Rotating device of friction welding spindle

A rotary device and friction welding technology, applied in transmission devices, gear transmission devices, welding equipment, etc., can solve the problems of angle error between spindle and workpiece, unstable welding quality, poor welding quality, etc., to achieve high rotary accuracy and improve welding. The effect of stable quality and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

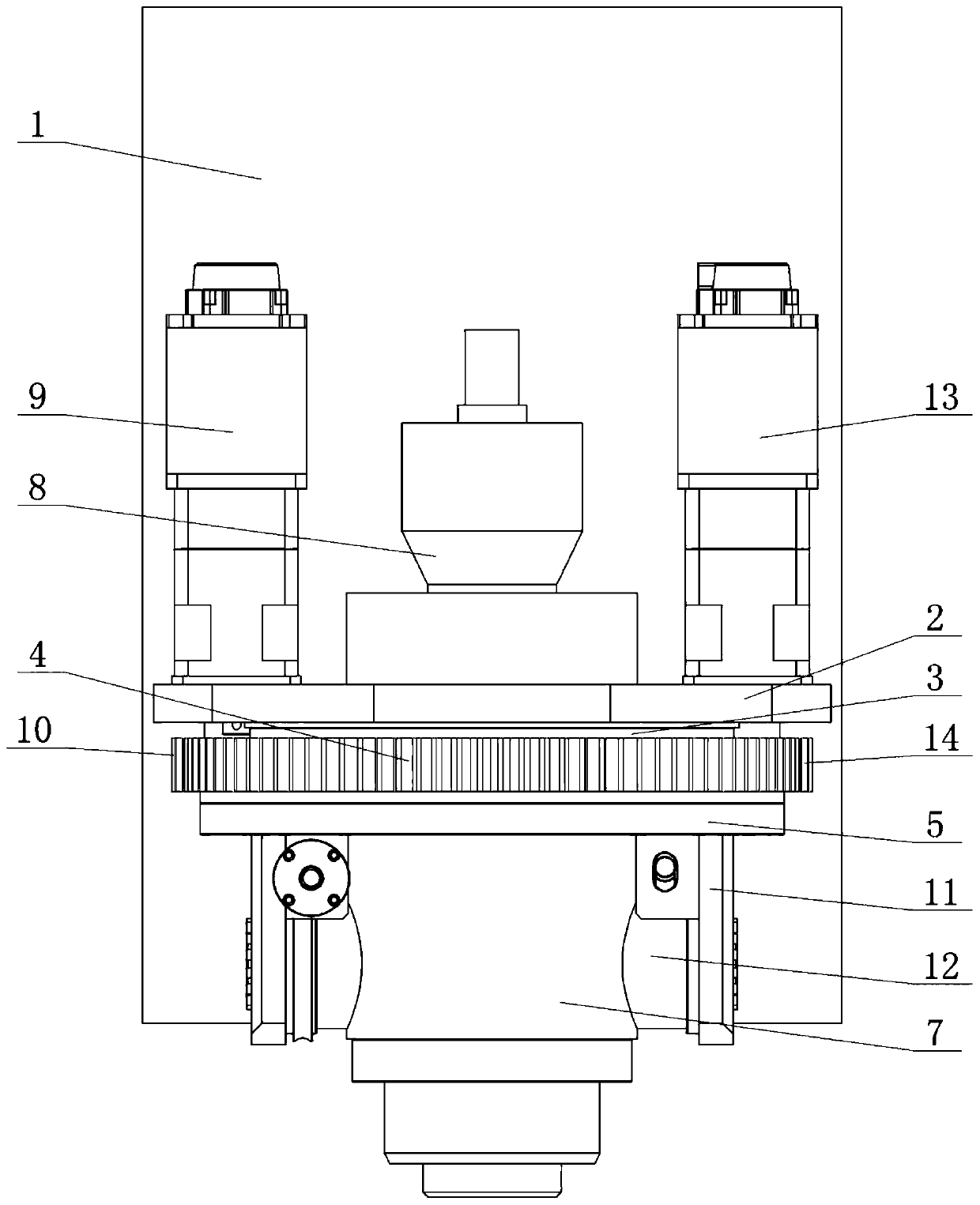

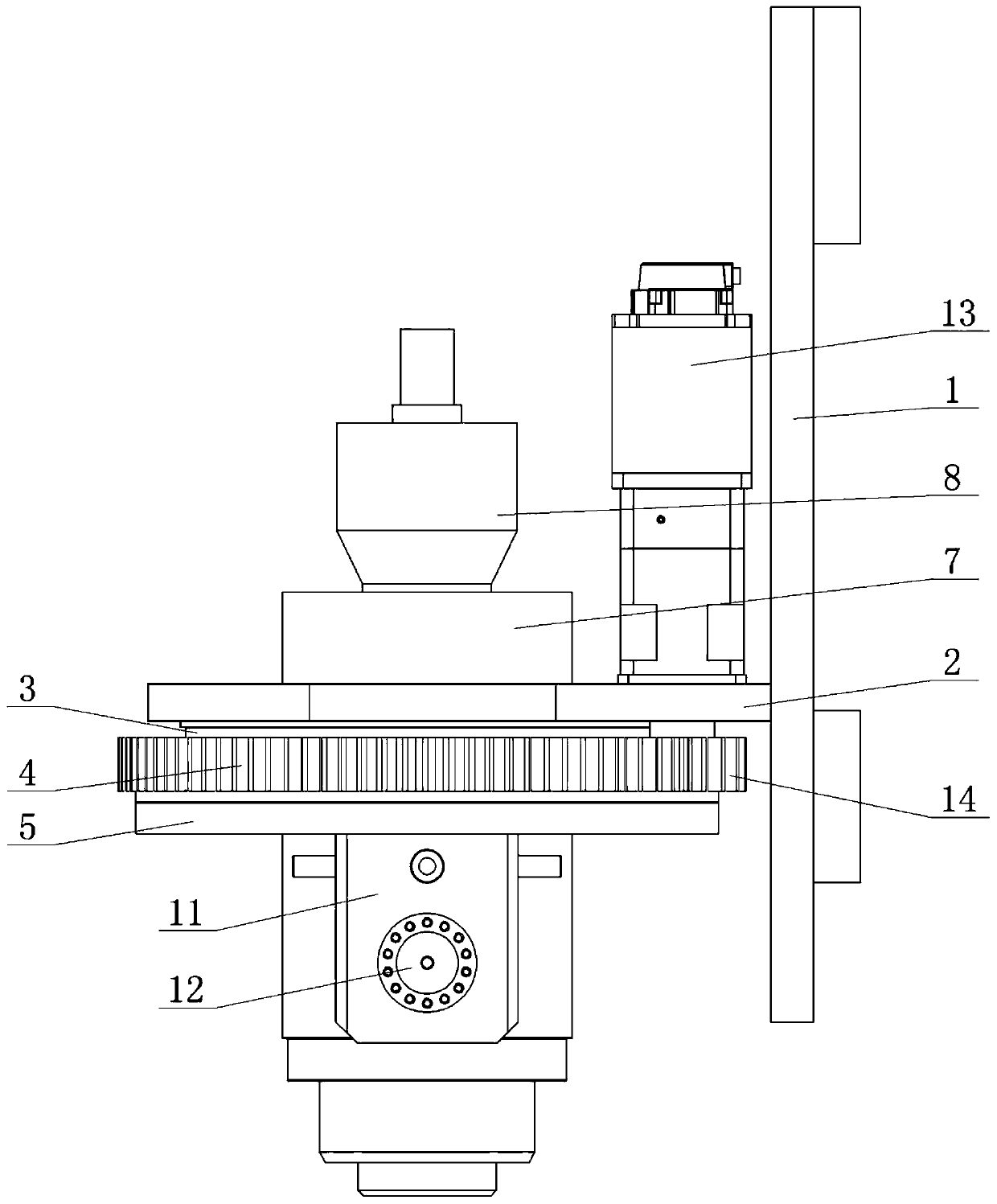

