A device for handling a yarn end, a method, and an annular spinning machine

A ring spinning machine, yarn technology, applied in the field of yarn end and sucking the yarn end into the mouth of the suction tube, which can solve the limitation of size and mobility of transfer equipment, small space, etc. problem, to achieve the effect of guaranteed layout, low weight, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

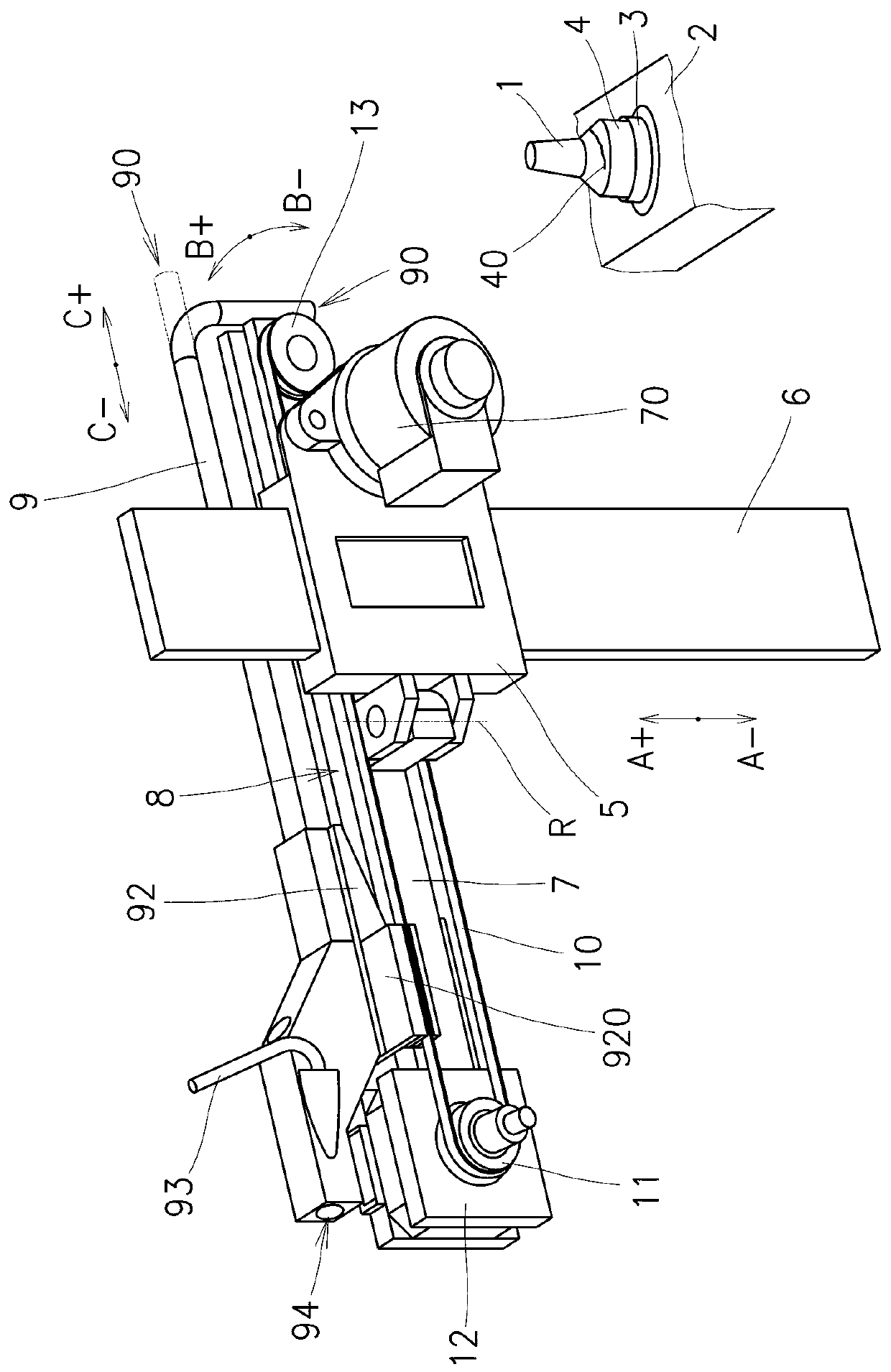

[0024] The invention will be described with reference to an exemplary embodiment of a yarn end transfer device at a spinning station (also understood as spinning unit) of a ring spinning machine.

[0025] A ring spinning machine comprises a row of identical spinning stations arranged next to each other. In principle, spinning stations are well known and therefore the entire spinning station will only be described in a simplified manner below. Those parts, elements and nodes of the spinning station which are of significance to the invention will be described in more detail. The spinning station comprises a roving drafting device, not shown, below which the yarn twisting and winding device is arranged. The roving is fed from a supply package, not shown, to the drafting device, after which the formed yarn passes through the guide eyelets, the balloon containment shield and then through the traveler which surrounds the ring 3 around the circumference of the flange, the ring 3 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap