Stud for tyre

A tire and nail clip technology, applied in special tires, tire parts, tire treads/tread patterns, etc., can solve the problem of not being able to use studs, and achieve the effect of reducing waste ratio and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is explained by examples below in conjunction with the accompanying drawings.

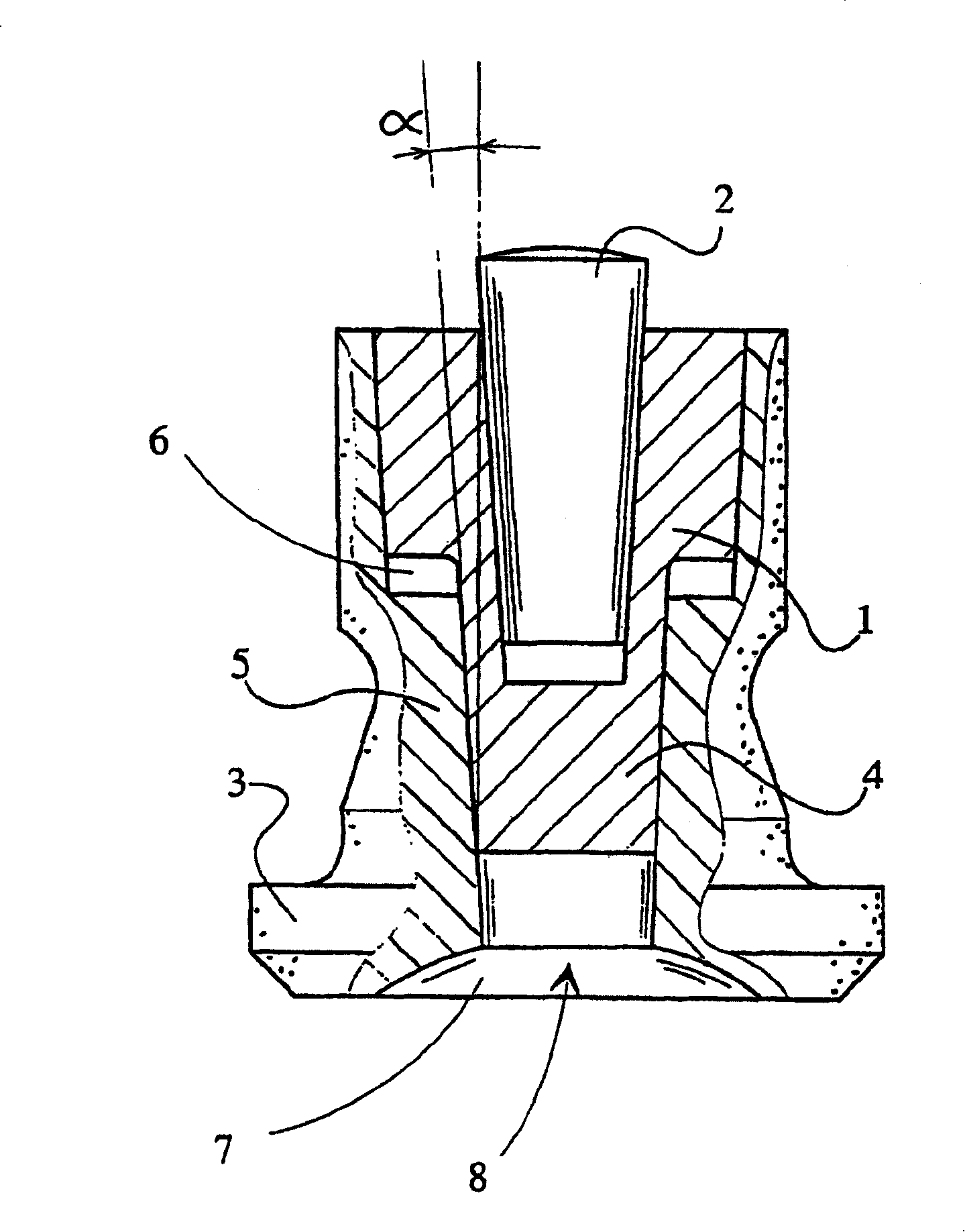

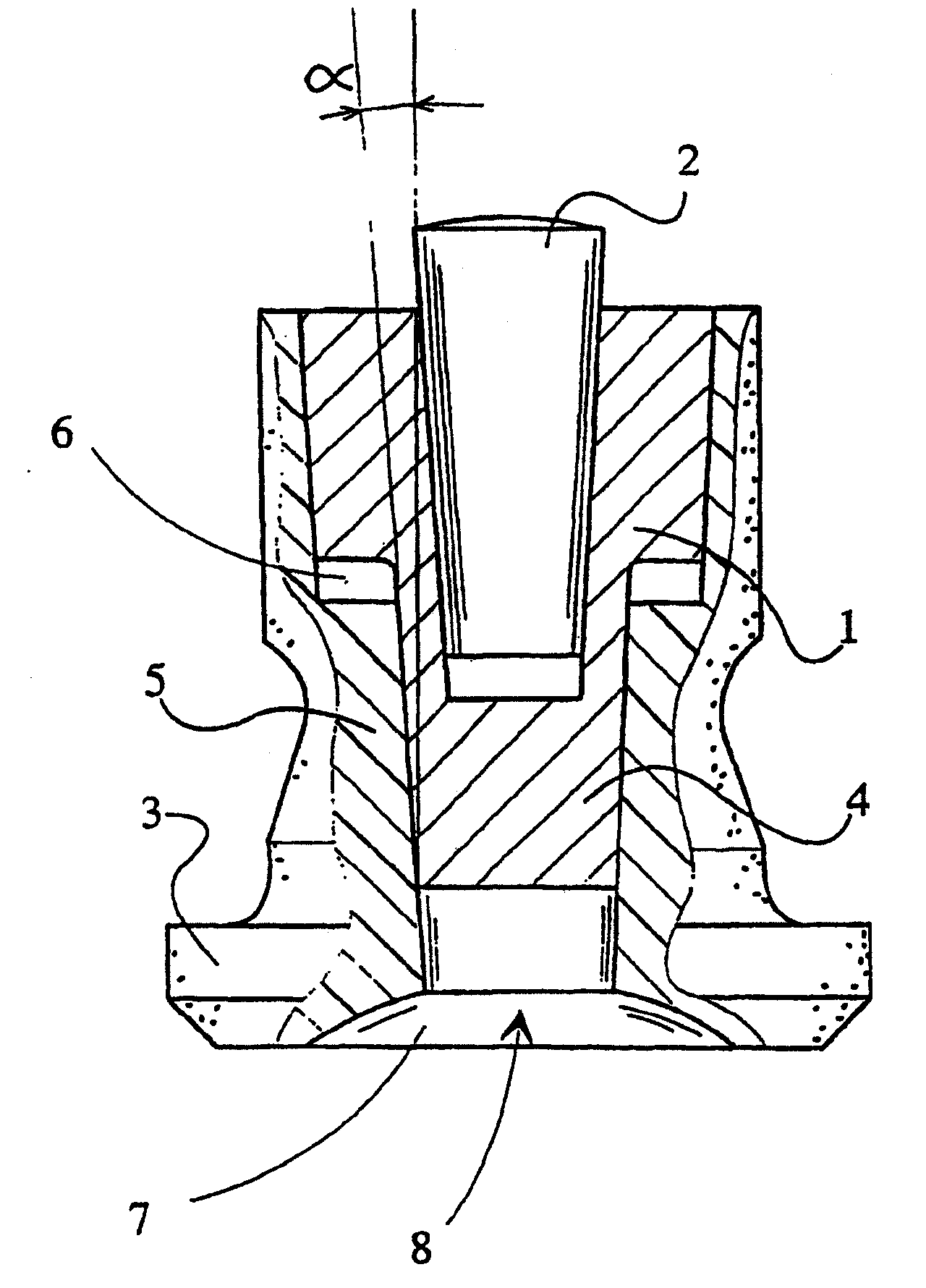

[0020] The stud comprises a socket-shaped body part 1 with a hard metal tip 2 at one end. At its other end, the body has a locking flange 3 which clamps the stud in the tire. The locking flange 3 is made of plastic. The stud body part 1 has a pin 4 extending towards the locking flange, on the upper part of which a tubular sleeve part 5 of the locking flange is fixed. The body part 1 is tapered to clamp as a wedge in a corresponding tapered sleeve part 5 . The body part 1 has a graduated tapered surface, the diameter of which is greater at the hard metal tip 2 than at one end 4 of the locking flange 3 . At the stepped position of the tapered surface of the body part 1 and at the stepped position of the tapered surface of the sleeve part 5 there is a hollow annular space 6 which allows the body part 1 to be wedged when pressure is applied to the stud Go deeper. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com