Automatic shelf carrying system and carrying method thereof

A handling system and shelf technology, which is applied in the field of warehousing and logistics, can solve the problems of large gaps and waste of storage space, and achieve the effects of increasing storage capacity, optimizing design, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to better understand the technical content of the present invention, specific embodiments are given together with the accompanying drawings for description as follows.

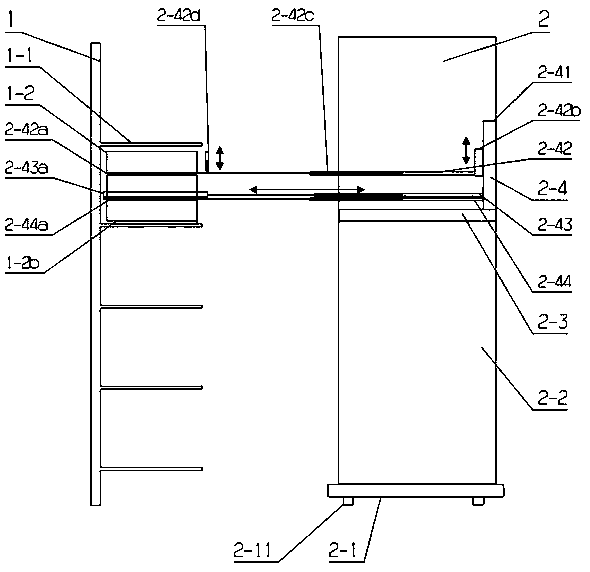

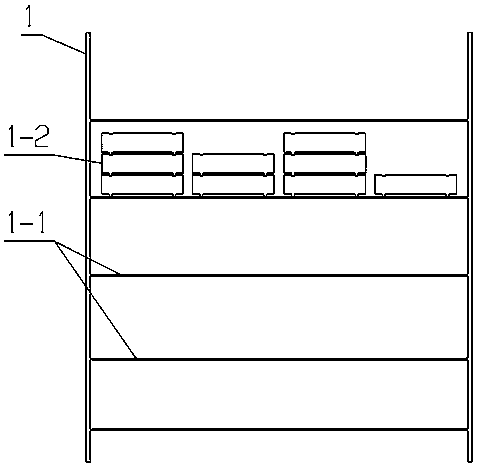

[0063] Such as Figure 1 to Figure 8 As shown, according to a preferred embodiment of the present invention, a kind of automated shelf handling system includes a storage rack 1 with a multi-layer rack 1-1, a turnover box 1-2 stored on the rack 1-1, at least two racks with The handling car 2 of the automatic driving system (such as the AGV car) and the remote cloud platform.

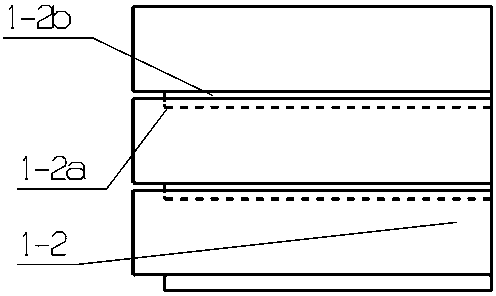

[0064] Store multi-layer turnover boxes 1-2 stacked from bottom to top on each shelf 1-1. Each group of stacked turnover boxes 1-2 has the same width and variable height. Each turnover box 1-2 is provided with a card slot 1-2a on its top, and a card post 1-2b at its bottom, and the card slot 1-2a is set to be compatible with another turnover box 1-2. The bottom clamping column 1-2b cooperates and allows the clamping col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com