A buffer energy-absorbing structure with multiple energy-absorbing effects with microfiltration membrane

A technology of energy-absorbing structures and microfiltration membranes, which is applied in the direction of springs/shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as honeycomb sandwich structure failure, industrial equipment production accidents, loss of the country and people, etc. , to achieve the effect of simple structure, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

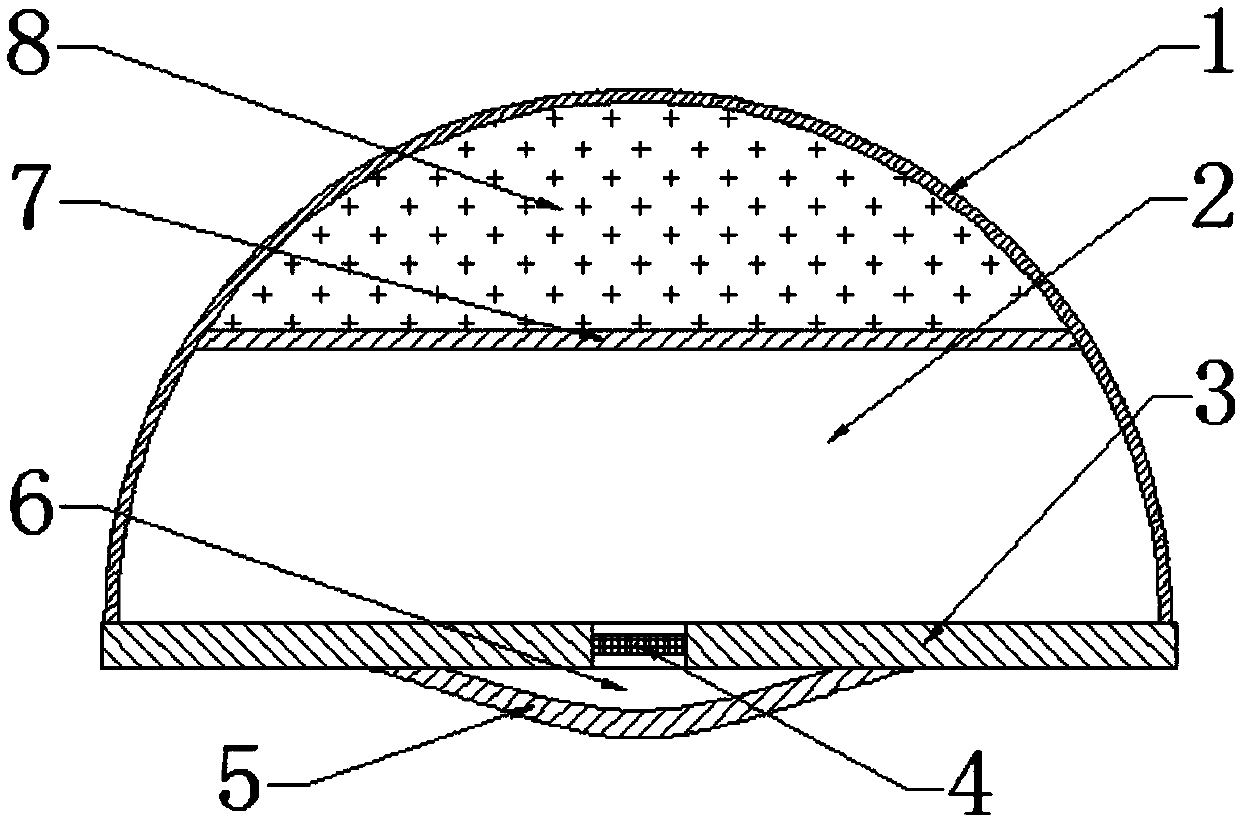

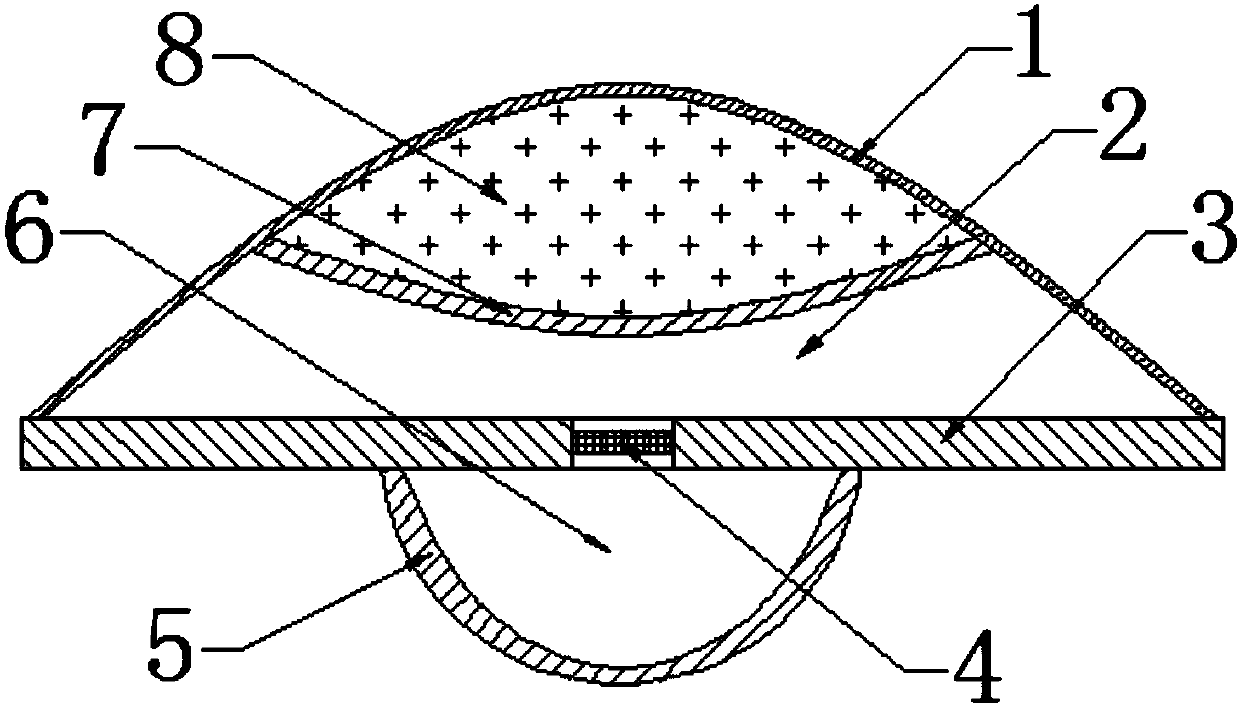

[0041] In this embodiment, a multi-energy-absorbing energy-absorbing buffer structure with a microfiltration membrane includes a first shell 1, a second shell 5, and a spacer layer 7 made of fiber reinforced rubber, and a substrate made of titanium alloy 3. The thickness of the second housing 5 is 3 times the thickness of the first housing 1,

[0042] The first shell 1 and the intermediate spacer layer 7 enclose the first cavity 8, the first shell 1, the intermediate spacer layer 7 and the substrate 3 enclose the second cavity 2, and the second shell 5 and the substrate 3 enclose the first cavity. Three-chamber 6,

[0043] A microfiltration membrane 4 is installed in the middle of the substrate 3, and the microfiltration membrane 3 communicates with the second cavity 2 and the third cavity 6.

[0044] The second cavity 2 and the third cavity 6 are filled with ether gas, and the first cavity 8 is filled with silica particles to form a buffer energy absorption structure with multiple ...

Embodiment 2

[0046] In this embodiment, a buffer energy-absorbing structure with multiple energy-absorbing effects with a microfiltration membrane includes a first shell 1, a second shell 5, and a middle spacer layer 7 made of fiber reinforced rubber, and made of niobium-zirconium alloy The thickness of the substrate 3 and the second housing 5 is 4 times the thickness of the first housing 1,

