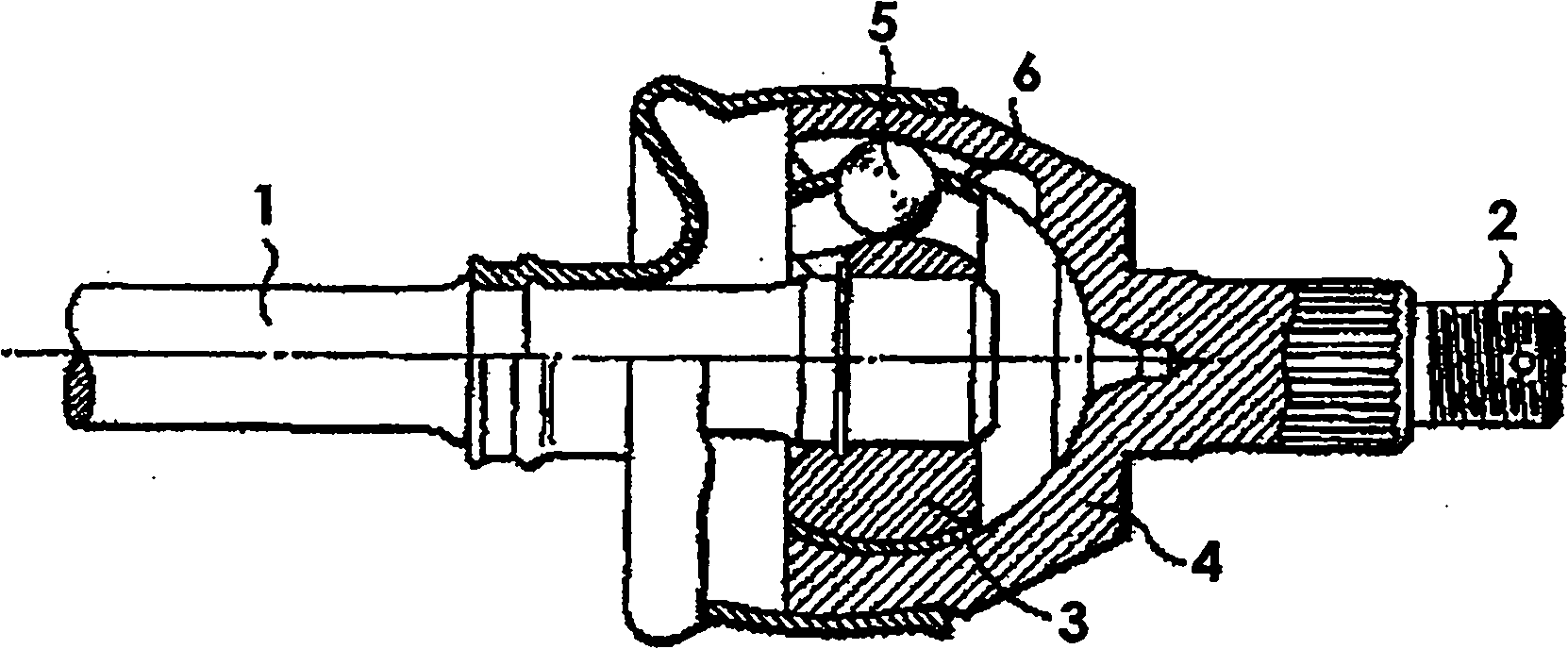

Steel for CVJ ball cages

A technology of isolation rings and balls, applied in furnace types, couplings, furnaces, etc., can solve the problems of high alloy cost, reduced manufacturability, and reduced life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] Steel materials with the chemical compositions shown in Table 1 and Table 2 were smelted, hot forged and rolled to produce a 25mm thick, 120mm wide, and 550mm long plate, and after normalizing at 920°C, tempering was performed at 720°C. Fire to soften it. Next, after removing the surface scale, it was cold-worked to a thickness of 16 mm, and tempered again at 720° C. to soften it.

