Cleaning equipment for pipe fitting

A technology for cleaning equipment and pipe fittings, which is applied in the direction of lighting and heating equipment, dust removal, conveyor objects, etc. It can solve the problems affecting the cleaning effect of quartz tubes and the cleanliness of cleaning tanks, so as to save cleaning liquid, improve loading and unloading efficiency, The effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

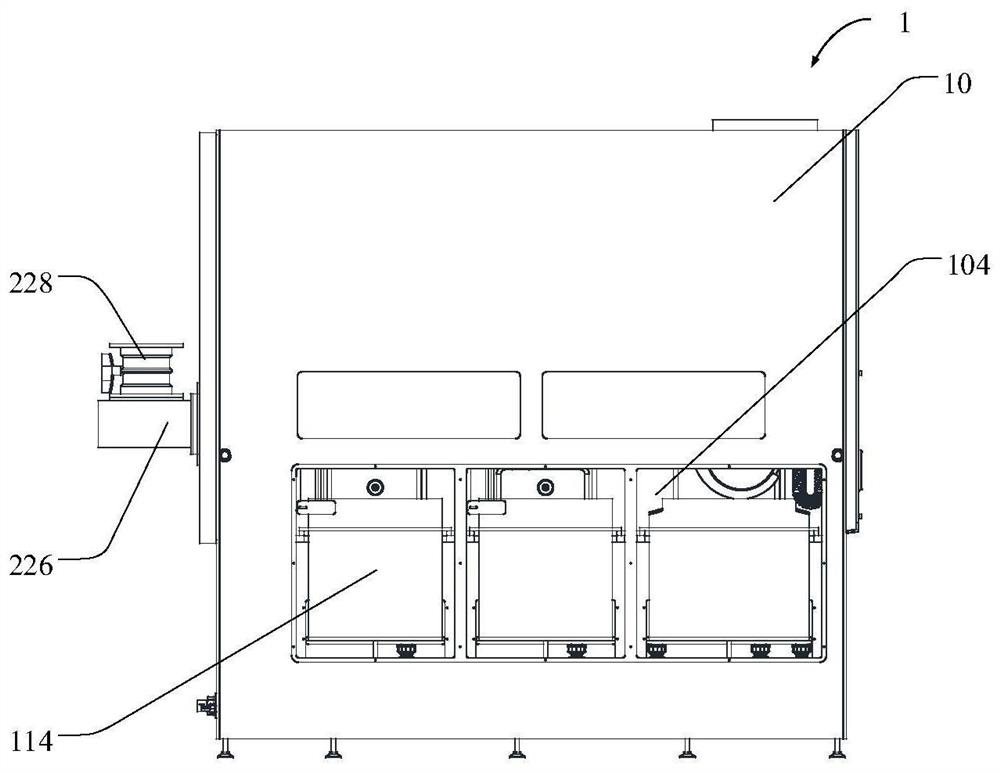

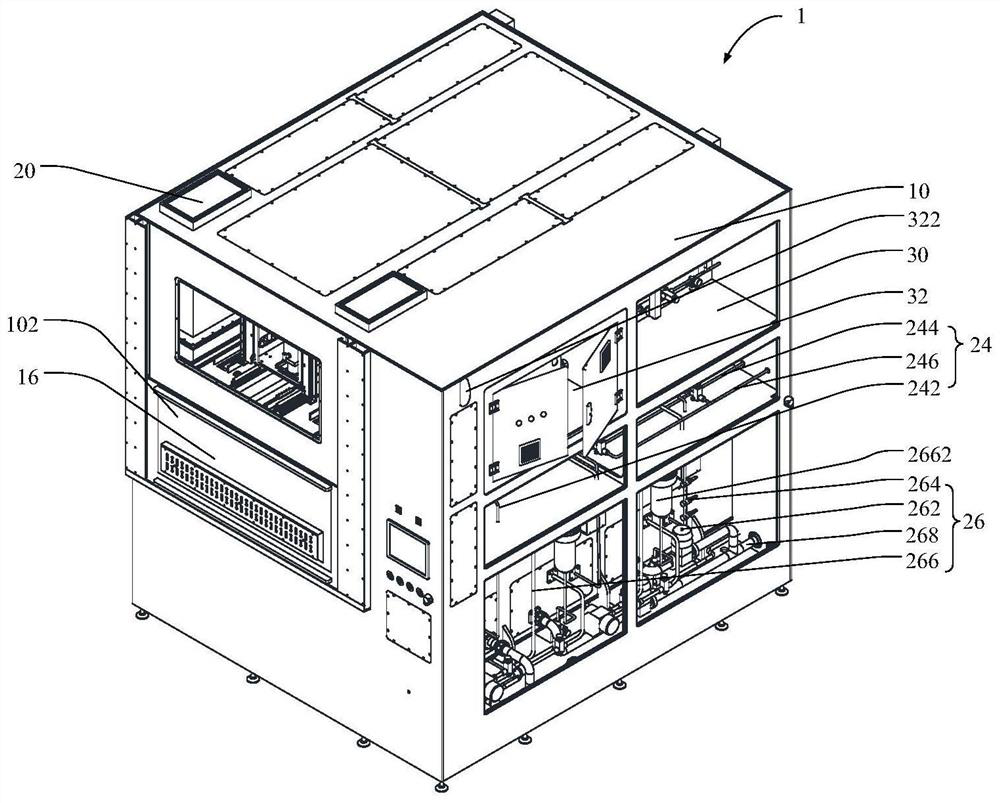

[0051] Such as Figure 1 to Figure 5 As shown, an embodiment of the present invention provides a pipe cleaning device 1 , including: a housing 10 , a mounting plate 110 , and a cleaning tank 114 . Wherein, the housing 10 is provided with a feeding port 102 and a slot opening 104, and the housing 10 is provided with a feeding chamber 106 and a cleaning chamber 108, the feeding port 102 communicates with the feeding chamber 106, and the slot opening 104 is connected with the cleaning chamber 108. The cleaning chamber 108 is connected, and the feeding chamber 106 is located above the cleaning chamber 108 . The mounting plate 110 is connected to the housing 10 , the mounting plate 110 is located in the cleaning cavity 108 , and the cleaning tank 114 can be mounted on the mounting plate 110 .

[0052] The housing 10 of the pipe fitting cleaning device 1 provided in this embodiment is provided with a feeding chamber 106 and a cleaning chamber 108, wherein the pipe fittings to be cl...

Embodiment 2

[0056] Such as Figure 1 to Figure 6 As shown, an embodiment of the present invention provides a pipe cleaning device 1 , including: a housing 10 , a mounting plate 110 , a cleaning tank 114 and an overflow hole 112 . Wherein, the housing 10 is provided with a feeding port 