Patents

Literature

32results about How to "Meet the handling needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

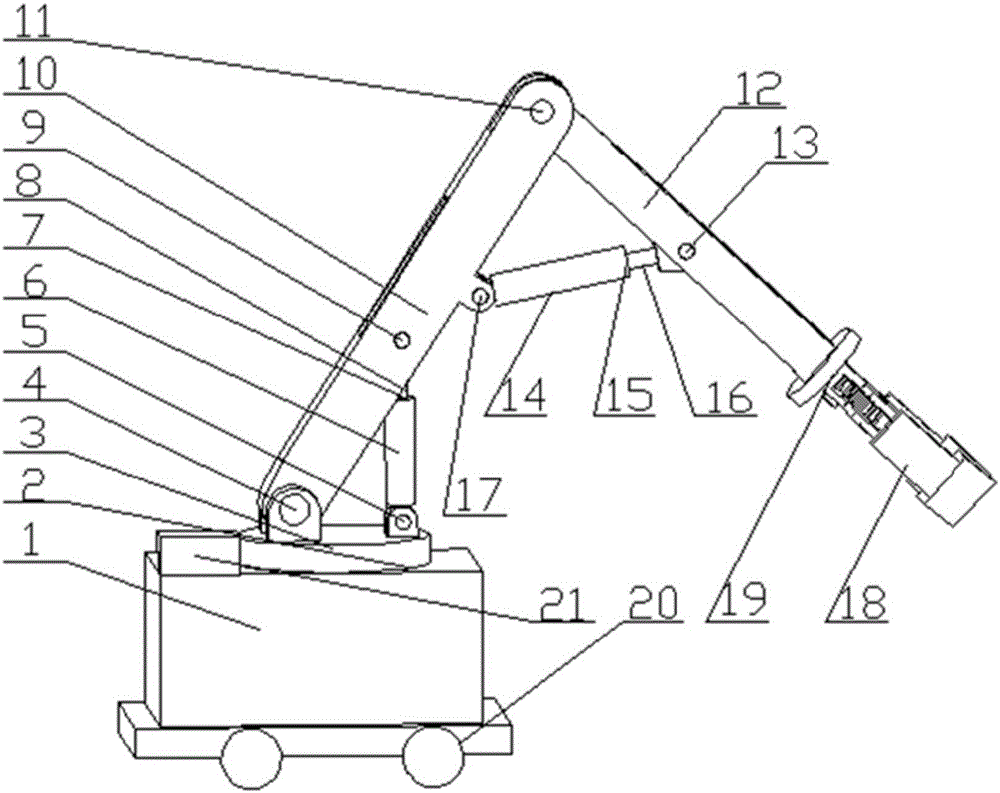

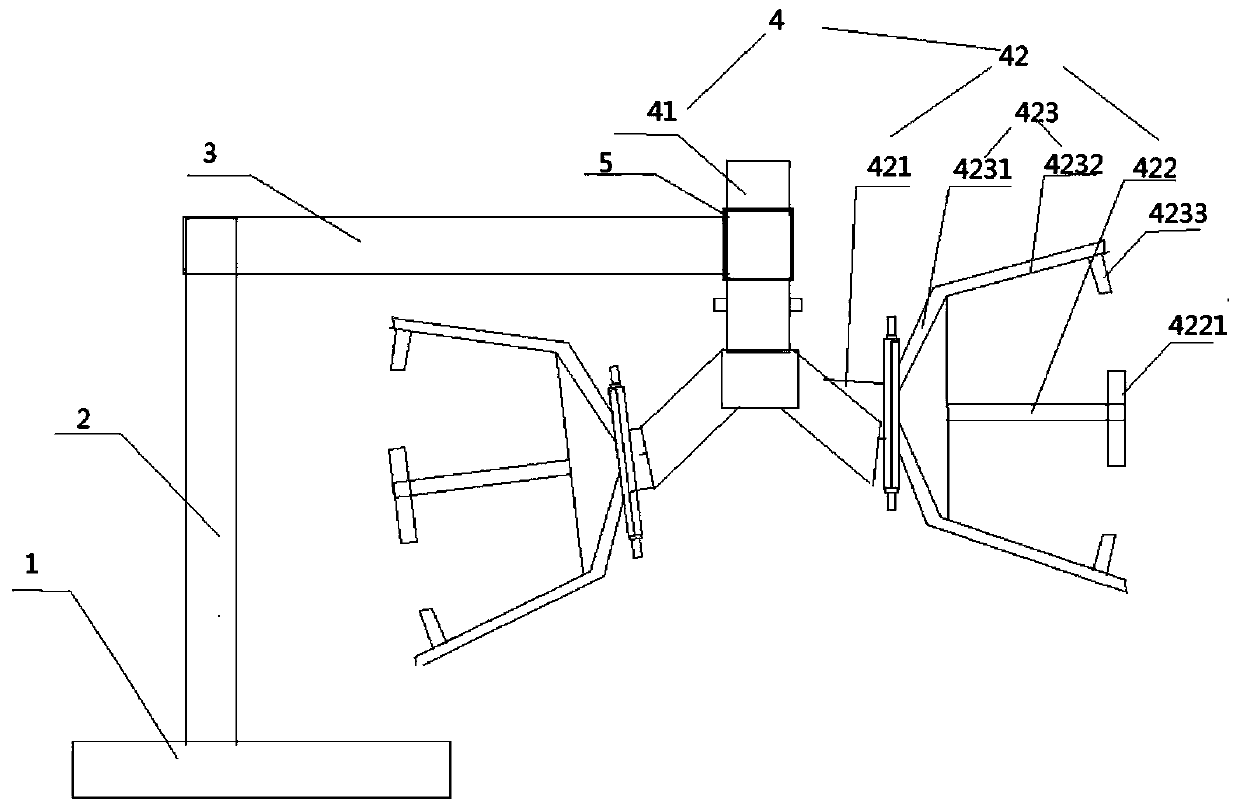

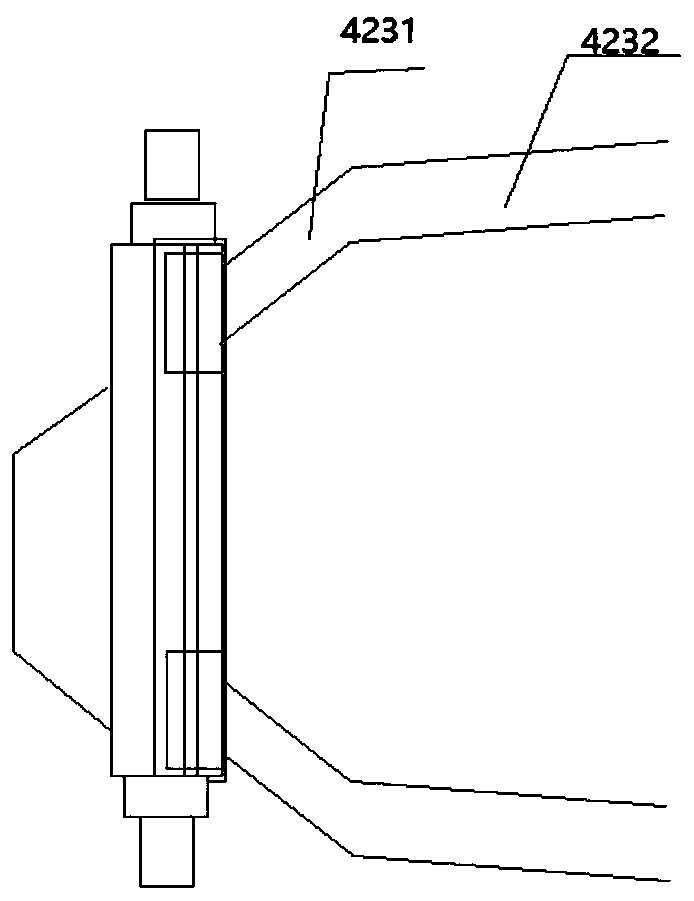

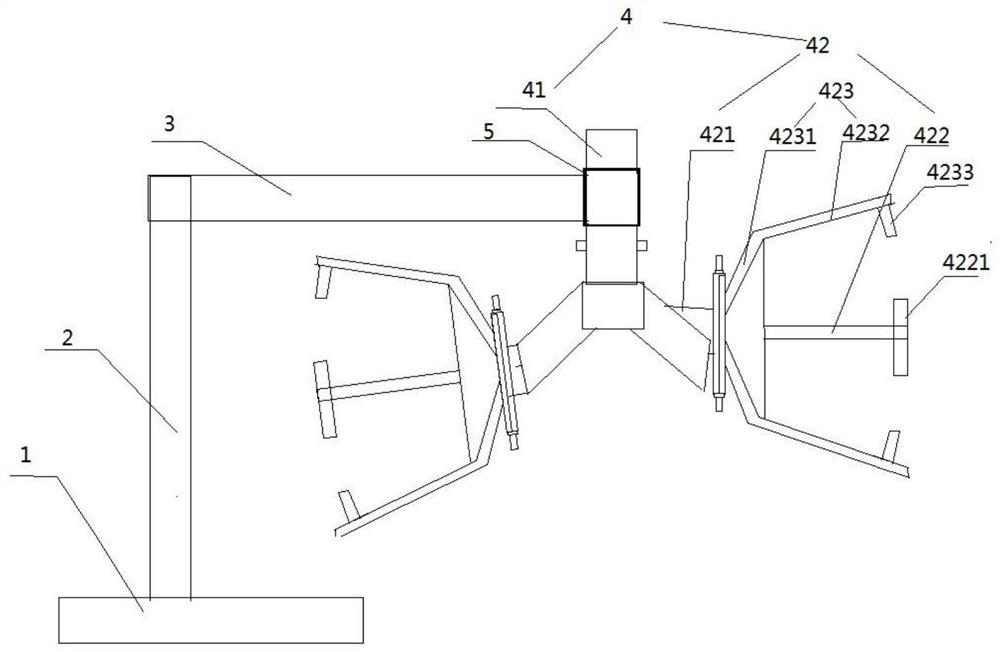

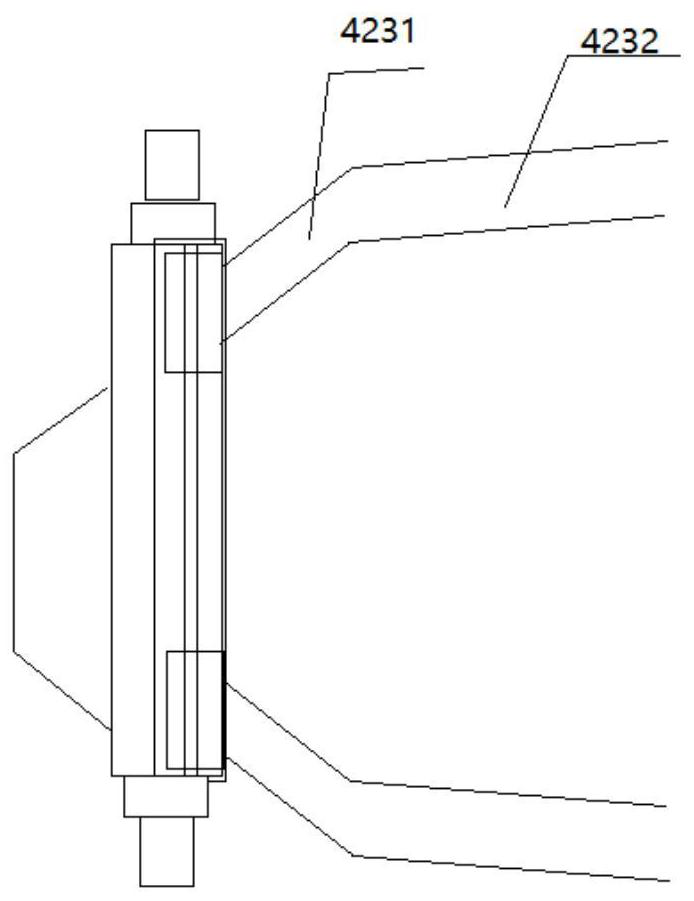

Multifunctional carrying device

InactiveCN105881489ASimple structureGood overall operabilityProgramme-controlled manipulatorGripping headsMultiple functionActuator

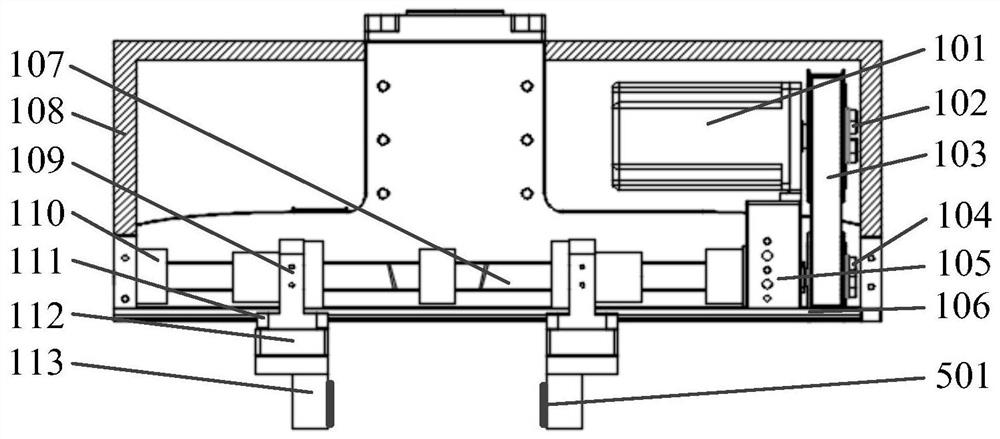

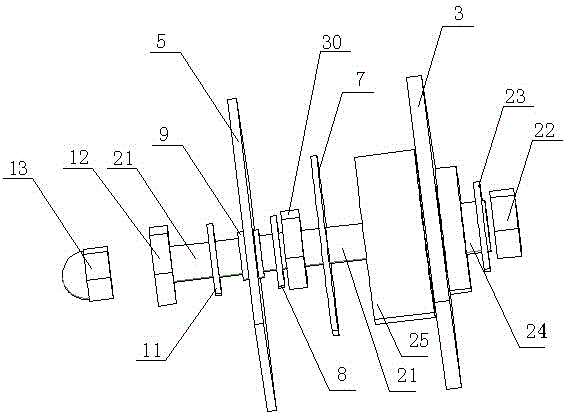

The invention discloses a multifunctional carrying device which comprises a vehicle body, a rotation pair I, a rotary base, a rotation pair II, a rotation pair III, a hydraulic cylinder I body, a sliding pair I, a hydraulic cylinder I extension bar, a rotation pair IV, a big mechanical arm, a rotation pair V, a small mechanical arm, a rotation pair VI, a hydraulic cylinder II body, a sliding pair II, a hydraulic cylinder II extension bar, a rotation pair VII, an end actuator, a rotation pair VIII, wheels and a controller. The multifunctional carrying device provided by the invention has a simple structure, good overall operability, high flexibility and high efficiency, works reliably, can reduce the manufacturing cost, increases the production efficiency and can be used independently.

Owner:范志豪

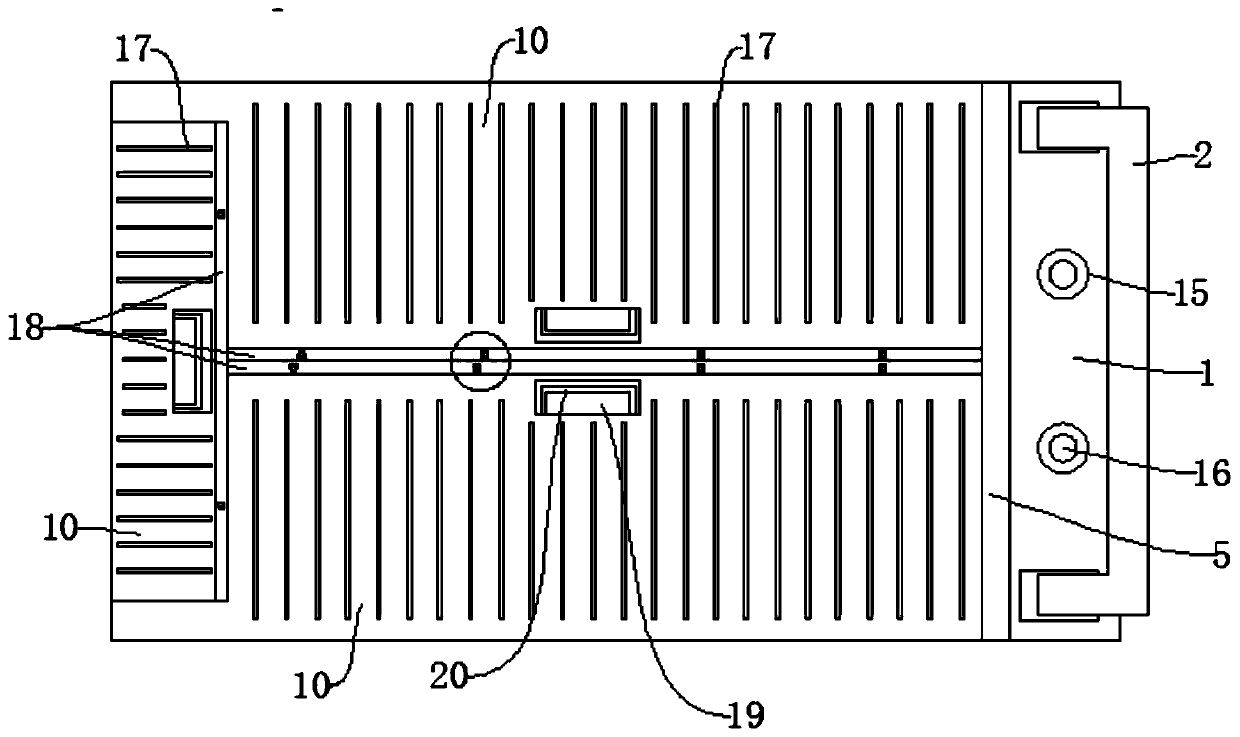

Cleaning equipment for pipe fitting

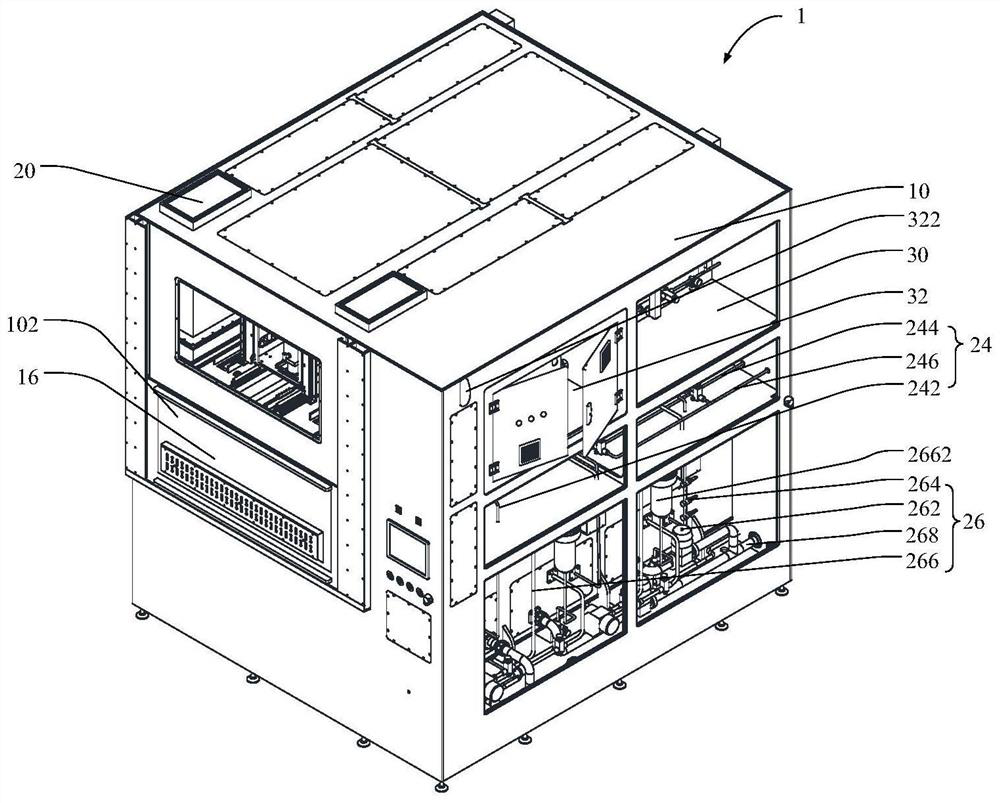

PendingCN111715631AImprove loading and unloading efficiencyReduce the difficulty of operationHollow article cleaningDrying gas arrangementsChemical solutionPipe fitting

The invention provides cleaning equipment for a pipe fitting. The cleaning equipment for the pipe fitting comprises a shell body, an installation plate and a cleaning groove. A charge port and a groove inlet port are formed in the shell body; a charge cavity and a cleaning cavity are formed in the shell body; the charge cavity is located above the cleaning cavity; the installation plate is connected with the shell body; the installation plate is located in the cleaning cavity; and the cleaning groove is capable of being installed on the installation plate. The cleaning groove specifically comprises a main groove cavity, an auxiliary groove cavity, a rotary element, a transmission element and a sealing element. The main groove cavity is used for placing a cleaning groove; the rotary elementis located in the main groove cavity; one end of the rotary element penetrates through a partition and stretches into the auxiliary groove cavity; the transmission element is located in the auxiliarygroove cavity; and the sealing element is located between the rotary element and the partition. When the transmission element drives the rotary element to rotate, the transmission element does not make contact with the chemical solution in the main groove cavity; and moreover, in the rotating process of the transmission element, the chippings and residues which are generated by the transmission element are intercepted by the sealing element between the rotary element and the partition, so that no pollution to the cleaning solution in the main groove cavity is further ensured, the cleaning effect is improved, and the service life of the cleaning solution is prolonged.

Owner:CHANGZHOU S C EXACT EQUIP

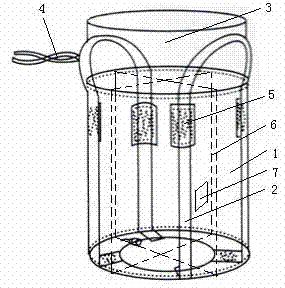

Flame-retardant and antistatic container bag

InactiveCN104773406AExtend your lifeMeet the handling needsLarge containersEngineeringAntistatic Materials

The invention discloses a flame-retardant and antistatic container bag, and belongs to the field of container bags. The flame-retardant and antistatic container bag comprises a body, hanging belts, a feeding hole, a tying rope, reinforcing belts, inner blocking plates and a label bag, wherein the body is made of a flame-retardant and antistatic material; the hanging belts pass through the bottom of the body in a crossed mode to be arranged on the side face of the top of the body; the feeding hole is formed in the top of the body; the tying rope is arranged on one side of the feeding hole; the inner blocking plates are arranged inside the body; the label bag is arranged outside any side face of the body; the reinforcing belts are arranged on the hanging belts and are fixed outside the body. The container bag disclosed by the invention is simple in structure, convenient to assemble and disassemble, high in bearing capacity, flame-retardant, antistatic, long in service life and wide in application range, and has a wide market prospect.

Owner:NANTONG LIANRONG GRP

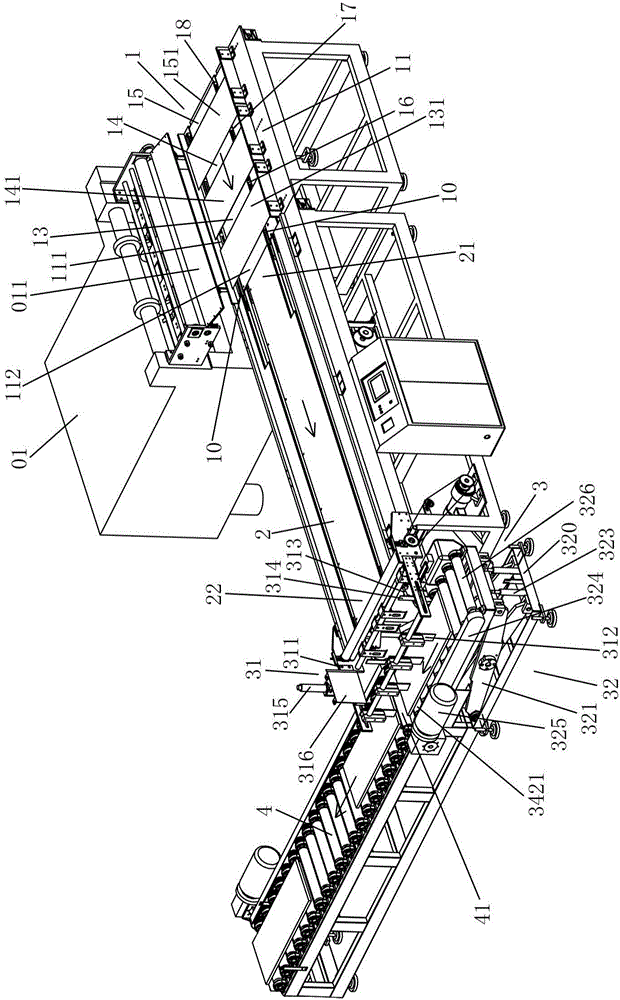

Conveyer for iron sheets used for making large cans

PendingCN106697966AReasonable structureInnovative designConveyorsStacking articlesSheet pileMechanical engineering

The invention discloses a conveyer for iron sheets used for making large cans. The conveyer comprises a stepped conveying mechanism, a horizontal conveying mechanism, a lifting collection mechanism and a roller conveying mechanism, wherein a material end is arranged on one side of the stepped conveying mechanism; a material inlet end of the horizontal conveying mechanism is connected with a material outlet end of the stepped conveying mechanism; the lifting collection mechanism is arranged on a material outlet end of the horizontal conveying mechanism; and a material inlet end of a roller conveying mechanism is connected with a material outlet end of the lifting collection mechanism. By adopting the conveyer for the iron sheets used for making the large cans, the iron sheets used for making the large cans can be conveyed, so that conveying requirement of the iron sheets used for making the large cans is met; when the conveyer for the iron sheets used for making the large cans, time and labor are saved; energy consumption is lowered, and production efficiency is improved; besides, an iron sheet pile for making the large cans is conveyed out through the roller conveying mechanism; and the roller conveying mechanism can bear the weight of the iron sheet pile for making the large cans, and conveying is stable, high-speed and energy-saving.

Owner:SHANTOU XINQING CANNERY MACHINERY

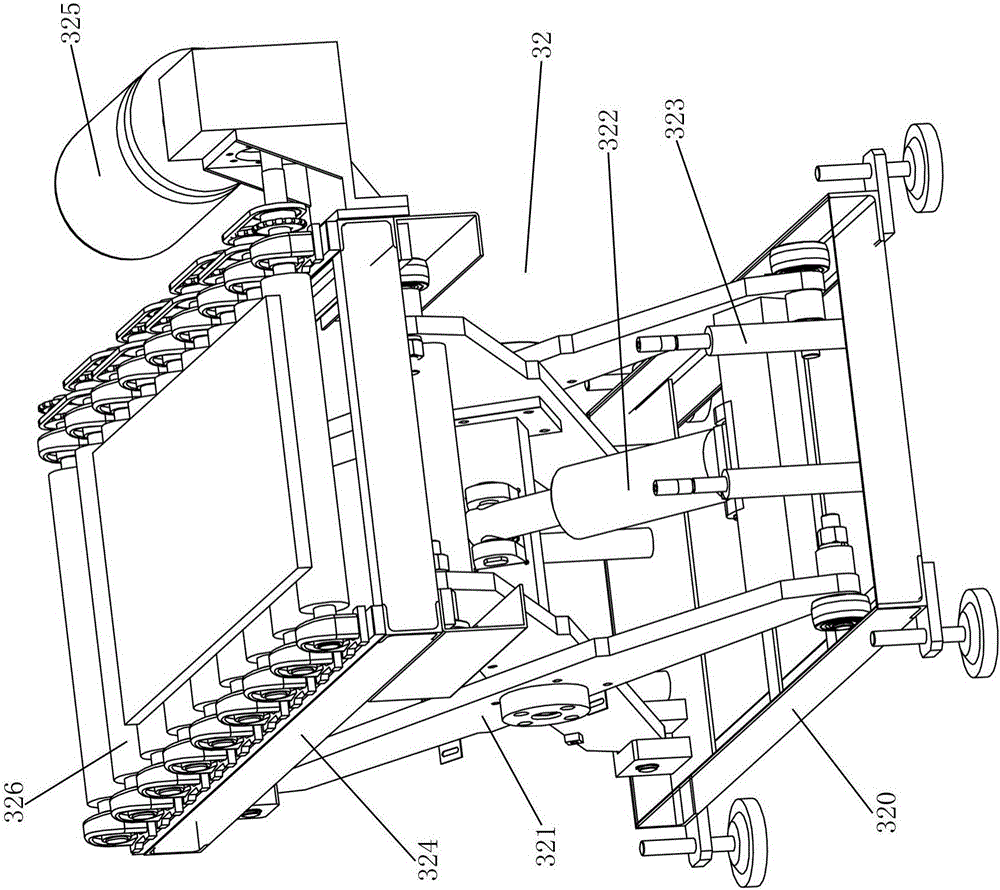

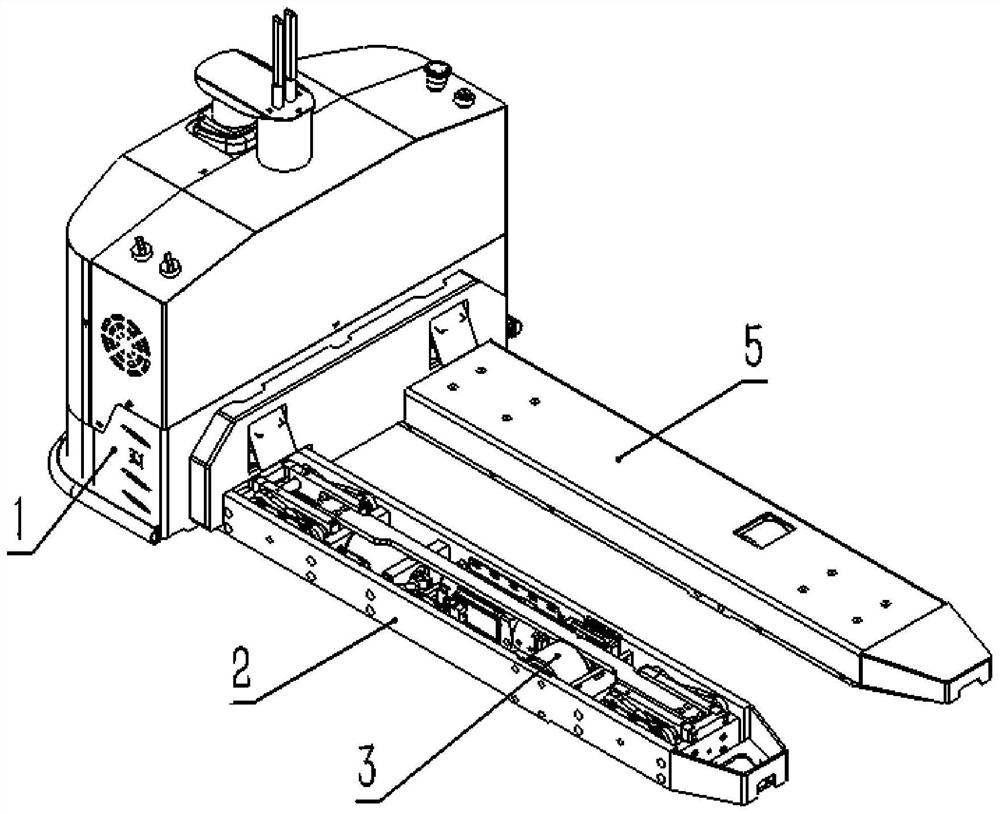

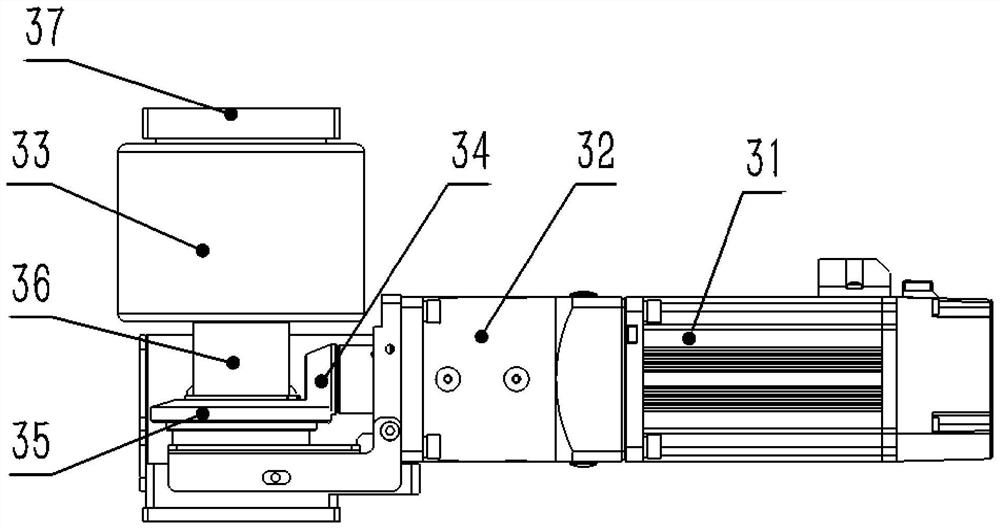

Unmanned carrying automated guided vehicle and guiding method thereof

InactiveCN111776990APrevent goods from shakingReduce volumeLifting devicesAutomated guided vehicleBevel gear

The invention discloses an unmanned carrying automated guided vehicle and a guiding method thereof. The automated guided vehicle comprises a vehicle body, two fork legs, two driving wheel mechanisms,a driven wheel mechanism, a hydraulic system and a covering fork. Each driving wheel mechanism is installed in a corresponding fork leg. Each driving wheel mechanism comprises a servo motor, a drivingwheel, a bevel gear set, a driving shaft and a fixing plate. Each driving shaft is driven to rotate by the corresponding servo motor through the corresponding bevel gear set. The output shaft of eachservo motor is perpendicular to the corresponding driving shaft. The driving shafts are rotatably installed on the fixing plates. The fixing plates are fixed to corresponding fork legs. The driven wheel mechanism is installed in the vehicle body and comprises two driven wheels, a rotary frame, a rotary shaft and a first fixing seat. The hydraulic system comprises a pump station, a synchronous valve and two jacking devices. According to the unmanned carrying automated guided vehicle, the vehicle body does not move when the automated guided vehicle rises and falls, goods can be lifted and lowered smoothly, shaking of the goods is avoided, and stability of carrying can be improved; the overall dimension of the automatic guided vehicle (AGV) is lowered; and the navigation accuracy is improved.

Owner:HEFEI GEN SONG AUTOMATION TECH

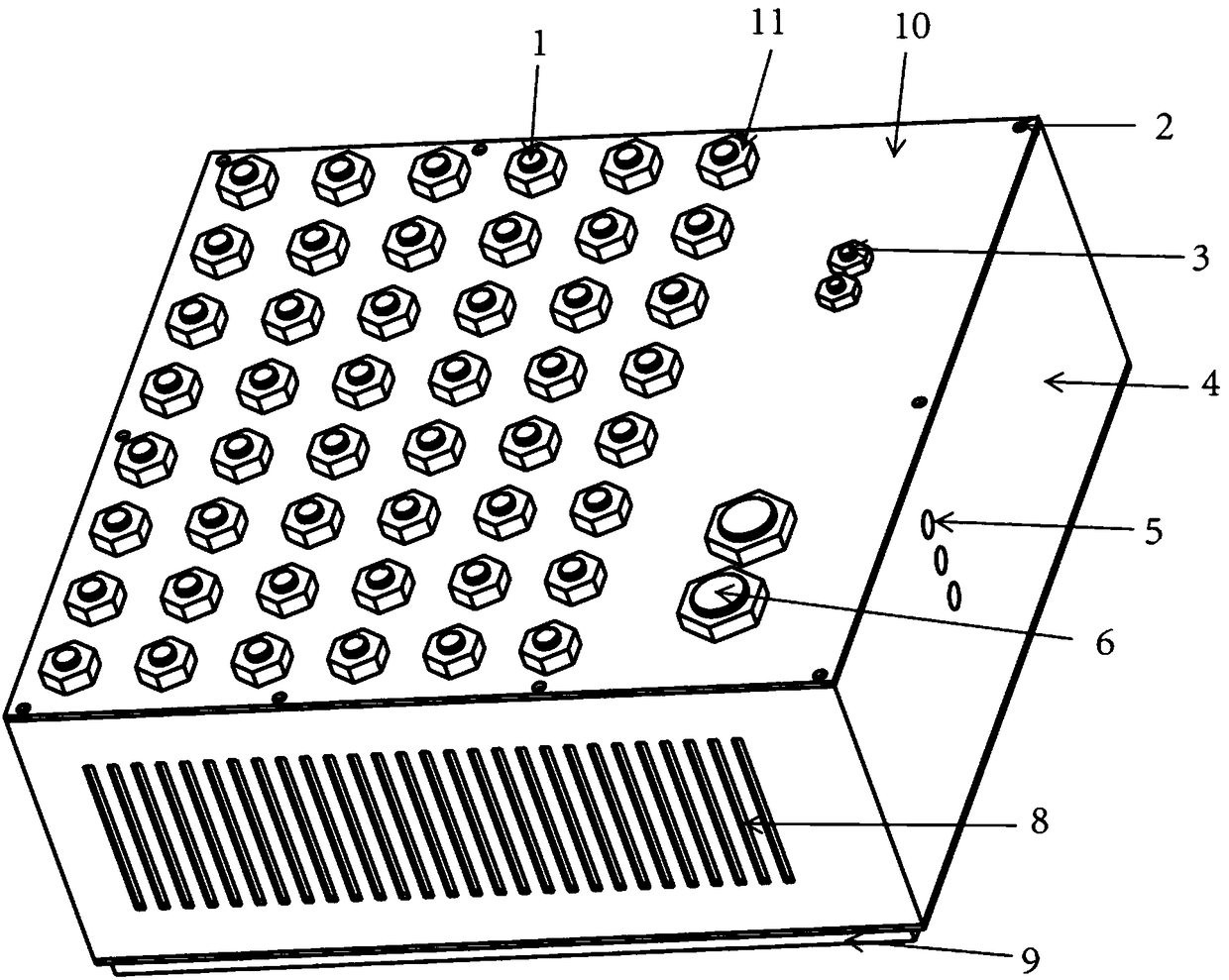

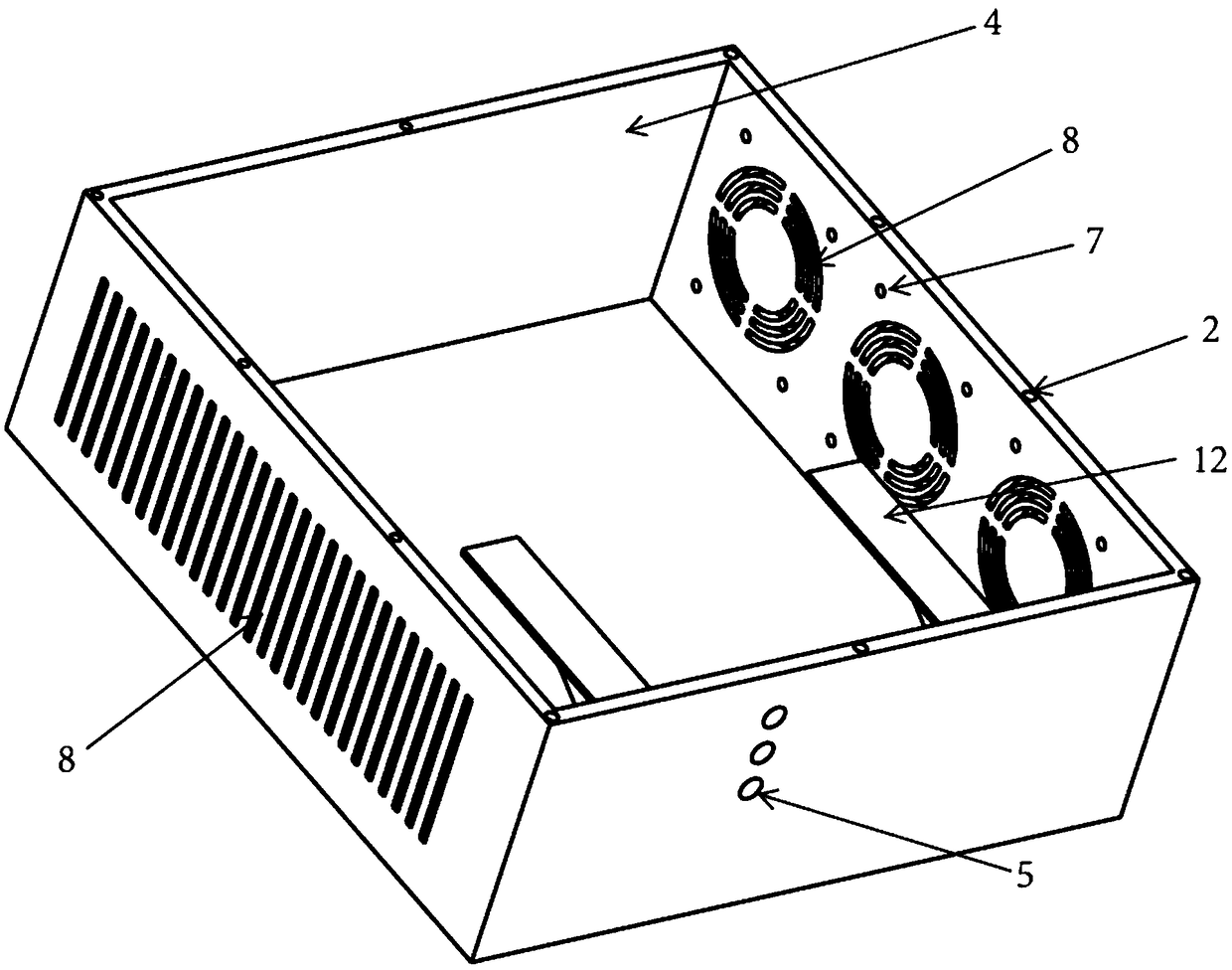

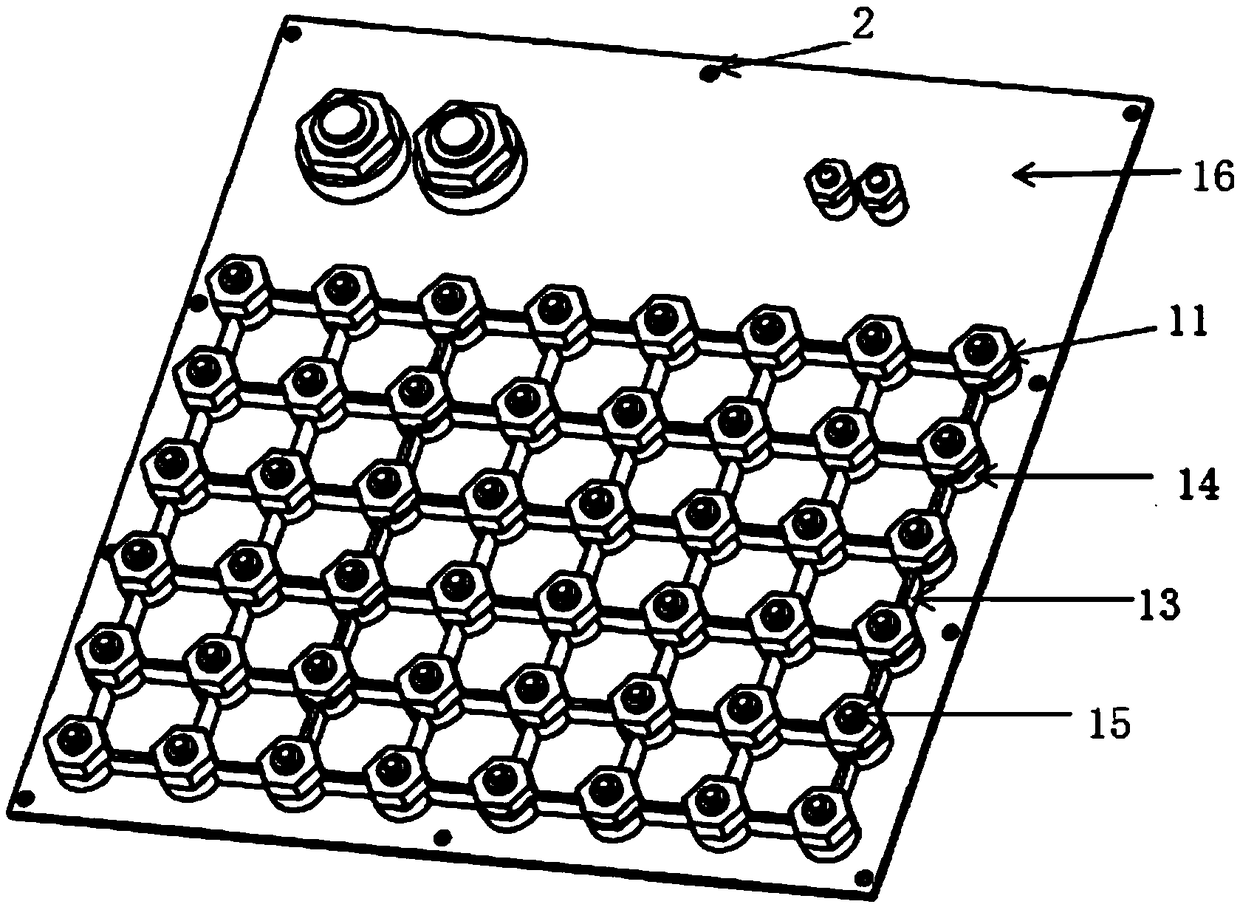

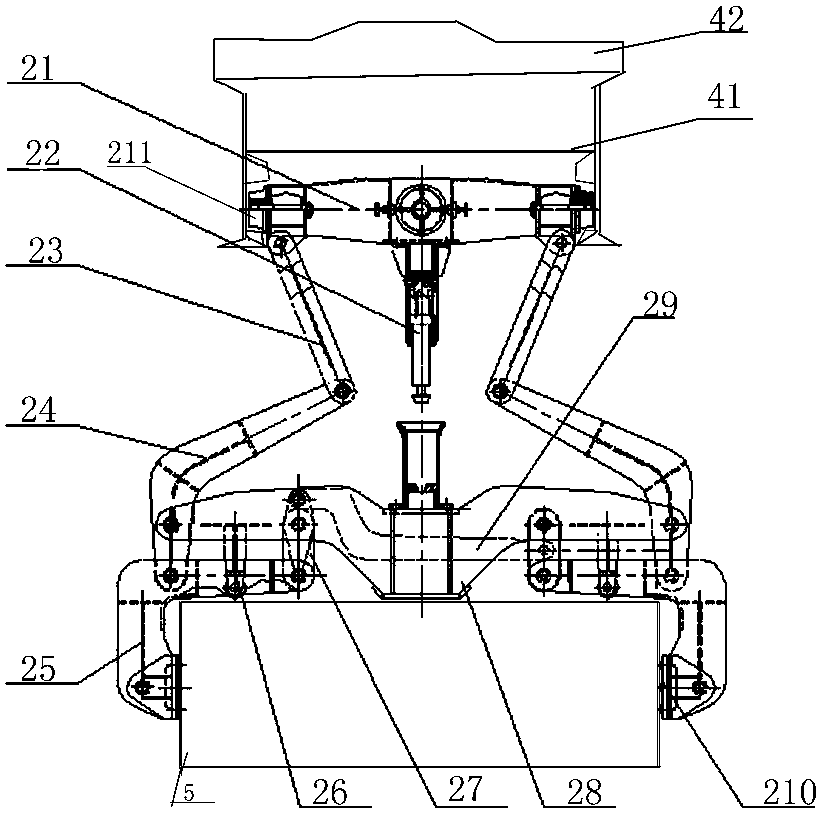

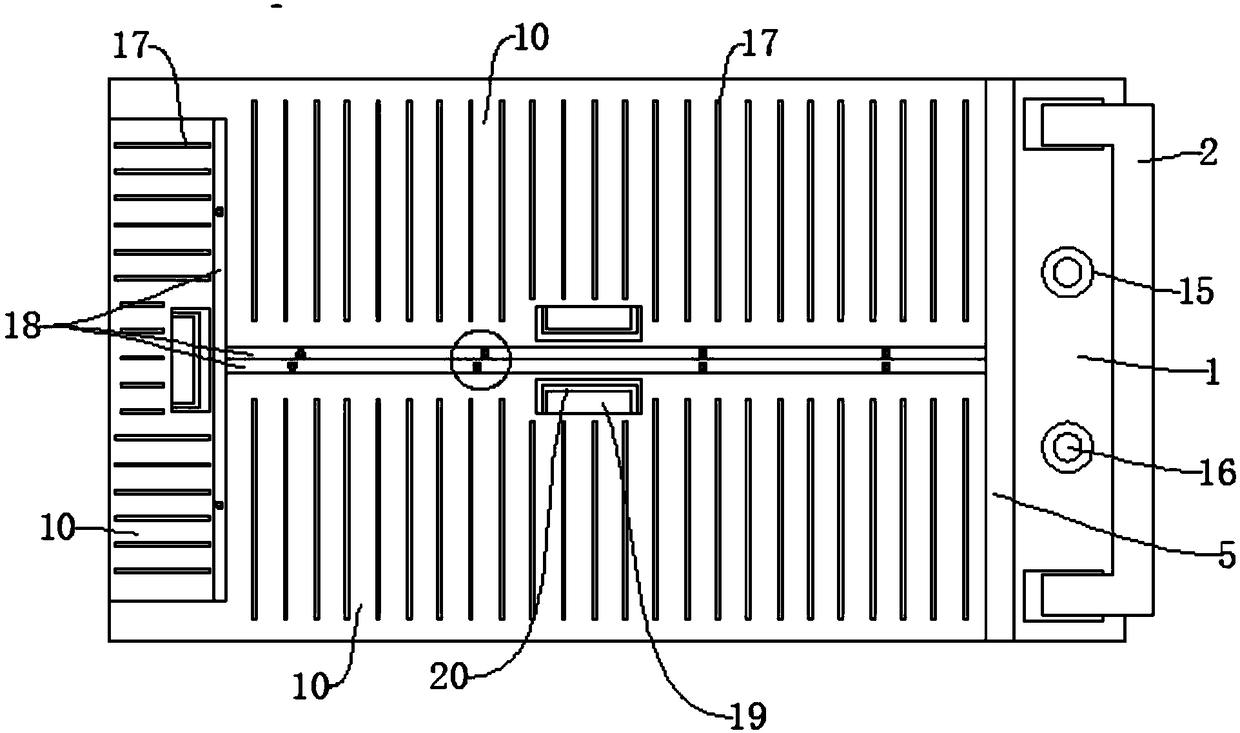

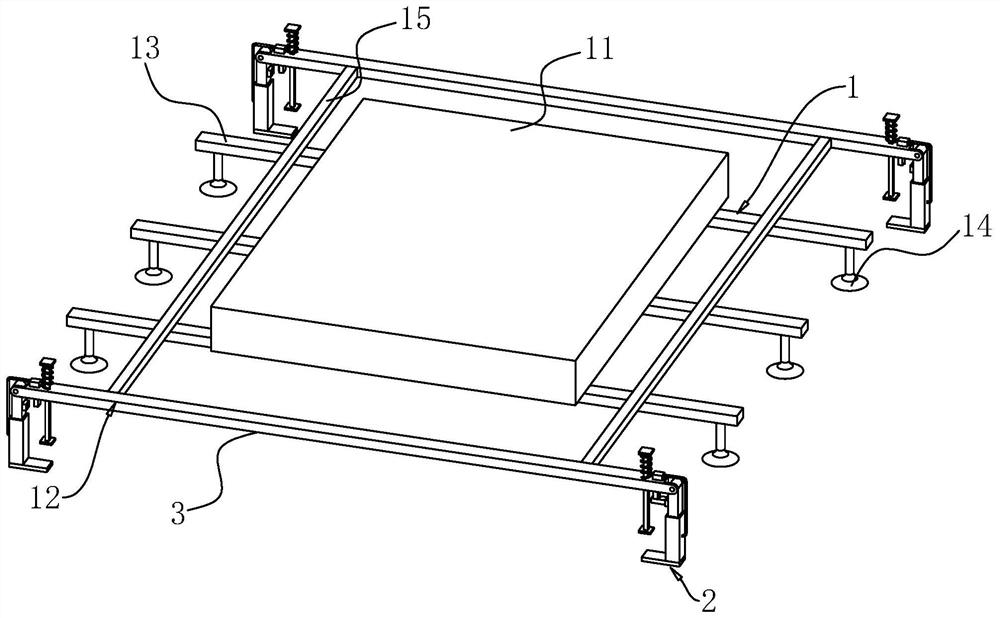

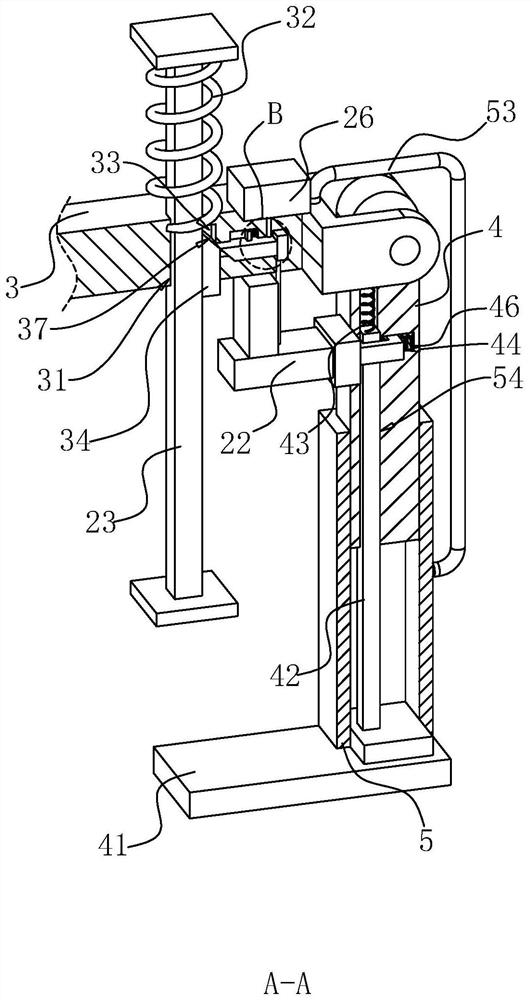

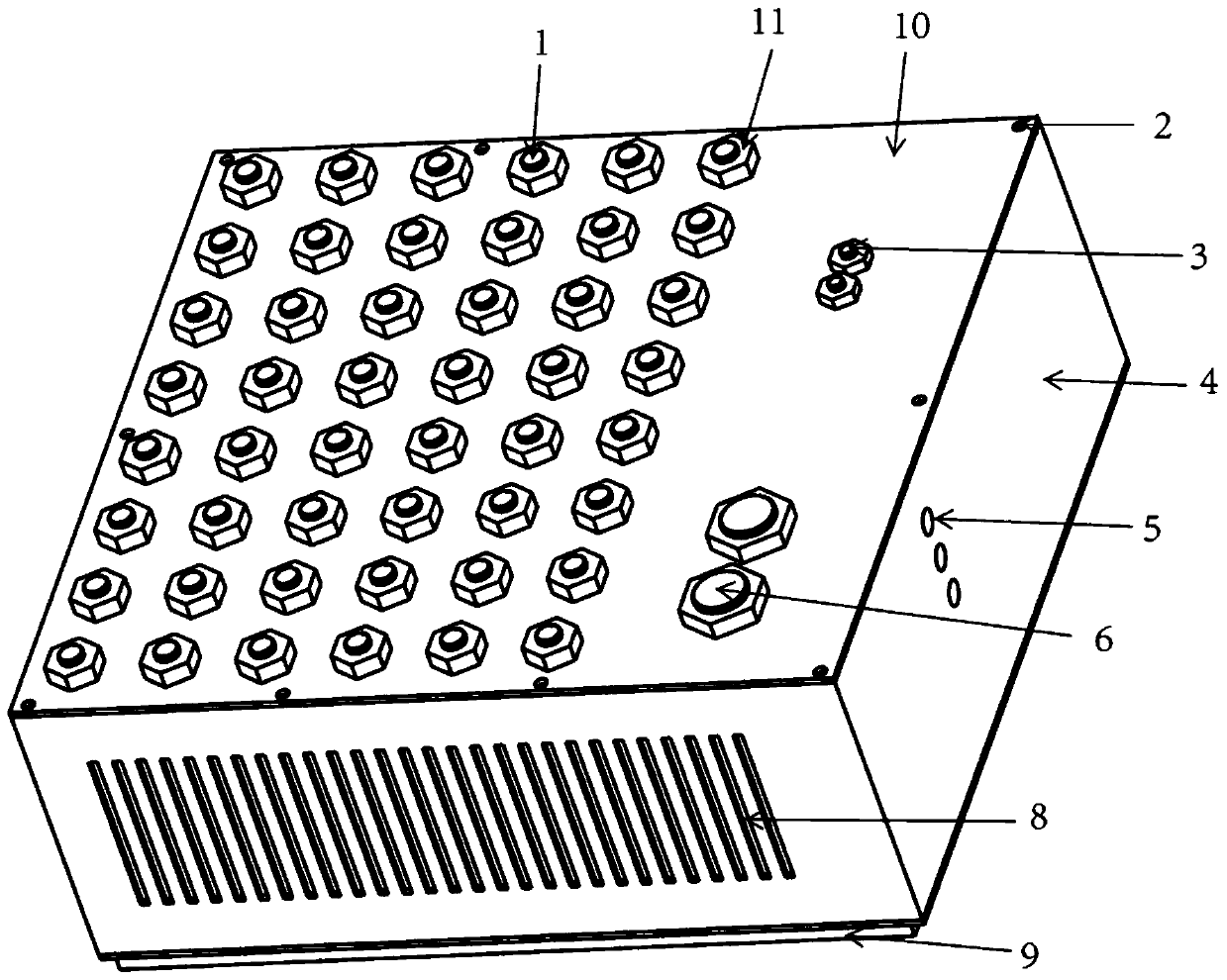

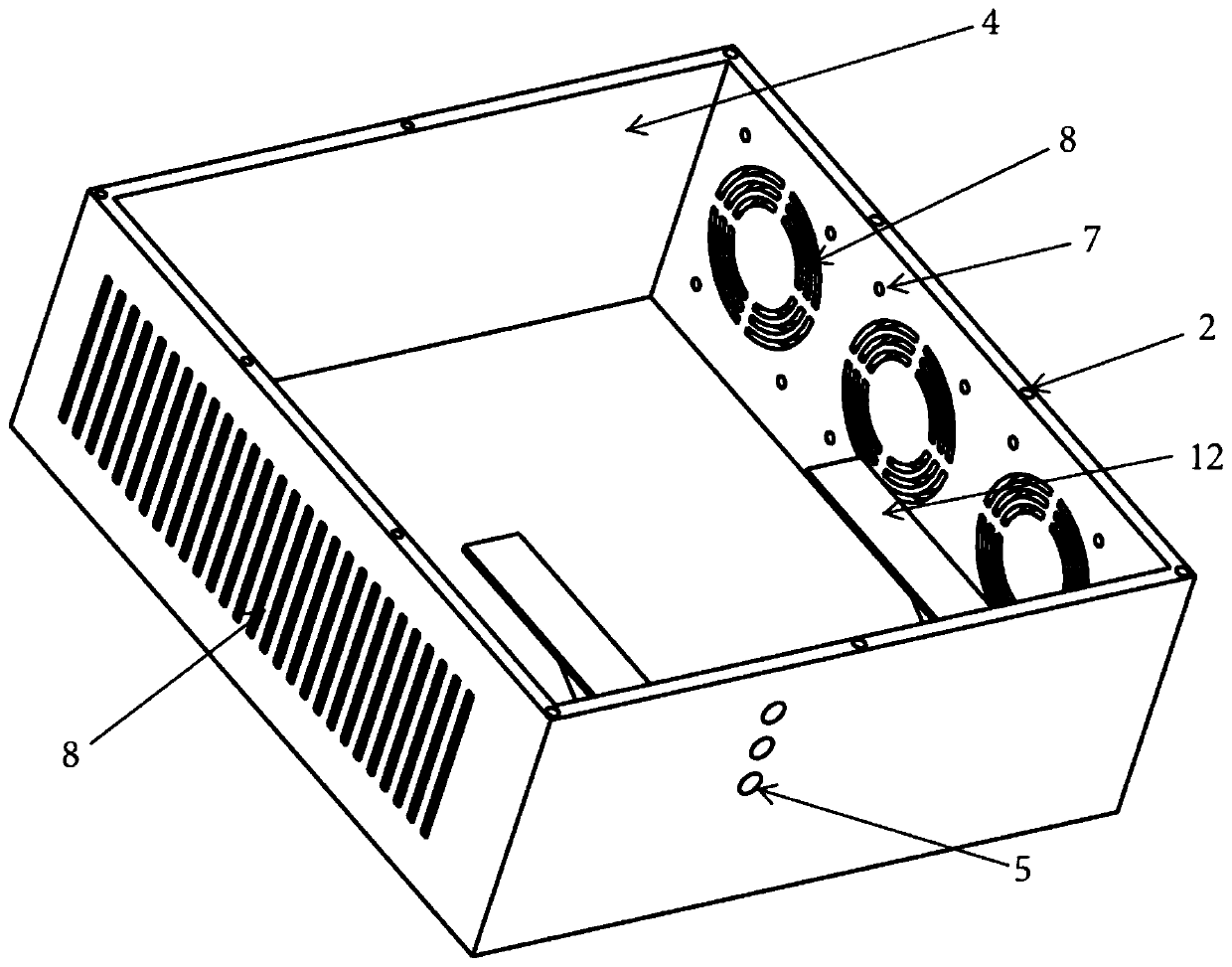

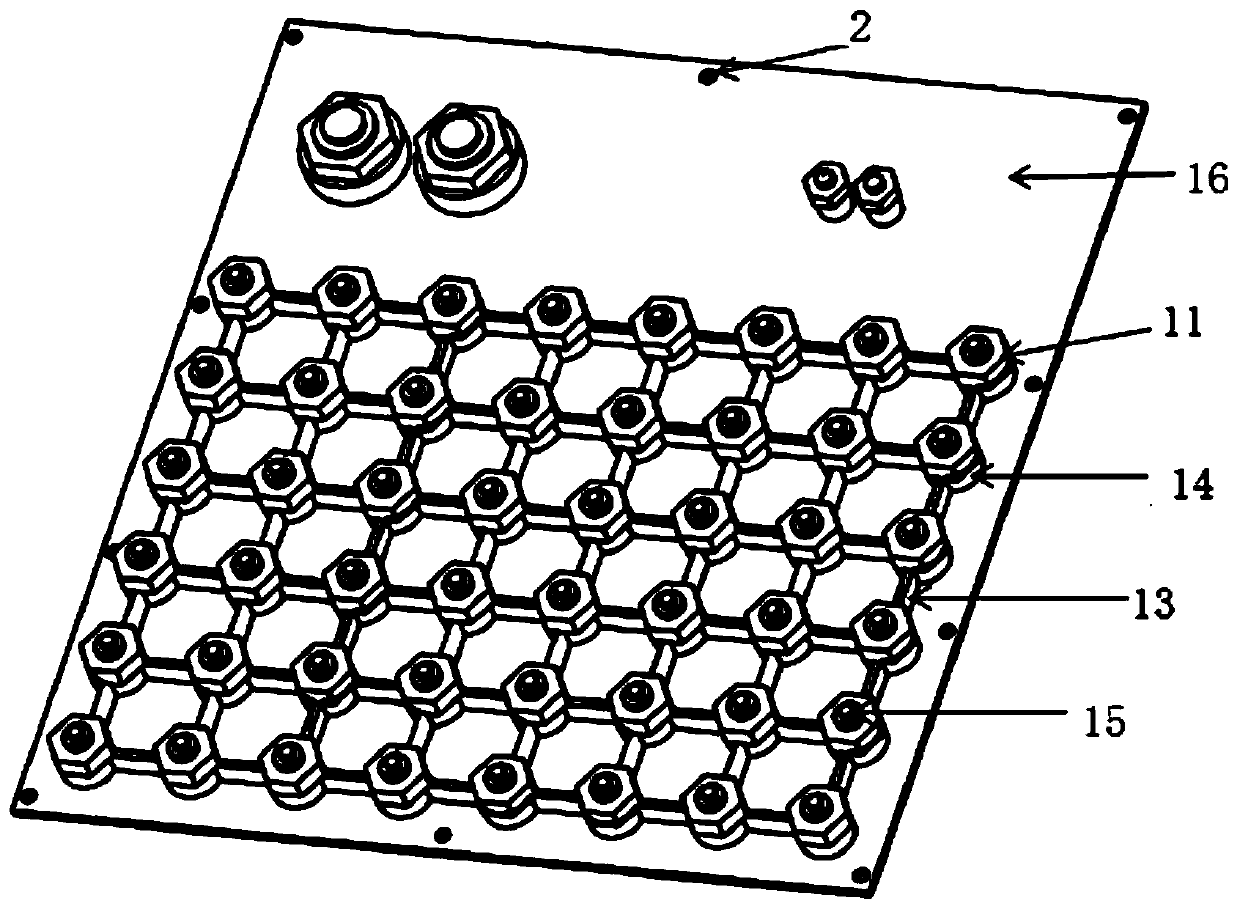

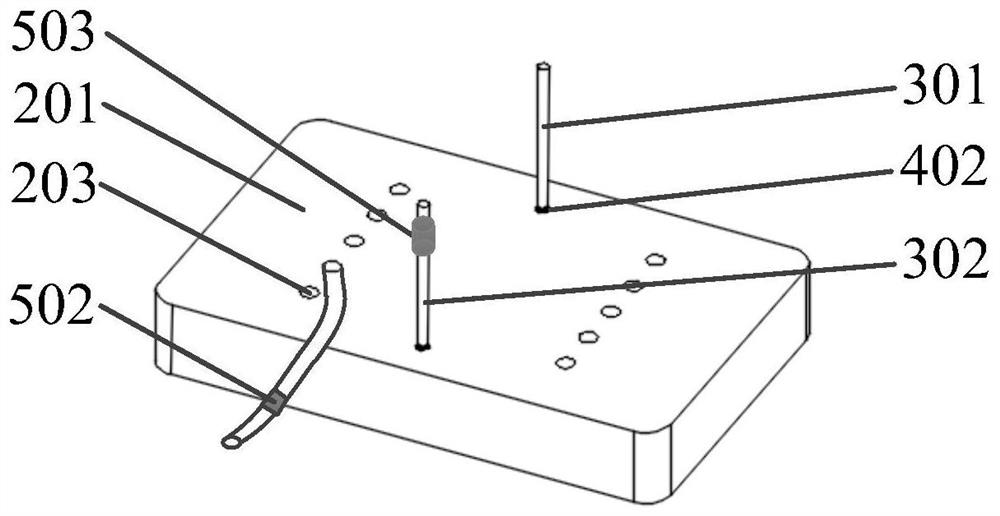

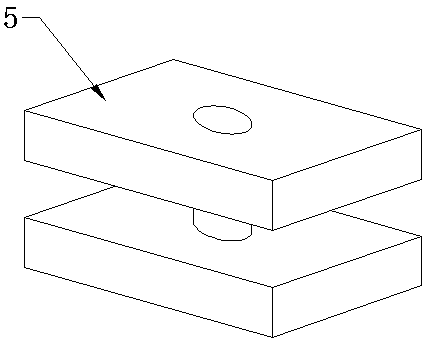

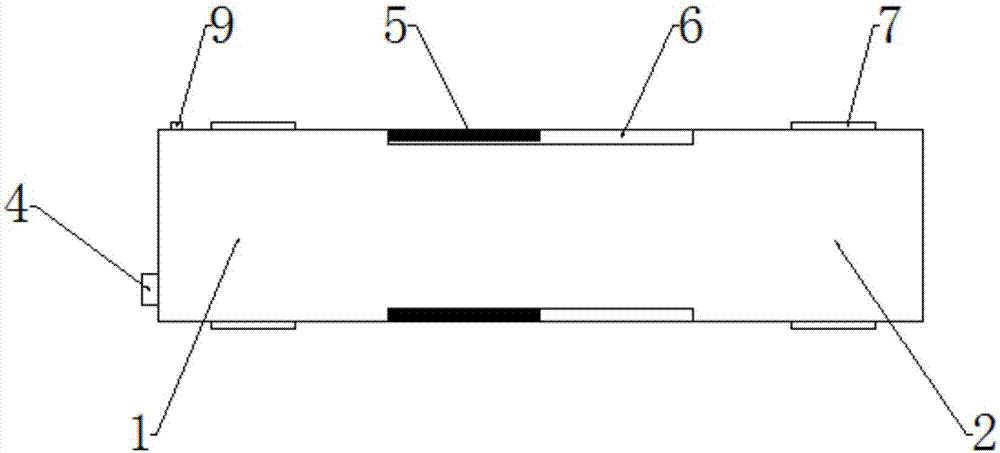

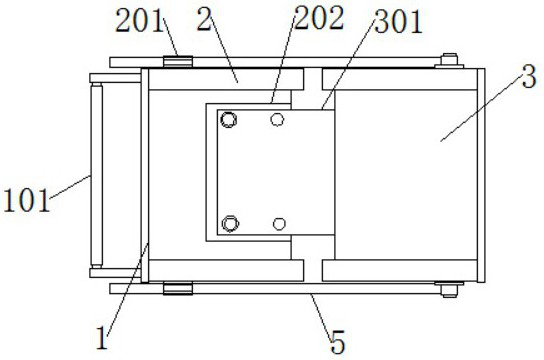

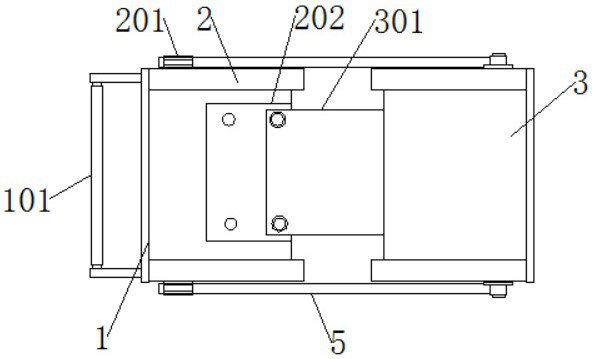

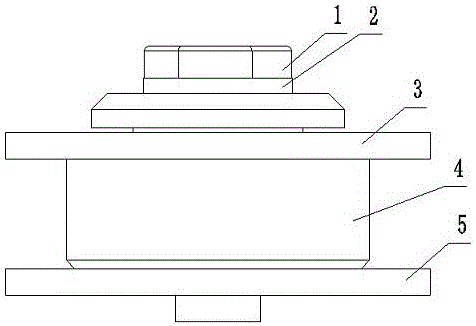

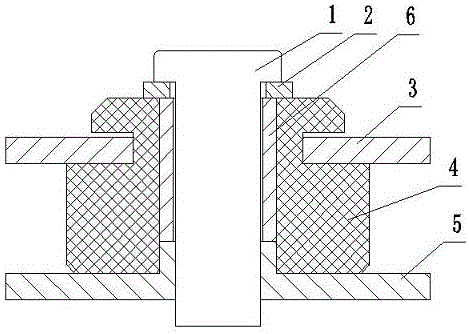

Calibration tooling for automatic calibration system for formation and capacity grading testing power supply

The invention discloses a calibration tooling for an automatic calibration system for a formation and capacity grading testing power supply. The calibration tooling comprises an upper top plate, a lower bottom plate and a side plate frame; a plurality of probes are arranged on the upper top plate and the lower bottom plate; probe points are arranged on the tops of the probes; the probes on the upper top plate and the lower bottom plate are in one-to-one correspondence; the probes are fixed by bolt and nut sets; and bolts are of a hollow structure and used for wrapping the probes. The probes ofthe calibration tooling of the invention are simple in structure and reasonable in design, are compatible with various specifications of test power supplies, and can be combined with the automatic calibration system to sample the current and voltage of the test power supply.

