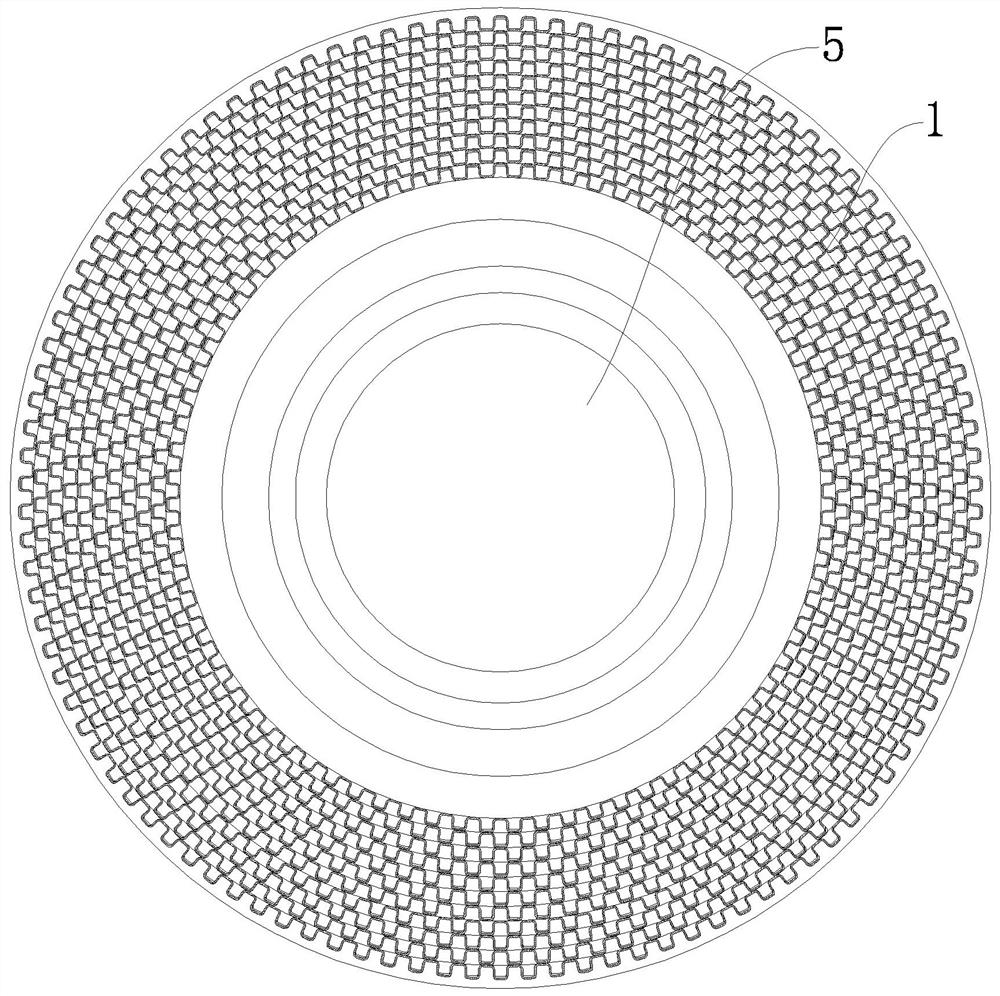

[0027] The hedging type flame arrester assembly in this embodiment includes at least three layers of annular flame retardant sheets 1 that are coaxially nested. Each layer of flame retardant sheet 1 has an annular body composed of elongated sheet bodies connected end to end, and bosses 1a protruding radially outward are formed on the annular body at intervals. There are transverse airflow channels 11 and vertical airflow channels 12 between adjacent bosses 1a. The side wall of each boss 1a has at least one through hole 13 penetrating the annular body.

[0028] Each boss 1a is provided with corresponding through holes 13 on opposite sides. The airflow comes out from the through holes 13 on both sides of the boss 1a. Since the through holes 13 of the adjacent bosses 1a are opposite to each other, the flames sprayed from the through holes 13 of the two adjacent bosses 1a can form a positive hedge.

[0029] The bottom of the boss 1a is an arc surface 1b. The bottom of the boss ...

Embodiment 2

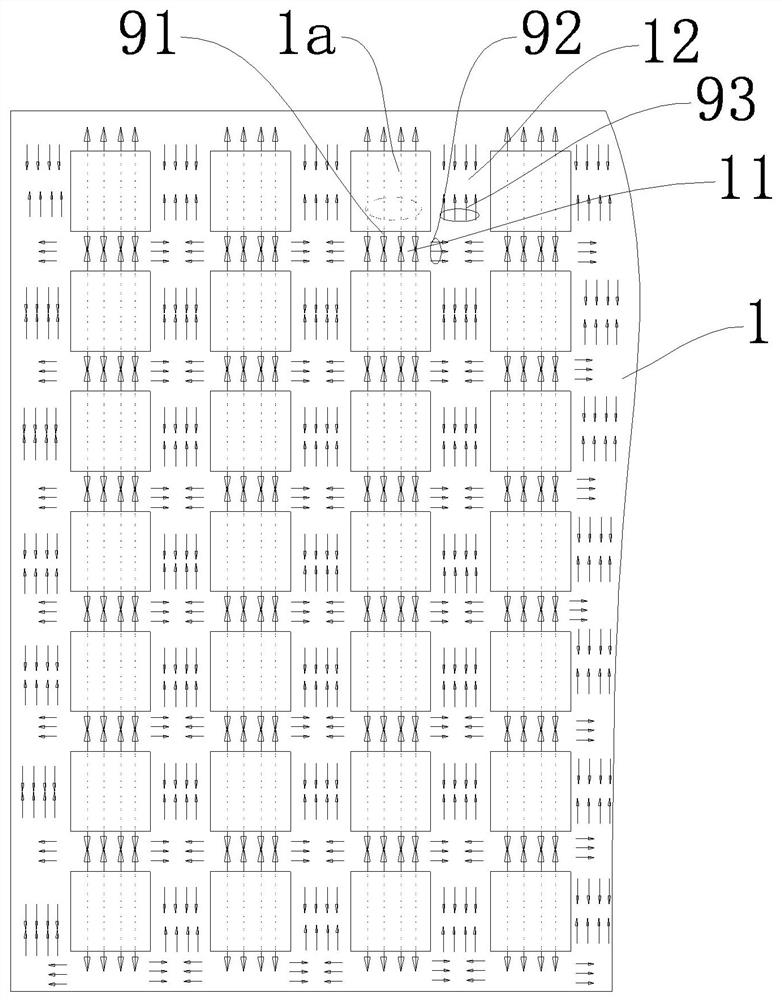

[0040] The difference between Embodiment 2 and Embodiment 1 is that each boss 1a is provided with through holes 13 in the same direction on the same side. like Image 6 As shown, since only one side of each boss 1a is provided with a through hole 13, the through hole 13 faces the wall surface of the adjacent boss 1a. After the explosion, the flame first collides and refracts with the wall surface of the first layer of flame retardant sheet 1 to change the direction of the flame, resulting in the first loss of flame energy. Then the flame escapes from the through hole 13 on one side of the boss 1a to form a flame 91. The flame 91 collides with the wall surface of the adjacent boss 1a to cause a second energy loss, and changes direction to form a flame 92. Between the bosses 1a and the front and rear two layers of flame retardant sheets 1 form a transverse airflow channel 11 to hedge, resulting in a third flame energy loss and a reduction in the propagation speed. After the flam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com