Intelligent compound robot for wafer box transferring

A robot and cassette technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem that it is difficult to meet the needs of high precision, large load, and large space operations at the same time, and the composite transfer robot is difficult to meet industry needs. Insufficient battery life and other problems, to achieve the effect of compact overall structure, high load, and large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

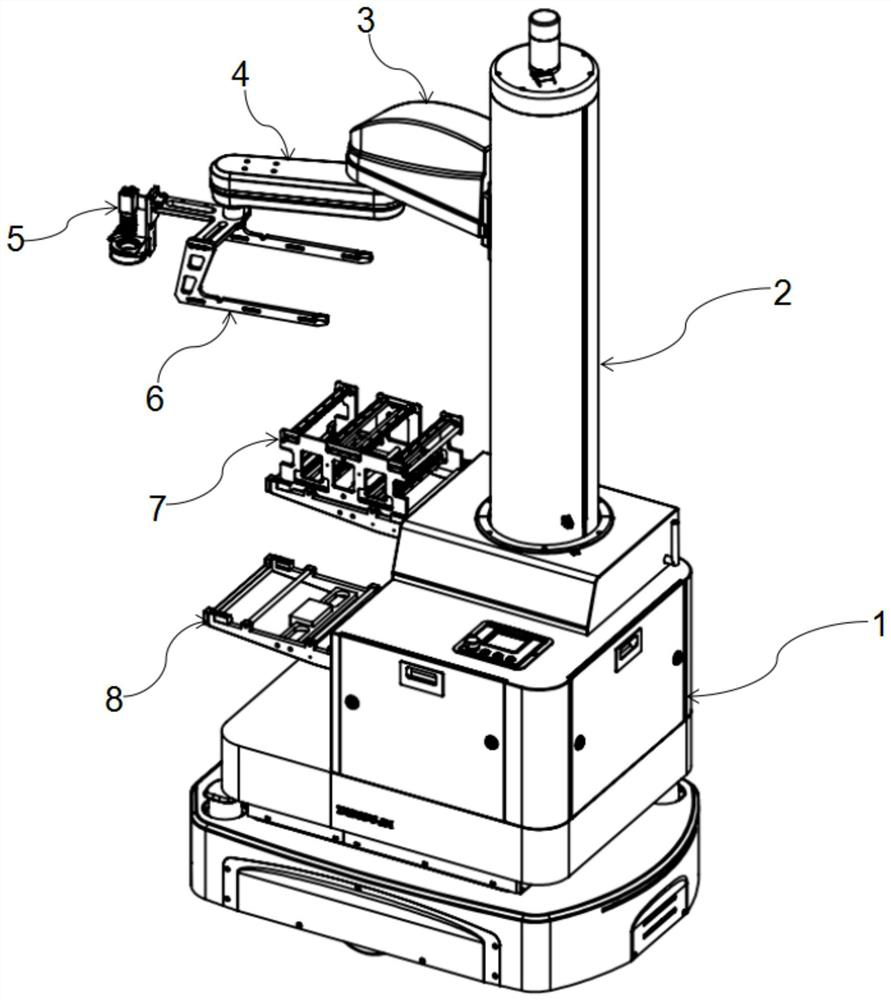

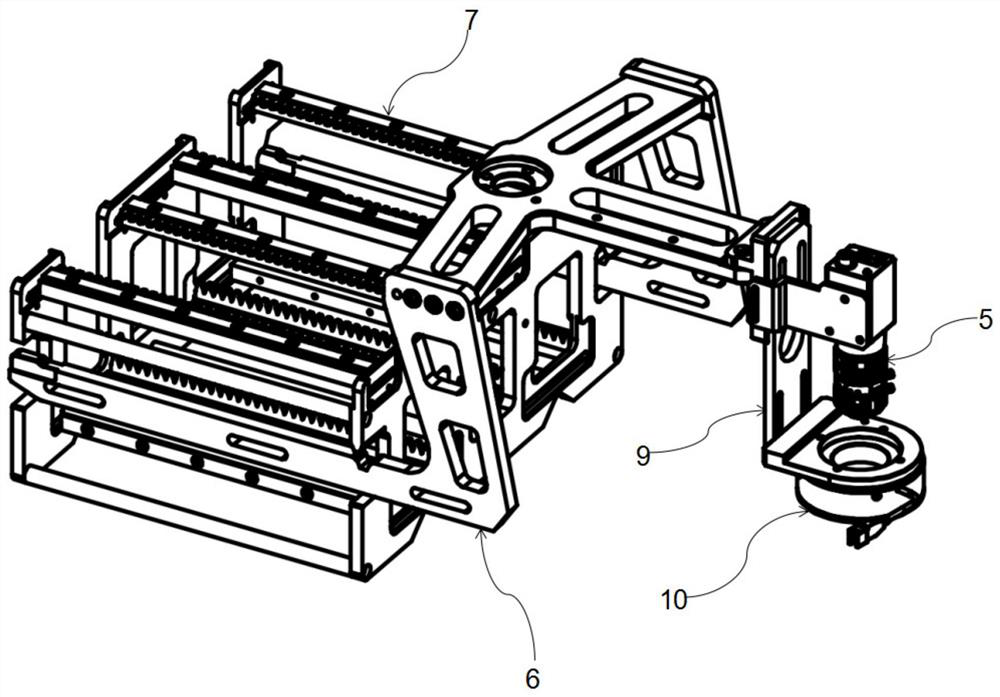

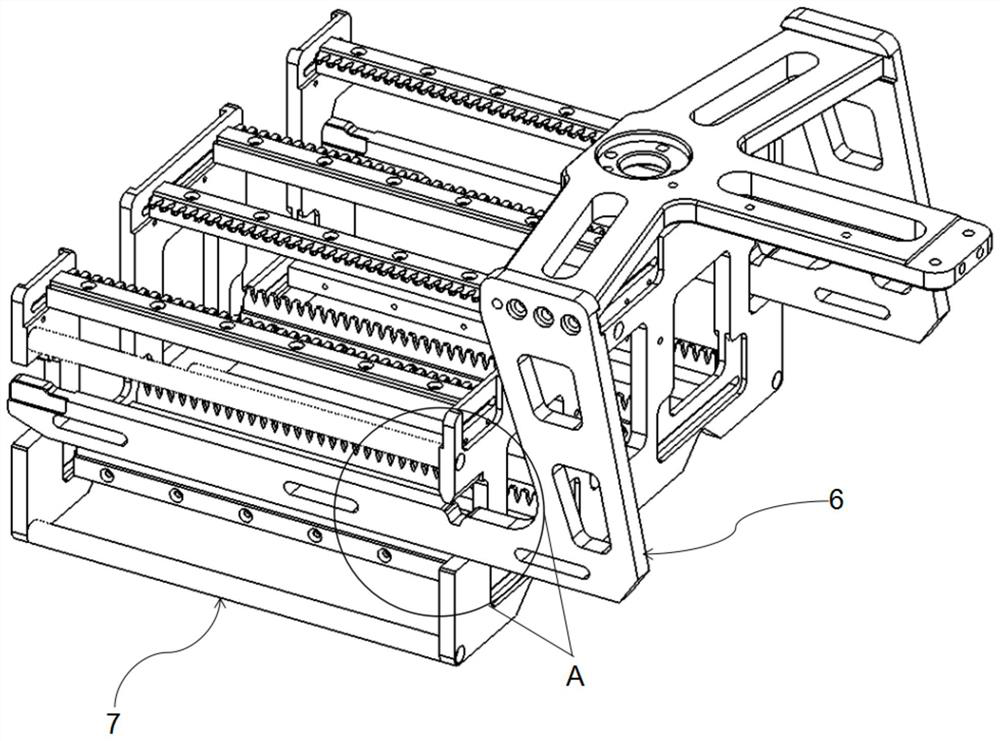

[0075] Such as figure 1 As shown, in this embodiment, a kind of intelligent composite robot for transferring cassettes 7 is specifically provided, which is designed for the composite handling of high load (10kg) and large stroke (working radius 900mm) for AGV transfer vehicle 1, especially for composite AGV The special 4-level articulated robot developed for the handling of 7 types of film boxes is designed to realize the handling of 7 types of film boxes through this composite robot. The composite robot mainly includes: AGV transfer vehicle 1, located on the AGV The mechanical arm on the vehicle 1, the inserting mechanism installed on the mechanical arm, the product placement mechanism for placing the film cassette 7, and the visual positioning device installed on the inserting mechanism, realize the film cassette through the coordinated operation of each part. 7 handling needs.

[0076] (1) Arm part

[0077] Such as Figure 10 As shown, the manipulator is the core compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com