[0078] Table 1

[0079]

[0080] Table 2

[0081]

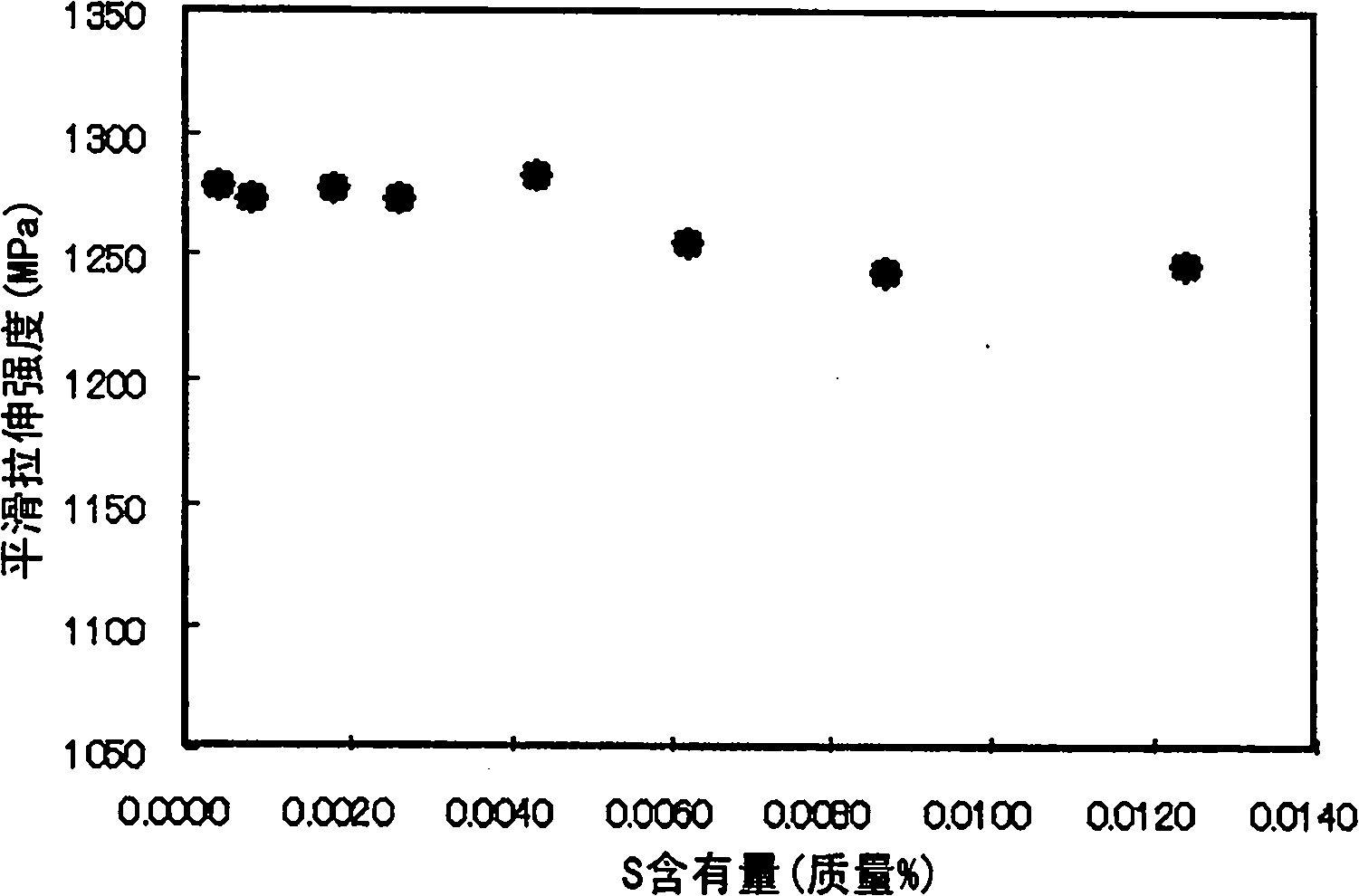

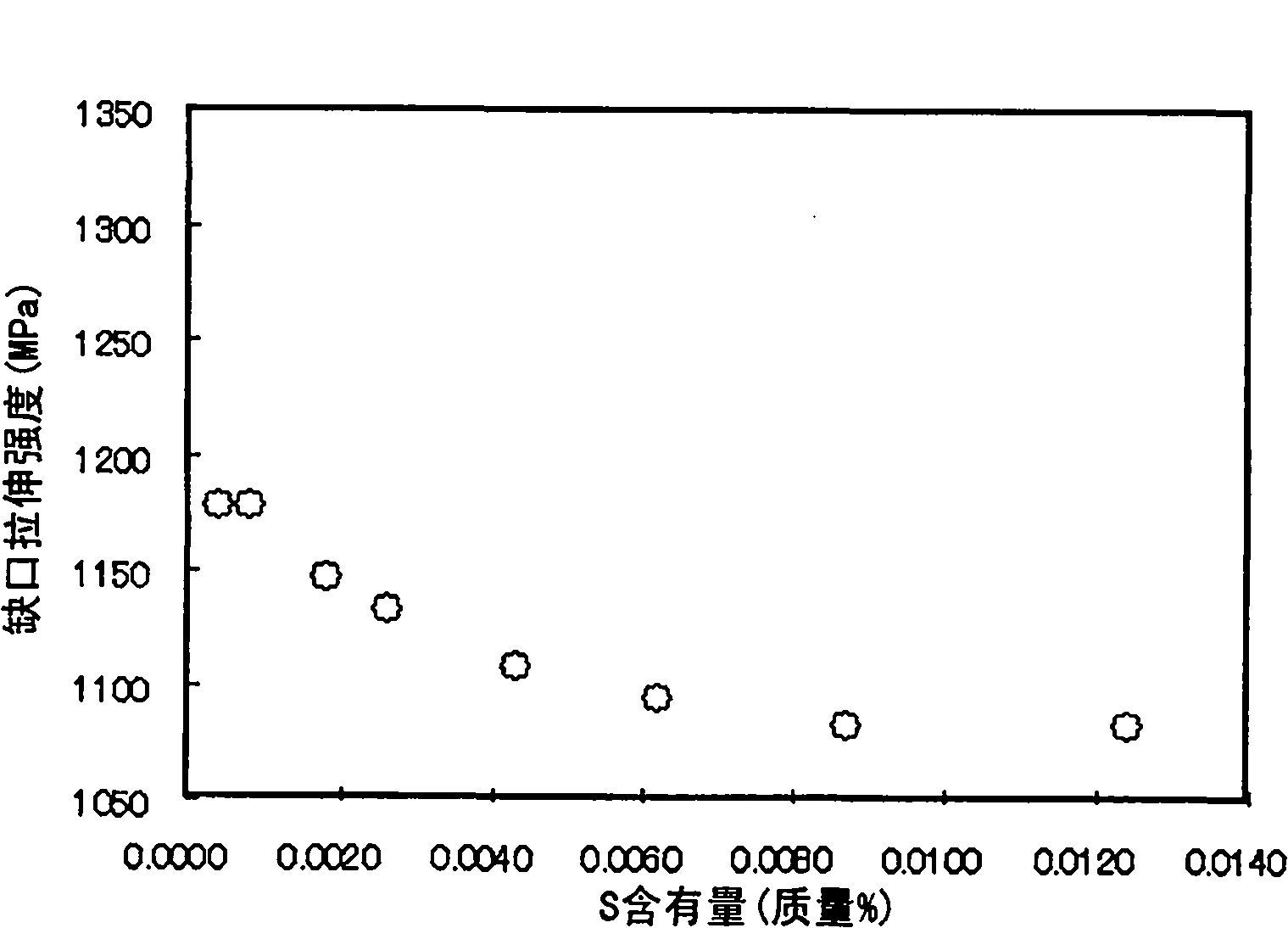

[0082] A smooth tensile test piece with a diameter of 8 mm in the parallel portion and a notched tensile test piece with a diameter of 8 mm in the parallel portion and a notch with a depth of 1 mm were taken from the raw material in the T direction, which is a direction perpendicular to the rolling direction. . Then, carburizing treatment and heat treatment were performed on the test piece under the following conditions.

[0083] First, carburizing was carried out at 930° C. for 130 minutes at a carbon potential of 0.9%, followe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com