Owner:元山(济南)电子科技有限公司

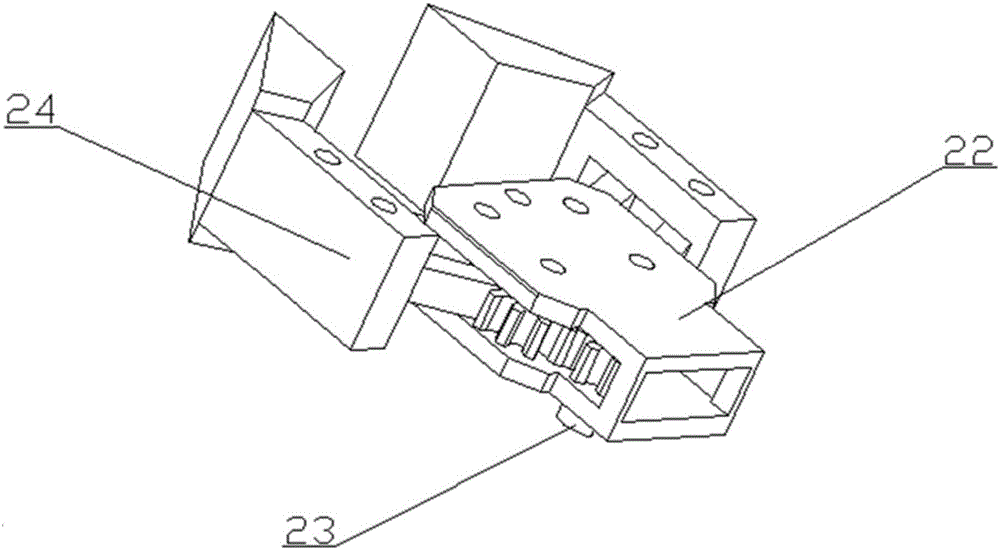

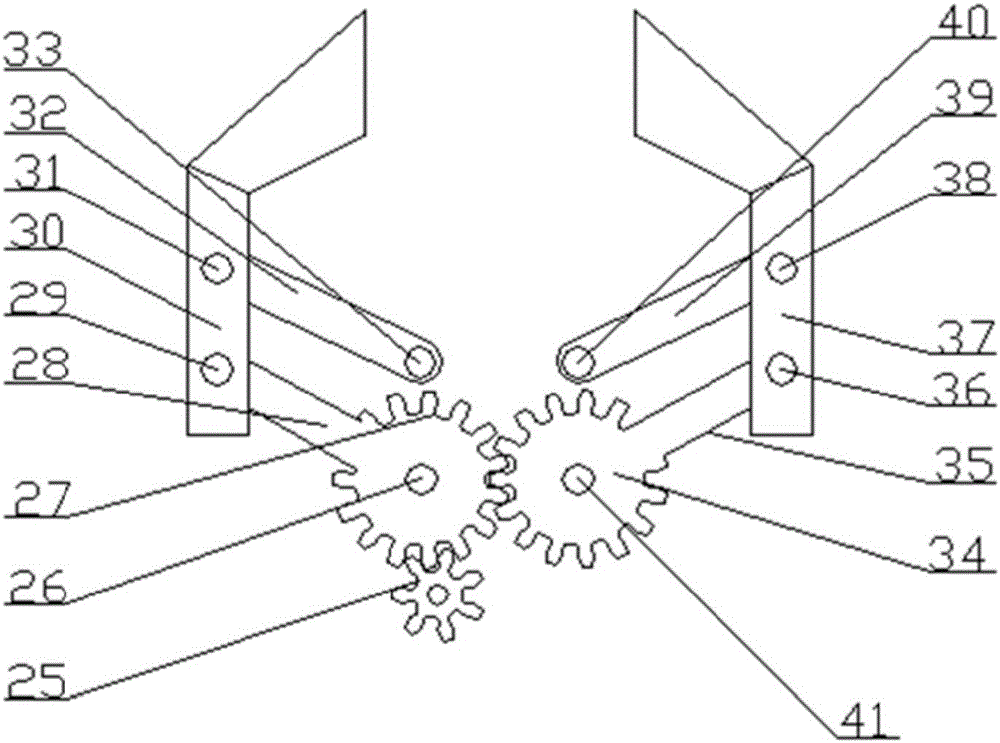

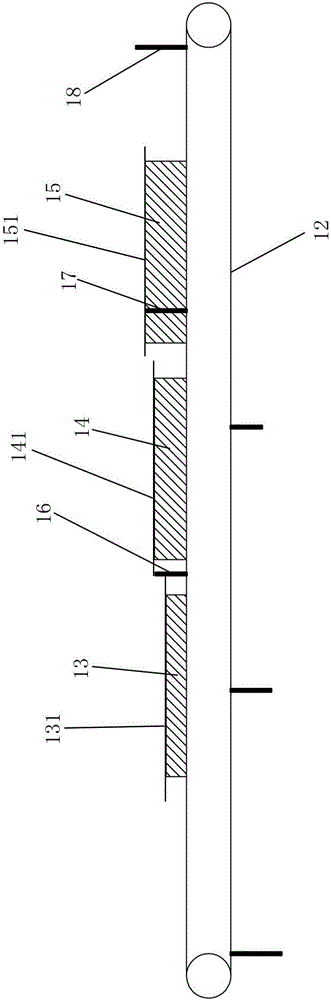

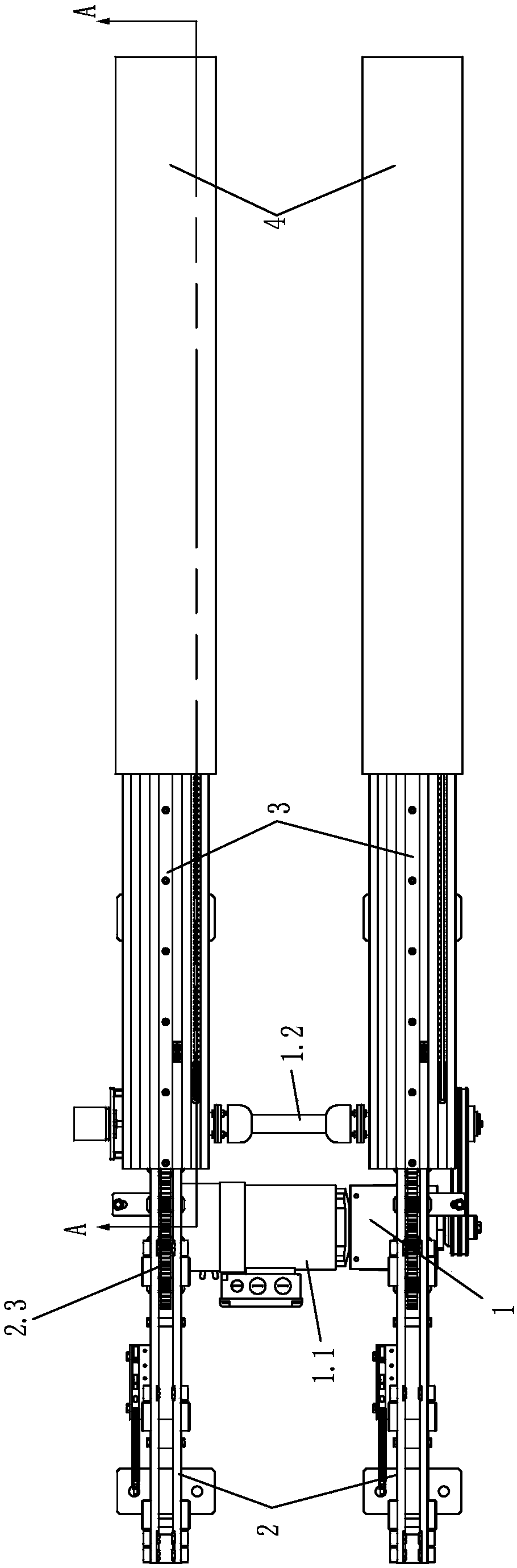

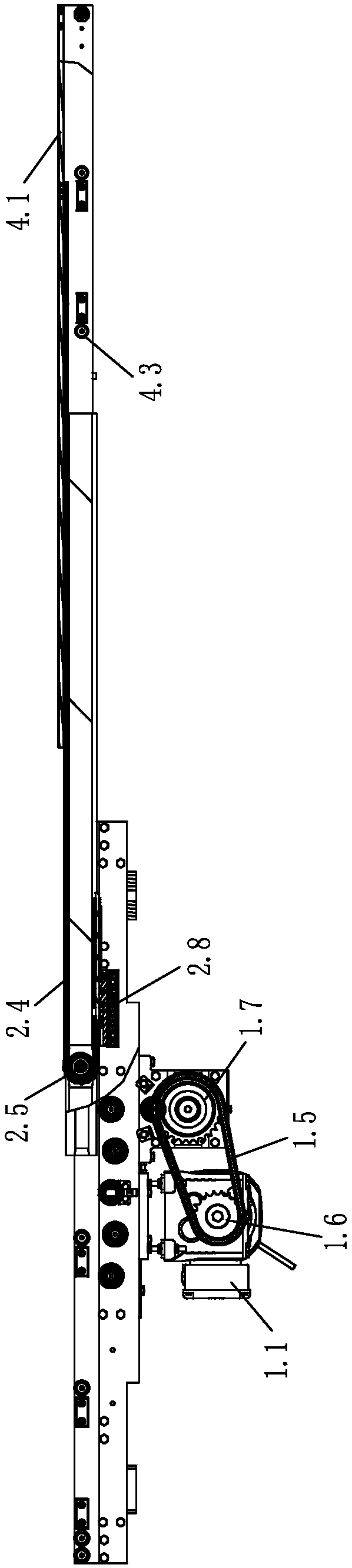

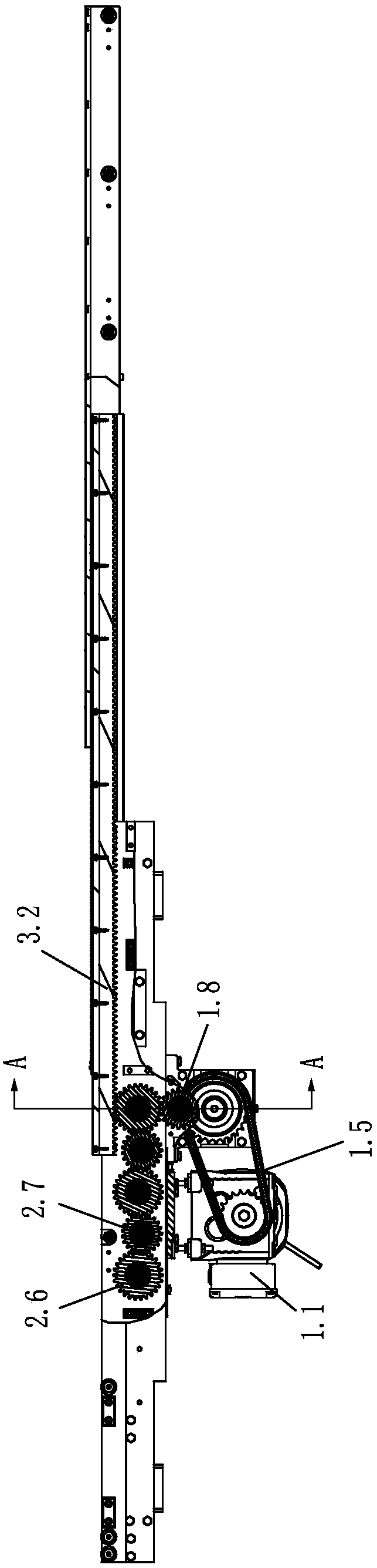

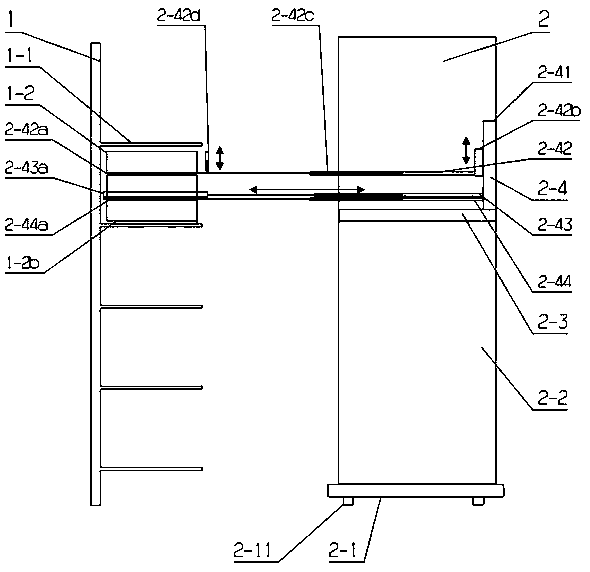

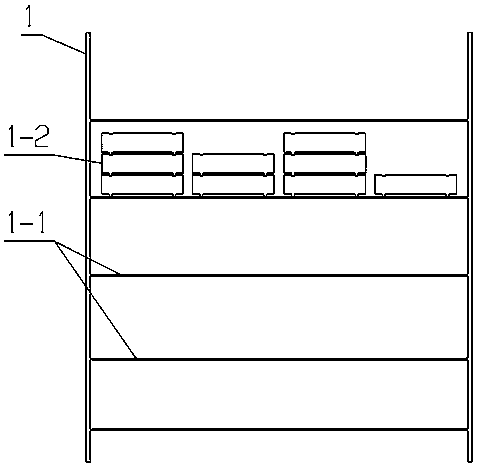

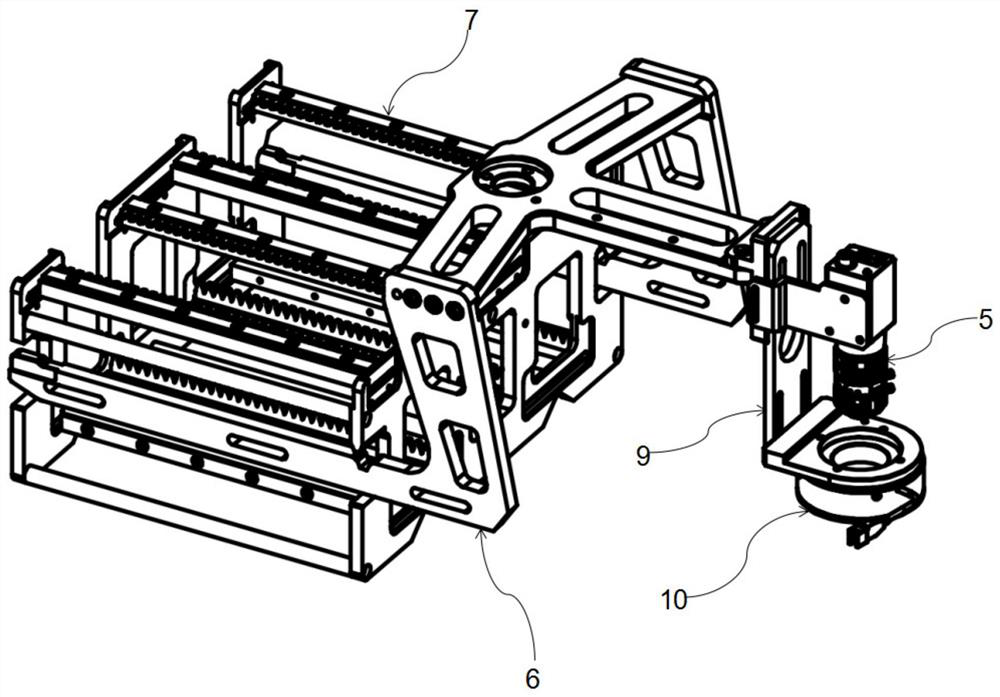

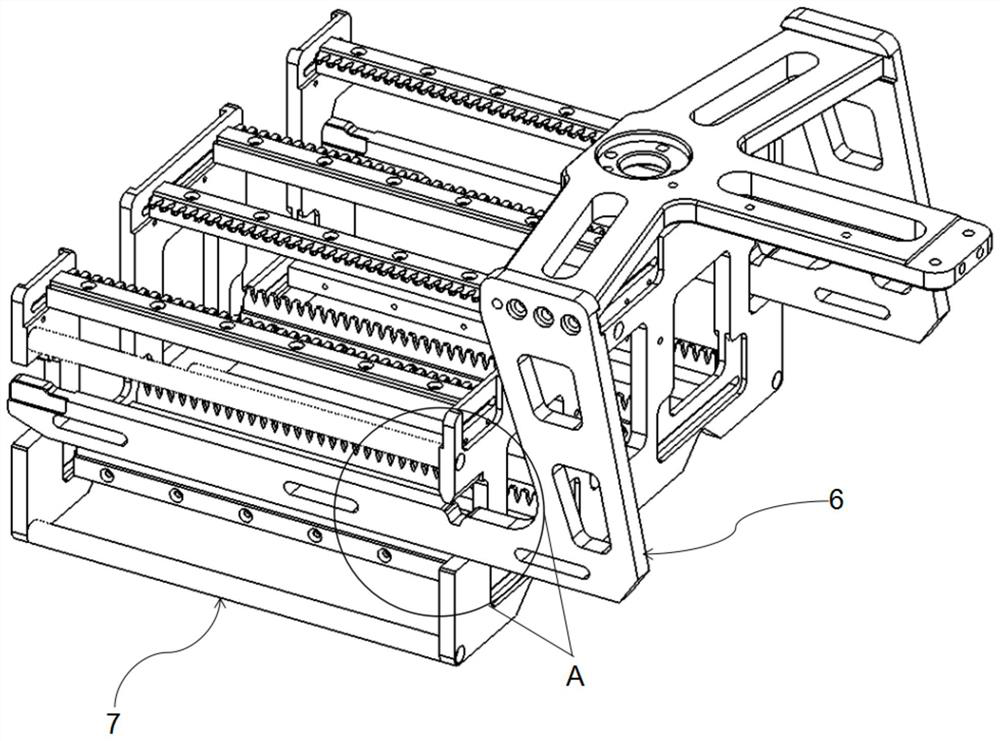

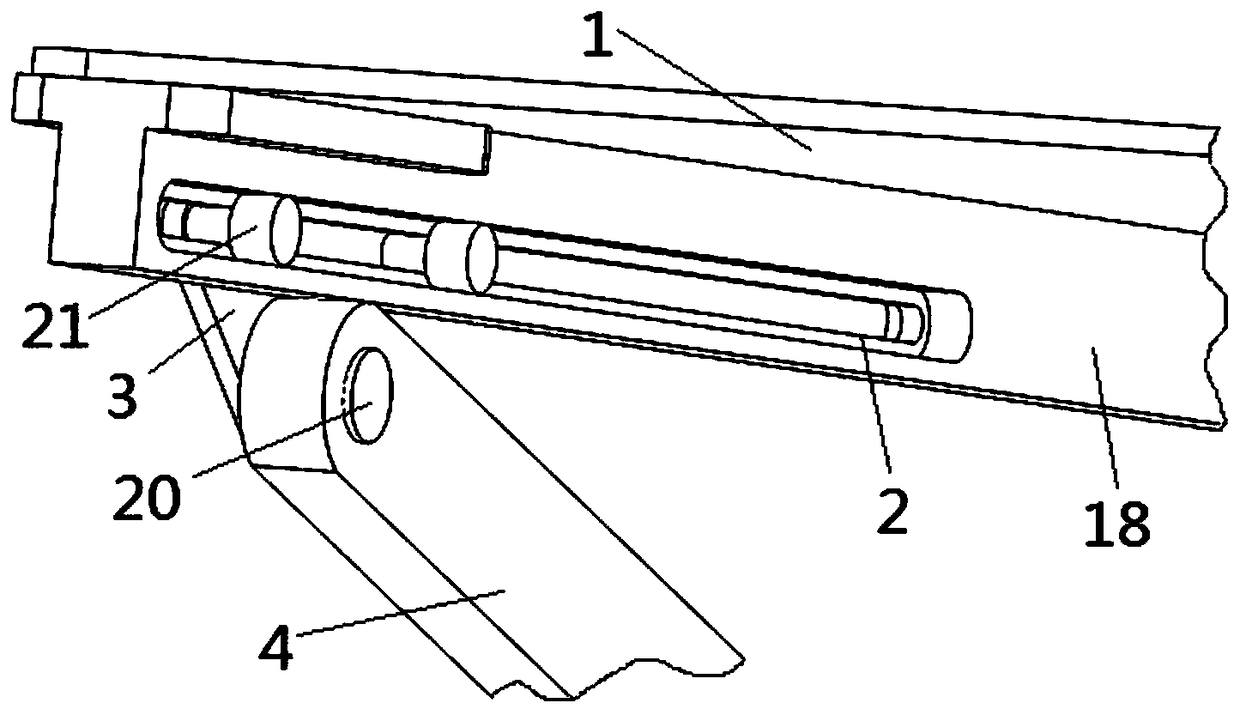

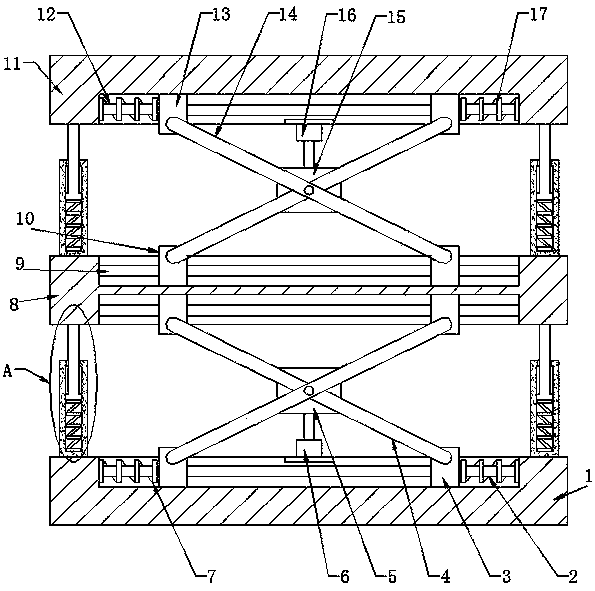

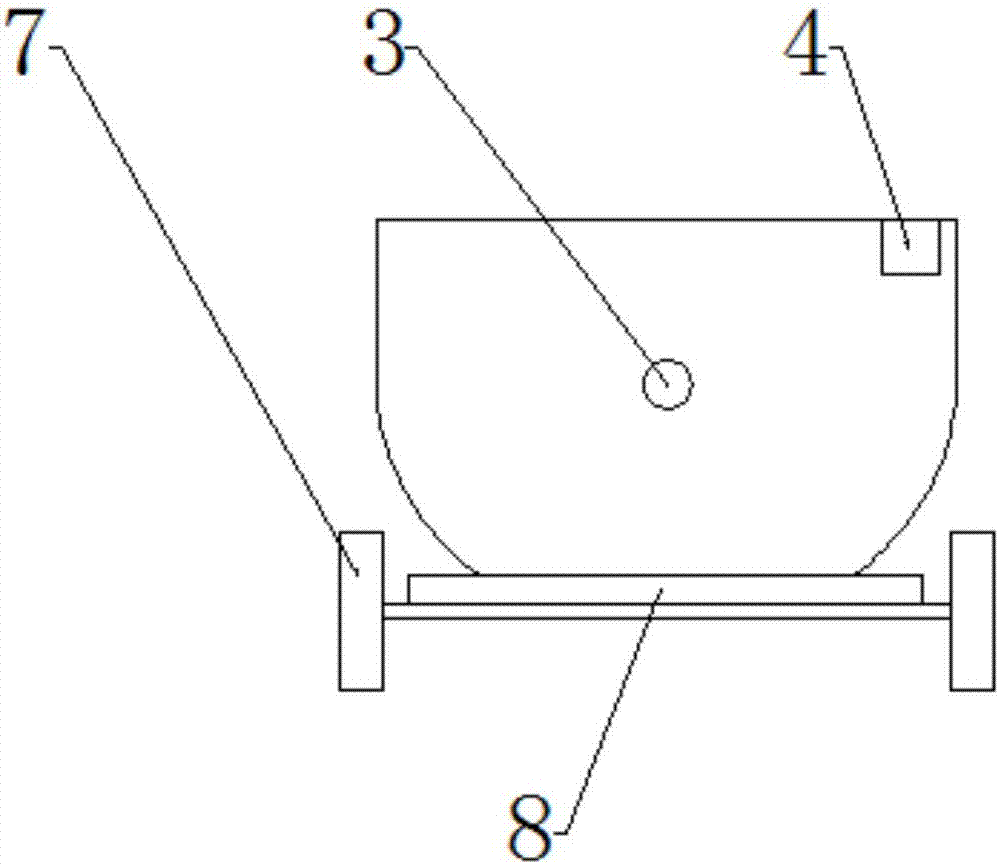

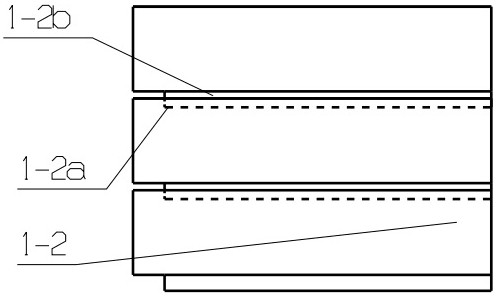

Double-arm large-stroke bidirectional fork device

The invention discloses a double-arm large-stroke bidirectional fork device. The double-arm large-stroke bidirectional fork device comprises a left fork body unit and a right fork body unit. The double-arm large-stroke bidirectional fork device is characterized in that each fork body unit comprises an upper fork body unit, a middle fork body unit and a lower fork body unit; the left fork body unit and the right fork body unit are synchronously driven through a drive unit; the drive unit comprises a motor, a transmission belt, a belt wheel, a drive shaft, a left drive gear and a right drive gear; an output shaft of the motor drives the belt wheel through the transmission belt; the belt wheel is arranged on the drive shaft in a sleeving manner; the left drive gear and the right drive gear are arranged on the drive shaft separately; the left drive gear and the right drive gear are in engagement connection with the transmission gear separately; the transmission gear is engaged with a gear group in the lower fork body unit; and a rack in the middle fork body unit is driven to move by the gear group. According to the double-arm large-stroke bidirectional fork device disclosed by the invention, the drive unit drives the gear group by virtue of the transmission gear, the middle fork body and the upper fork body are driven to synchronously move, and a rotation direction of the gears is changed to control a movement direction of the fork bodies, so that bidirectionally free cargo carrying is realized.

Owner:太仓爱致递机器人自动化有限公司

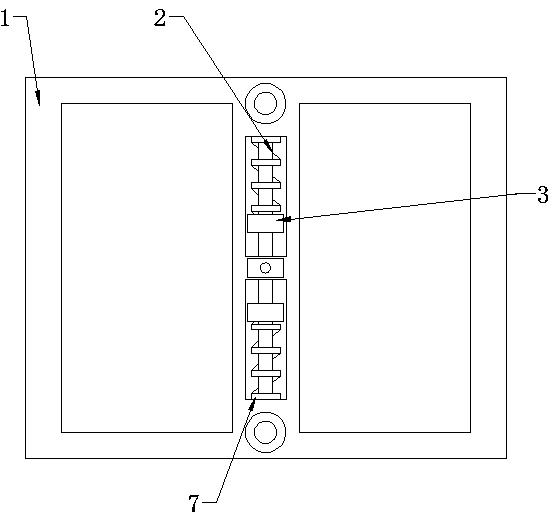

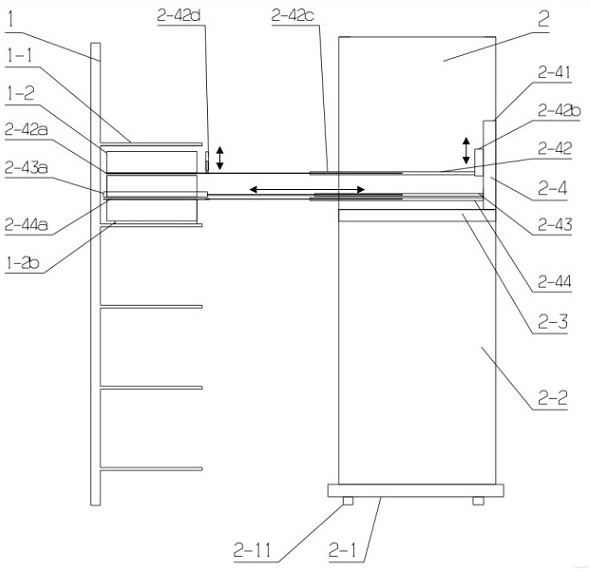

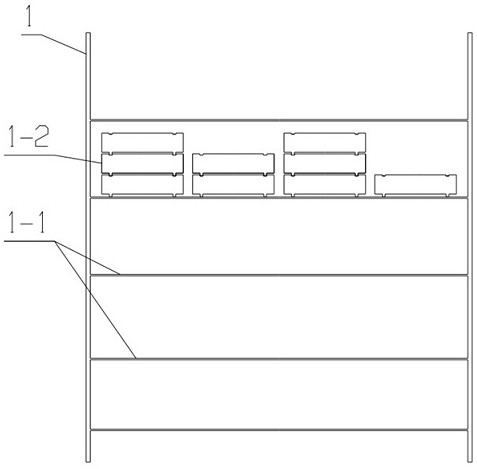

Automatic shelf carrying system and carrying method thereof

The invention provides an automatic shelf carrying system that comprises a storage rack, turnover boxes, carrying trolleys and a cloud platform;multiple layers of turnover boxes are stored on each layer of shelf. Clamping grooves are formed in the tops of the turnover boxes, clamping columns are arranged at the bottoms of the turnover boxes, and the clamping grooves can be matched with bottom clamping columns of another turnover box and allow the clamping columns to be inserted. The carrying trolley comprises a moving chassis, a lifting unit, a picking unit and a control unit; the lifting unitis integrally arranged on the movable chassis. The whole picking unit can vertically move along with the lifting unit; an upper supporting part, a clamping part and a lower limiting part are furtherarranged from top to bottom on the picking unit. According to the carrying method of the automatic shelf carrying system, multiple layers of turnover boxes or containers can be placed on each layer ofshelf, so that gaps between the tops of the turnover boxes or containers on each layer of shelf and the bottom of the previous layer of shelf are reduced, and the storage space is saved; and throughthe upper supporting part and the lower limiting part of the picking unit, it is guaranteed that the carrying trolleys can execute carrying tasks separately without mutual interference.

Owner:GUANGDONG SUNLI IND EQUIP CO LTD

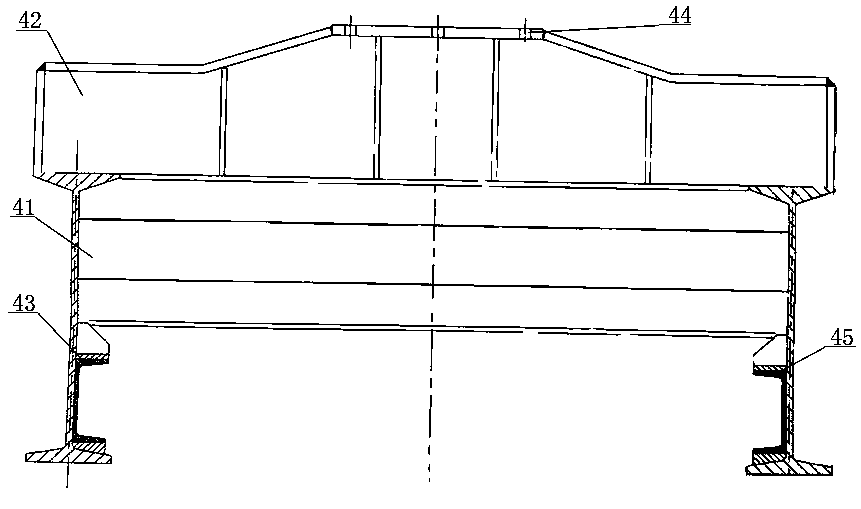

Movable combined clamp tongs

PendingCN108946459AExtended service lifeImprove handling efficiencyLoad-engaging elementsElectrical controlEngineering

The invention discloses a pair of movable combined clamp tongs. The pair of movable combined clamp tongs comprise a hanging beam device. Connection seats I used for being connected with a guide deviceand connection seats II used for being connected with a lifting mechanism are symmetrically and fixedly installed on the hanging beam device. At least three movable gravity clamp tongs are evenly arranged on the lower side of the hanging beam device. An electrical control box is installed on the upper side of the middle of the hanging beam device. The two sides of the electrical control box are both provided with drive devices. The drive devices drive the movable gravity clamp tongs to horizontally move on the hanging beam device. The connection seats II are located between the connection seats I and the drive devices. Compared with the prior art, the pair of movable combined clamp tongs meets the demand for carrying materials of different specifications and dimensions, replacement of clamp tongs is not needed, the service life is long, and the carrying efficiency is high; the pair of movable combined clamping tongs can achieve that the multiple movable gravity clamp tongs horizontally move on the hanging beam device and achieves batch carrying of the materials, and the pair of movable combined clamp tongs can also control the single pair of movable gravity clamp tongs to conductclamping, moving and other operation one by one, and the requirement for moving the single pair of clamp tongs of a user can be met.

Owner:HENAN WEIHUA HEAVY MACHINE

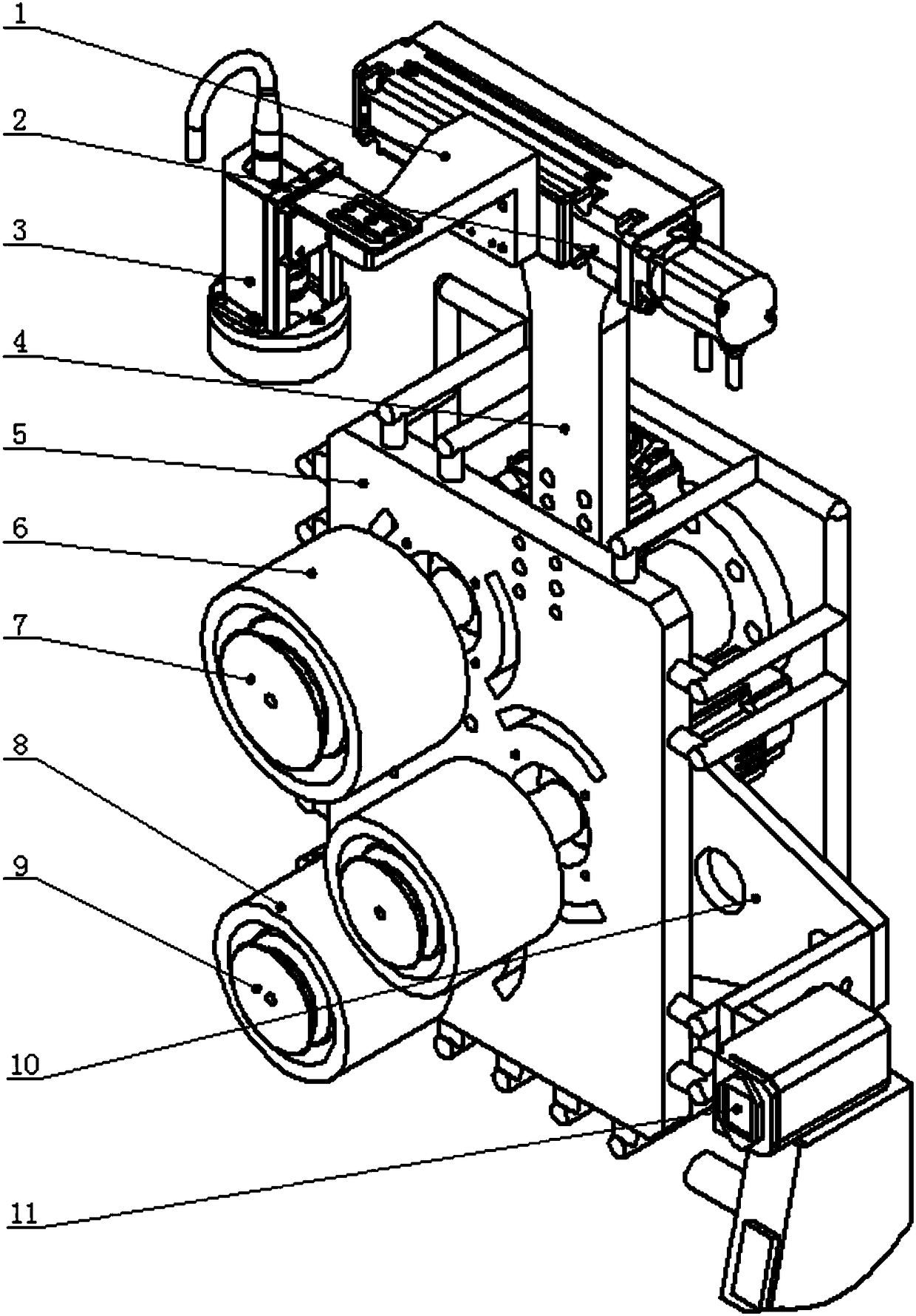

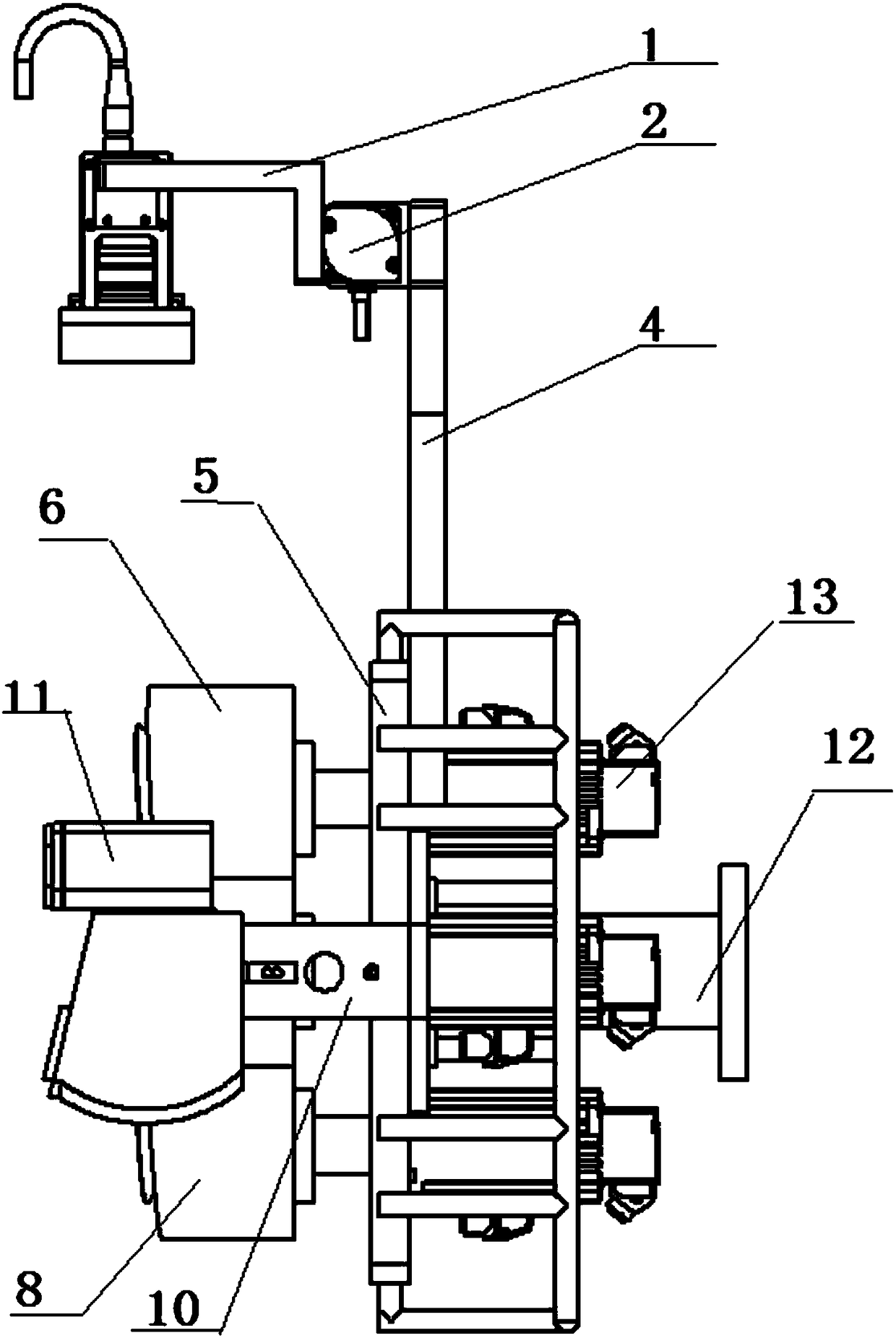

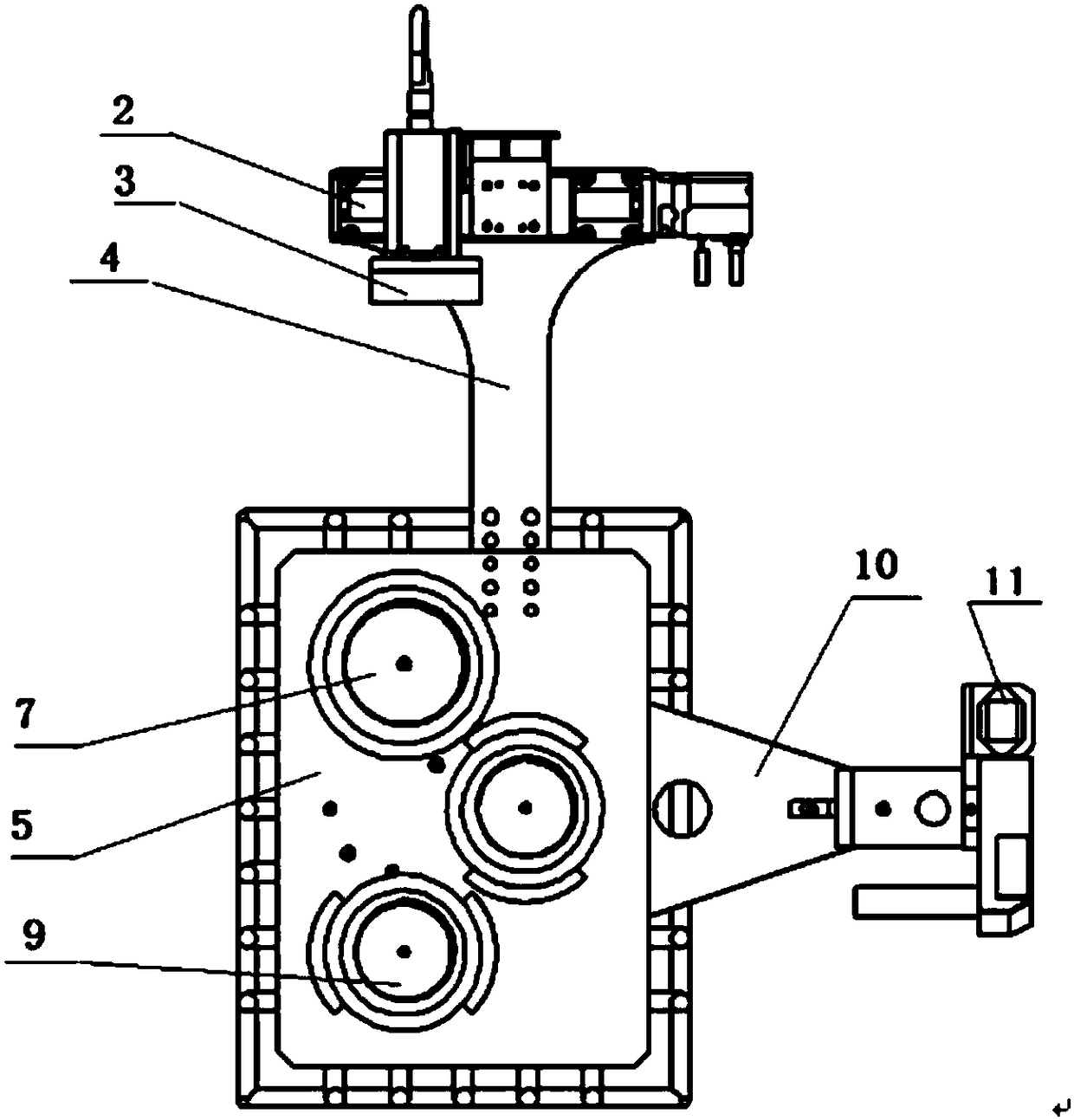

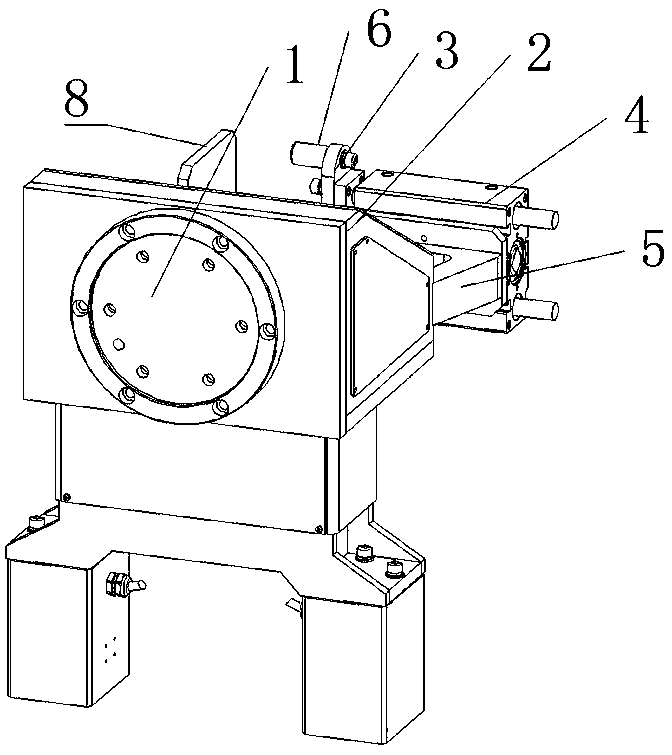

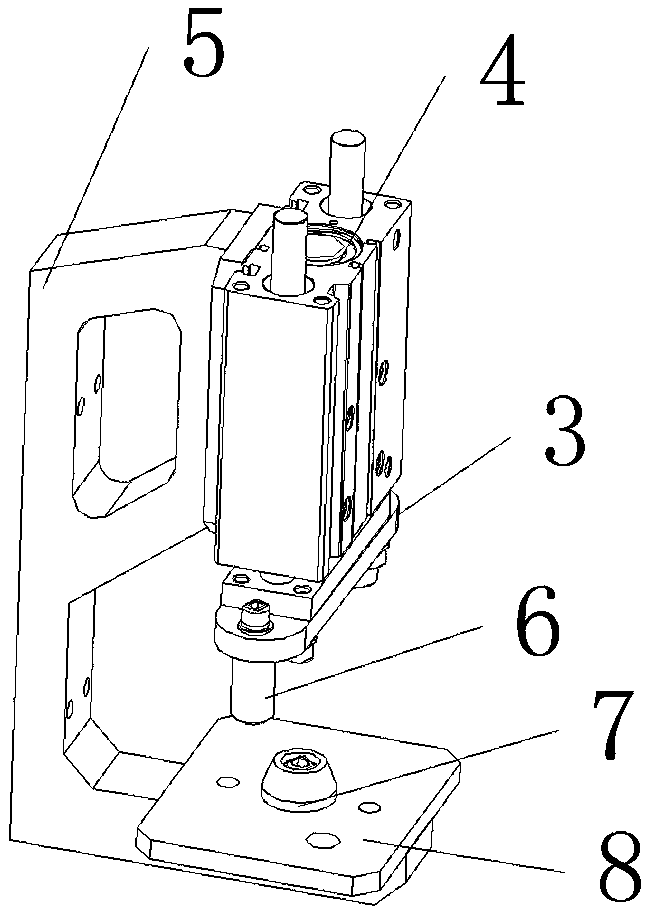

Robot servo gripper for double-machine cooperative carrying of vehicle bumpers

PendingCN108568835AReduce jitterLow costProgramme-controlled manipulatorGripping headsProduction lineMotor drive

The invention discloses a robot servo gripper for double-machine cooperative carrying of vehicle bumpers. At least one robot servo gripper is arranged on a support; each robot servo gripper comprisesa fixing device, a visual device and an adsorption device, wherein a connecting plate is fixedly mounted above a substrate, the visual device comprises a 2D visual camera and a 3D visual camera, the 3D visual camera is mounted above the support and used for shooting and recognizing feature points of bumper suction surfaces, the adsorption device is used for sucking the bumpers, end parts of a large profile sleeve and small profile sleeves are inclined planes, servo motors drive the large profile sleeve and the small profile sleeves to rotate respectively, and thus, workpieces after being sucked by suckers are tightly attached to end surfaces of the profile sleeves. The gripper is applied in order to increase the degree of automation of vehicle bumper production, the carrying demand of thebumpers of various vehicle models can be met by a pair of robot grippers, cost of a production enterprise is reduced, and flexibility of a production line is improved.

Owner:SHANGHAI FANUC ROBOTICS

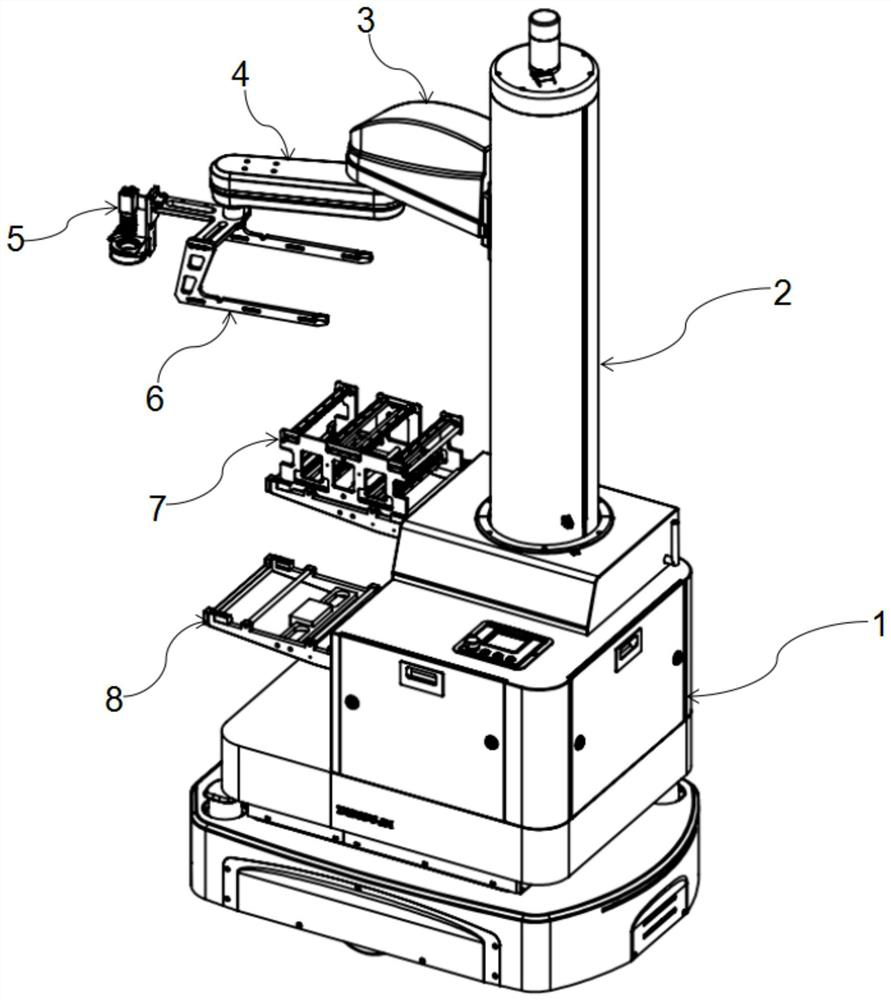

Intelligent compound robot for wafer box transferring

PendingCN112093466AFor precise pick and placeReduced secondary warp damageConveyorsConveyor partsEngineeringHigh load

The invention discloses an intelligent compound robot for wafer box transferring, and belongs to the technical field of automatic robots. The robot comprises an AGV transfer vehicle, a mechanical arm,an inserting frame mechanism and a visual positioning device. The mechanical arm is arranged on the AGV transfer vehicle; the inserting frame mechanism is installed on the mechanical arm, the inserting frame mechanism is driven by the mechanical arm to do axial movement and 360-degree steering movement synchronously or independently, and the axial movement comprises resultant displacement in theX direction, the Y direction and the Z direction in a single direction or in multiple axial directions at the same time; and the visual positioning device arranged on the inserting frame mechanism compensates the moving error of the AGV transfer vehicle so as to achieve the purpose of high-precision carrying of products under the conditions of high load and large operation radius.

Owner:成都拓米电子装备制造有限公司

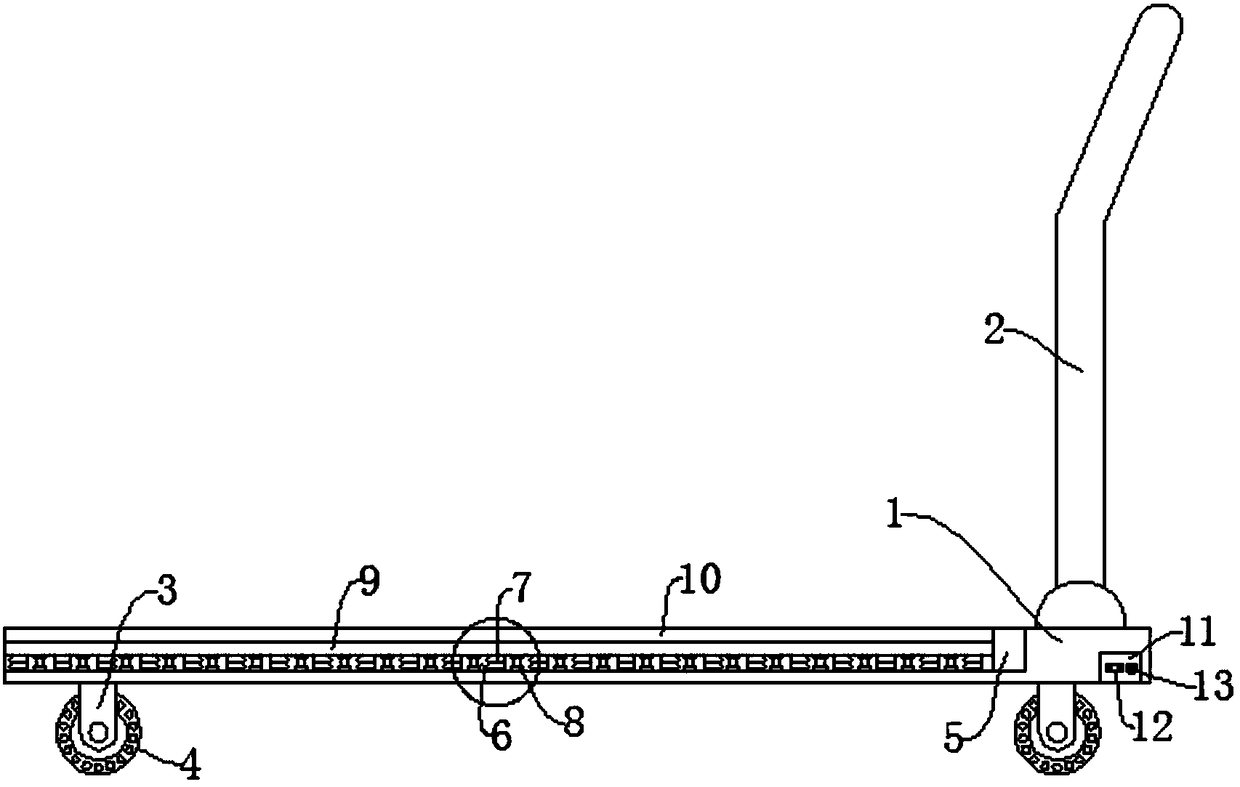

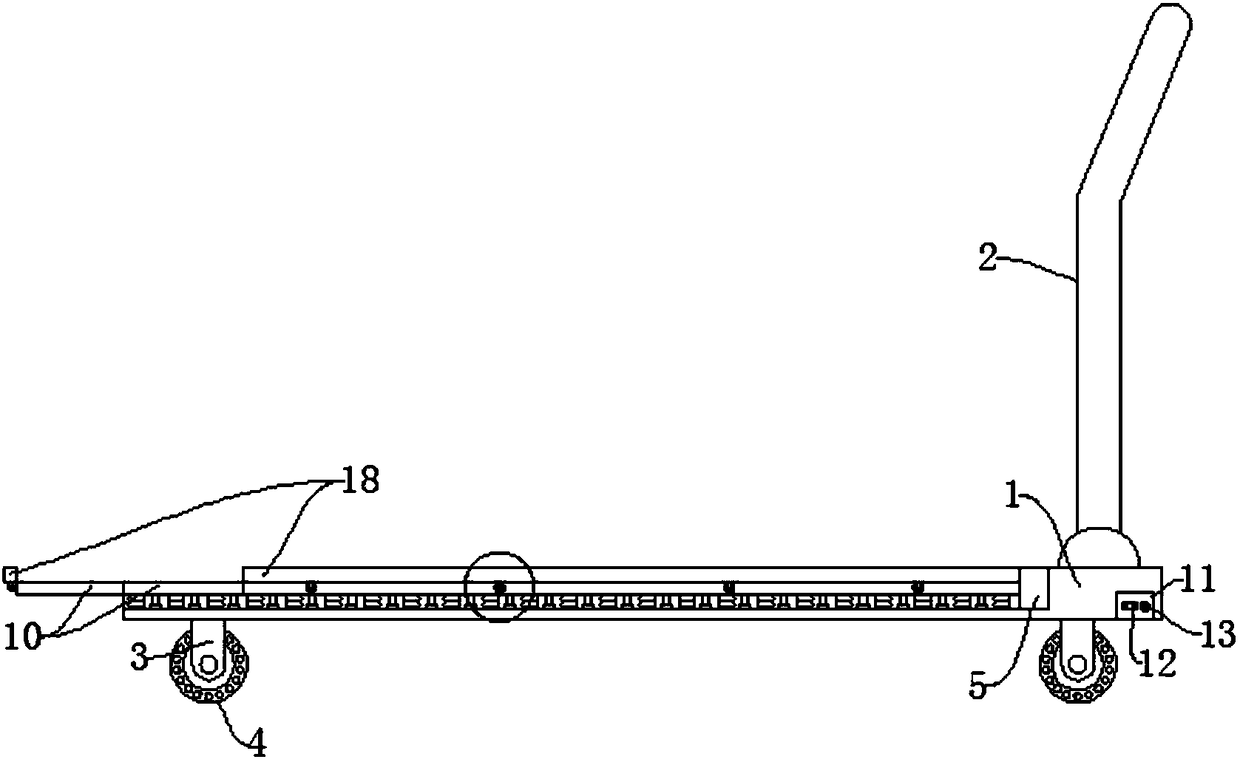

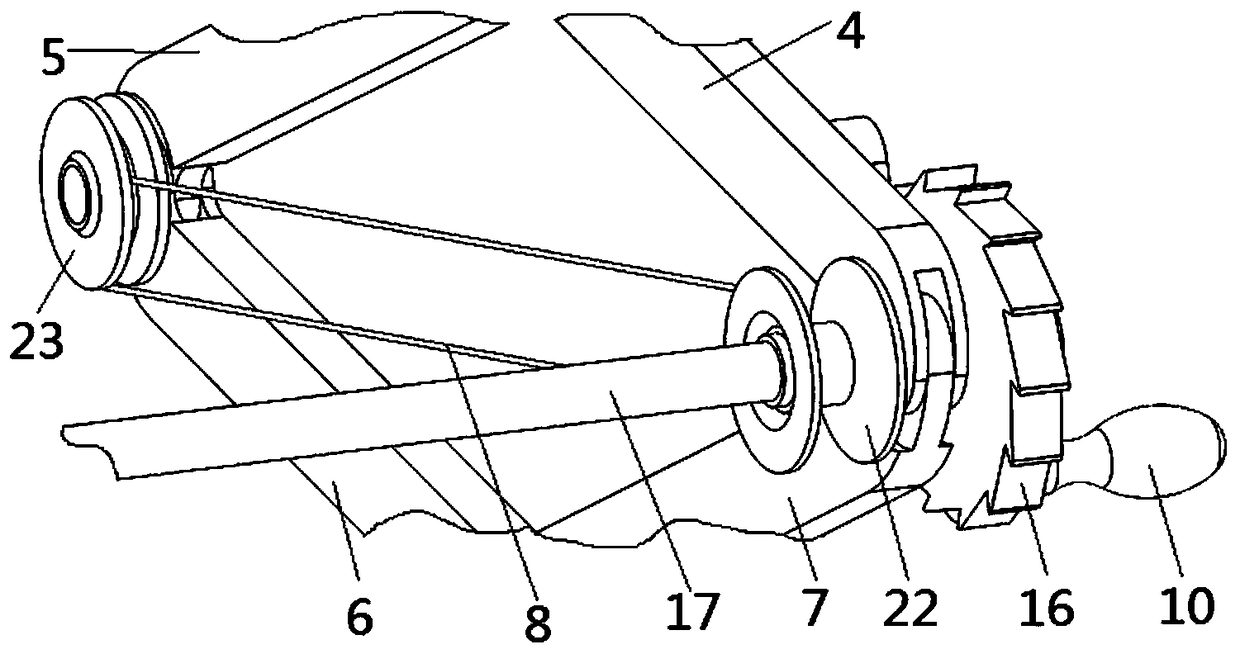

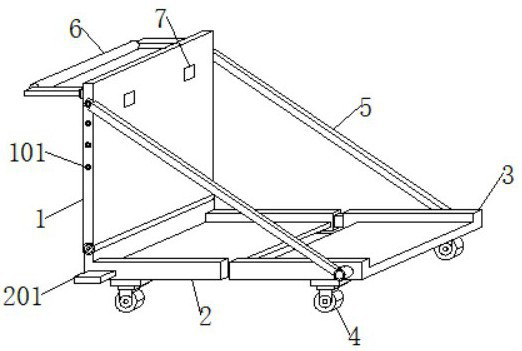

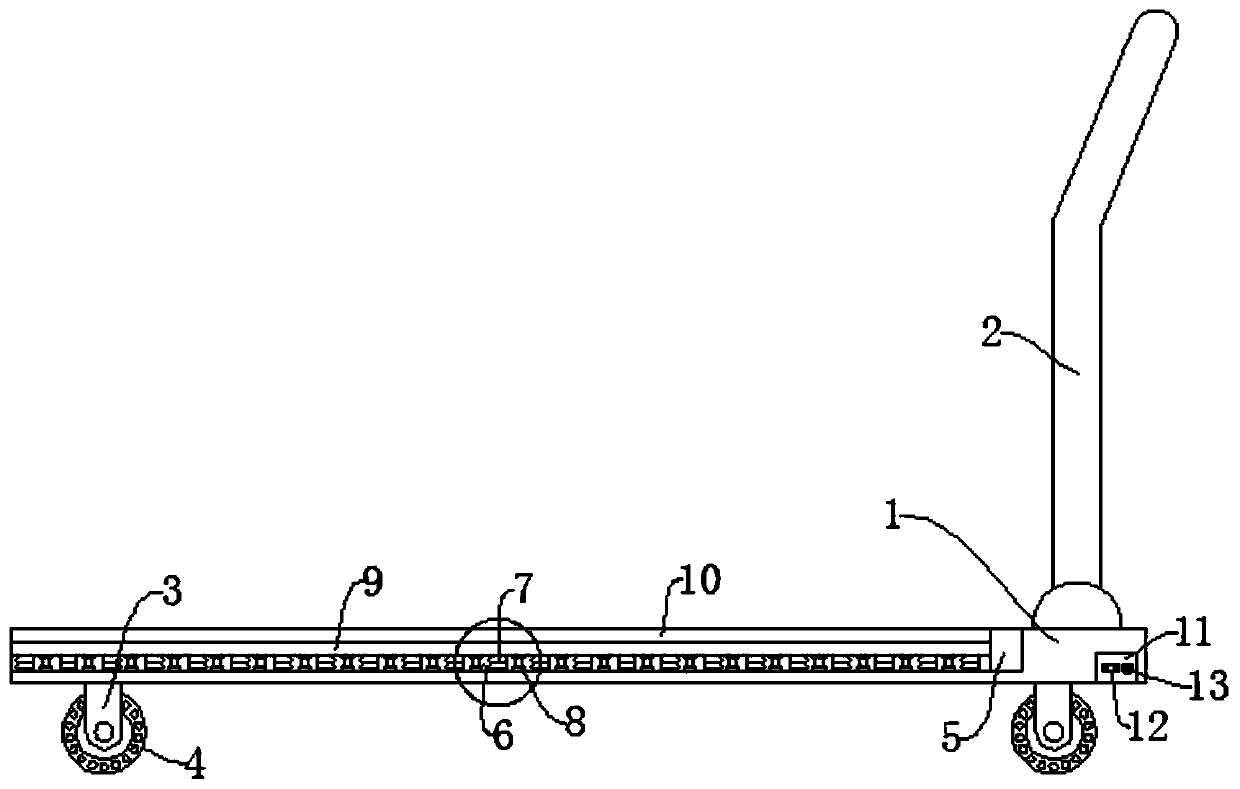

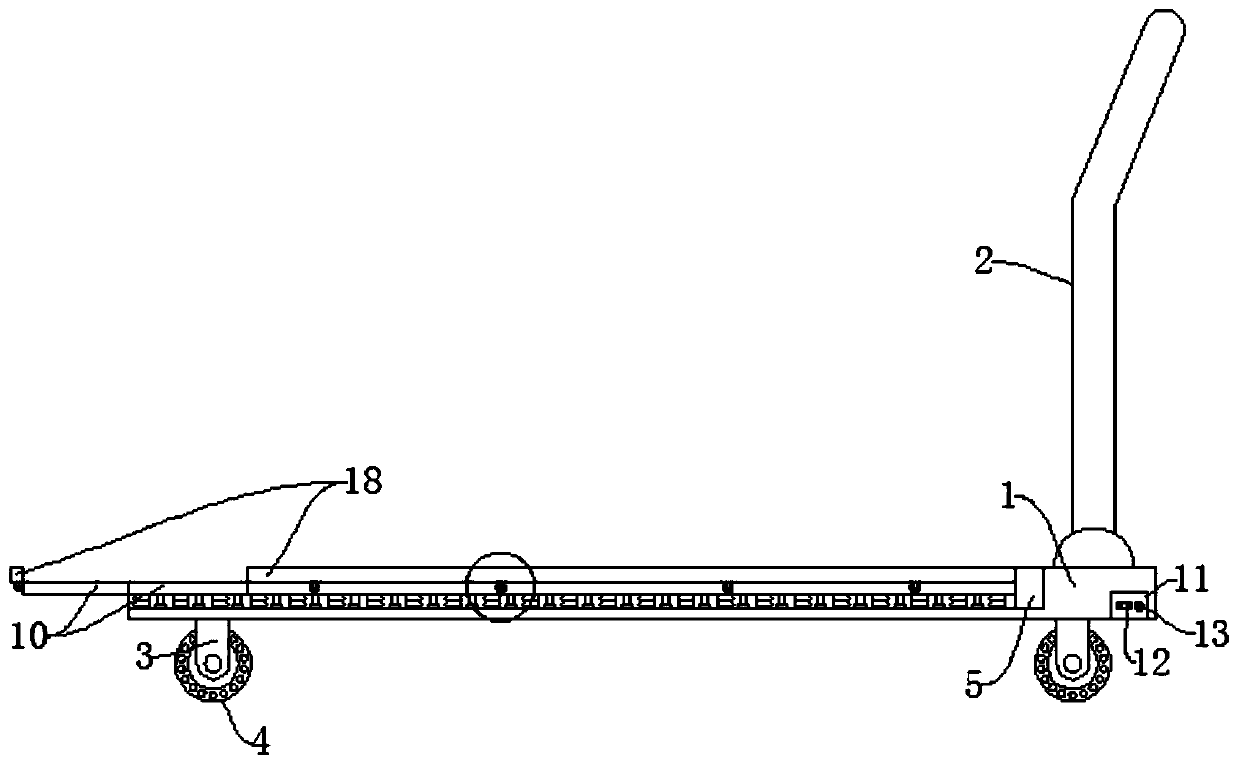

Foldable flat panel damping cart

ActiveCN108248655AEasy to carry and transportMeet the handling needsHand carts with multiple axesHand cart accessoriesVehicle frameAir spring

The invention discloses a foldable flat panel damping cart, which comprises a cart bottom plate, a push rod frame hinged at the edge of one end of the upper surface of the cart bottom plate, and frames installed at front and back ends of the lower surface of the cart bottom plate in a rolling manner; wheels are arranged on the frames, and the upper surface of the cart bottom plate is provided withan installing slot, and the upper surface of the installing slot is provided with multiple air springs and a hydraulic buffer; upper surfaces of the air springs and the hydraulic buffer are providedwith placing plates, front and back ends and one side of the placing plates are hinged with folding plates; one side of each folding plate far from the placing plates is hinged with a baffle. The foldable flat panel damping cart has the beneficial effects of freely adjusting the cart body of the flat panel cart, conveniently transporting and conveying large-volume articles; meanwhile, the foldableflat panel damping cart is good in damping performance and good in practicability, and can effectively meet the conveying demand of fragile articles and enlarge the application range of the flat panel cart.

Owner:浙江年代建设工程有限公司

Working method of mechanical hands for carrying tires

ActiveCN110921302AImprove stability and securityIncrease the scope of applicationControl devices for conveyorsEngineeringStructural engineering

The invention discloses a working method of mechanical hands for carrying tires. The working method comprises the steps that the size of one tire is detected by a detection device; a controller receives data and then adjusts grabbing hand rods to be located at the appropriate opening and closing angles according to the received data and the result; then one mechanical hand grabs the tire, namely,a supporting rod is inserted into the middle of the tire, and the corresponding grabbing hand rods are clamped on the outer side of the tire; after the tire is placed on the mechanical hand, the tireis limited; and after the tire on one side is well located, a suspension frame is rotated. According to the working method of the mechanical hands for carrying the tires, the tires are carried by themechanical hands, and therefore the problem that the workload of the current manual carrying operation is high is well solved. Meanwhile, the mechanical hands are symmetrically arranged, and thereforethe multiple tires can be simultaneously carried, the balance of the whole mechanical hands can also be kept, each mechanical hand is prevented from toppling towards one side, and the stability and the safety of the carrying operation of the mechanical hands are greatly improved.

Owner:徐州欧普莱斯工业机械有限公司

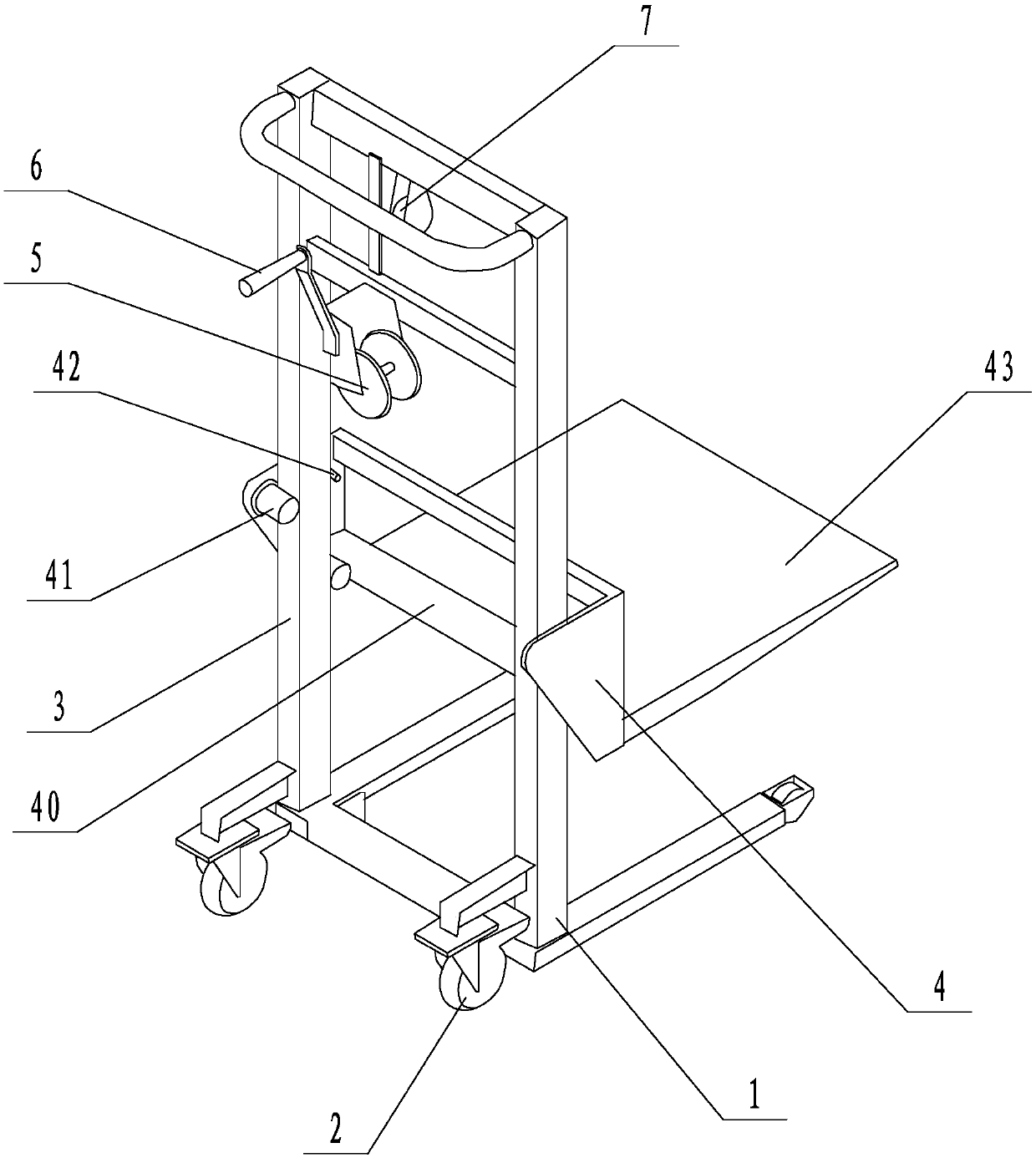

Portable forklift

PendingCN107857213ASmall sizeMeet the handling needsLifting devicesElectric machineryManual handling

The invention discloses a portable forklift. The portable forklift comprises a frame; trundles are mounted at the bottom of the frame; vertical guide rails are arranged on two sides of the upper partof the frame; a bracket is slidingly mounted on the guide rails; a lifting device is mounted at the top of the frame; the lifting device comprises a winding disc and a hand wheel; the hand wheel is connected with the winding disc; the winding disc is wound with a steel wire rope; and the winding disc is connected with the tail end of the bracket by the steel wire rope bypassing through a pulley atthe top of the frame. Through the arrangement, the portable forklift is simpler in structure, and can realize a smaller size to achieve carrying; and the portable forklift adopts the manual-operatedsimple lifting device without installing complicated hydraulic mechanism or motor mechanism, so that the cost is low, the carrying demands of lighter objects can be met, and the use convenience is improved.

Owner:GUANGDONG AKODI NEW MATERIAL TECH CO LTD

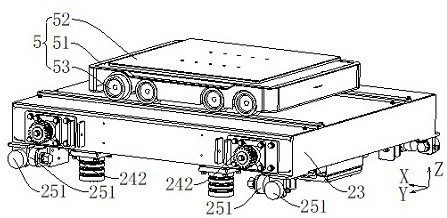

A pick-and-place device and storage system

The invention provides a pick-and-place device and a storage system. The pick-and-place device includes a carrying device and a sub-shuttle. The carrying device includes a carrying frame, a four-way shuttle, a carrying seat, a drive assembly and a guide assembly; the bottom of the carrying frame is connected to the four-way shuttle; the carrying frame includes at least four carrying Each bearing column is arranged at intervals and together forms accommodating space for the bearing seat; a guide assembly is arranged between the bearing seat and the bearing column, and the bearing seat is used to realize the support for the sub-shuttle car, and the sub-shuttle car is used for Lift the cargo unit from below and transfer the cargo unit inside and outside the bearing seat; the drive assembly includes a second rack, a second gear, and a driving member that is drivingly connected to the second gear, and at least one load column is provided with a second rack, The bearing seat is provided with a second gear which meshes correspondingly with the second rack. The pick-and-place device has compact structure, four-way transfer capability, strong carrying capacity, and high motion stability, which can reduce costs and improve operating efficiency.

Owner:SANY AUTOMOBILE MFG CO LTD

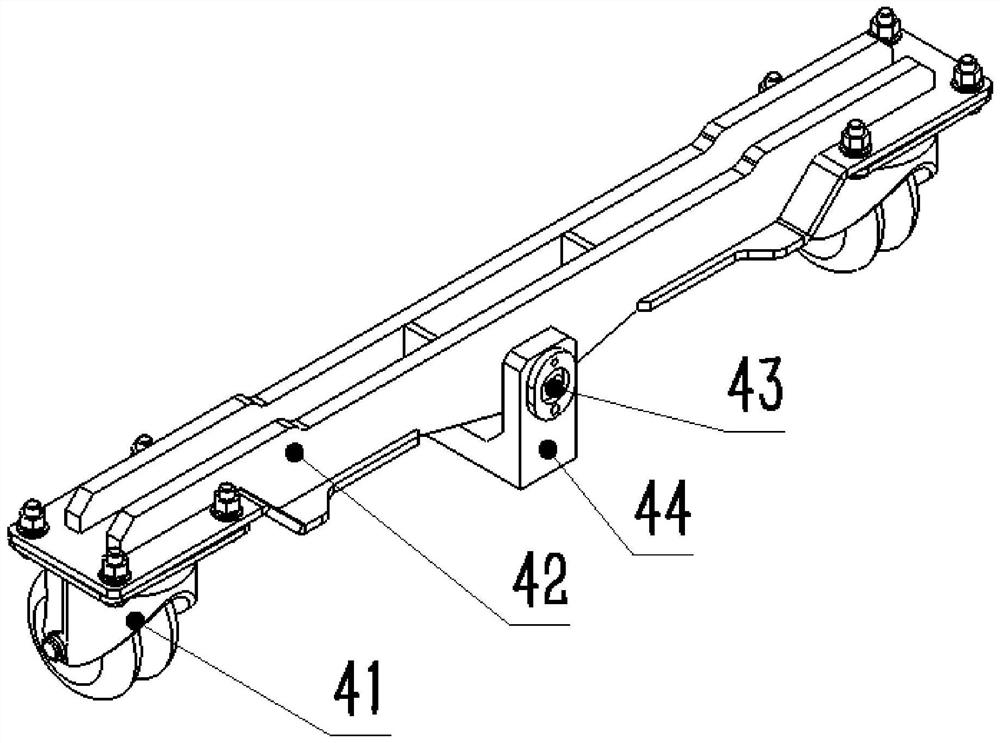

Carrying trolley

InactiveCN107673273AWith shock absorption functionReduce volumeElectric propulsion mountingLifting devicesEngineeringMechanical engineering

Owner:SHANGHAI ATOVO ROBOTICS CO LTD

Flexible gripper device for robot

PendingCN109465846AGuaranteed reliabilityMeet the handling needsGripping headsConveyor partsEngineeringMagnet

A flexible gripper device for a robot is disclosed and is characterized by including a robot connecting plate, a U-shaped mounting block, a mechanical gripper mechanism and an electric permanent magnet gripper mechanism, wherein the U-shaped mounting block is arranged along the left and right horizontal direction, the robot connecting plate is vertically fixed on the front side surface of the U-shaped mounting block, the mechanical gripper mechanism is clamped on the U-shaped mounting block, and the upper end of the electric permanent magnet gripper mechanism is connected with the lower side surface of the U-shaped mounting block. To sum up, the invention has the advantages of simple structure, convenient use and high reliability for grasping the workpiece.

Owner:郑州科慧科技股份有限公司

Production equipment and production method of energy-saving environment-friendly building board

PendingCN114055903AReduces the possibility of getting out of the vacuum hoistImprove firmnessLaminationLamination apparatusSolid woodArchitectural engineering

The invention relates to production equipment and a production method of an energy-saving environment-friendly building board, belonging to the field of building board production. The production equipment of the energy-saving environment-friendly building board comprises a crane, wherein the crane comprises a hanging plate and a mounting frame fixed to the bottom of the hanging plate; the mounting frame is provided with a supporting mechanism used for providing support for the board; the supporting mechanism comprises a supporting arm hinged to the end of the mounting frame and an electromagnet fixed to the bottom face of the mounting frame; and a magnetic attraction ring used for being attracted to the electromagnet is fixed to the bottom face of the supporting arm. The production method of the energy-saving environment-friendly building board comprises the following steps: paving melamine impregnated decorative paper in a hot pressing device in advance, and paving the melamine impregnated decorative paper on the top surface and the bottom surface of a multi-layer board; and under the condition of 60-80 DEG C, subjecting the multi-layer board and the melamine-impregnated decorative paper on the upper surface and the lower surface of the multi-layer board to hot pressing forming so as to obtain a melamine solid wood multi-layer board. The production equipment and the production method provided by the invention have the effect of improving the connecting capacity of the crane and the board.

