Process for producing dimethyl sulfone by double-column rectification

A technology of dimethyl sulfone and double-column rectification is applied in the field of double-column rectification to produce dimethyl sulfone, and can solve the problems such as difficulty in realizing the improvement of the purity of dimethyl sulfone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

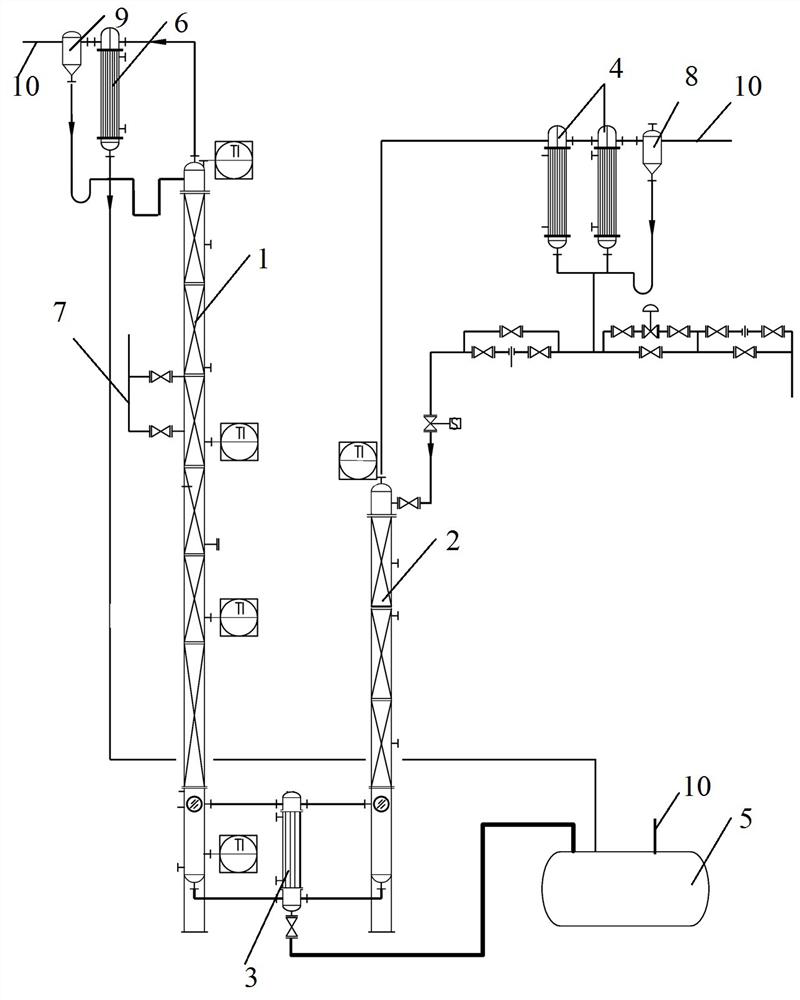

[0018] A device for producing dimethyl sulfone by rectification with two towers, the feed pipe 7 is connected to the middle part of the mother rectification tower 1, the bottom of the mother rectification tower 1 is connected to the reboiler 3, and the reboiler 3 is connected to the bottom of the sub rectification tower 2 , the top of the sub-distillation tower 2 is connected to the atomizing crystallizer 4, the atomizing crystallizer 4 is connected to the storage tank one 8, and the bottom of the atomizing crystallizer 4 and the storage tank one 8 are connected to the product area through pipelines respectively, and the one way Connected to sub-rectification column 2 upper part.

[0019] The top of the mother rectification tower 1 is connected to the condenser 6 , and the bottom of the condenser 6 is connected to the upper part of the mother rectification tower 1 .

[0020] The condenser 6 is connected to the second storage tank 9, and the second storage tank 9 is connected t...

Embodiment 2

[0024] A kind of operation of the process scheme of producing high-purity dimethyl sulfone by utilizing the double-tower rectification principle:

[0025] The fraction to be separated enters the mother tower from the feeding point of the mother tower, and water, dimethyl sulfoxide and a small amount of dimethyl sulfone are extracted from the top of the mother tower;

[0026] Through the control of the reflux ratio, a large amount of high-purity dimethyl sulfone is extracted from the top of the sub-tower; the bottom of the sub-tower adopts continuous or intermittent operation mode to remove the dimethyl sulfone solution with increasing inorganic salt concentration in time; After pretreatment, the overhead distillate from the residual and parent tower returns to the twin towers together with the fraction to be separated, so as to realize the recovery and utilization of dimethyl sulfone. The top fraction of the sub-column is granulated and screened by an atomization crystallizer ...

Embodiment 3

[0028] An operational example of a process scheme for producing high-purity dimethyl sulfone using the principle of double-column rectification:

[0029] When the vacuum degree in the tower reaches above 85KPa, the fraction to be separated (dimethyl sulfone content ≥ 95%, water ≤ 2%, inorganic salt ≤ 2%, dimethyl sulfoxide ≤ 1%) is sent from the mother rectification tower The feed point enters the mother tower, and the temperature at the bottom of the tower is controlled at about 160°C. Since water and dimethyl sulfoxide with low boiling points cannot reach the bottom of the mother rectification tower, they rise directly from the stripping section of the mother rectification tower, entraining A small amount of dimethyl sulfone is extracted from the top of the mother distillation column; dimethyl sulfone and salts with higher boiling points enter the sub-rectification column through the reboiler, and the temperature at the top of the column is maintained by controlling the reflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com