[0047] The first shell 1 and the intermediate spacer layer 7 enclose the first cavity 8, the first shell 1, the intermediate spacer layer 7 and the substrate 3 enclose the second cavity 2, and the second shell 5 and the substrate 3 enclose the first cavity. Three-chamber 6,

[0048] A microfiltration membrane 4 is installed in the middle of the substrate 3, and the microfiltration membrane 3 communicates with the second cavity 2 and the third cavity 6.

[0049] The second cavity 2 and the third cavity 6 are filled with air, and the first cavity 8 is filled with silica particles to form a buffer energy abso...

Embodiment 3

[0051] In this embodiment, a buffering energy-absorbing structure with multiple energy-absorbing effects with a microfiltration membrane includes a first shell 1, a second shell 5, and a middle spacer layer 7 made of modified rubber, and a substrate made of aluminum alloy 3. The thickness of the second housing 5 is 3 times the thickness of the first housing 1,

[0052] The first shell 1 and the intermediate spacer layer 7 enclose the first cavity 8, the first shell 1, the intermediate spacer layer 7 and the substrate 3 enclose the second cavity 2, and the second shell 5 and the substrate 3 enclose the first cavity. Three-chamber 6,

[0053] A microfiltration membrane 4 is installed in the middle of the substrate 3, and the microfiltration membrane 3 communicates with the second cavity 2 and the third cavity 6.

[0054] The second cavity 2 and the third cavity 6 are filled with nitrogen, and the first cavity 8 is filled with sand to form a buffer energy absorption structure with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com