Owner:合肥轩赢木业有限公司

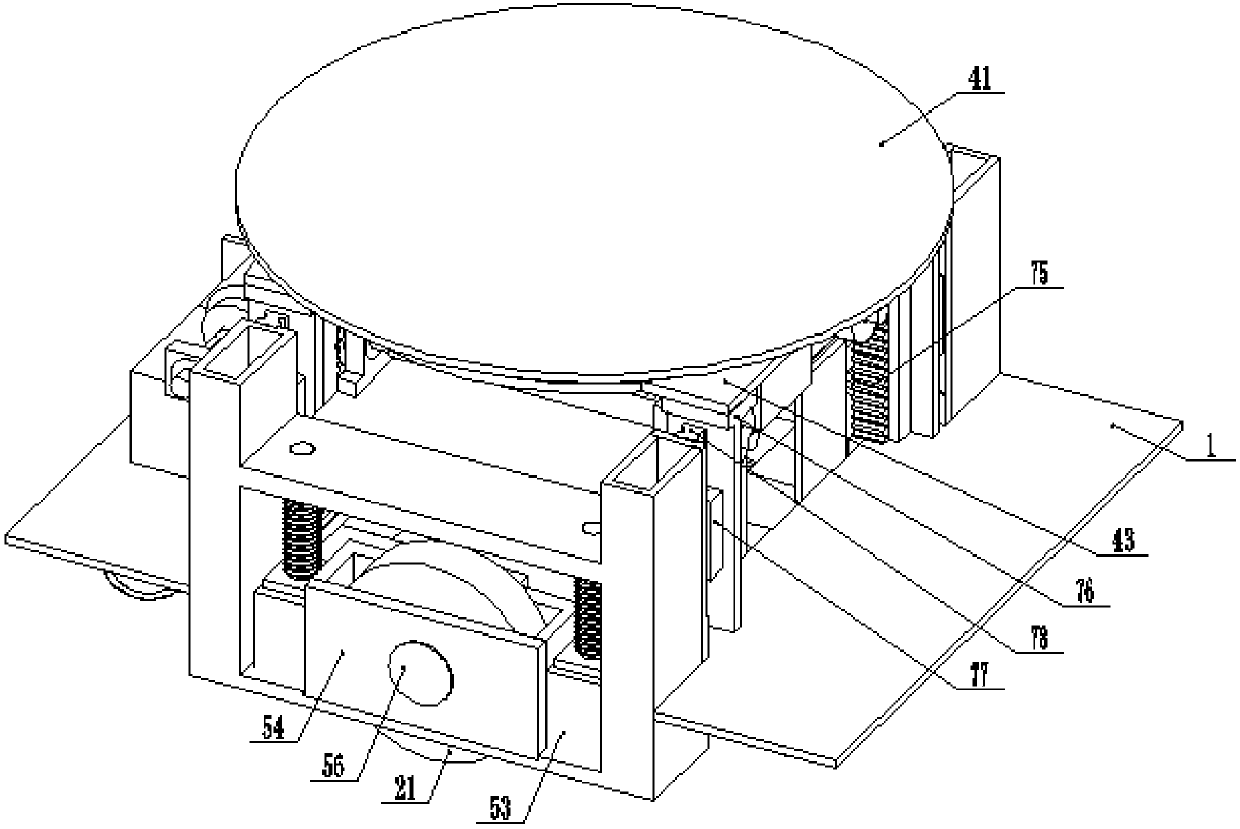

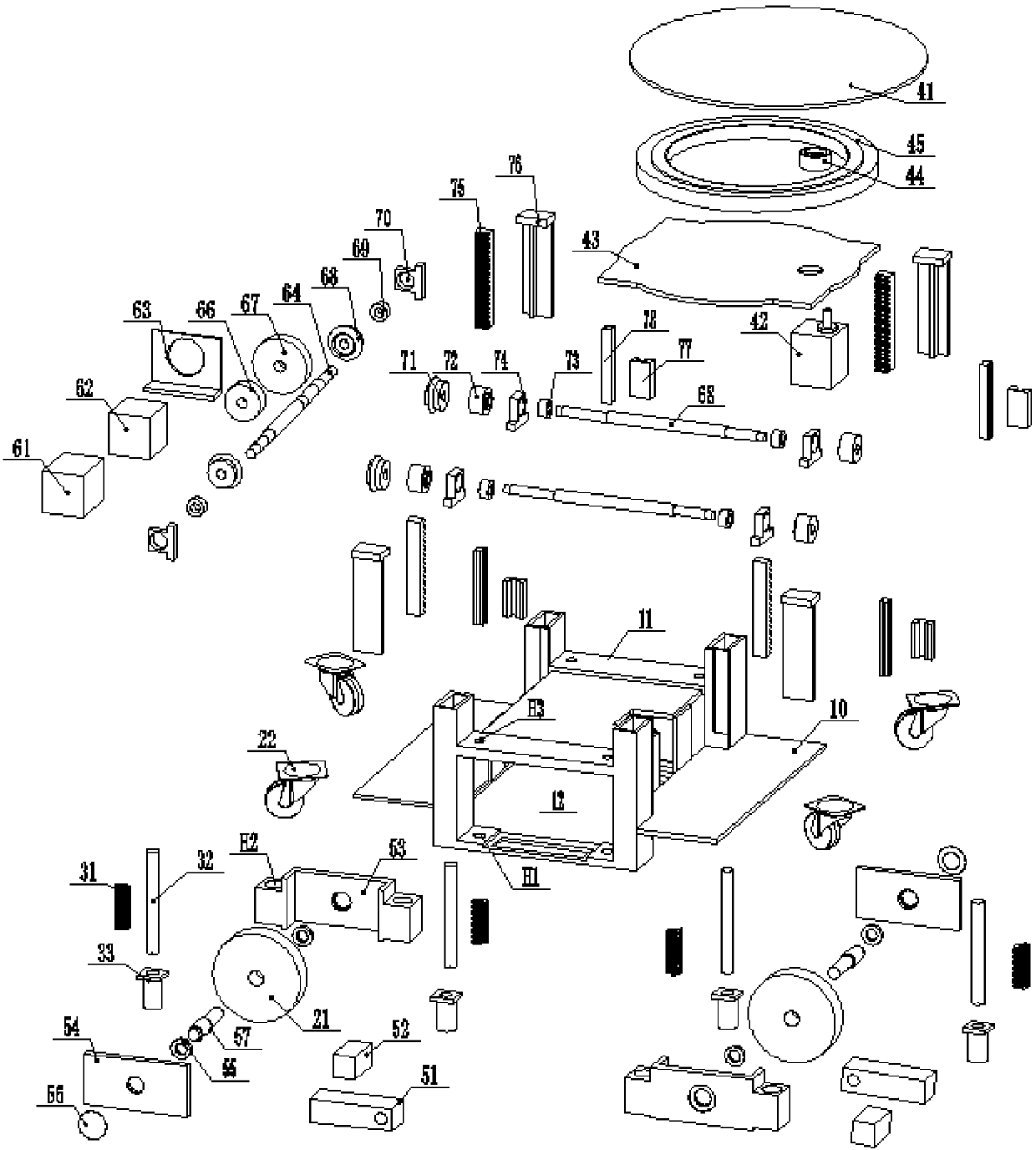

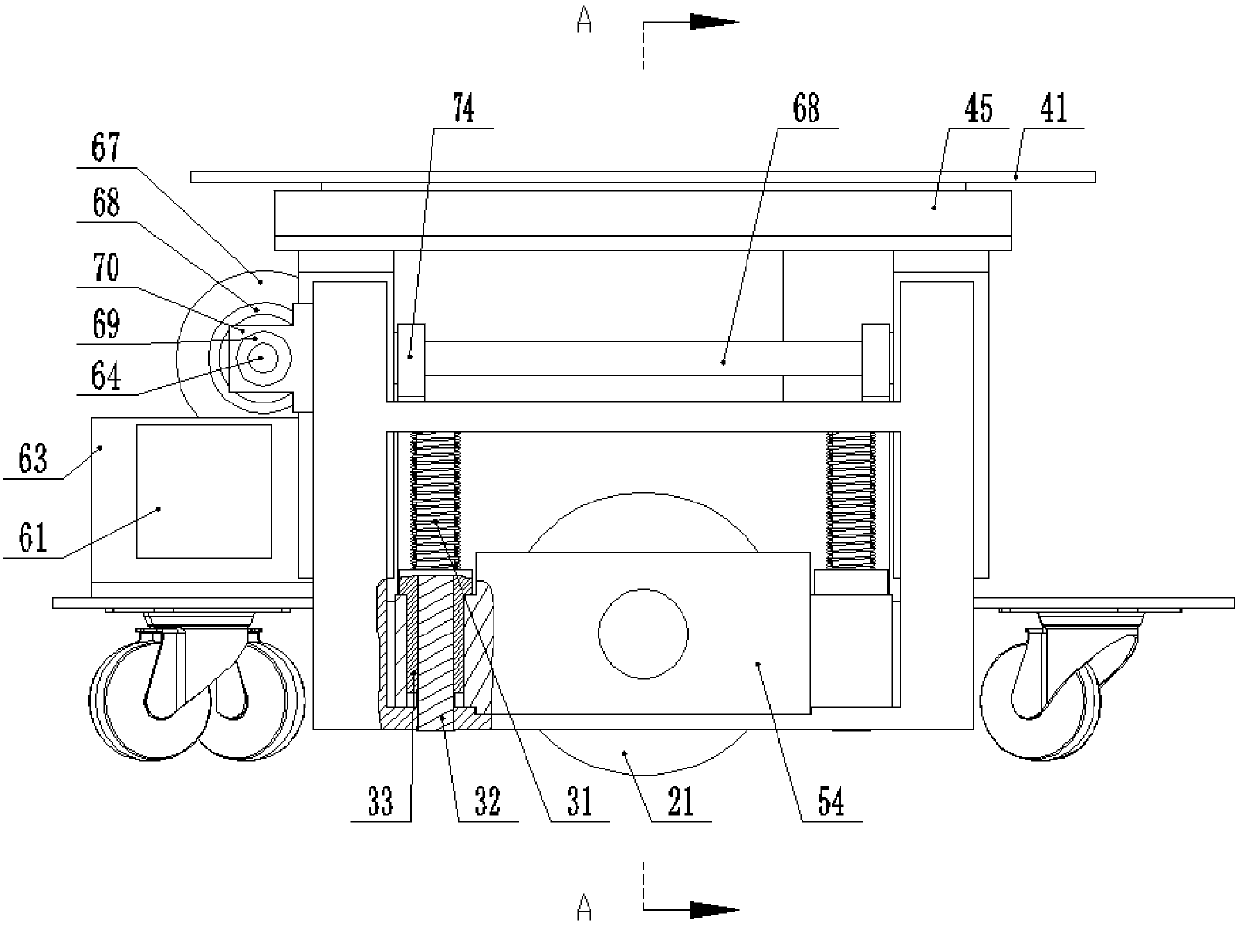

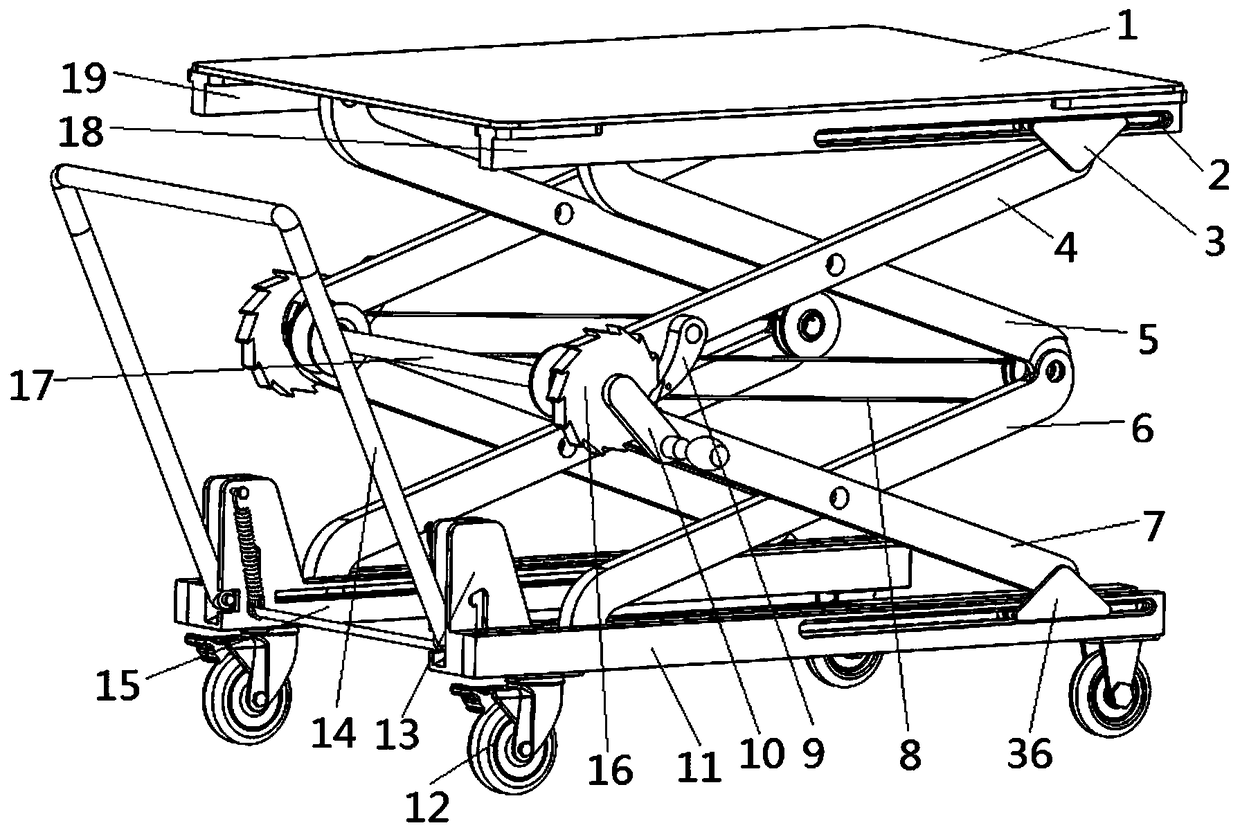

A kind of multi-functional logistics carrier trolley

InactiveCN106185696BAchieve liftingLabor-saving loading and unloadingLifting framesClimbing stairsElectrical and Electronics engineering

The invention discloses a multifunctional logistics carrying trolley. According to the structure of the multifunctional logistics carrying trolley, a lifting carrying trolley used for lifting goods on the flat ground and a stair climbing carrying trolley which climb stairs step by step are formed through combination of parts of the multifunctional logistics carrying trolley. In the goods carrying process, when the form of the lifting carrying trolley is adopted, goods lifting can be achieved, and the requirement for carrying goods with different heights is met; and when the form of the stair climbing carrying trolley is adopted, three wheels of a planet wheel of the stair climbing carrying trolley can be used for intermittently rotating to work to achieve a stair climbing function. According to the multifunctional logistics carrying trolley, lifting of carried goods can be achieved, and labor is saved during loading and unloading; heavy large goods can be transported, the stair climbing function can also be achieved, and labor is saved during carrying; and the application range is wide, the labor intensity of manual work during logistics carrying is lowered, and therefore goods carrying is more convenient and more labor is saved.

Owner:WUHAN UNIV OF TECH

A calibration tool for automatic calibration system of chemical composition and volume test power supply

ActiveCN108614232BSimple structureReasonable designElectrical measurementsTest powerChemical composition

The invention discloses a calibration tooling for an automatic calibration system for a formation and capacity grading testing power supply. The calibration tooling comprises an upper top plate, a lower bottom plate and a side plate frame; a plurality of probes are arranged on the upper top plate and the lower bottom plate; probe points are arranged on the tops of the probes; the probes on the upper top plate and the lower bottom plate are in one-to-one correspondence; the probes are fixed by bolt and nut sets; and bolts are of a hollow structure and used for wrapping the probes. The probes ofthe calibration tooling of the invention are simple in structure and reasonable in design, are compatible with various specifications of test power supplies, and can be combined with the automatic calibration system to sample the current and voltage of the test power supply.

Owner:元山(济南)电子科技有限公司

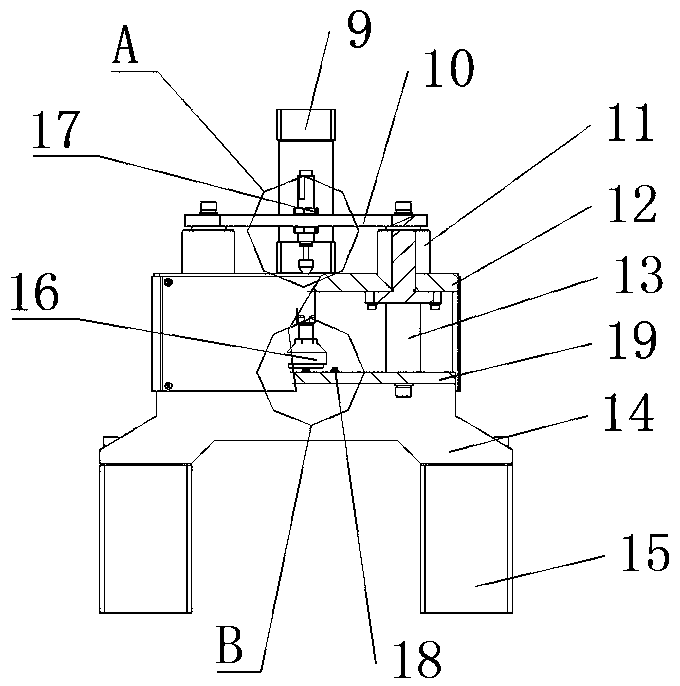

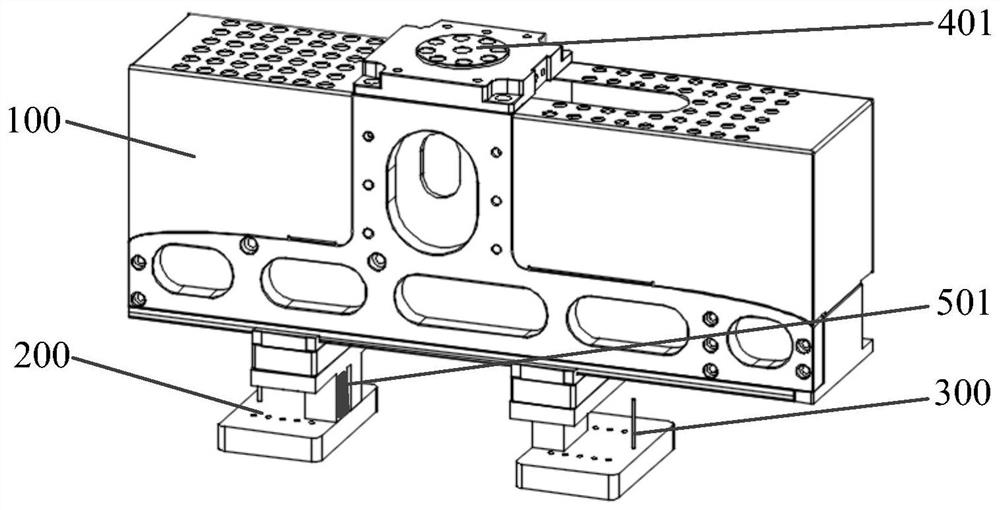

An intelligent end effector device for handling various materials

The invention discloses an intelligent end effector device for various material handling, which comprises a clamping and transporting mechanism module, a pneumatic adsorption transporting mechanism module and an electromagnetic adsorption transporting mechanism module; the clamping and transporting mechanism module includes a clamping and transporting mechanism The main body, the jaws, and the driving mechanism that drives the opening and closing movement of the jaws. The clamping and transporting mechanism body is fixedly installed at the end of the actuator; the pneumatic adsorption transporting mechanism module includes an adsorption housing with an air inlet. The adsorption shell is a five-sided shell structure with an open lower end, the adsorption shell is fixedly installed on the bottom surface of the jaw, the air intake hole is connected to the external air pump through the air intake pipeline; the electromagnetic adsorption transport mechanism module is The suction cup realizes electromagnetic adsorption. The invention can solve the material handling requirements of materials of different sizes and large loads, has strong adaptability and broad market prospect.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

Flower seedling transferring device

PendingCN111572954AIncrease flexibilityAvoid damageLiving organism packagingTransplantingAgricultural engineeringStructural engineering

The invention discloses a flower seedling transferring device. The flower seedling transferring device comprises a base, a movable frame and a supporting plate, a first sliding groove is formed in thetop of the base, a first fixing shaft is fixed in the first sliding groove, first sliding blocks are slidably connected to the two ends of the first fixing shaft, a first connecting rod is rotatablyconnected to the tops of the two first sliding blocks, a first hydraulic cylinder is mounted at the top of the base, a first movable seat is fixed to a piston rod of the first hydraulic cylinder, anda second sliding groove is formed in the bottom of the supporting plate. By adjusting the distance between the base and the movable frame and the distance between the movable frame and the supportingplate, the requirement for carrying different flower seedlings is met, the flower seedlings of different heights cannot be bent during carrying, and the use flexibility of the device is greatly improved; and multiple sets of first springs, second springs and telescopic mechanisms are arranged to buffer the base and the movable frame and buffer the movable frame and the supporting plate correspondingly, and the stability and safety of the device are improved.

Owner:SANSUI NONGFENG FRUITS & VEGETABLES PROFESSIONAL COOP

Silent single-beam European style crane

InactiveCN113060650ASmooth rideAvoid collisionTravelling cranesSound producing devicesNoise generationNoise

The invention discloses a silent single-beam European style crane. The crane comprises a cross beam, wherein a mounting frame is movably arranged at the bottom of the cross beam; a telescopic outer rod is movably arranged on the mounting frame; a telescopic inner rod is movably arranged at the inner side of the telescopic outer rod; two auxiliary connecting arms are arranged below a main connecting arm; and two electromagnetic chucks are fixedly arranged at the bottom of the auxiliary connecting arms. By arranging a first electromagnet, a first coil winding, a second electromagnet and a second coil winding, a movable rack is kept stable in the running process, a first pulley and a second pulley are prevented from colliding with a track, and noise is avoided; the movable rack and the track are wrapped through the cross beam, sound is effectively isolated, and the sound is absorbed through a sponge plate in the cross beam, so that the silence performance of the crane is greatly improved; the telescopic outer rod and the telescopic inner rod are high in stability in the carrying process, the possibility of collision is avoided, and sound is prevented; and the crane can meet the carrying requirements of objects at different positions and is wide in applicability.

Owner:安徽江河智能装备集团有限公司

Early-warning retractable mine car

InactiveCN107878481AImplement resizingMeet the handling needsRailway signalling and safetyMine carsEngineeringOperational safety

The invention discloses a telescopic mine car capable of early warning, comprising a front compartment, a rear compartment, an infrared detector, an audible and visual alarm, a signal receiver, a slideway and a slider, and an infrared detector is installed at the front end of the front compartment , the infrared detector is connected to the signal receiver, the signal receiver is connected to the sound and light alarm, the front compartment and the rear compartment are movably connected through the slider and the slideway, and the side parts of the slider and the slideway are provided with bolt holes. When the mineral material needs to be transported, according to the amount of mineral material, adjust the position of the slider and the slideway to adjust the position of the two compartments. After adjustment, insert the bolts into the corresponding bolt holes to realize the fixing of the two compartments. The infrared detectors, signal receivers and sound and light alarms installed in the front compartment can detect whether there are staff blocking the mine car on the way, and remind in time to avoid it, which can effectively reduce the occurrence of safety accidents and protect the safety of mine vehicles. The personal safety of the staff increases the safe operability of the equipment.

Owner:MIYI YUANTONG FERROTITANIUM

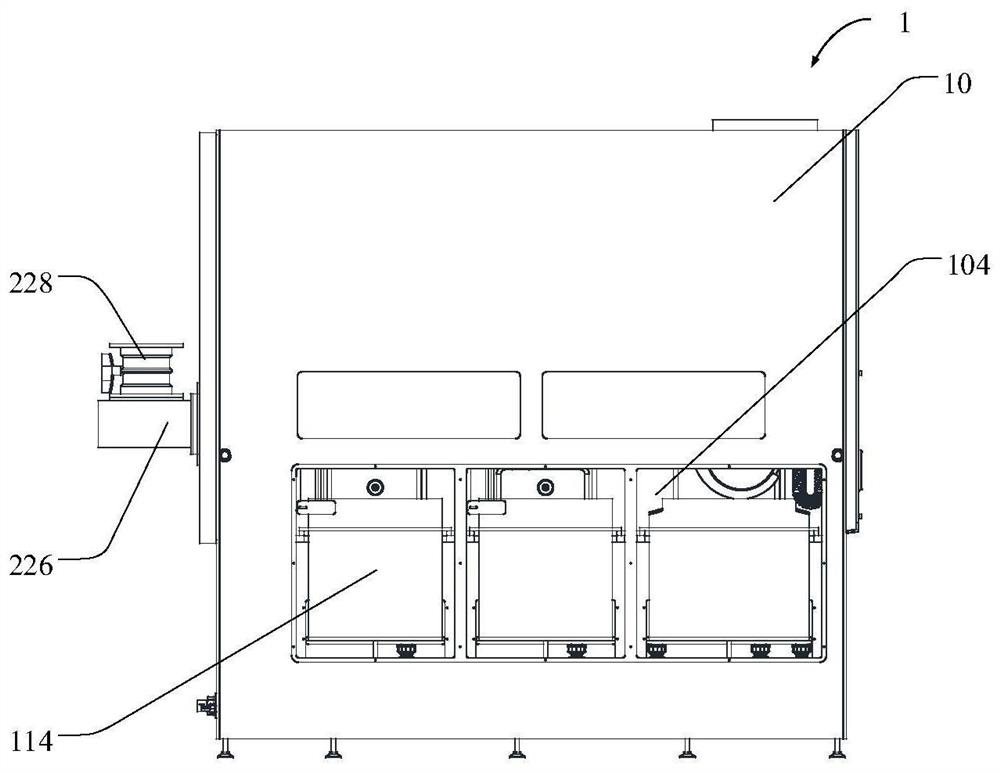

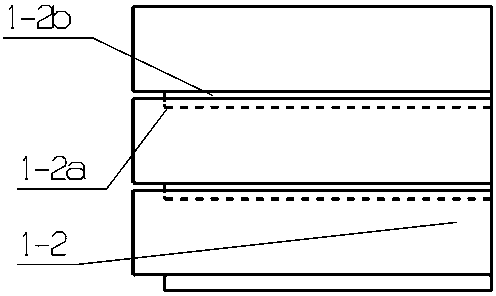

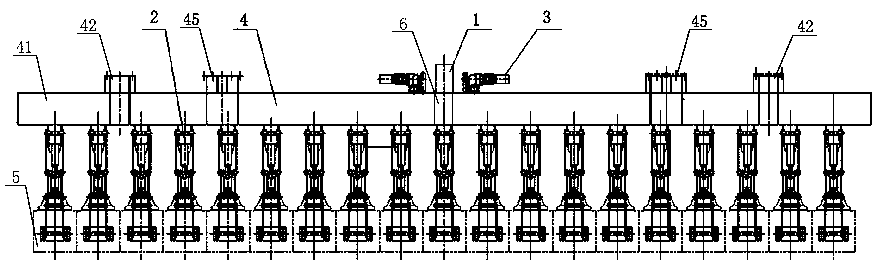

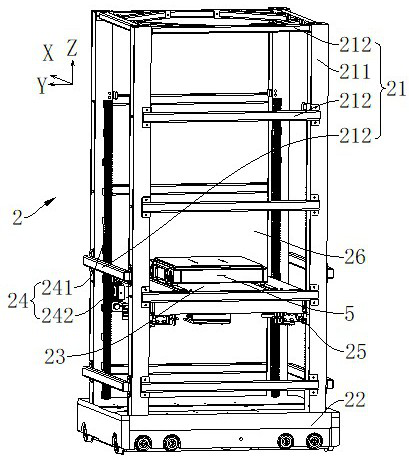

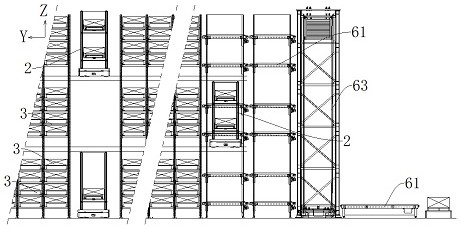

Automated shelf handling system and handling method thereof

ActiveCN110525866BMeet the handling needsSave storage spaceStorage devicesControl engineeringHandling system

The invention provides an automated shelf handling system, including a storage rack, a turnover box, a handling trolley and a cloud platform. Store multi-layer turnover boxes on each shelf. A card slot is provided on the top of the turnover box, and a card post is provided at the bottom thereof, and the card slot can cooperate with a card post at the bottom of another turnover box and allow the card post to be inserted. The handling trolley includes a mobile chassis, a lifting unit, a picking unit and a control unit. The lifting unit is integrally arranged on the mobile chassis. The pick-up unit as a whole can move vertically along with the lifting unit; it is also provided with an upper support part, a clamping part and a lower limit part from top to bottom. In the handling method of the automatic shelf handling system proposed by the present invention, each layer of shelves can be placed with multiple layers of turnover boxes or containers, so that the gap between the top of the turnover box (or container) on each layer of shelves and the bottom of the upper layer of shelves becomes smaller. , saving storage space; and the upper support part and lower limit part of the pick-up unit ensure that the transport trolleys can perform their own transport tasks without interfering with each other.

