Flame-retardant and antistatic container bag

A flame-retardant, anti-static, container bag technology, applied in the field of container bags, can solve problems such as affecting the life of the sling, deformation of the container bag, inability to meet, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

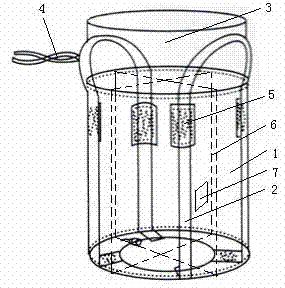

[0018] Such as figure 1 As shown, a flame retardant and antistatic container bag includes a body 1, a sling 2, a feed port 3, a tie rope 4, a reinforcement belt 5, an inner stopper 6 and a label bag 7, and the body 1 adopts a resistance Combust antistatic material, the sling 2 crosses through the bottom of the body 1 and is set on the side of the top of the body 1, the feed inlet 3 is set on the top of the body 1, and the tie rope 4 is set on the top of the body 1 On one side of the feed port 3, the inner flap 6 is arranged inside the body 1, the label bag 7 is arranged outside any side of the body 1, and the reinforcing belt 5 is arranged on the sling 2 fixed on the outside of the main body 1.

[0019] The inner retaining piece 6 is arranged inside the main body 1 in a cross shape. The body 1 is cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com