High-pressure electronic igniter with mechanical temperature protection

An electronic igniter and igniter technology, applied in the direction of ignition, combustion ignition, incandescent ignition, etc. using electric sparks, can solve problems such as burnout, the overall heating equipment cannot work normally, and the ignition time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

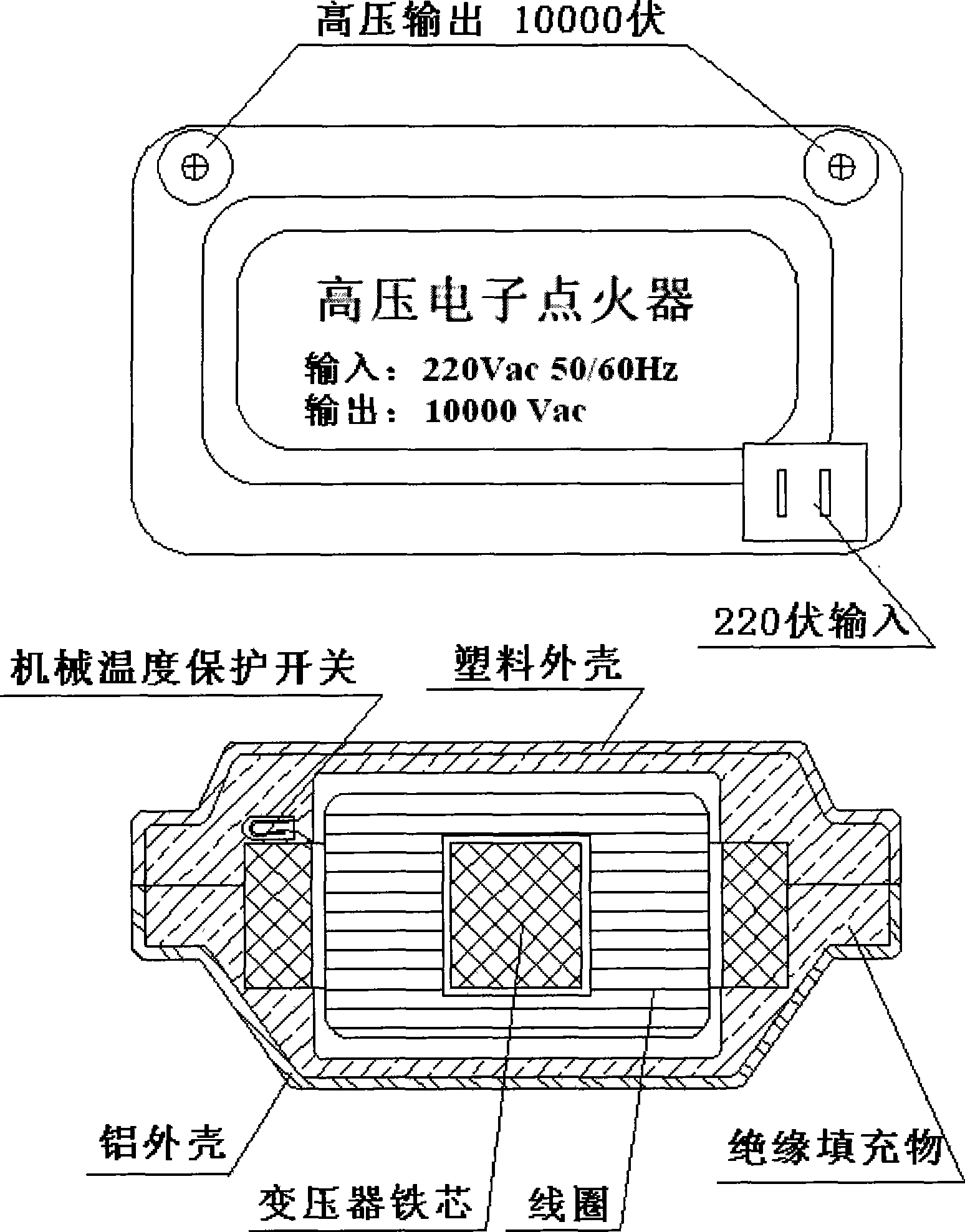

[0013] The device consists of a high-voltage generator, a bimetallic solid-state temperature protection switch, an aluminum, plastic composite shell and epoxy resin sealing insulation material.

