A Tooling Equipment Facilitating Precise Positioning

A tooling equipment and precise positioning technology, applied in the field of machining, can solve problems such as difficulty in ensuring accurate positioning, achieve high coaxiality and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

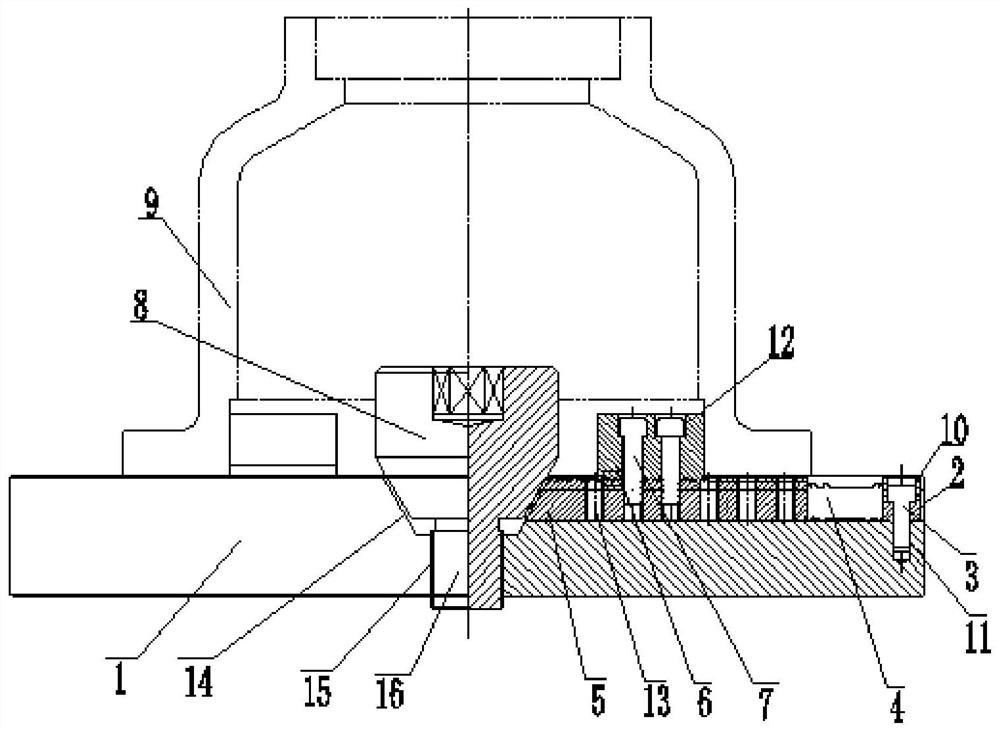

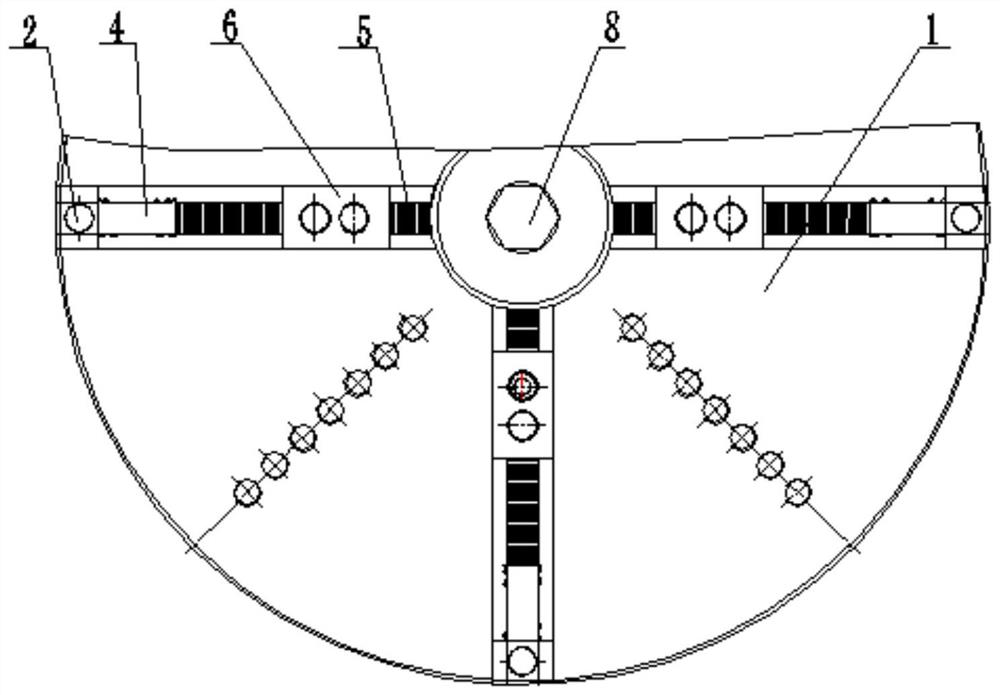

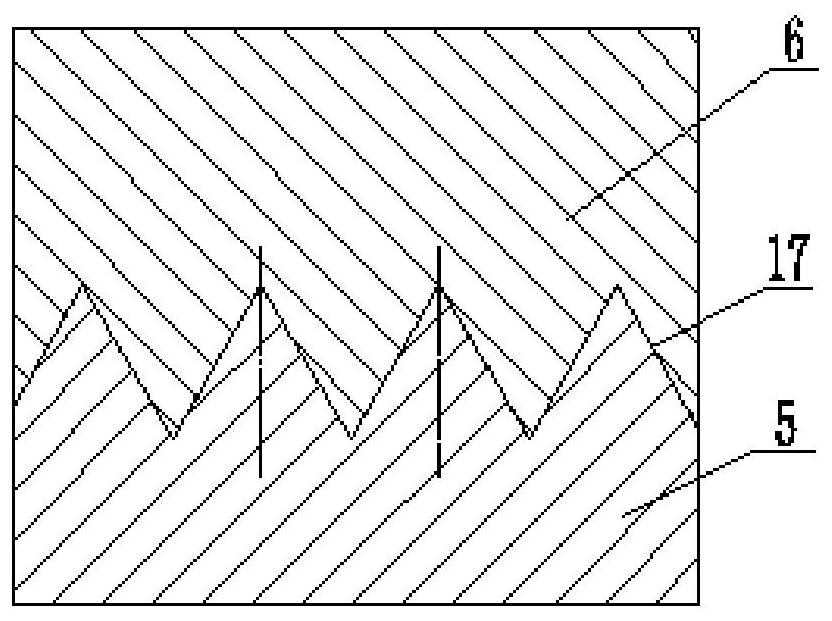

[0027] refer to Figure 1-6 , a tooling device convenient for precise positioning, including a faceplate 1, a part 9 is provided on the top side of the faceplate 1, a tapered groove 14 is opened on the top side of the faceplate 1, and a taper adjustment block 8 is movably installed in the tapered groove 14, and the cone The inner wall of the bottom side of the shape groove 14 is provided with a fixed groove 15, and the bottom side of the taper adjustment block 8 is fixedly equipped with a fixed column 16. T-shaped rack slider 5, one side of the T-shaped rack slider 5 is in contact with one side of the taper adjustment block 8, and the top side of the T-shaped rack slider 5 is movably installed with a positioning block 6, and the positioning block 6 One side is in contact with the inner wall of one side of the part 9, one side of the T-shaped rack slider 5 is fixedly installed with one end of the tension spring 4, and the other end of the tension spring 4 is fixedly installed w...

Embodiment 2

[0038] refer to Figure 1-6 , refer to Figure 1-5 , a tooling device convenient for precise positioning, including a faceplate 1, a part 9 is provided on the top side of the faceplate 1, a tapered groove 14 is opened on the top side of the faceplate 1, and a taper adjustment block 8 is movably installed in the tapered groove 14, and the cone The bottom side inner wall of shaped groove 14 is provided with fixed groove 15, and the bottom side of taper adjustment block 8 is fixedly installed with fixed column 16 by welding, and the bottom end of fixed column 16 extends in the fixed groove 15, and the top side of faceplate 1 is provided with Four T-shaped rack sliders 5, one side of the T-shaped rack slider 5 is in contact with one side of the taper adjustment block 8, and a positioning block 6 is installed on the top side of the T-shaped rack slider 5, and the positioning block One side of 6 is in contact with the inner wall of one side of part 9, one side of T-shaped rack slid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap