Environment-friendly water-based elastic surface layer and construction process thereof

An elastic surface, environmentally friendly technology, applied in the direction of coagulation pavement, roads, roads and other directions paved on site, can solve the problems of lack of elasticity, easy sanding, discoloration, insufficient protection performance, etc., to enhance the anti-aging performance, The effect of enhancing the vividness and saving the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

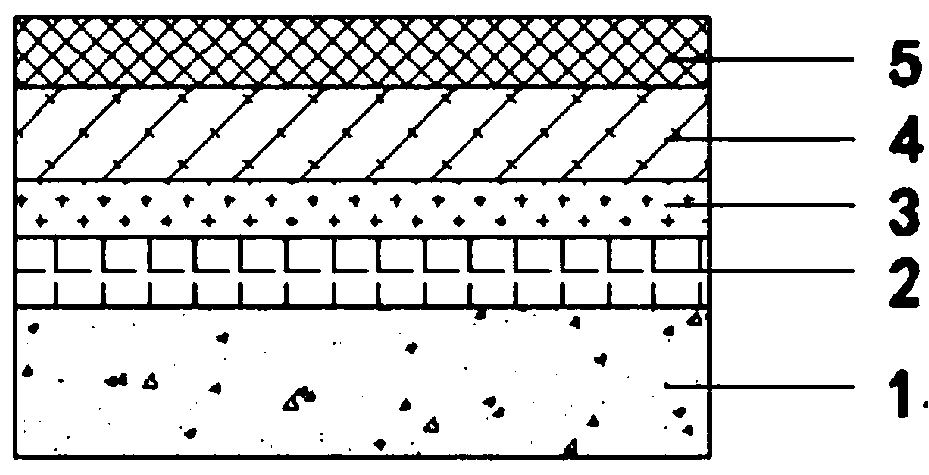

[0037] The elastic surface layer is made of colored room temperature high-elastic composite water emulsion, high-elasticity and high-purity EPDM and styrene-butadiene rubber powder mixed by adding a certain proportion of high-stiffness mixed additives, so that the entire surface layer has high elasticity and high strength. characteristics.

[0038] The components of the high-stiffness mixed additive are proportioned in parts by weight as follows: 75 parts of graded quartz sand, 20 parts of curing agent, and 5 parts of filler powder.

[0039] The reinforcement layer is a high-elasticity and high-strength colored base layer, which can not only enhance the strength, but also save costs; the thickness of the reinforcement layer is 1cm.

[0040] The waterproof adhesive layer is a high-viscosity and high-elasticity composite water emulsion, the dosage per square is 0.2kg, and the thickness of the waterproof adhesive layer is 0.3mm.

[0041] The reinforcing layer is provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com