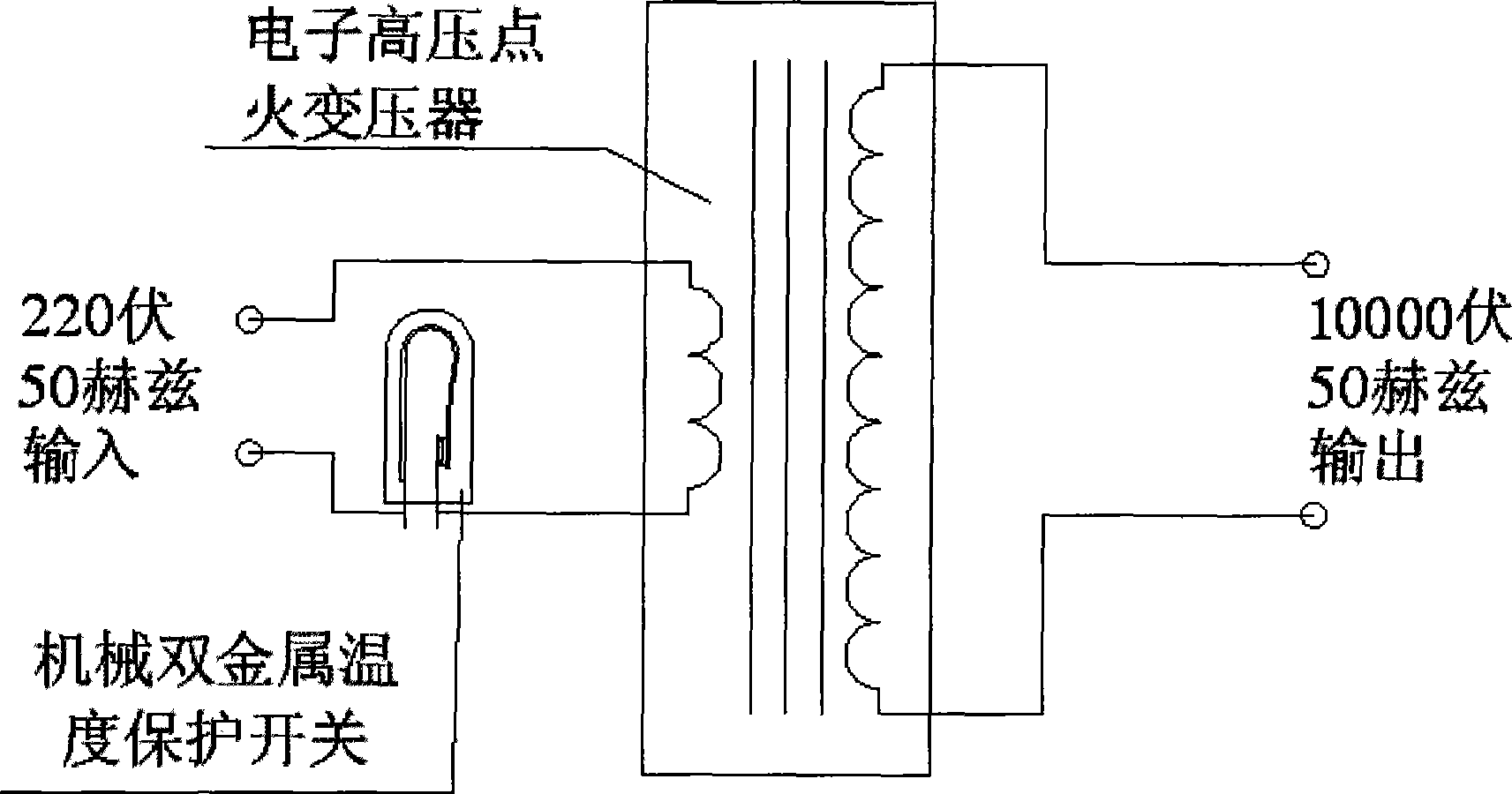

[0014] The high voltage generator is composed of a high voltage transformer. The input voltage of the primary coil is 220 volts, and the output voltage of the secondary coil is 10000 volts. A bimetal solid-state temperature protection switch is connected in series in the primary coil power supply line. The principle is as follows figure 1 shown.

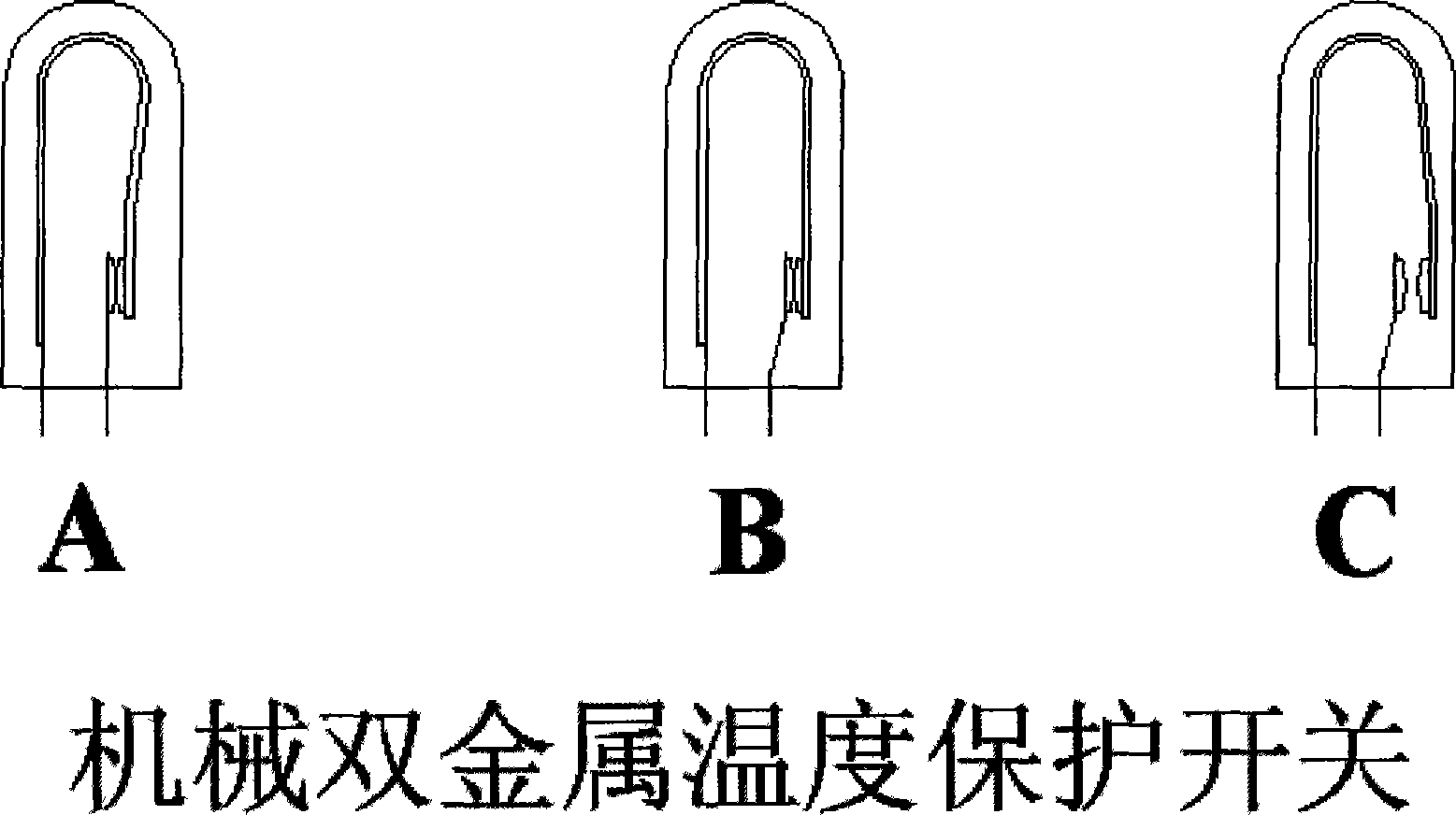

[0015] When not working, the bimetallic solid-state temperature protection switch is in the closed state, such as figure 2 As shown in Figure A in the middle; after the high-voltage lighter starts to work, the coil and transformer begin to heat up, and the bimetal sheet begins to deform. Such as figure 2 Shown in B. As long as the transformer temperature is within the allowable temperature range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com