Preparation method of dimethyl sulfone

A technology of dimethyl sulfone and dimethyl sulfoxide, which is applied in the field of preparation of dimethyl sulfone, can solve the problems of flying temperature, affecting reaction efficiency, shutdown and the like, and achieves avoiding flying temperature, high conversion rate and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The invention provides a method for preparing dimethyl sulfone, the method comprising: under oxidation reaction conditions, using dimethyl sulfoxide and at least one oxidizing agent and at least one titanium-silicon molecular sieve as a catalyst in the reaction zone of the reactor During the contact process, the titanium-silicon molecular sieve moves in the reaction zone along the axial direction of the reactor.

[0011] According to the method of the present invention, during the contact process, the titanium-silicon molecular sieve as the catalyst moves in the reaction zone along the axial direction of the reactor (ie, the reaction zone), which can effectively avoid fixing the catalyst bed. When in the reactor, it is prone to the problem of excessive local temperature in the catalyst bed during the reaction. In the present invention, the "reaction zone" refers to a zone for bringing dimethyl sulfoxide into contact with an oxidizing agent and a catalyst to carry out an...

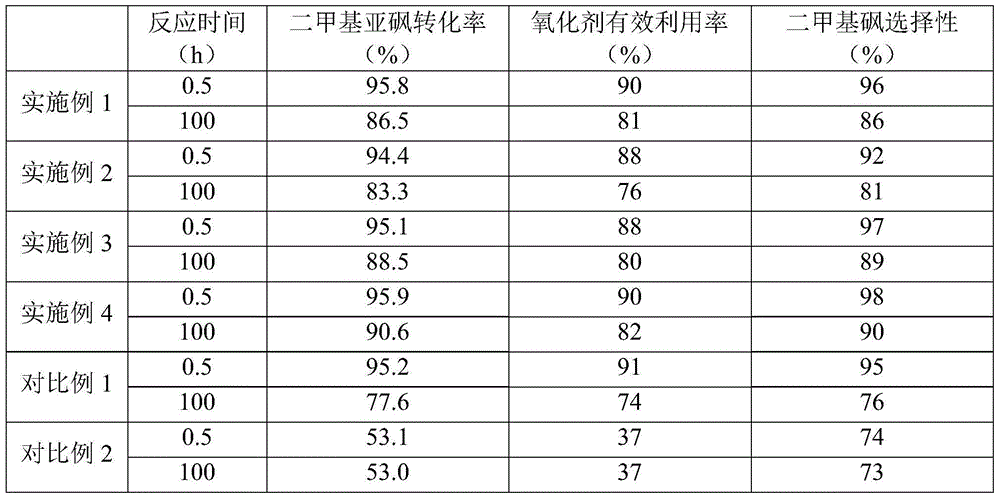

Embodiment 1

[0055] Dimethyl sulfoxide, oxidant, methanol as a solvent, and a shaped hollow titanium-silicon molecular sieve as a catalyst (the average particle diameter is 1.2 μm, based on the total amount of the shaped hollow titanium-silicon molecular sieve, the content of the hollow titanium-silicon molecular sieve is 80 % by weight, the content of silicon oxide as a binder is 20% by weight) respectively and continuously sent into the moving bed reactor for contact reaction. Wherein, dimethyl sulfoxide is sent from the lower feed port of the reactor, and the mixture of oxidant and solvent and the catalyst are sent into the reactor from the liquid phase feed port and the solid phase feed port at the top of the reactor respectively. . Wherein, the oxidizing agent is 27.5% by weight of hydrogen peroxide, the molar ratio of dimethyl sulfoxide to the oxidizing agent in terms of hydrogen peroxide is 1:1.5, the mass ratio of dimethyl sulfoxide to methanol as a solvent is 1:5, two The mass ra...

Embodiment 2

[0058] Adopt the same method as Example 1 to prepare dimethyl sulfone, the difference is that the same amount of shaped titanium-silicon molecular sieve TS-1 (average particle size is 1.2 μm, based on the total amount of shaped titanium-silicon molecular sieve TS-1 , the content of titanium-silicon molecular sieve TS-1 is 80% by weight, and the content of silicon oxide as a binder is 20% by weight) instead of forming hollow titanium-silicon molecular sieve.

[0059] The reaction mixture obtained at 0.5h and 100h after the start of the reaction was analyzed by gas chromatography, and the conversion rate of dimethyl sulfoxide, the effective utilization rate of the oxidant and the selectivity of dimethyl sulfone were calculated. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com