An intelligent end effector device for handling various materials

A handling mechanism and end-execution technology, applied in the field of intelligent end-effector devices, can solve the problems of poor practicability, single material and shape material, etc., and achieve the effects of improving stability, reducing occupied space, and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

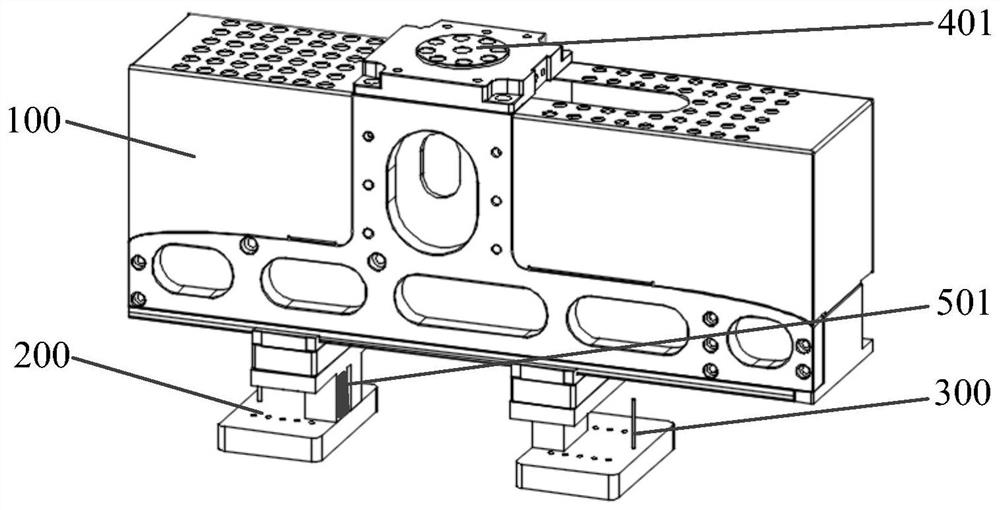

[0032] see figure 1 , an intelligent end effector device for handling various materials, including a clamping transport mechanism module 100 , a pneumatic adsorption transport mechanism module 200 and an electromagnetic adsorption transport mechanism module 300 . The clamping and transporting mechanism module 100 is fixedly installed on the end of the mechanical arm and other actuators through the connection flange 401. The mechanical arm and other actuators are used as the main body, and cooperate with the intelligent terminal actuator device for various material handling to complete the material handling. .

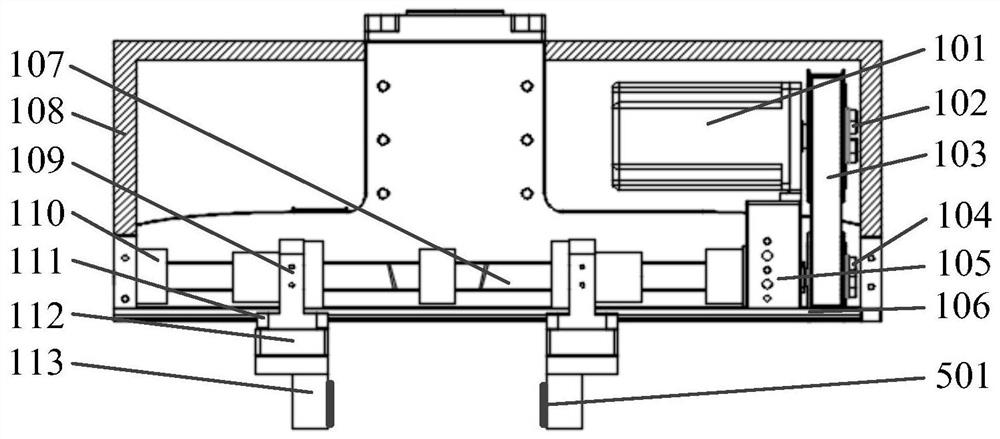

[0033] see figure 2 , the clamping and transporting mechanism module 100 is driven by the servo motor 101, and the motion is transmitted to the screw shaft 107 through the synchronous belt 103. The forward and reverse rotation of the servo motor 101 drives the ball screw pair to rotate forward and reverse synchronously, Realize the opening and closing movement of the...

Embodiment 2

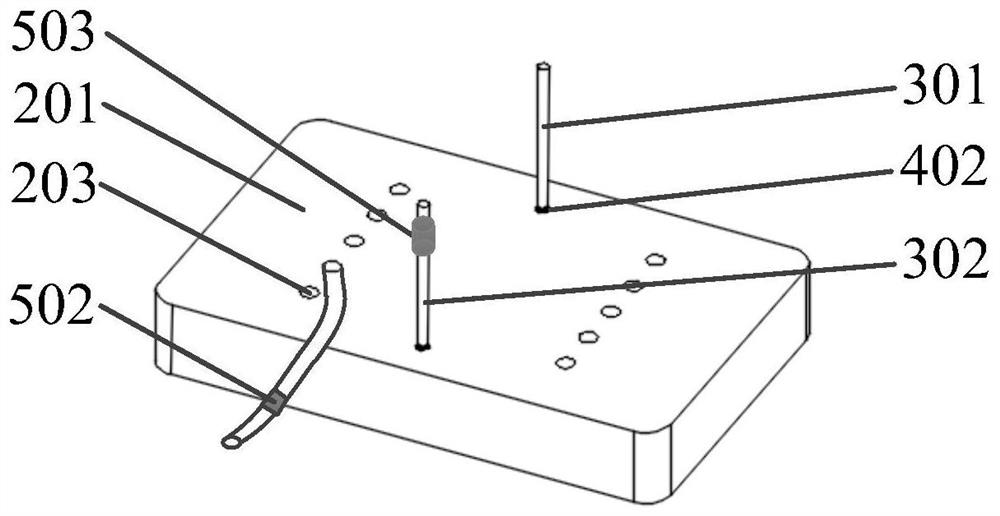

[0042] Same as Embodiment 1, the difference is that it also includes an intelligent sensing unit 500, which is composed of a pressure sensor 501, an air pressure sensor 502 and a Hall sensor 503; the pressure sensor 501 is installed on the gripper 113 Real-time detection of the clamping force of the jaws 113 acting on the material; the air pressure sensor 502 is installed in the air intake pipeline connected to the air inlet 203 to detect the adsorption force of the material in real time; the Hall sensor 503 is installed On the negative electrode 302, the electromagnetic adsorption force of the material is detected in real time.

[0043] The mechanism is integrated with a pressure sensor 501, an air pressure sensor 502 and a Hall sensor 503 to detect the conveying force in real time to ensure safe and controllable conveying of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com