102 and a slot opening 104, and the housing 10 is provided with a feeding chamber 106 and a cleaning chamber 108, the feeding port 102 communicates with the feeding chamber 106, and the slot opening 104 is connected with the cleaning chamber 108. The cleaning chamber 108 is connected, and the feeding chamber 106 is located above the cleaning chamber 108 . The mounting plate 110 is connected to the housing 10 , the mounting plate 110 is located in the cleaning cavity 108 , and the cleaning tank 114 can be mounted on the mounting plate 110 .

[0057] The housing 10 of the pipe fitting cleaning device 1 provided in this embodiment is provided with a feeding chamber 106 and a cleaning chamber 108, wherein the p...

Embodiment 3

[0063] Such as Figure 5 , Figure 7 and Figure 8 As shown, in any of the above embodiments, further, the pipe cleaning equipment 1 further includes: a handling assembly 14 . Wherein, the transport assembly 14 is disposed in the casing 10 and located in the feeding cavity 106 .

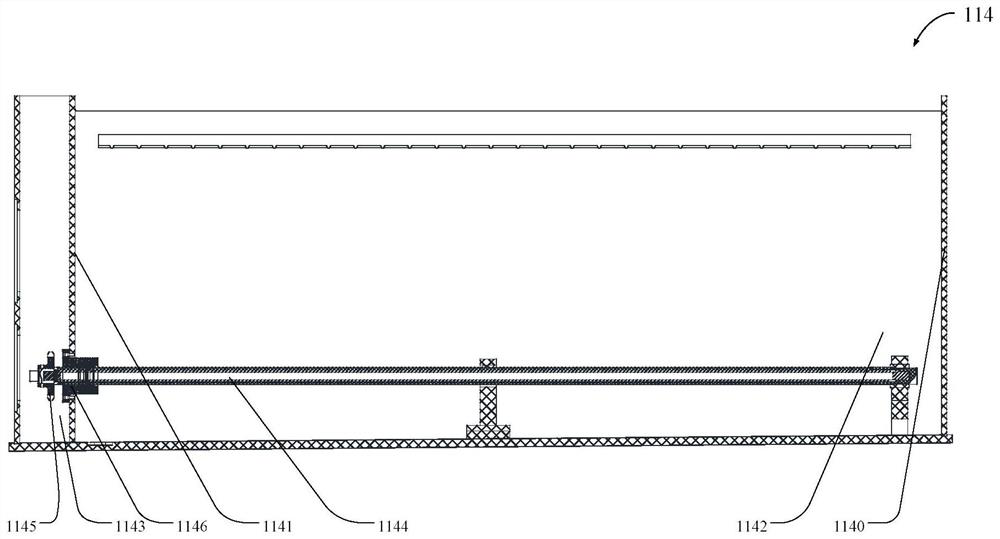

[0064] Specifically, the transport assembly 14 includes an installation frame 141 , a lifting frame 143 , a first lifting arm 144 , a second lifting arm 145 , and a hook assembly 146 . The hook assembly 146 specifically includes a hook beam 1462 , a first hook 1464 , a second hook 1466 and a limiting plate 1468 .

[0065] In this embodiment, the feeding chamber 106 in the tube cleaning device 1 is provided with a transport assembly 14 for transporting the tubes to various work stations. Wherein, the installation frame 141 of the transport assembly 14 is connected with the housing 10 , and the lifting frame 143 can slide along the sliding rail 142 on the installation frame 141 , and then transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com