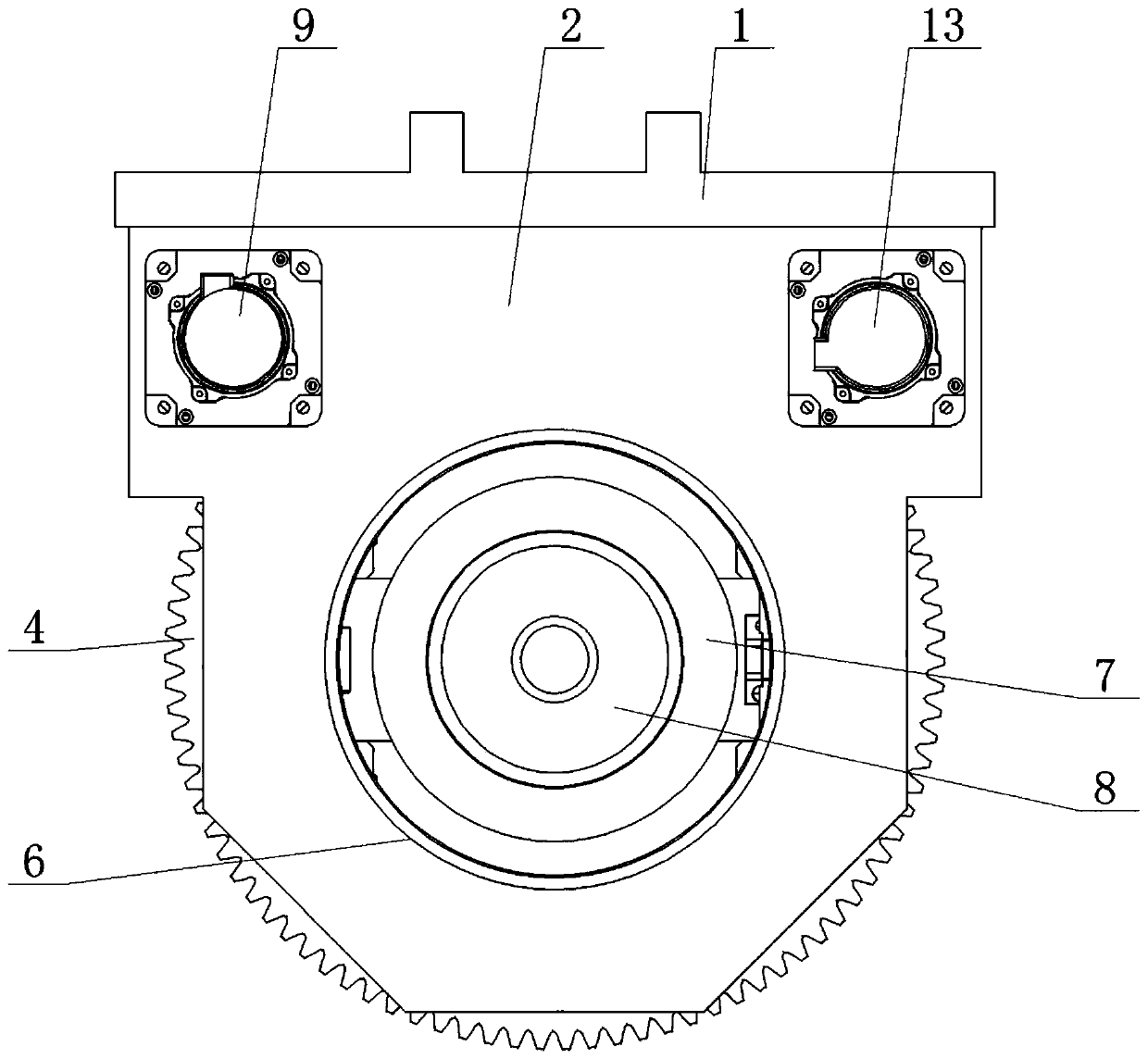

[0007] Spindle swivel devices for friction welding, such as Figure 1-4 As shown, it includes the vertical plate 1, the horizontal plate 2 is installed on the vertical plate 1, the bearing 3 is installed on the lower part of the horizontal plate 2, the ring gear 4 is installed on the outer circumference of the bearing 3, the rotary plate 5 is installed on the lower part of the ring gear 4, and the avoidance hole is opened on the horizontal plate 2 6. A shaft sleeve 7 is set in the avoidance hole 6, and the shaft sleeve 7 passes through the avoidance hole 6, the bearing 3 and the rotary plate 5 in sequence, the shaft sleeve 7 is connected with the rotary plate 5, the main shaft 8 is installed in the shaft sleeve 7, and the horizontal plate 2 is installed The first motor 9, the first gear 10 is installed on the output shaft of the first motor 9, and the first gear 10 meshes with the ring gear 4. This structure enables the main shaft 8 to be installed on the rotary plate 5 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com