Conveyer for iron sheets used for making large cans

A technology of handling machine and iron sheet, which is applied in the direction of conveyor, transportation and packaging, stacking of objects, etc., can solve the problems of being unable to withstand the stacking weight of large cans of iron sheets, and unable to meet the handling of large cans of iron sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

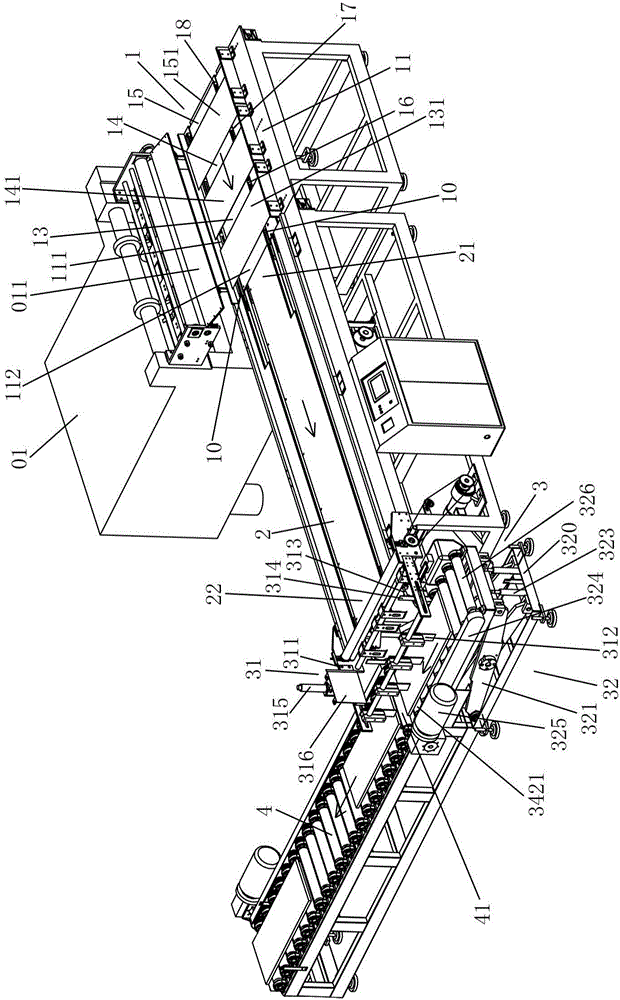

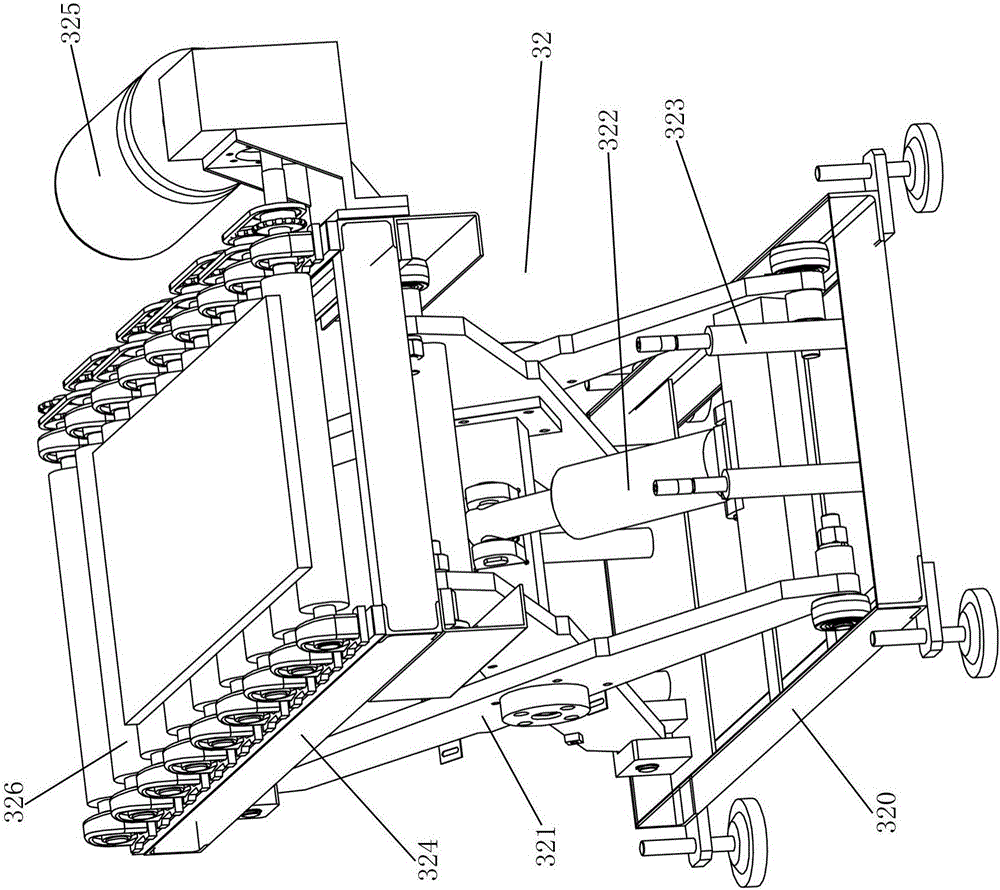

[0059] Such as figure 1 , figure 2 and image 3 As shown, the can-making sheet metal conveying machine in this preferred embodiment includes a step conveying mechanism 1 , a horizontal conveying mechanism 2 , a lifting and collecting mechanism 3 and a roller conveying mechanism 4 .

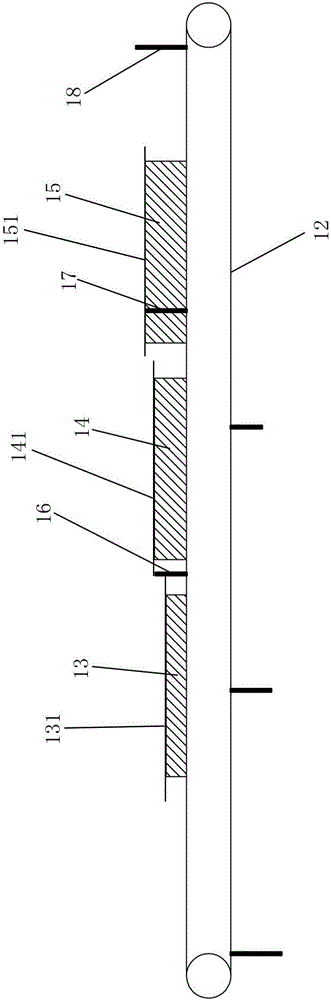

[0060] The above-mentioned stepped conveying mechanism 1 includes a conveying platform 11, two annular transmission parts 12, a low receiving platform 13, a middle receiving platform 14, a high receiving platform 15, a low push claw 16, a middle push claw 17 and a high push claw 18;

[0061] One side of the above-mentioned delivery table 11 is a feed end 111, and the discharge end 112 of the above-mentioned delivery table 11 is connected with the feed end 21 of the horizontal conveying mechanism 2; the above-mentioned delivery table 11 is along the conveying direction (see figure 1 The direction indicated by the middle arrow) is provided with two parallel slits 10;

[0062] The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com