Owner:GUANGDONG SUNLI IND EQUIP CO LTD

Telescopic adjustable placing rack for tempered glass production

PendingCN111746609AIncrease profitMeet the handling needsHand carts with multiple axesHand cart accessoriesEngineeringToughened glass

The invention provides a telescopic adjustable placing rack for tempered glass production. The telescopic adjustable placing rack comprises a baffle, a main bottom plate and a handrail; one side of the bottom of the baffle is rotationally connected with the main bottom plate through a rotating shaft; the handrail is fixedly mounted on one side of the top of the baffle through bolts; a plurality offixing holes are formed in two sides of the baffle; a sliding groove is formed in an opening in one side in the main bottom plate; a connecting plate is slidably connected into the sliding groove; anauxiliary bottom plate is fixedly installed on one side of the connecting plate through bolts; universal wheels are arranged at the bottoms of the auxiliary bottom plate and the main bottom plate respectively; two supporting rods are rotatably connected with the two sides of the auxiliary bottom plate through rotating shafts, and the other ends of the supporting rods are fixedly installed in thefixing holes through bolts; and a strong magnetic sheet is arranged on one side of the baffle. According to the telescopic adjustable placing rack for tempered glass production, the utilization rate of space resources can be increased, the carrying requirements of goods of different sizes are met, and the cost for purchasing different placing racks is reduced.

Owner:湖南衡波特种玻璃科技有限公司

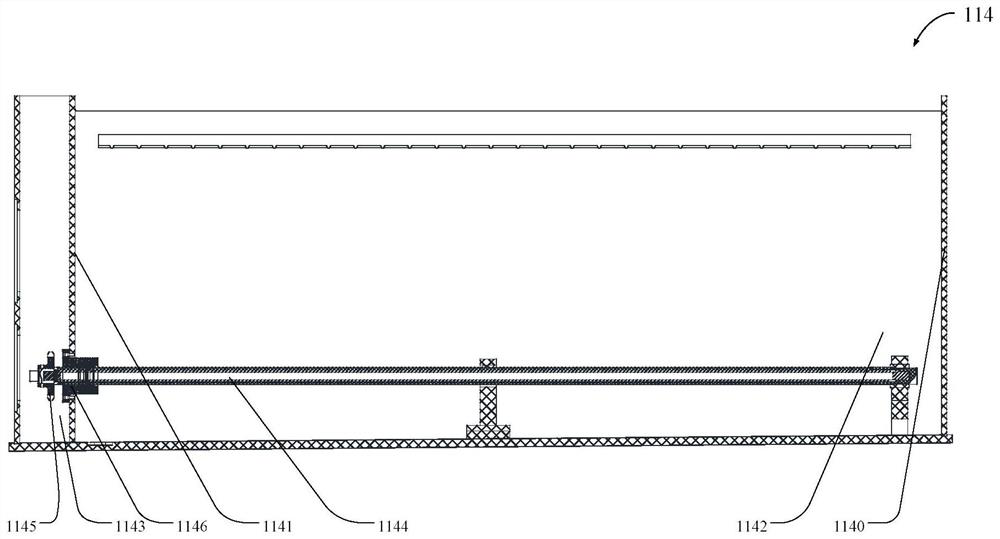

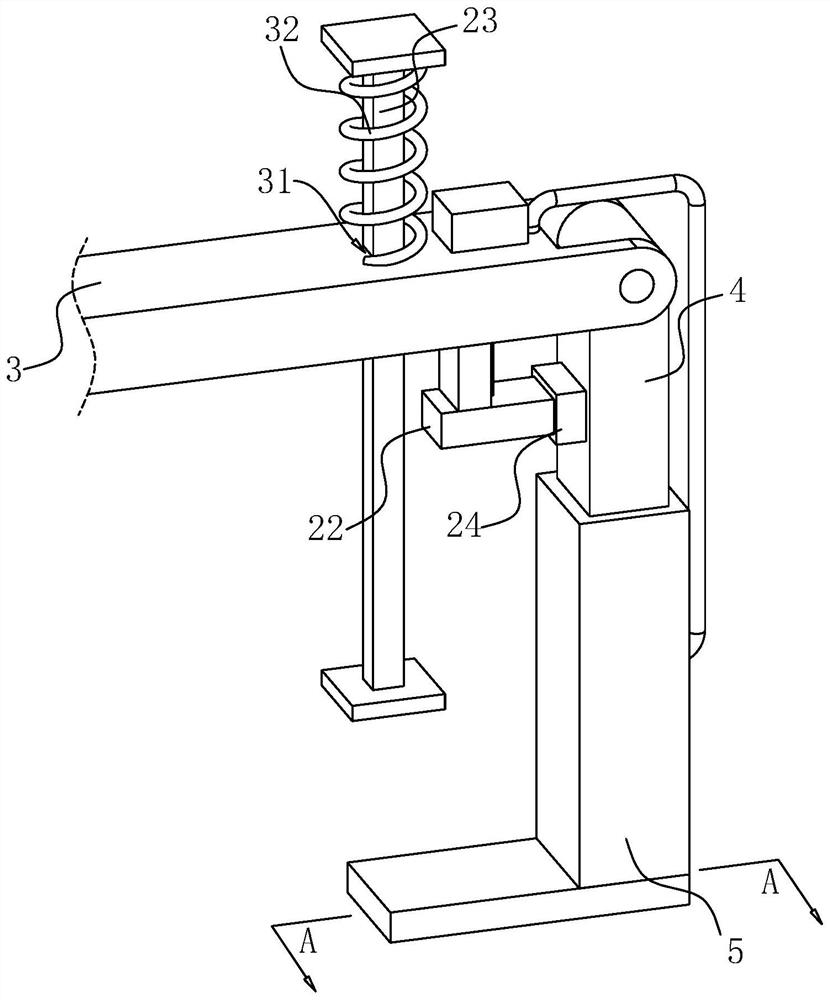

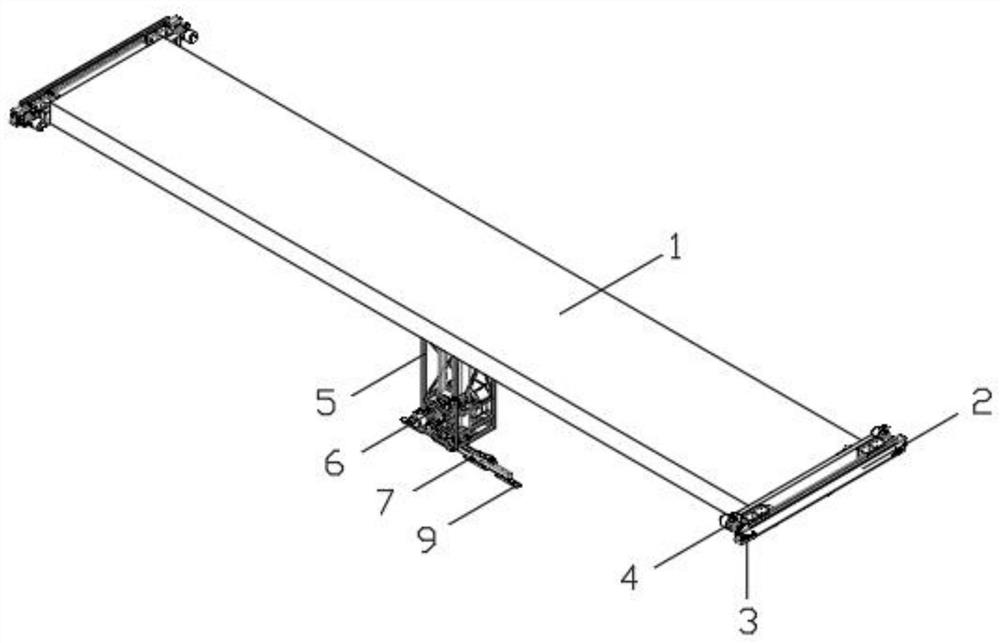

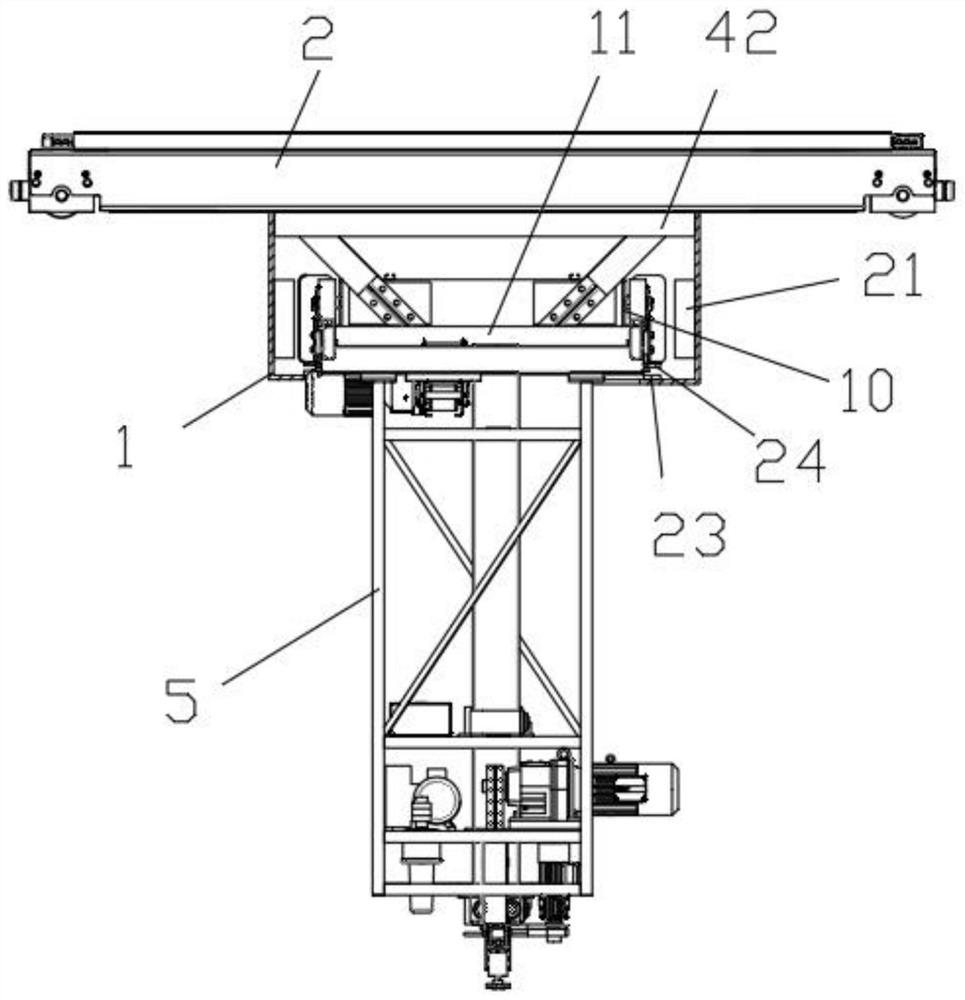

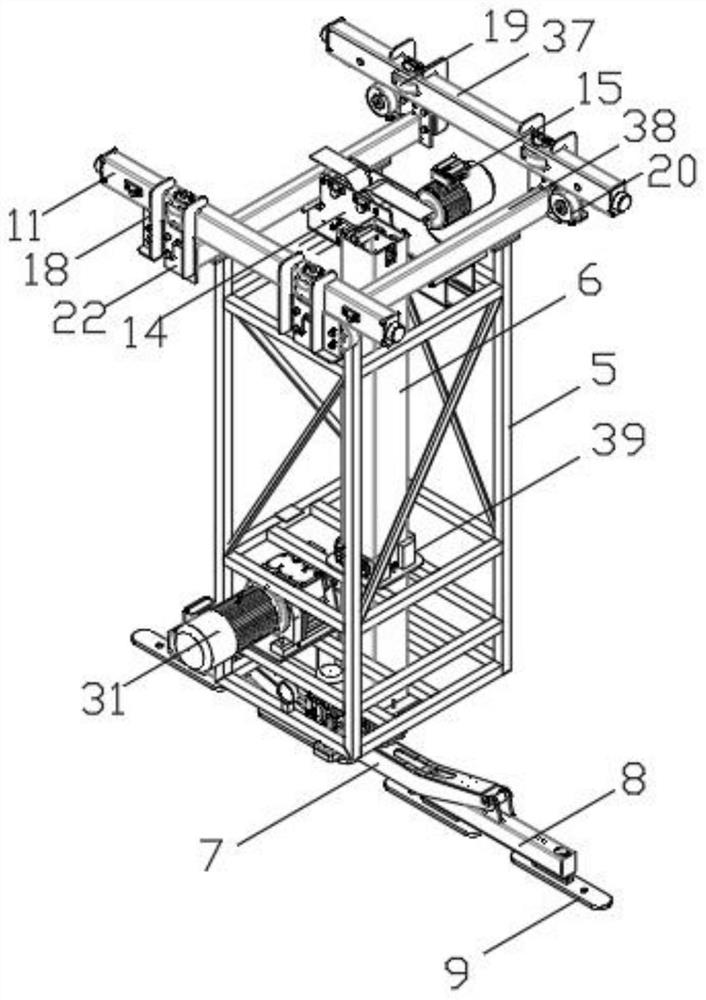

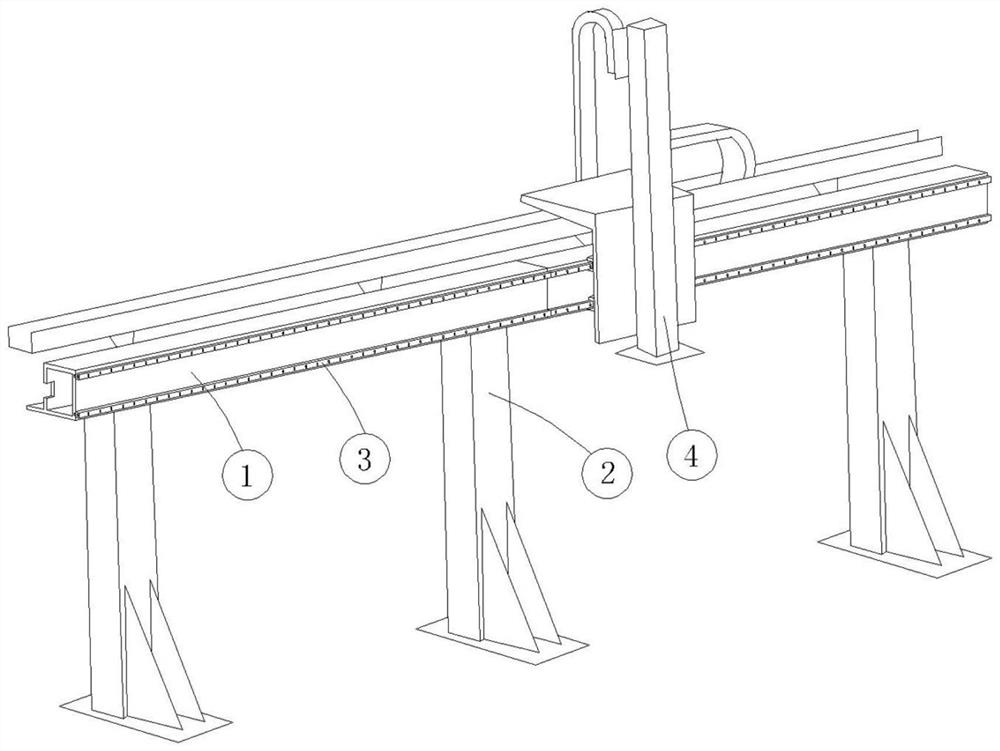

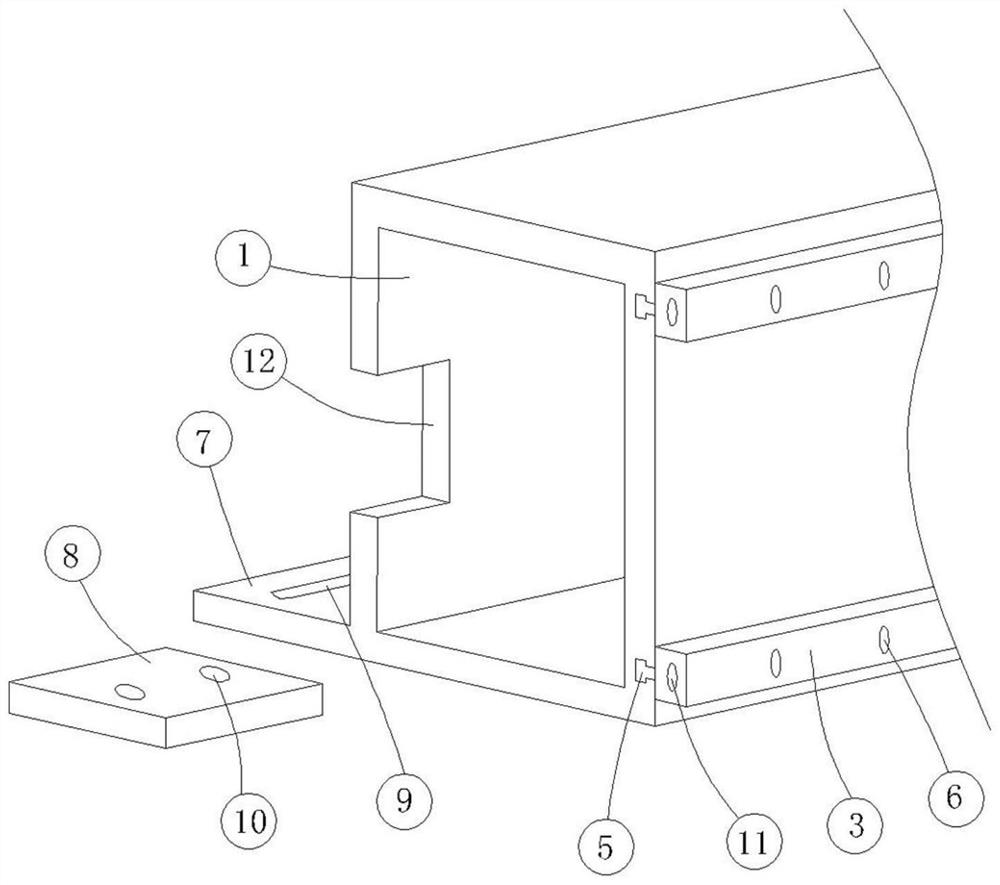

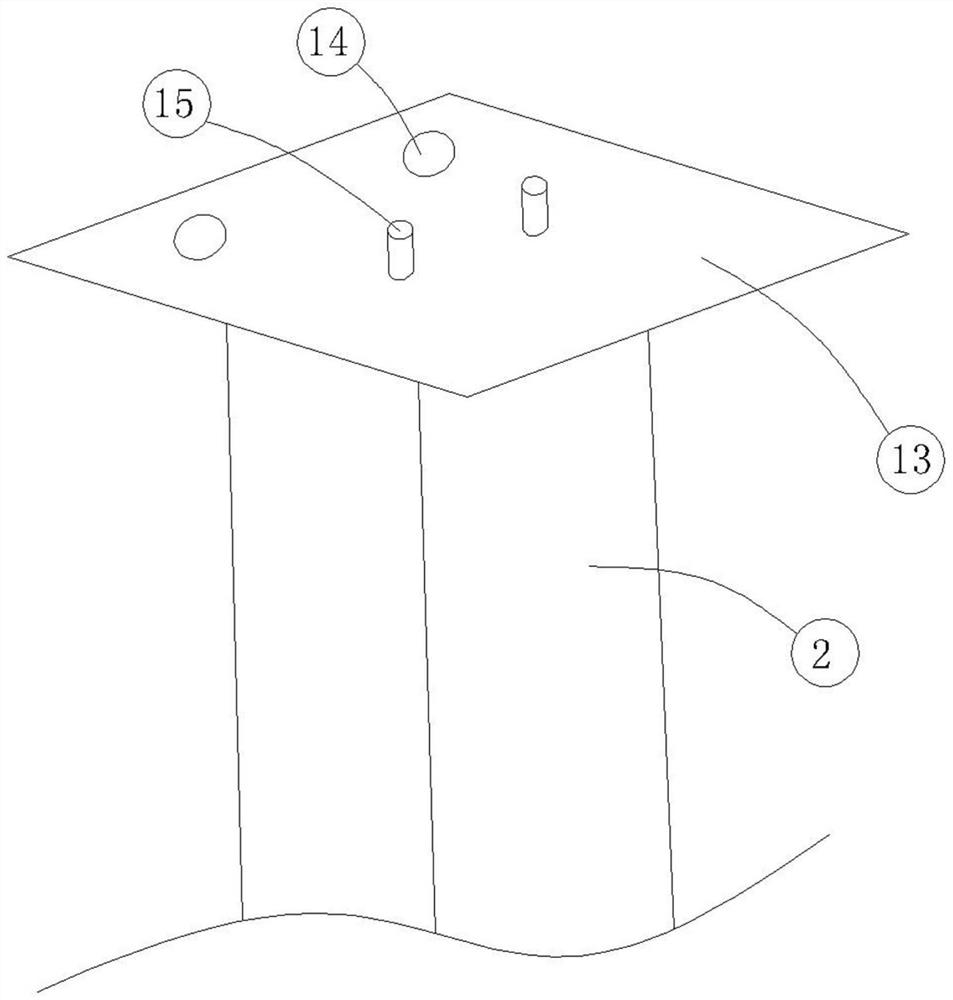

Truss carrying manipulator

The invention provides a truss carrying manipulator which comprises a carrying manipulator body and at least two cross beams, a supporting leg is supported below each cross beam, a linear guide rail is transversely arranged at the same position of the front face of each cross beam, the carrying manipulator body is arranged on the linear guide rail, and a T-shaped mounting groove is transversely formed in the front face of each cross beam. A plurality of T-shaped installation grooves are formed in the cross beams, a plurality of T-shaped nuts are arranged in the T-shaped installation grooves, a plurality of installation round holes are formed in the linear guide rails, first screws are arranged in the installation round holes, the first screws penetrate through the installation round holes and then are connected with the T-shaped nuts so as to connect the linear guide rails and the cross beams, the lower ends of the rear faces of the cross beams extend backwards to form connecting plates, and the connecting plates of every two adjacent cross beams are connected through a connecting block. The cross beams and the linear guide rails can be infinitely spliced according to needs, movement and transportation are convenient, the length of the truss carrying manipulator can be adjusted according to needs, and the carrying requirement for rigid structural parts in the assembly type house building process is met.

Owner:湖南嘉晟住建科技有限公司

A support structure for a refrigerator compressor

ActiveCN104132497BMeet the handling needsGood vibration and noise reductionLighting and heating apparatusRefrigeration devicesFoot supportsEngineering

The invention discloses a refrigerator compressor support structure, which comprises a support rod, a rubber pad, a compressor foot plate, a refrigerator bottom plate, a pressing block, an upper bush and a lower bush, and the inner hole of the rubber pad is inserted into the upper bush After being assembled with the support rod, the compressor foot plate is locked on the upper part of the support rod and above the rubber pad; there is a mounting hole on the bottom plate of the refrigerator, and the diameter of the mounting hole is slightly larger than the outer diameter of the lower bushing. The inner diameter is slightly larger than the outer diameter of the support rod, and the height of the lower bush is greater than the thickness of the bottom plate of the refrigerator. The sleeve is fastened under the top block; the pressing block is connected to the support bar, and it fastens the lower bush to the support bar from the bottom. The support structure of the present invention not only realizes the purpose of directly supporting the compressor on the ground, but also meets the transportation requirements of the refrigerator, and has a remarkable effect on vibration reduction and noise reduction of the refrigerator.

Owner:JIAXIPERA COMPRESSOR

A foldable flat shock-absorbing trolley

ActiveCN108248655BEasy to carry and transportMeet the handling needsHand carts with multiple axesHand cart accessoriesVehicle frameAir spring

Owner:浙江年代建设工程有限公司

A stable and safe manipulator for tire handling

The invention discloses a stable and safe manipulator for handling tires, comprising: a base, a column, a mechanical arm and a set of manipulators, the column is arranged on the base, the mechanical arm is installed on the column, the The manipulator is installed on the mechanical arm; the manipulator is provided with a suspension frame and a grabbing hand, the suspension frame is installed on the installation shaft of the mechanical arm, and a group of grabbing hands is relatively provided on the suspension frame. The hand is symmetrically and misplaced, and the installation shaft and the mechanical arm are arranged in a rotating manner. In the present invention, a stable and safe manipulator for tire handling is used to transport the tires, which solves the problem of heavy workload of manual handling at present. At the same time, the manipulator described in this application is arranged symmetrically, Not only can it carry multiple tires at the same time, but it can also maintain the balance of the entire manipulator and prevent it from falling to one side, which greatly improves the stability and safety of its handling.

Owner:徐州欧普莱斯工业机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com